吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (3): 663-673.doi: 10.13229/j.cnki.jdxbgxb.20221525

• 材料科学与工程 • 上一篇

氟化石墨烯/聚酰亚胺复合膜的导热和电绝缘性能

- 1.桂林理工大学 无机纳米粉体及应用工程研究中心,广西 桂林 541004

2.广西路建工程集团有限公司 总工程师办公室,南宁 530001

3.广西交通职业技术学院 路桥工程学院,南宁 530023

Thermal conductivity and electrical insulation properties of fluorographene/polyimide composite films

Chao YANG1( ),Qing-yun YAO2,Shuang-mei TANG2,Qi-long CHEN3,Feng QIN3

),Qing-yun YAO2,Shuang-mei TANG2,Qi-long CHEN3,Feng QIN3

- 1.Research Center for Inorganic Nanopowder and Application Engineering,Guilin University of Technology,Guilin 541004,China

2.Chief Engineer's Office,Guangxi Road Construction Engineering Group Co. ,Ltd. ,Nanning 530001,China

3.College of Road and Bridge Engineering,Guangxi Institute of Communications Technology,Nanning 530023,China

摘要:

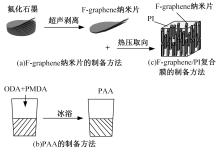

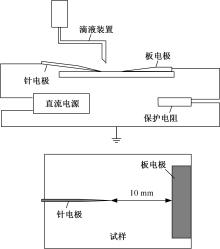

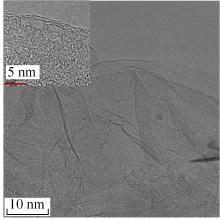

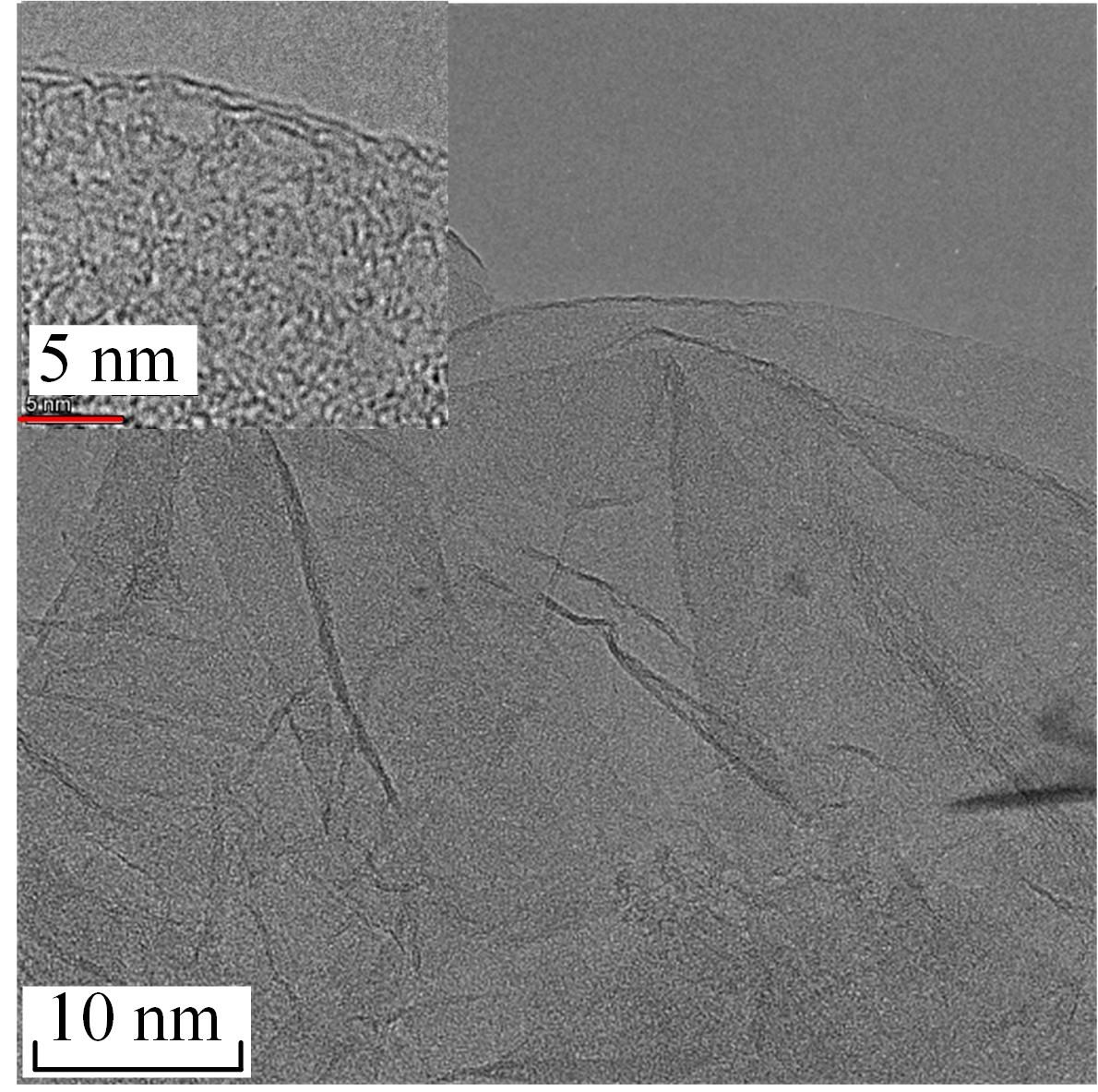

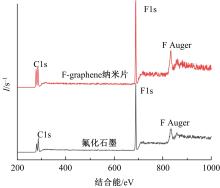

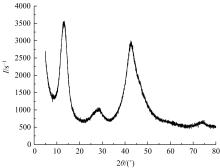

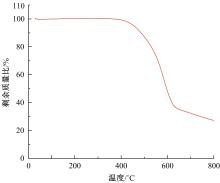

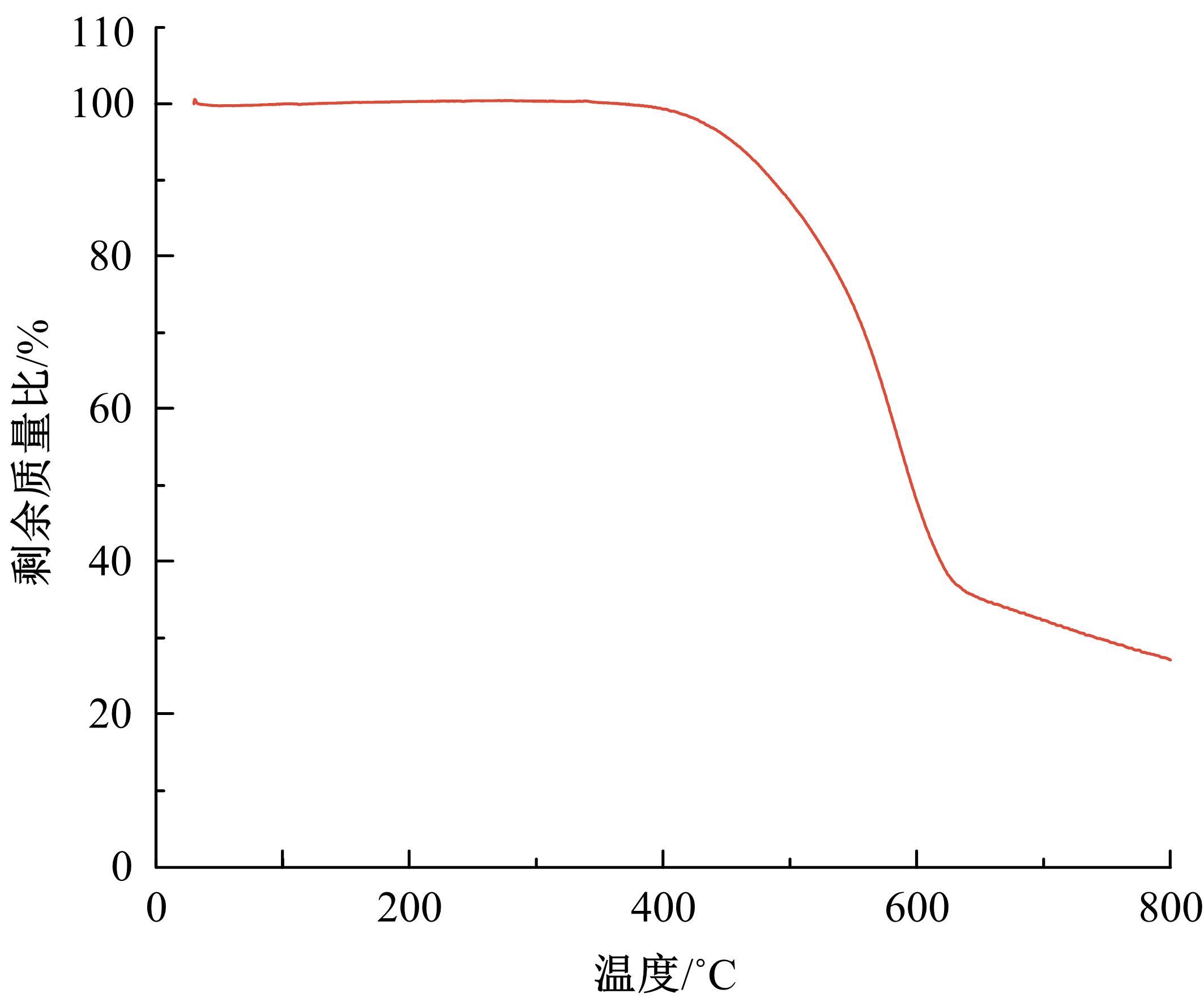

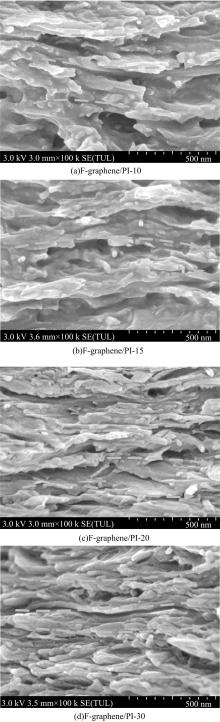

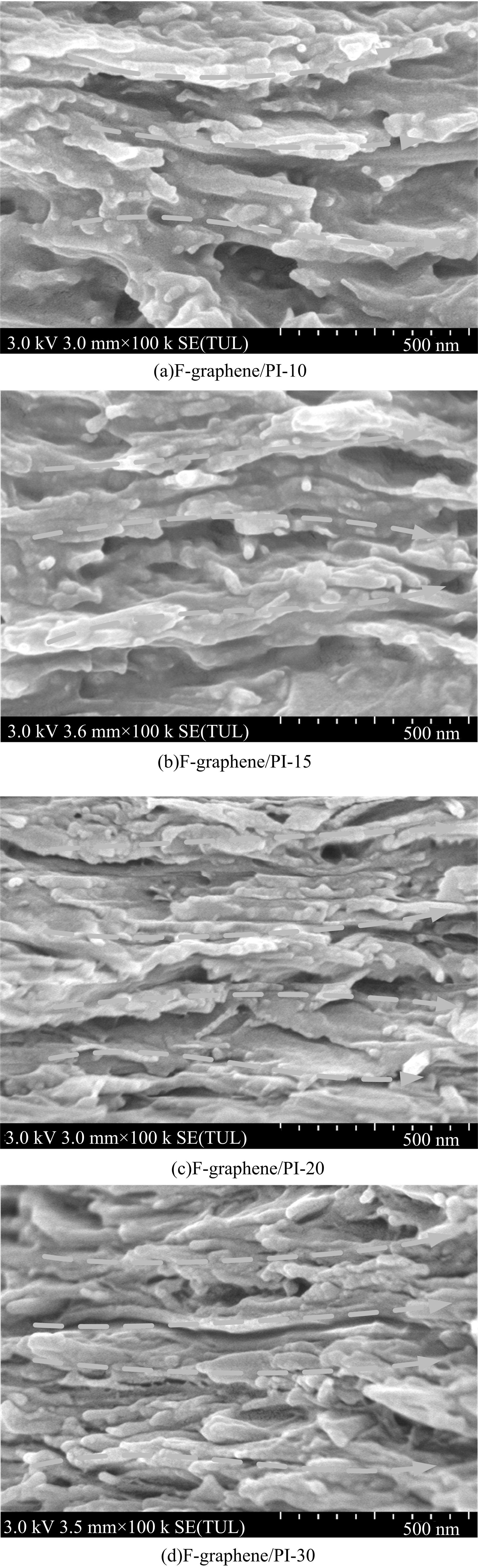

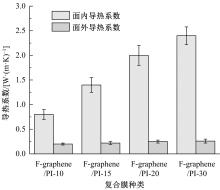

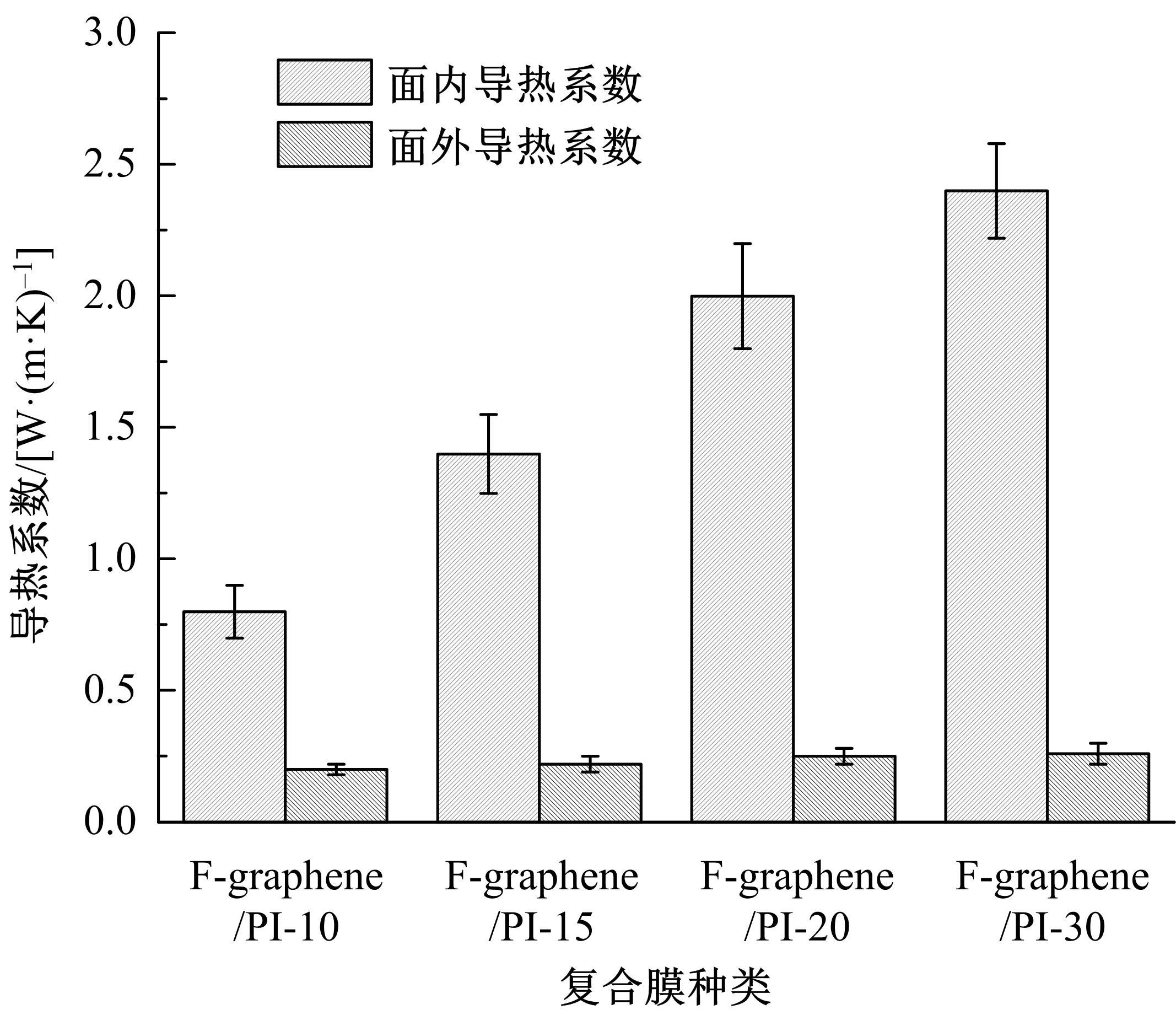

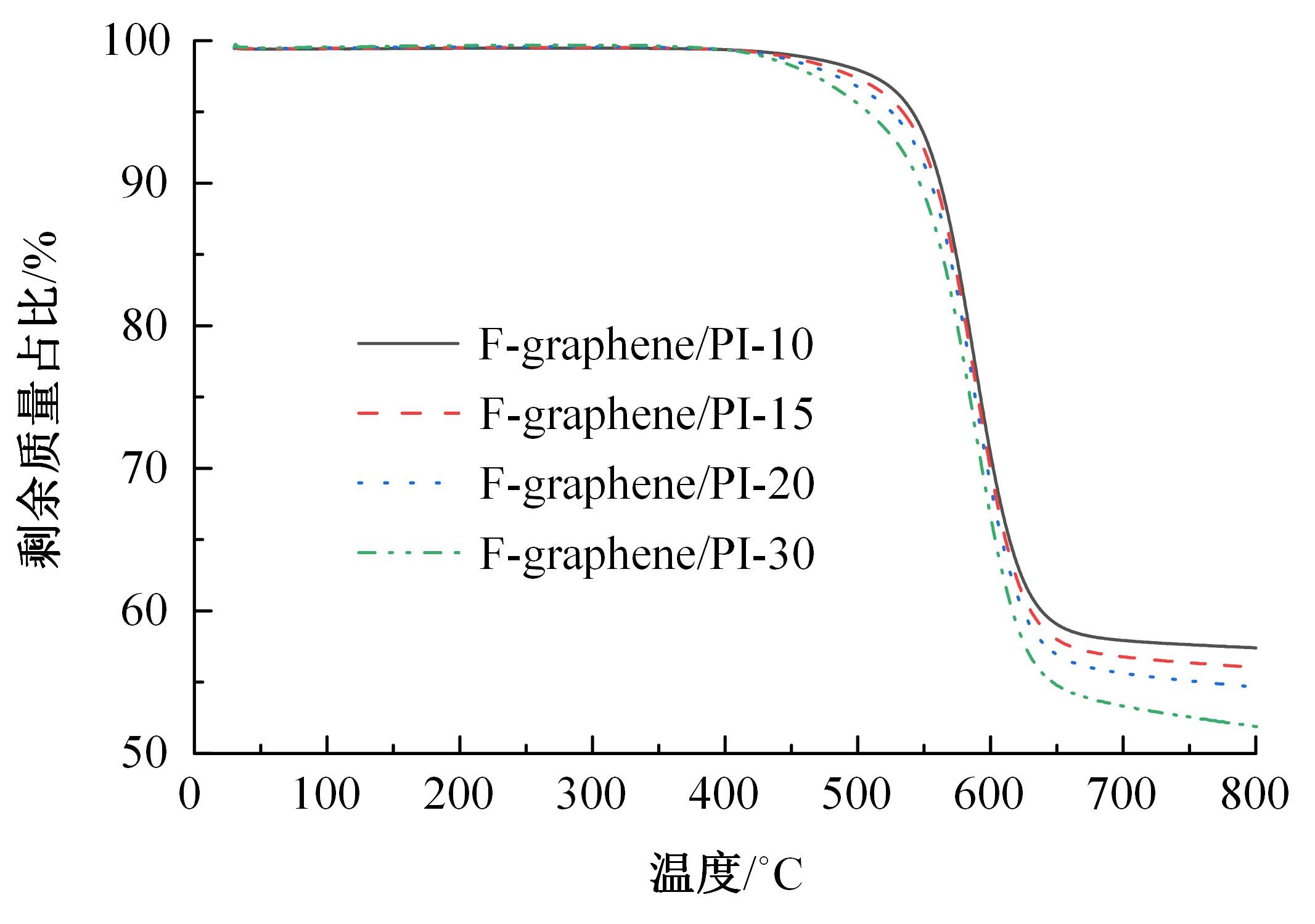

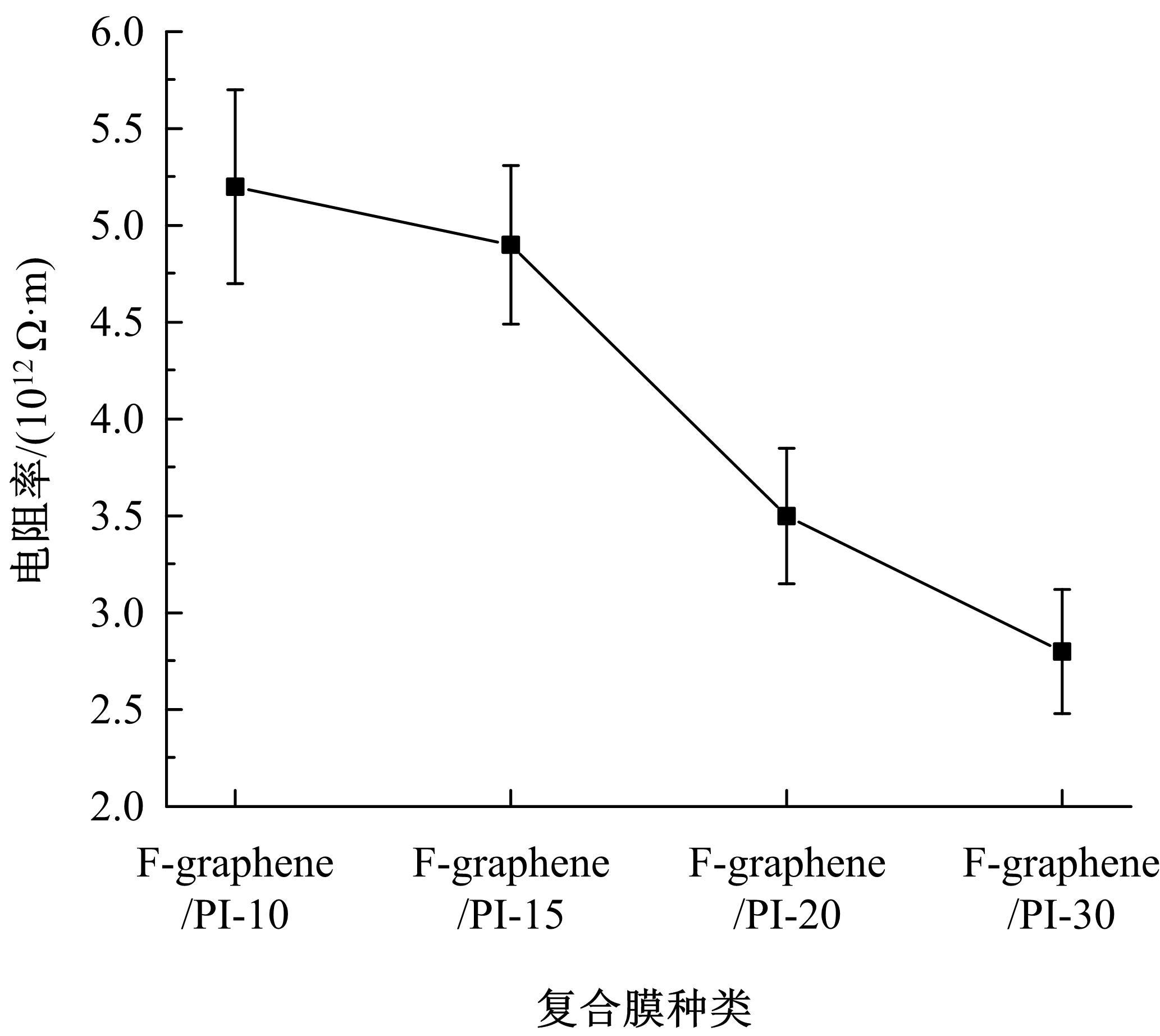

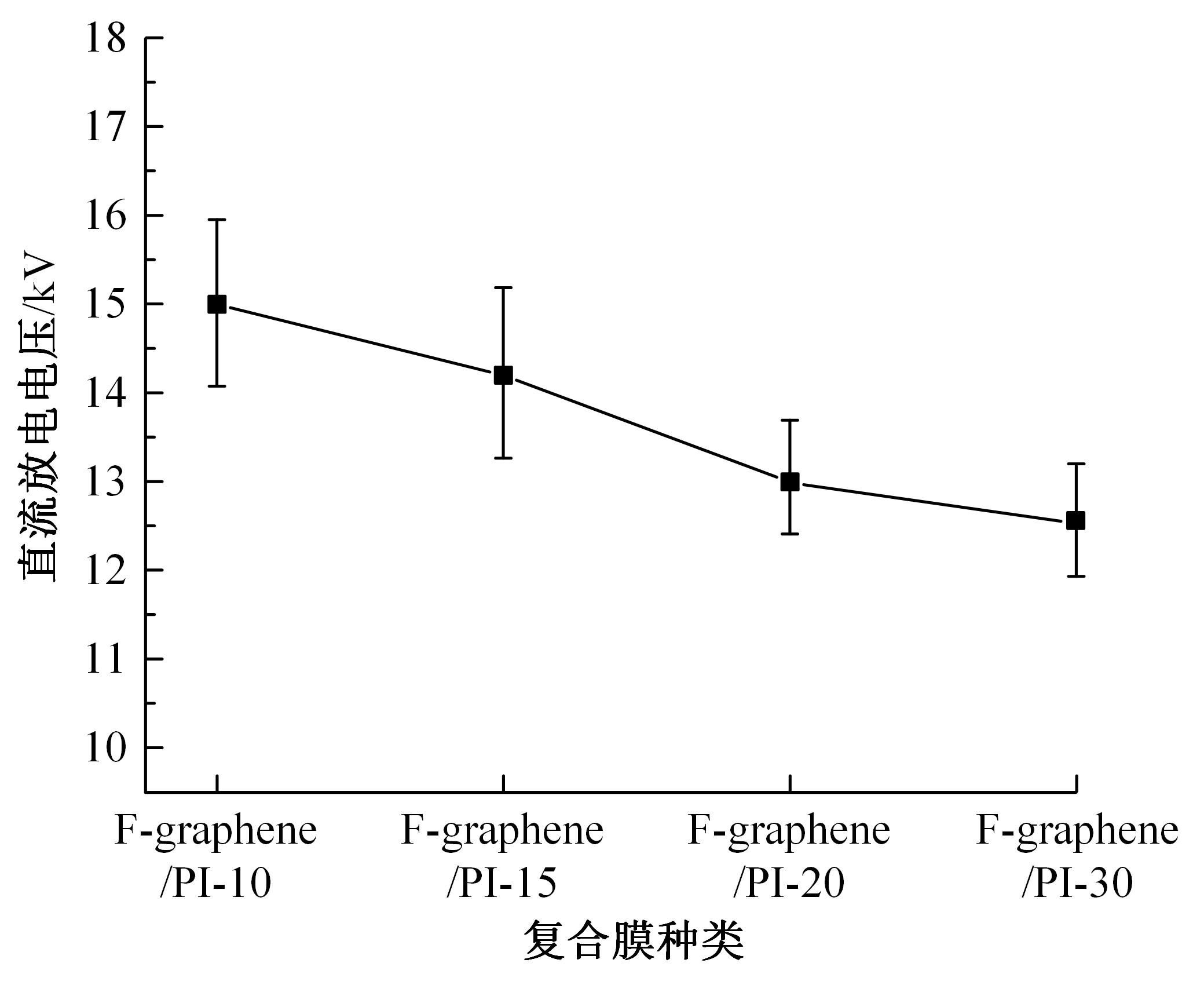

