吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (5): 1368-1376.doi: 10.13229/j.cnki.jdxbgxb.20230002

• 交通运输工程·土木工程 • 上一篇

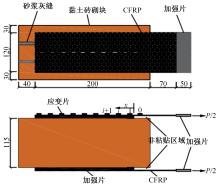

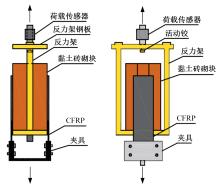

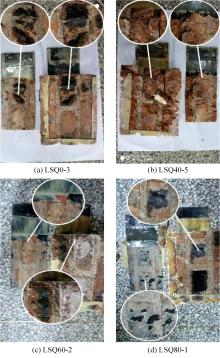

硫酸盐干湿环境下碳纤维布-黏土砖砌体界面性能试验

靳文强1,2( ),胡珈源1,王琦3,李超鹏1,于永辉1,张家玮1,2

),胡珈源1,王琦3,李超鹏1,于永辉1,张家玮1,2

- 1.兰州交通大学 土木工程学院,兰州 730070

2.兰州交通大学 道桥工程灾害防治技术国家地方联合工程实验室,兰州 730070

3.中国铁路设计集团有限公司,天津 300308

Experiment on interfacial bonding performance between CFRP and clay brick under sulfate attack of wetting-drying cycles

Wen-qiang JIN1,2( ),Jia-yuan HU1,Qi WANG3,Chao-peng LI1,Yong-hui YU1,Jia-wei ZHANG1,2

),Jia-yuan HU1,Qi WANG3,Chao-peng LI1,Yong-hui YU1,Jia-wei ZHANG1,2

- 1.School of Civil Engineering,Lanzhou Jiaotong University,Lanzhou 730070,China

2.National and Provincial Joint Engineering Laboratory of Road & Bridge Disaster Prevention and Control,Lanzhou Jiaotong University,Lanzhou 730070,China

3.China Railway Design Corporation,Tianjin 300308,China

摘要:

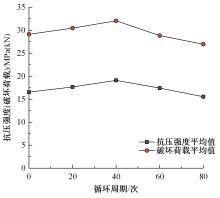

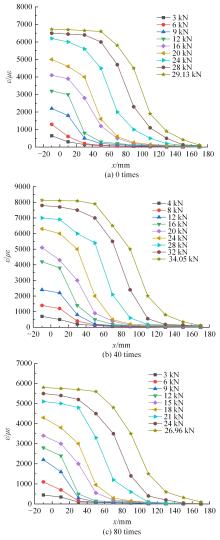

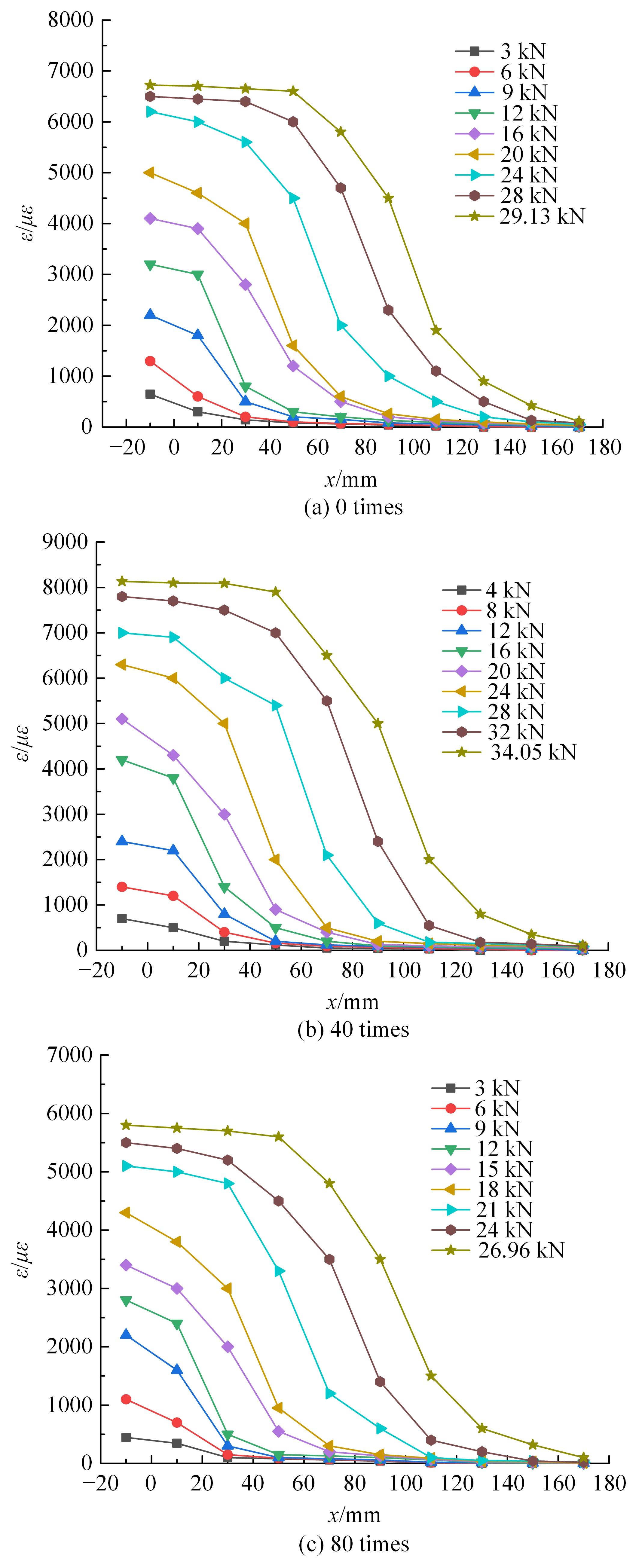

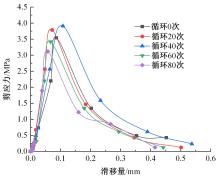

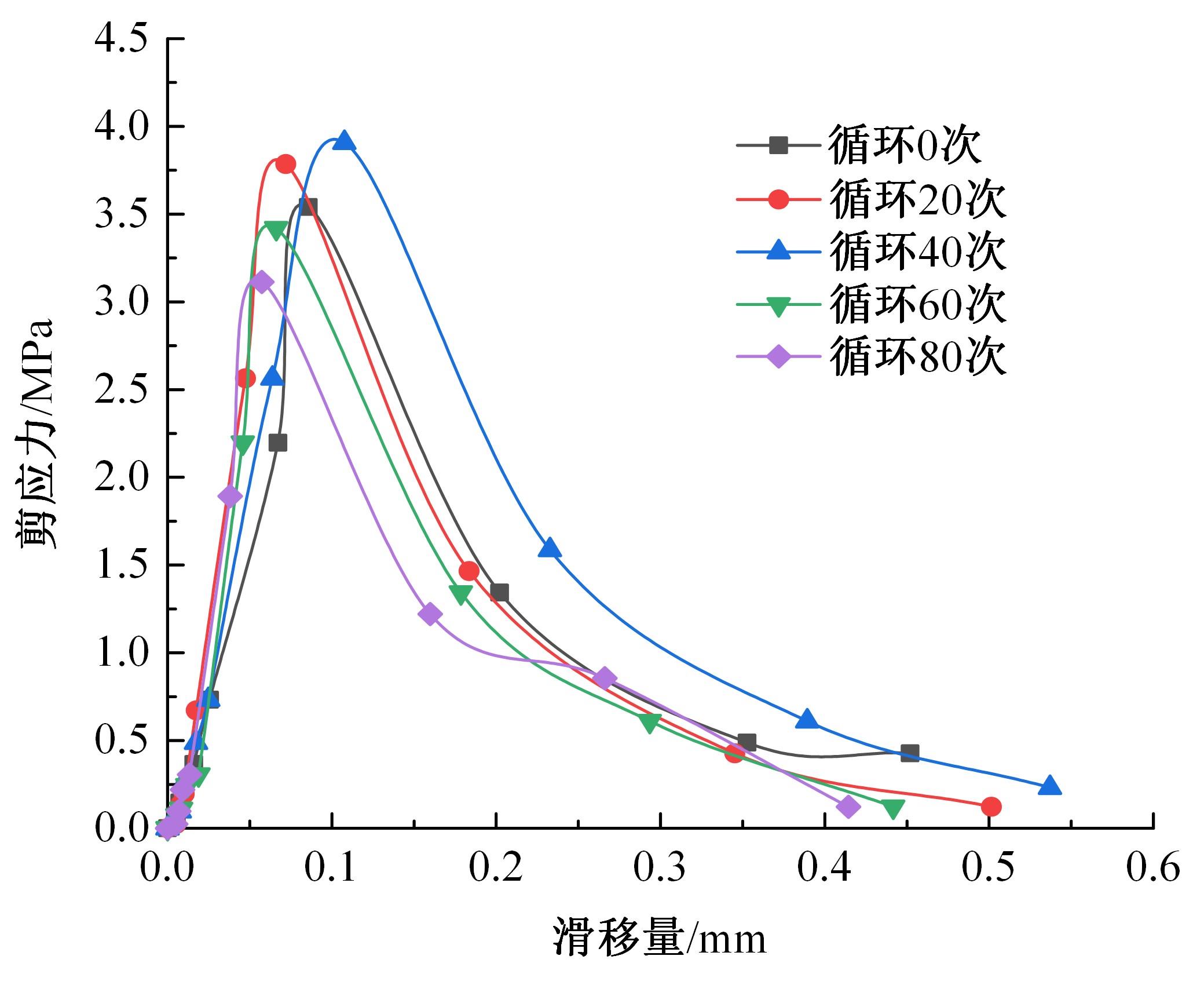

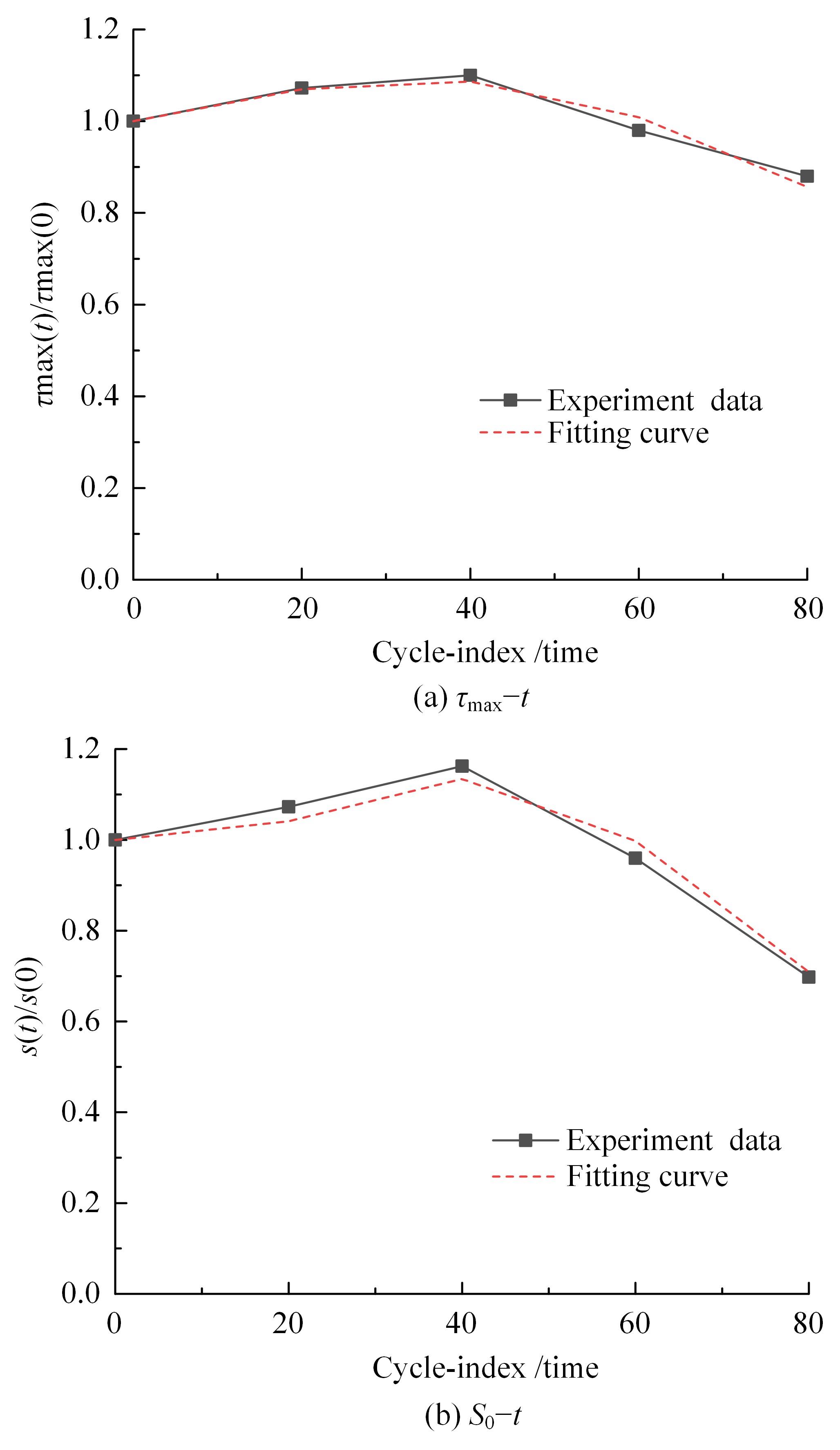

对粘贴碳纤维增强复合材料(CFRP)的烧结黏土砖砌块进行双面剪切试验,考察硫酸盐干湿循环不同周期下CFRP -黏土砖砌块界面破坏形态和粘结性能,讨论了硫酸盐腐蚀下CFRP-黏土砖砌块界面粘结性能退化机理。结果表明:CFRP-黏土砖砌块界面的破坏形态受硫酸盐干湿循坏影响较大;界面粘结性能(极限承载力、峰值剪应力)随循环时间呈先小幅增加后加速下降的趋势。提出了受循环周期影响的CFRP-黏土砖砌块界面粘结-滑移模型,将预测值与试验值对比,该模型能较准确地反映硫酸盐干湿循环作用下界面粘结性能的退化规律。

中图分类号:

- TB332

| 1 | 叶列平,冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3): 24-34. |

