吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2423-2431.doi: 10.13229/j.cnki.jdxbgxb.20221424

• 车辆工程·机械工程 • 上一篇

基于离散元方法的立式螺旋搅拌磨机工作性能

- 吉林大学 机械与航空航天工程学院,长春 130022

Working performance of vertical screw stirring mill based on discrete element method

Peng-shu XIE( ),Da CUI(

),Da CUI( ),Guo-qiang WANG,Kai LI

),Guo-qiang WANG,Kai LI

- School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

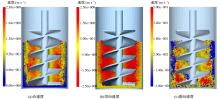

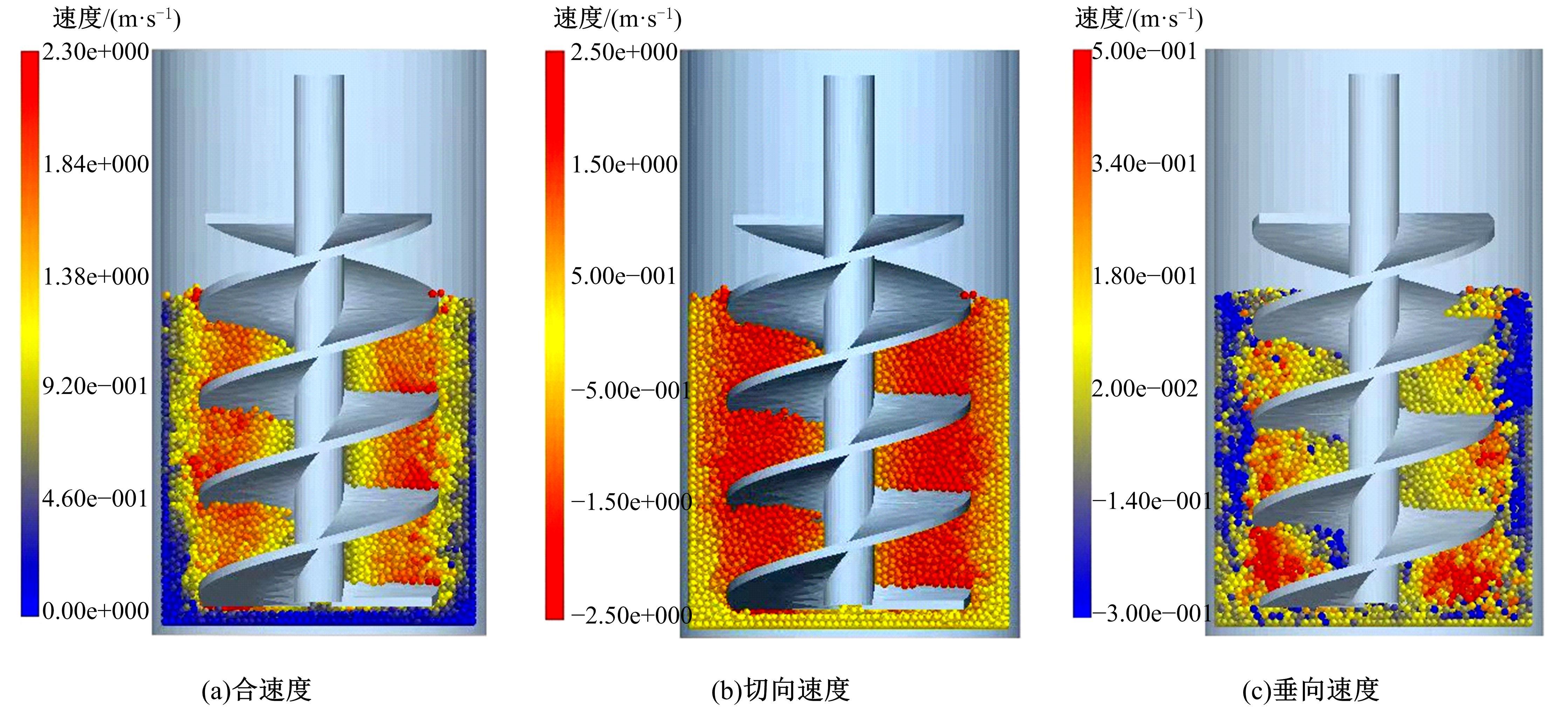

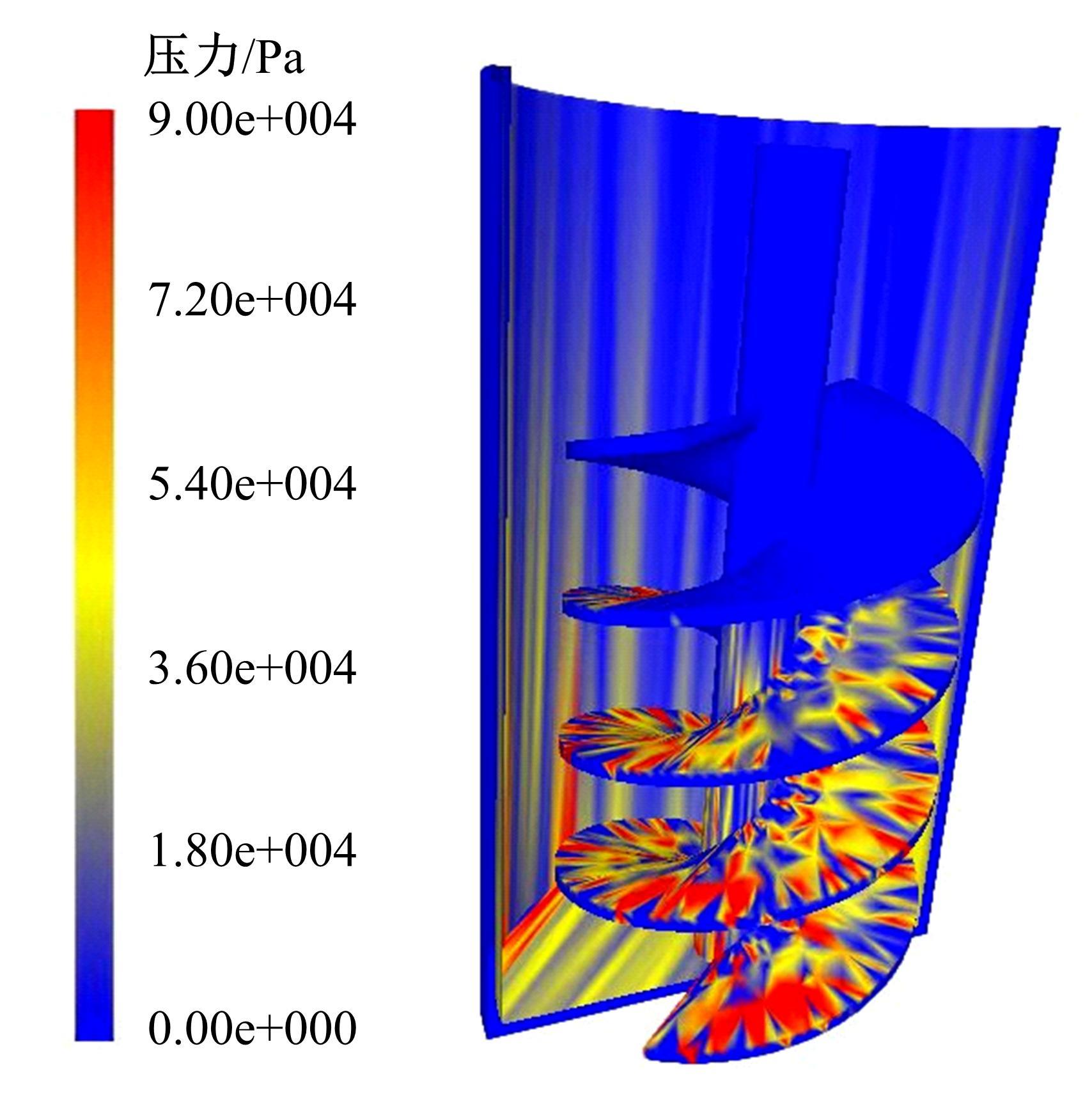

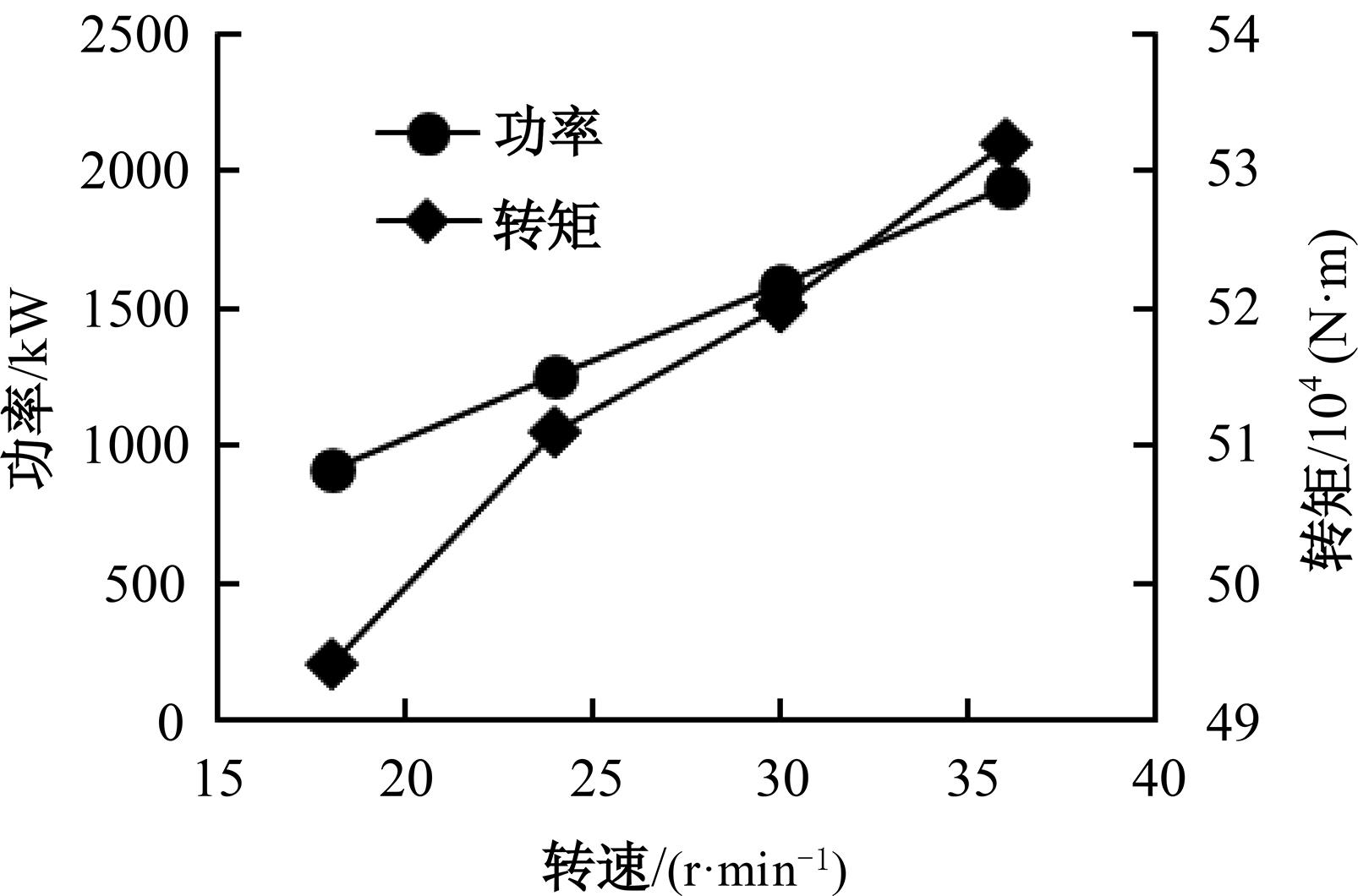