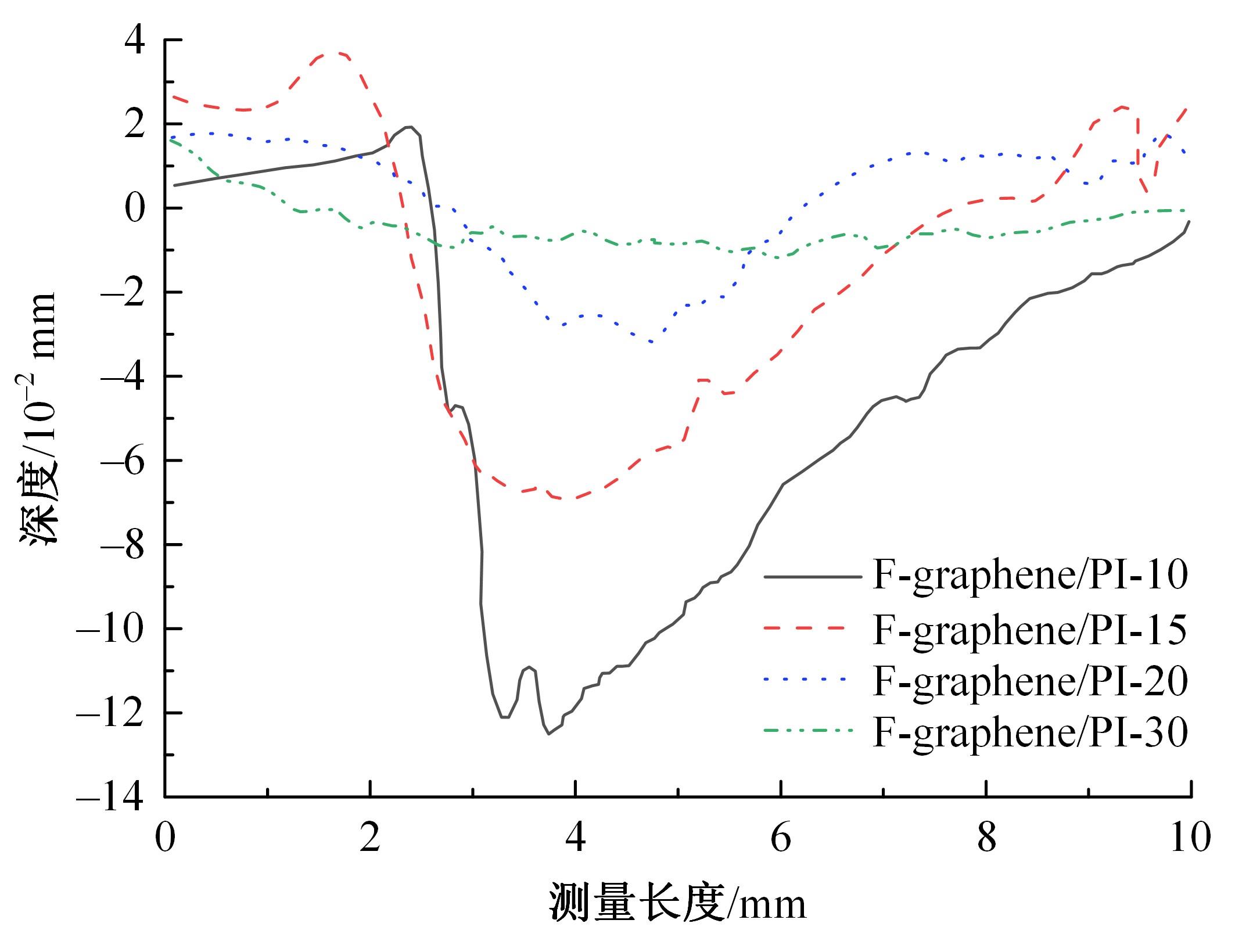

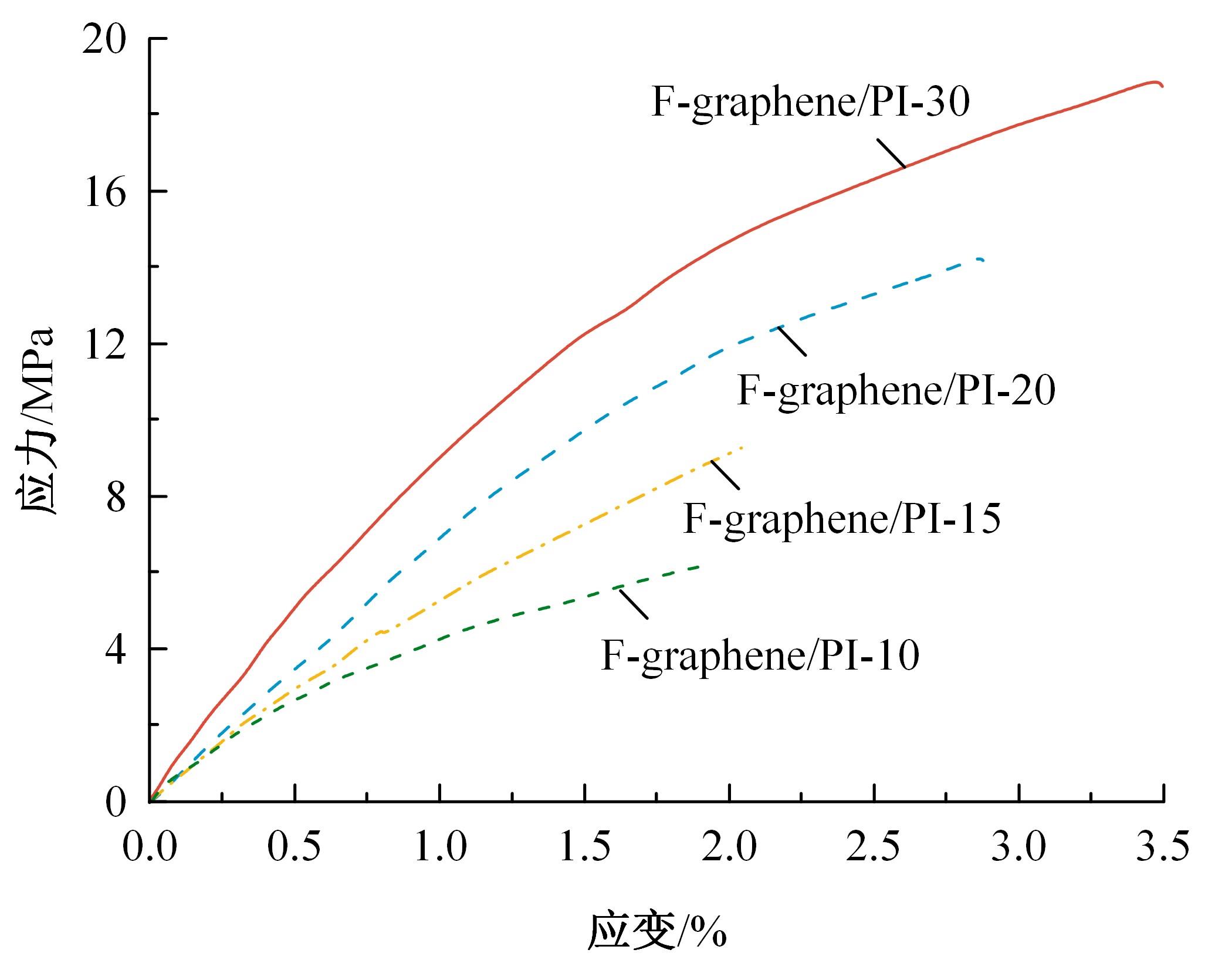

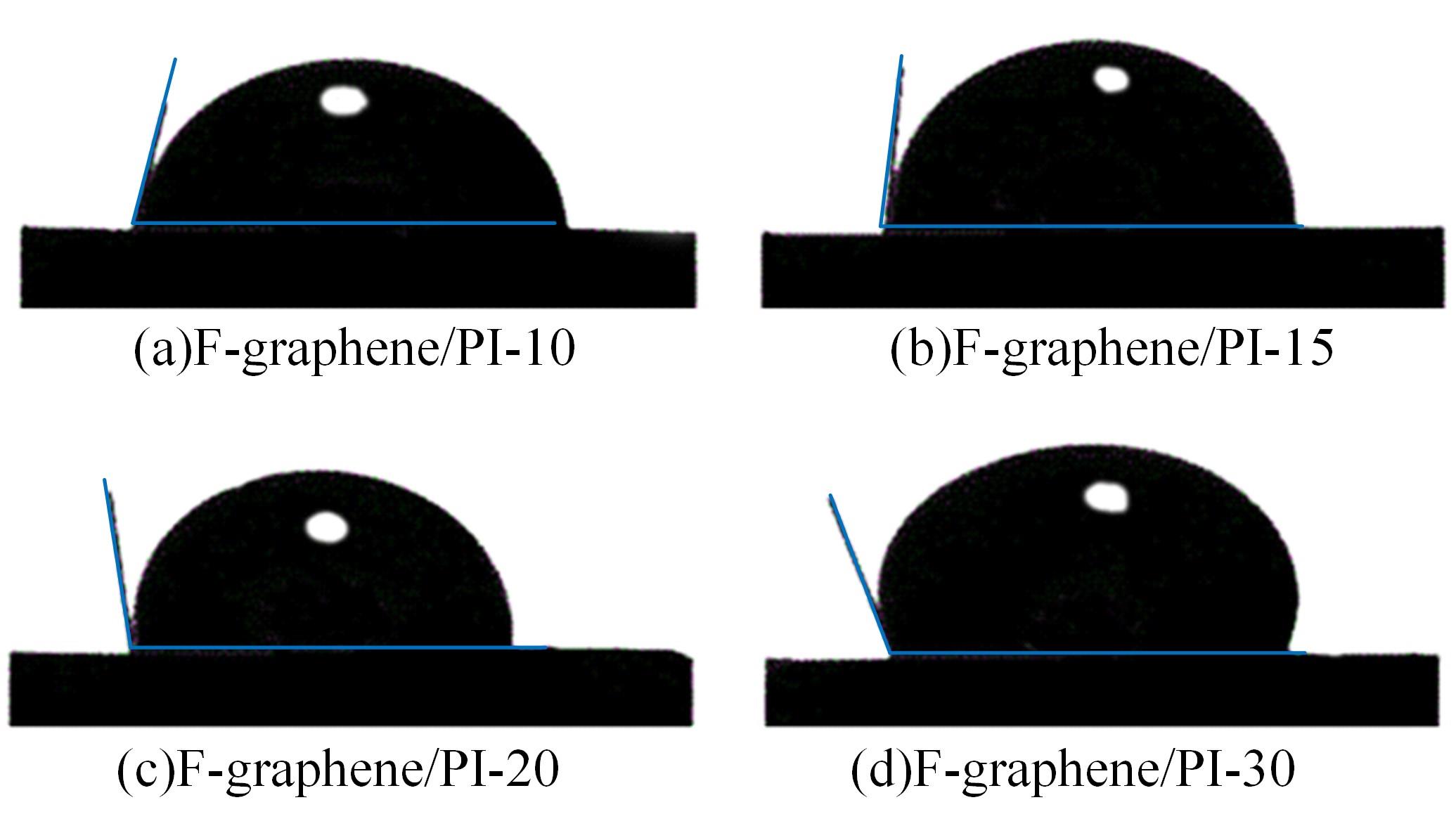

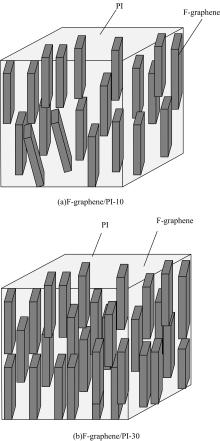

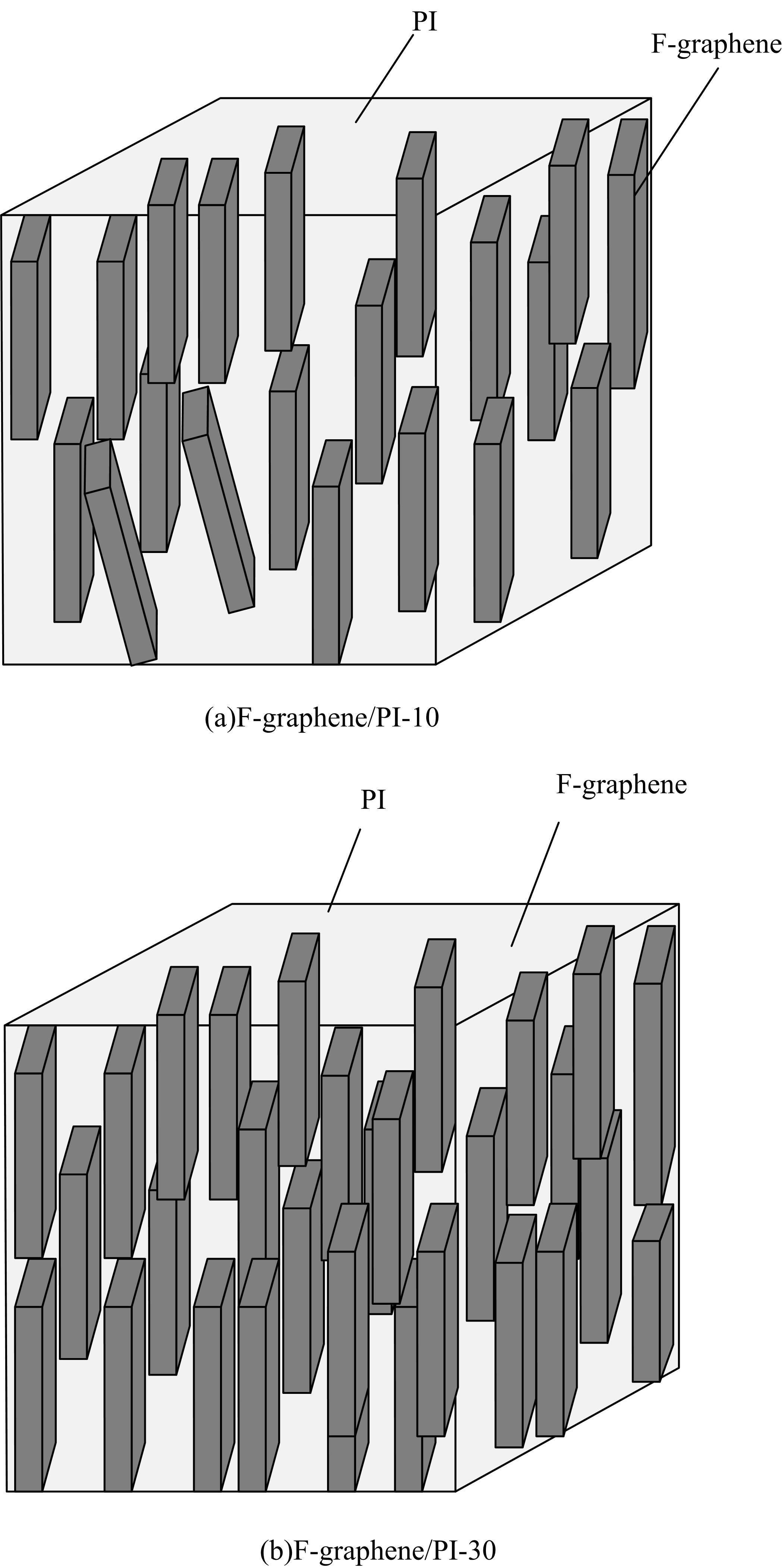

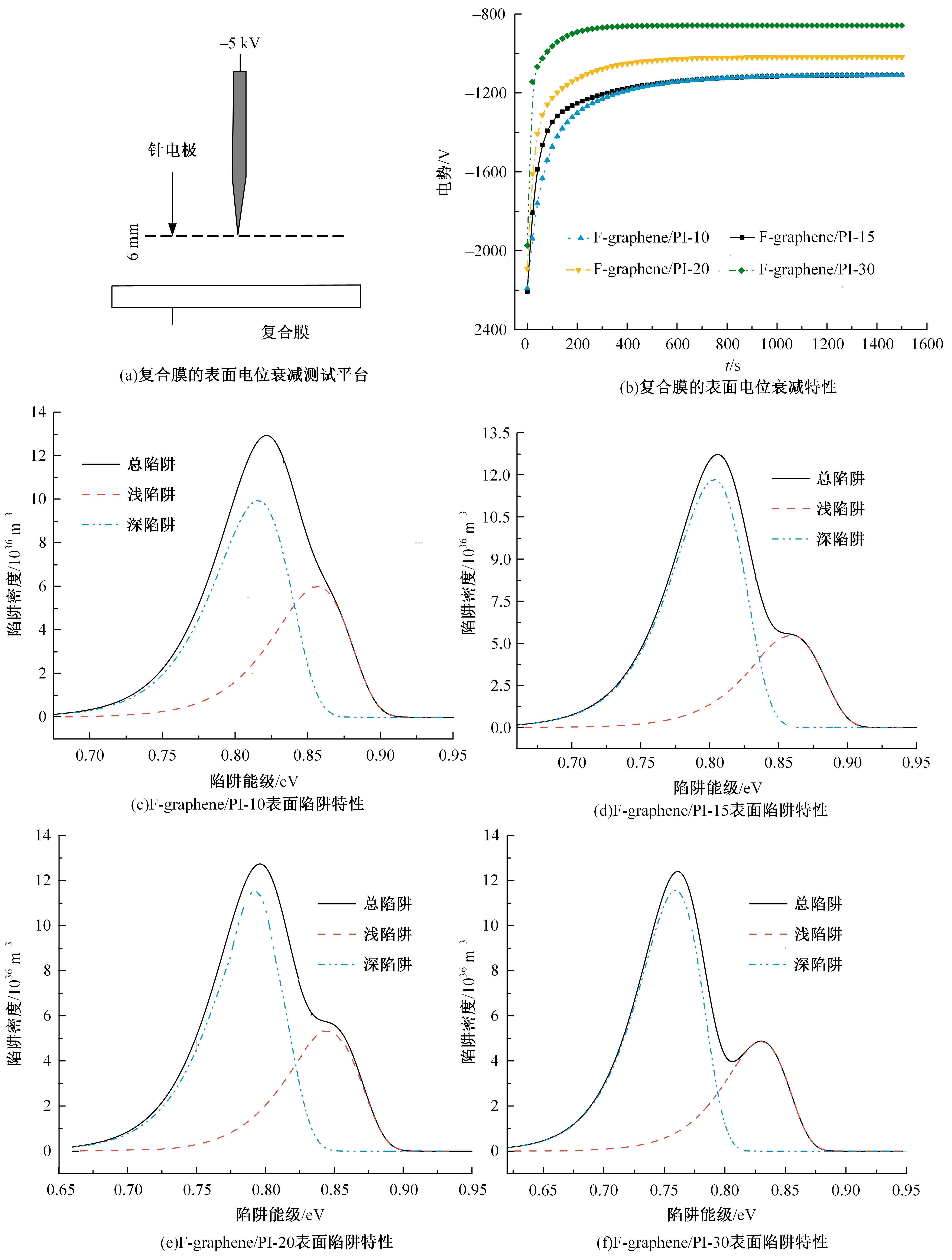

为提高聚酰亚胺基复合材料的导热和电绝缘性能,通过超声剥离制备了氟化石墨烯纳米片,采用热压取向制备了具有水平定向导热特性的氟化石墨烯/聚酰亚胺复合膜,研究了氟化石墨烯添加量对复合膜导热和电绝缘性能的影响规律。结果表明:增加氟化石墨烯添加量能提高复合膜的面内导热系数,氟化石墨烯质量分数为30%时,复合膜的面内导热系数为2.4 W/(m·K);氟化石墨烯添加量增加时,复合膜的直流耐压性能略有降低,但复合膜表面耐电痕性能增加,原因在于声子在复合膜中传递效率提升。上述研究结果可为制备高导热系数、高电绝缘性能的复合膜提供参考。

中图分类号:

- TB383

| 1 | Castellan S, Menis R, Tessarolo A, et al. A review of power electronics equipment for all-electric ship MVDC power systems[J]. International Journal of Electrical Power and Energy Systems, 2018, 96: 306-323. |