| Ye Lie-ping, Feng Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006, 39(3): 24-34. | |

| 2 | 李春良, 程永春. 碳纤维布加固钢筋混凝土梁的预应力控制过程[J]. 吉林大学学报: 工学版, 2018, 38(2): 393-398. |

| Li Chun-liang, Cheng Yong-chun. Pre-tension control of reinforced concrete beam strengthened with CFRP sheets[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 38(2): 393-398. | |

| 3 | Mosallam A, Banerjee S. Enhancement inInplane shear capacity of unreinforced masonry (URM)walls strengthenedwith fiber reinforced polymer composites[J]. Composites Part B-Engineering, 2011, 42(6): 1657-1670. |

| 4 | 郑文忠,万夫雄,李时光. 用无机胶粘贴CFRP布加固混凝土板火灾后受力性能[J]. 吉林大学学报: 工学版, 2010, 40(5): 1244-1249. |

| Zheng Wen-zhong, Wan Fu-xiong, Li Shi-guang. Mechanical performance of reinforced concrete slabs strengthened with CFRP sheets bonded with an inorganic adhesive after fire[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(5): 1244-1249. | |

| 5 | 郑怡, 李莉, 刘明, 等. FRP与砌体界面的粘结承载力[J]. 沈阳建筑大学学报,2010,26(1): 27-30. |

| Zheng Yi, Li Li, Liu Ming, et al. Study on anchorage strength models for FRP attached to masonry[J]. Journal of Shenyang Jianzhu University, 2010, 26(1): 27-30. | |