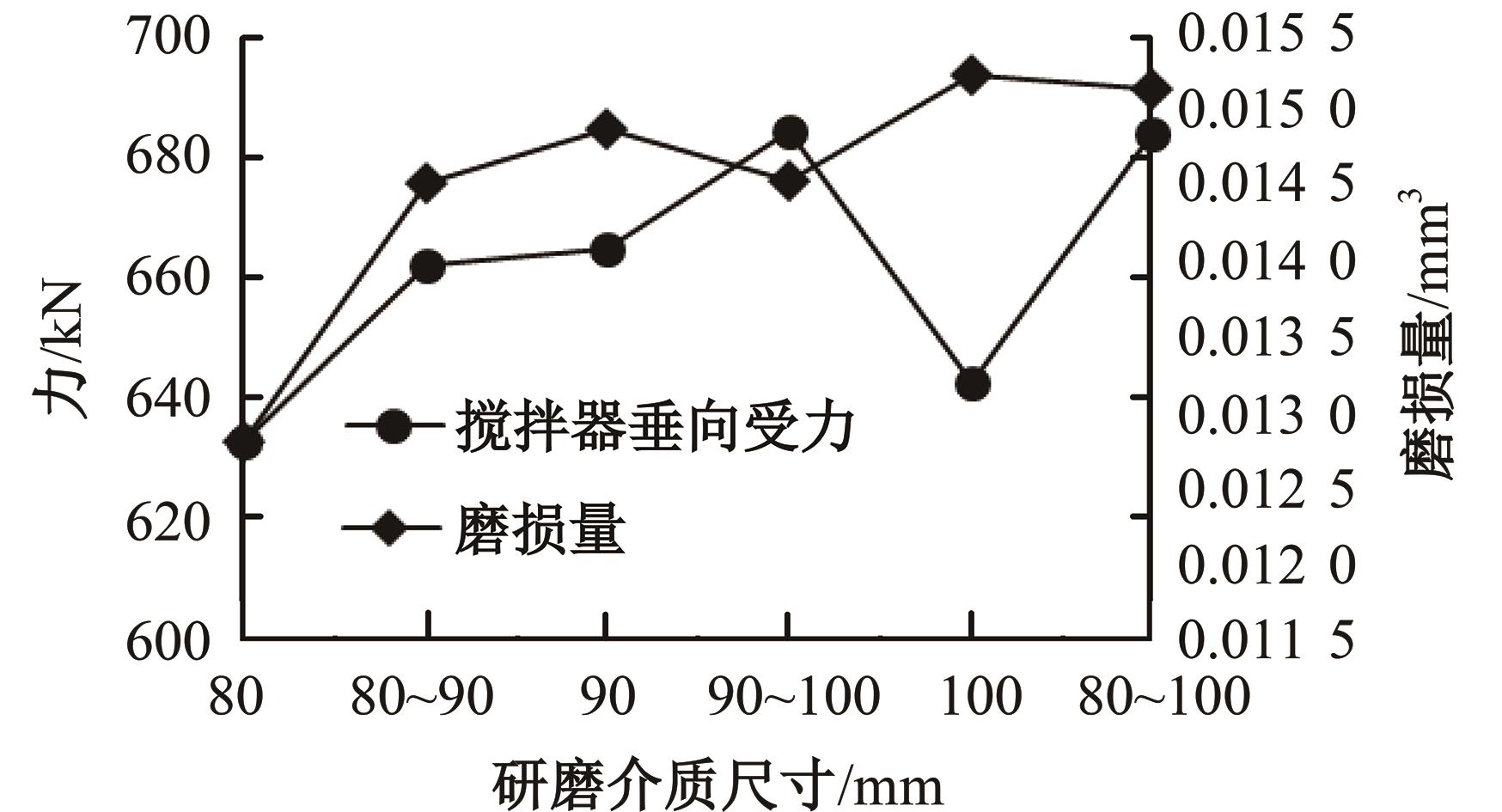

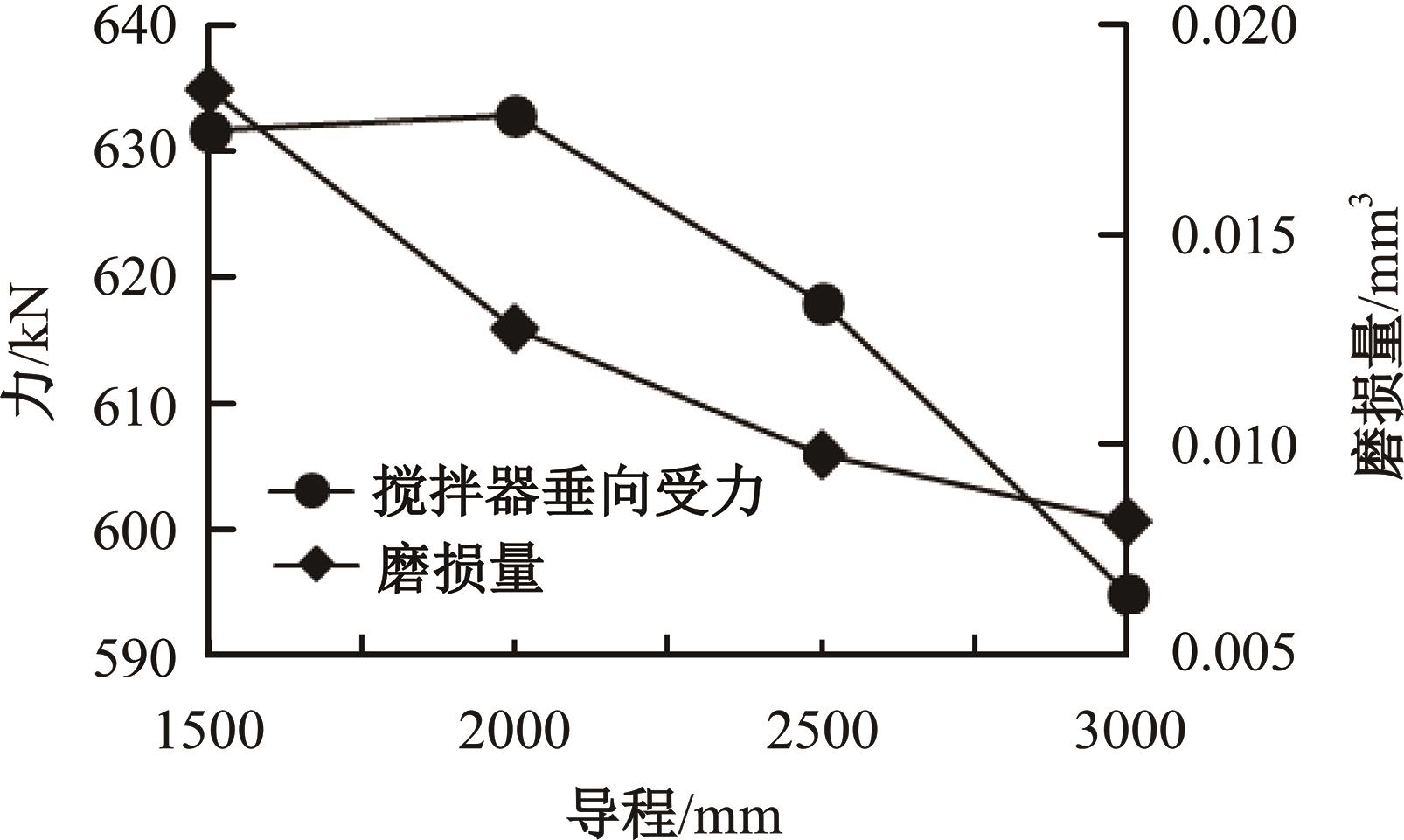

对影响立式螺旋搅拌磨机工作性能的主要结构及特征参数进行分析研究,提出了关键工作参数选择方法。基于离散元方法,首先建立了立式螺旋搅拌磨机的仿真模型,分析了主轴转速、搅拌器导程和研磨介质尺寸分布对磨矿性能的影响;然后,提出综合磨矿性能指标,对各参数进行正交试验,得到磨矿效果的量化值;最后,得到在特定权重系数下的最优工作参数组合,为磨机的优化设计提供了参考方法。

中图分类号:

- TD453

| 1 | 石立. 基于Simulink立式螺旋搅拌磨机启动规律研究[D]. 长沙:长沙矿冶研究院有限责任公司, 2013. |

| Shi Li. Research on start-up law of vertical spiral stirring mill based on Simulink[D]. Changsha: Changsha Mining and Metallurgy Research Institute Co., Ltd., 2013. | |