| 2 | 解志诚,黄英,王志强,等. 2.45 GHz柔性微带天线的设计及传感特性[J]. 吉林大学学报: 理学版, 2019, 57(1): 160-165. |

| Xie Zhi-cheng, Huang Ying, Wang Zhi-qiang, et al. Design and sensing characteristics of flexible micostrip antenna for 2.45 GHz[J]. Journal of Jilin University (Science Edition), 2019, 57(1): 160-165. | |

| 3 | 杨传超, 徐鸿杰, 田国峰, 等. 高强高模聚酰亚胺纤维的空间环境适应性研究及在航天领域的应用前景分析[J]. 材料导报, 2022, 36(22): 184-188. |

| Yang Chuan-chao, Xu Hong-jie, Tian Guo-feng, et al. Research on space environment adaptability of polyimide fiber with high-strength and high-modulus and analysis of its application prospects in aerospace field[J]. Materials Reports, 2022, 36(22): 184-188. | |

| 4 | Zhou S G, Li W T, Zhao W J, et al. Tribological behaviors of polyimide composite films enhanced with fluorographene[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019, 580: No. 123707. |

| 5 | Li W T, Zhao W J, Mao L S, et al. Investigating the fluorination degree of FG nanosheets on the tribological properties of FG/PI composite coatings[J]. Progress in Organic Coatings, 2020, 139: No. 105481. |

| 6 | 孙承月, 郭鑫鑫, 吴忧, 等. 聚酰亚胺气凝胶材料的电子/紫外辐照效应及机理分析[J]. 材料导报, 2022, 36(22): 161-168. |

| Sun Cheng-yue, Guo Xin-xin, Wu You, et al. Electron /vacuum ultraviolet irradiation effect and mechanism analysis of polyimide aerogel materials[J]. Materials Reports, 2022, 36(22): 161-168. | |

| 7 | 查俊伟,王帆. 高导热聚酰亚胺电介质薄膜研究进展[J]. 物理学报, 2022, 71(23): 190-207. |