| 6 | 王全凤, 陈莹, 黄奕辉, 等. GFRP复合材料与粘土砖单剪粘结试验研究[J]. 建筑结构, 2008, 38(5): 106-108. |

| Wang Quan-feng, Chen Ying, Huang Yi-hui, et al. Experimental study on single shear strength between GFRP and clay brick[J]. Building Structure, 2008, 38(5): 106-108. | |

| 7 | 陈莹,王全凤,黄奕辉,等. GFRP 复合材料与砖界面粘结性能的数值模拟[J]. 工程力学, 2007, 24(5): 119-124. |

| Chen Ying, Wang Quan-feng, Huang Yi-hui, et al. Numerical analysis for bonding in the interface between GFRP and clay brick[J]. Engineering Mechanics, 2007, 24(5): 119-124. | |

| 8 | 刘连新. 察尔汗盐湖及超盐渍土地区混凝土侵蚀及预防初探[J]. 建筑材料学报, 2001, 4(4): 395-400 . |

| Liu Lian-xin. Brief introduction on the study of erosion and prevention of concrete in salt lake and saline soil area of chaerhan, chaidamu[J]. Journal of Building Materials, 2001, 4(4): 395-400. | |

| 9 | 袁杰, 陈歆, 何虹霖, 等. 微生物矿化作用下混凝土裂缝修复与性能补偿[J]. 吉林大学学报: 工学版, 2020,50(2): 641-647. |

| Yuan Jie, Chen Xin, He Hong-lin, et al. Repair and rejuvenation of cracked concrete by microbiologically -induced calcite-precipitation[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(2): 641-647. | |

| 10 | Yarigarravesh M, Toufigh V, Mofid M. Experimentaland analytical evaluation of FRPs bonded to masonry-long term[J]. Surface & Coatings Technology, 2018, 344(1): 729-741. |

| 11 | Tedeschi C, Kwiecień A, Valluzzi M R,et al. Effect of thermalageing and salt decay on bond between FRP and masonry[J]. Materials and Structures,2014,47(12): 2051 -2065. |

| 12 | 李趁趁, 高丹盈, 黄承逵. 碳纤维与玻璃纤维增强聚合物复合材料耐久性[J]. 哈尔滨工业大学学报, 2009, 41(2): 150-154. |

| Li Chen-chen, Gao Dan-ying, Huang Cheng-kui. Durability of carbon and glass fiber reinforced polymer composites[J]. Journal of Harbin Institute of Technology, 2009, 41(2): 150-154. | |

| 13 | 雷真, 白柳, 郭洪波, 等. FRP加固砌体结构的界面粘结性能综述[J]. 材料科学, 2018, 8(11): 1038-1046. |

| Lei Zhen, Bai Liu, Guo Hong-bo, et al. A review of interfacial adhesion propertiesbetween FRP and masonry structures reinforced with FRP[J]. Material Sciences,2018, 8(11): 1038-1046. | |

| 14 | 宦文娟. 多因素耦合作用下砖及其砌体的性能劣化规律与机理研究[D]. 南京: 东南大学土木工程学院, 2013. |

| Huan Wen-juan. Investigation of deterioration and mechanism of brick and masonry subjected to multi-factor coupling effect[D]. Nanjing: College of Civil Engineering, Southeast University, 2013. | |

| 15 | 马蕾, 温勇, 张文艺, 等. 干湿循环作用下灌注性水泥砂浆抗硫酸盐侵蚀研究[J]. 新型建筑材料, 2019, 46(3): 40-44. |

| Ma Lei, Wen Yong, Zhang Wen-yi,et al. Study on resistance to sulfate attack of poured cement mortar under dry and wet cycle[J]. New Building Materials, 2019, 46(3): 40-44. | |

| 16 | . 普通混凝土长期性能和耐久性能试验方法标准 [S]. |

| 17 | 刘明, 刘新强, 刘骥夫, 等. FRP加固砌体拉拔力与纤维布应变关系的试验研究[J]. 福州大学学报: 自然科学版, 2005: 33(): 223-227. |