| 2 | Datta A, Rajamani R K. A direct approach of modeling batch grinding in ball mills using population balance principles and impact energy distribution[J]. International Journal of Mineral Processing, 2002, 64(4): 181-200. |

| 3 | Van Nierop M A, Glover G, Hinde A L, et al. A discrete element method investigation of the charge motion and power draw of an experimental two-dimensional mill[J]. International Journal of Mineral Processing, 2001, 61(2): 77-92. |

| 4 | Bor A, Batjargal U, Jargalsaikhan B, et al. Particle morphology change and quantitative input energy variation during stirred ball milling process by DEM simulation on various experimental conditions[J]. Korean Journal of Materials Research, 2018, 28(3): 148-158. |

| 5 | Sinnott M, Cleary P W, Morrison R. Analysis of stirred mill performance using DEM simulation: Part 1 - Media motion, energy consumption and collisional environment[J]. Minerals Engineering, 2006, 19(15): 1537-1550. |

| 6 | Wilkinson S K, Turnbull S A, Yan Z, et al. A parametric evaluation of powder flowability using a Freeman rheometer through statistical and sensitivity analysis: a discrete element method (DEM) study[J]. Computers & Chemical Engineering, 2017, 97: 161-174. |

| 7 | Fukui S, Tsunazawa Y, Hisatomi S, et al. Effect of agitator shaft direction on grinding performance in media stirred mill: investigation using DEM simulation[J]. Materials Transactions, 2018, 59(3): 488-493. |

| 8 | Daraio D, Villoria J, Ingram A, et al. Investigating grinding media dynamics inside a vertical stirred mill using the discrete element method: effect of impeller arm length[J]. Powder Technology, 2020, 364: 1049-1061. |

| 9 | Oliveira A L R, Rodriguez V A, De Carvalho R M, et al. Mechanistic modeling and simulation of a batch vertical stirred mill[J]. Minerals Engineering, 2020, 156: No.106487. |

| 10 | de Oliveira A L R, De Carvalho R M, Tavares L M. Predicting the effect of operating and design variables in grinding in a vertical stirred mill using a mechanistic mill model[J]. Powder Technology, 2021, 387: 560-574. |

| 11 | 袁东. 转速和填充率对立式搅拌磨粉碎效果影响研究[D]. 昆明:昆明理工大学机电工程学院, 2013. |

| Yuan Dong. Research the effect of speed and filling rate on the vertical agitate mill[D]. Kunming: Faculty of Mechanical and Electrical Engineering, Kunming University of Science and Technology, 2013. | |