| Zha Jun-wei, Wang Fan. Progress of high thermal conductivity polyimide dielectric films[J]. Acta Physica Sinica, 2022, 71(23): 190-207. | |

| 8 | Wang N, Samani M K, Li H, et al. Tailoring the thermal and mechanical properties of graphene film by structural engineering[J]. Small, 2018, 14: No. 1801346. |

| 9 | Lu R G, Su C, Huang T, et al. Chemically modified graphene/polyimide composite films based on utilization of covalent bonding and oriented distribution[J]. ACS Applied Materials & Interfaces, 2012, 4(5): 2699-2708. |

| 10 | 翟庆洪. 氮化硼纳米片/聚酰亚胺复合泡沫的制备与性能研究[D]. 天津: 河北工业大学材料科学与工程学院, 2022. |

| Zhai Qing-hong. Preparation and properties of boron nitride nanosheets/polymide composite foams[D]. Tianjin: School of Materials Science and Engineering, Hebei University of Technology, 2022. | |

| 11 | 汪日圆, 陈浩然, 陈芳琳, 等. 多巴胺@氮化硼-碳纳米管/聚酰亚胺复合气凝胶太阳能蒸发器的制备与性能[J]. 复合材料学报, 2023, 40(3): 1494-1500. |

| Wang Ri-yuan, Chen Hao-ran, Chen Fang-lin, et al. Preparation and performance of ddopamine@boron nitridecarbon nanotubes/polyimide composite aerogel solar-driven[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1494-1500. | |

| 12 | 曲可新. 低介电高导热聚酰亚胺复合纤维膜的结构设计及性能研究[D]. 哈尔滨: 哈尔滨理工大学材料科学与化学工程学院, 2022. |

| Qu Ke-xin. Research on the structure design and performance of polyimide composite fiber membrane with low dielectric and high thermal conductivity[D]. Harbin: School of Materials Science and Chemical Engineering, Harbin University of Science and Technology, 2022. | |