| Liu Ming, Liu Xin-qiang, Liu Ji-fu,et al. Experimental study on relationships of strain in FRP sheet versus pulling force applied on FRP strengthened masonry[J]. Journal of Fuzhou University (Natural Science Edition), 2005, 33(Sup.1): 223-227. | |

| 18 | Ferracuti B, Savoia M, Mazzotti C. Interface law for FRP-concrete delamination[J]. Composite Structures, 2007, 80(4): 523-531. |

| 19 | 黄奕辉. FRP 与砖界面行为及其应用研究[D].厦门: 华侨大学土木工程学院, 2008. |

| Huang Yi-hui. Studies on FRP-brick interface and its application[D]. Xiamen: College of Civil Engineering, Hua Qiao University, 2008. |

| [1] | 范亮,徐英铭,谭阳. 集束群钉式装配组合梁界面滑移计算[J]. 吉林大学学报(工学版), 2023, 53(9): 2533-2541. |

| [2] | 吴迪,耿文华,李洪梅,孙大千. 铝/钢等离子弧熔⁃钎焊接头界面电子背散射衍射分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1331-1337. |

| [3] | 张惠,聂志玲,肖宏伟,王聃星. 无人驾驶汽车智能座舱人机交互界面色彩设计[J]. 吉林大学学报(工学版), 2023, 53(5): 1315-1321. |

| [4] | 关博文,邸文锦,王发平,吴佳育,张硕文,贾治勋. 干湿循环与交变荷载作用下混凝土硫酸盐侵蚀损伤[J]. 吉林大学学报(工学版), 2023, 53(4): 1112-1121. |

| [5] | 孙琪凯,张楠,刘潇,周子骥. 基于Timoshenko梁理论的钢-混组合梁动力折减系数[J]. 吉林大学学报(工学版), 2023, 53(2): 488-495. |

| [6] | 秦贵和,王曼莹,孙铭会. 多媒体终端上新型压力交互范式研究[J]. 吉林大学学报(工学版), 2023, 53(11): 3186-3193. |

| [7] | 崔凯,许鹏飞,黄井镜,于翔鹏,汪小海. 土遗址裂隙注浆浆⁃土界面粘结性能干旱环境耐久性对比[J]. 吉林大学学报(工学版), 2023, 53(10): 2856-2868. |

| [8] | 邓海,王超,杨京浩,王利忠,王明辉,李志刚. 碳纤维增强热塑性复合材料研究进展[J]. 吉林大学学报(工学版), 2023, 53(1): 18-30. |

| [9] | 石忠华,宋权威,康振航,谢强,章继峰. 机翼结构超声除冰系统数值模拟与实验[J]. 吉林大学学报(工学版), 2022, 52(7): 1561-1573. |

| [10] | 夏全平,高江平,罗浩原,张其功,李志杰,杨飞. 用于高模量沥青砼的复合改性硬质沥青低温性能[J]. 吉林大学学报(工学版), 2022, 52(3): 541-549. |

| [11] | 陈奕颖,金敬福,王家旭,齐迎春,王琳,陈廷坤. 冻结过程冰黏附界面应力特性规律与分析[J]. 吉林大学学报(工学版), 2022, 52(10): 2466-2473. |

| [12] | 王有志,赵文帅,刘金樟,邱凯,贾森. 斜拉体系加固桥梁桥下连接件力学性能[J]. 吉林大学学报(工学版), 2022, 52(10): 2376-2384. |

| [13] | 陈奕颖,金敬福,丛茜,陈廷坤,任露泉. 不同冰点介质对冰黏附强度的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1926-1932. |

| [14] | 谷晓燕,隋成龙,狄星,孟政宇,朱开轩,楚长春. 焊接能量对铜/钛超声波焊接接头性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1669-1676. |

| [15] | 陈华,陈耀嘉,谢斌,王鹏凯,邓朗妮. CFRP筋粘结式锚固体系界面失效演化机制及粘结强度计算[J]. 吉林大学学报(工学版), 2020, 50(5): 1698-1708. |

|

||