| 13 | 王兵, 吉海峰, 刘迎春, 等. 功能化氮化硼纳米片的制备及在导热聚氨酯复合材料中的应用[J]. 高分子材料科学与工程, 2022, 38(9): 66-71. |

| Wang Bing, Ji Hai-feng, Liu Ying-chun, et al. Preparation of functionalized boron nitride nanosheets and their application in thermally conductive composites on the matrix of polyurethane[J]. Polymer Materials Science and Engineering, 2022, 38(9): 66-71. | |

| 14 | Huang W X, Pei Q X, Liu Z S, et al. Thermal conductivity of fluorinated graphene: a non-equilibrium molecular dynamics study[J]. Chemical Physics Letters, 2012, 552: 97-101. |

| 15 | 晏年平, 贾志东, 邹晓兵. 加成型液体硅橡胶耐电痕化及蚀损性能提升方法研究[J]. 中国电机工程学报,2018,38(16): 4960-4968, 5000. |

| Yan Nian-ping, Jia Zhi-dong, Zou Xiao-bing. Improving the tracking and erosion resistance performance of addition-cure liquid silicone rubber[J]. Proceedings of the CSEE, 2018, 38(16): 4960-4968, 5000. | |

| 16 | Gong P W, Wang Z F, Wang J Q, et al. One-pot sonochemical preparation of fluorographene and selective tuning of its fluorine coverage[J]. Journal of Materials Chemistry, 2012, 22(33): 16950-16956. |

| 17 | Sun C B, Feng Y Y, Li Y, et al. Solvothermally exfoliated fluorographene for high-performance lithium primary batteries[J]. Nanoscale, 2014, 6(5): 2634-2641. |

| 18 | 袁端磊, 闵道敏, 黄印, 等. 掺杂含量对环氧纳米复合电介质陷阱与空间电荷的影响[J]. 物理学报, 2017, 66(9): 329-336. |

| Yuan Duan-lei, Min Dao-min, Huang Yin, et al. Influence of filler content on trap and space charge properties of epoxy resin nanocomposites[J]. Acta Physica Sinica, 2017, 66(9): 329-336. | |

| 19 | 吴运香, 雷霆, 高纪明, 等. 氮化硅晶须/氮化铝颗粒/聚酰亚胺复合材料的制备及性能[J]. 粉末冶金材料科学与工程, 2021, 26(3): 250-256. |

| Wu Yun-xiang, Lei Ting, Gao Ji-ming, et al. Preparation and properties of AlN/Si3N4/PI composites[J]. Materials Science and Engineering of Powder Metallurgy, 2021, 26(3): 250-256. | |

| 20 | Zhang L B, Wang J Q, Wang H G, et al. Preparation, mechanical and thermal properties of functionalized graphene/polyimide nanocomposites[J]. Composites Part A: Applied Science and Manufacturing, 2012, 43(9): 1537-1545. |

| 21 | Zhang T, Sun J, Ren L, et al. Nacre-inspired polymer composites with high thermal conductivity and enhanced mechanical strength[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 92-99. |

| 22 | 黄欣, 周远翔, 张灵, 等. 交直流复合电压下热老化油纸绝缘空间电荷特性[J]. 高电压技术,2022, 48(12): 4800-4808. |

| Huang Xin, Zhou Yuan-xiang, Zhang Ling, et al. Space charge characteristics of thermal aging oil paper insulation under AC/DC composite voltage[J]. High Voltage Engineering, 2022, 48(12): 4800-4808. | |

| 23 | 鹿海军, 刘晓丽, 李学山, 等. 石英纤维增强聚酰亚胺透波复合材料的高温热氧老化性能[J]. 航空材料学报, 2022,42(5): 127-134. |

| Lu Hai-jun, Liu Xiao-li, Li Xue-shan, et al. High-temperature thermal oxidative aging properties of quartz fiber reinforced polyimide composites[J]. Journal of Aeronautical Materials, 2022, 42(5): 127-134. | |

| 24 | 丁军, 索双富, 史纪军, 等. 微小航天推进器聚酰亚胺老化性能预测及形貌测试[J]. 工程塑料应用, 2022, 50(7): 117-121. |

| Ding Jun, Suo Shuang-fu, Shi Ji-jun, et al. Aging performance prediction and microstructure of polyimide for micro spacecraft propulsion[J]. Engineering Plastics Application, 2022, 50(7): 117-121. |

| [1] | 许良,肖景厚,宋万万,周松. 碳纤维复合材料层合板三点弯曲疲劳性能[J]. 吉林大学学报(工学版), 2024, 54(2): 400-409. |

| [2] | 郑植,袁佩,金轩慧,魏思斯,耿波. 桥墩复合材料柔性防撞护舷试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2581-2590. |

| [3] | 车佳玲,王俊,刘海峰,张居平. 沙漠砂制备高韧性水泥基复合材料在不同环境下的自愈合性能[J]. 吉林大学学报(工学版), 2023, 53(8): 2277-2286. |

| [4] | 许良,边钰博,周松,肖景厚. 高温水浸对T800/环氧树脂基复合材料性能的影响[J]. 吉林大学学报(工学版), 2023, 53(7): 1943-1950. |

| [5] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [6] | 魏海斌,马子鹏,毕海鹏,刘汉涛,韩栓业. 基于力学响应分析方法的导电橡胶复合路面铺装技术[J]. 吉林大学学报(工学版), 2023, 53(2): 531-537. |

| [7] | 郑植,耿波,王福敏,董俊宏,魏思斯. 既有低等级混凝土护栏防护能力提升[J]. 吉林大学学报(工学版), 2022, 52(6): 1362-1374. |

| [8] | 庄蔚敏,陈沈,吴迪. 碳纤维增强复合材料包裹强化形式对钢管横向冲击性能的影响[J]. 吉林大学学报(工学版), 2022, 52(4): 819-828. |

| [9] | 李伟,宋海生,陆浩宇,史文库,王强,王晓俊. 复合材料板簧迟滞特性线性辨识方法[J]. 吉林大学学报(工学版), 2022, 52(4): 829-836. |

| [10] | 于开锋,何小玲,李俊涛,梁策. 玄武岩纤维对不饱和聚酯树脂复合材料的增韧[J]. 吉林大学学报(工学版), 2022, 52(10): 2300-2306. |

| [11] | 卫宇璇,张明,刘佳,刘硕,路明雨,王洪雨. 基于模态缺陷的变刚度复合材料圆柱壳屈曲特性[J]. 吉林大学学报(工学版), 2022, 52(1): 91-100. |

| [12] | 谷拴成,聂红宾. 极温冻融-荷载作用下碳纤维复合材料修复试件损伤分析[J]. 吉林大学学报(工学版), 2021, 51(6): 2108-2120. |

| [13] | 佟金,高子博,霍超,王子阳,马云海,常志勇. 低温下铜纳米颗粒对UHMWPE复合材料摩擦磨损性能影响[J]. 吉林大学学报(工学版), 2021, 51(2): 493-500. |

| [14] | 慕文龙,那景新,谭伟,王广彬,申浩,栾建泽. 基于FTIR分析的CFRP-铝合金粘接接头剩余强度预测[J]. 吉林大学学报(工学版), 2021, 51(1): 139-146. |

| [15] | 杨帆,张旭东,赵蒙,折波,邓俊楷. 基于有限元计算的形状记忆合金⁃金属玻璃复合材料变形行为[J]. 吉林大学学报(工学版), 2021, 51(1): 172-180. |

|

||