| 12 | 母福生, 杨鹏. 搅拌磨机介质运动离散元数值模拟分析[J]. 中国机械工程, 2012, 23(20): 2465-2468. |

| Mu Fu-sheng, Yang Peng. Analysis of dem numerical simulation of media movement for a stirred mill[J]. China Mechanical Engineering, 2012, 23 (20): 2465-2468. | |

| 13 | 邓荣根. 基于离散元超细混合及粉碎的仿真[D]. 上海: 华东理工大学机械与动力工程学院, 2013. |

| Deng Rong-gen. Simulation of ultrafine mixture and disintegration based on discrete element method[D]. Shanghai: School of Mechanical and Power Engineering, East China University of Science and Technology, 2013. | |

| 14 | 朱春辉. 基于EDEM的双腔体立式搅拌磨机数值仿真研究[D]. 徐州:中国矿业大学化工学院, 2018. |

| Zhu Chun-hui. Study on the numerical simulation of the double chamber vertical stirred mill based on EDEM[D]. Xuzhou:School of Chemical Engineering & Technology, China University of Mining and Technology, 2018. | |

| 15 | 张国旺. 超细搅拌磨机的流场模拟和应用研究[D]. 长沙: 中南大学资源加工与生物工程学院, 2005. |

| Zhang Guo-wang.Flowfield numerical simulation and application of ultrafine stirred mill[D]. Changsha: School of Minerals Processing and Bioengineering,Central South University, 2005. | |

| 16 | 姚宗伟, 高旭东, 刘刚, 等. 基于数值仿真的大型塔式磨机工作特性分析[J]. 吉林大学学报:工学版, 2021, 51(5): 1642-1650. |

| Yao Zong-wei, Gao Xu-dong, Liu Gang, et al. Research on working performance of vertical screw stirring mill based on numerical simulations[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 51(5): 1642-1650. | |

| 17 | 黄胤淇. 磨矿条件对立式搅拌磨磨矿产品粒度特性的影响及应用[D]. 昆明:昆明理工大学国土资源工程学院, 2019. |

| Huang Yin-qi. Effect of grinding conditions on particle size characteristics of grinding products from vertical agitating mill and its application[D]. Kunming: Faculty of Land Resources Engineering, Kunming University of Science and Technology,2019. | |

| 18 | 任廷志, 李卓, 刘长远,等. 基于离散元法的塔磨机数值模拟分析[J]. 中国粉体技术, 2016, 22(4): 88-91. |

| Ren Ting-zhi, Li Zhuo, Liu Chang-yuan, et al. Numerical simulation analysis of tower mill based on discrete element method[J]. China Powder Science and Technology, 2016, 22(4): 88-91. | |

| 19 | 桑艳伟. 基于离散单元法的立磨机介质球运动及其关键参数研究[D].长沙: 长沙矿冶研究院, 2018. |

| Sang Yan-wei. Research on the motion and key parameters of medium ball in vertical mill based on discrete element method[D]. Changsha: Changsha Research Institute of Mining and Metallurgy, 2018. | |

| 20 | 徐长锋. 考虑海泡石矿粉粒径及分布宽度的螺旋搅拌磨机研制[D]. 湘潭:湘潭大学机械工程与力学学院, 2021. |

| Xu Chang-feng. Research and development of a spiral stirred mill considering the size and distribution width of sepiolite powder[D].Xiangtan: School of Mechanical Engineering and Mechanics,Xiangtan University, 2021. | |

| 21 | 廖阳. 搅拌磨机磨筒结构对磨矿介质运动的影响研究[D]. 昆明: 昆明理工大学机电工程学院, 2022. |

| Liao Yang. The influence of grinding cylinder structure of stirred mill on the motion of grinding media[D]. Kunming: Faculty of Mechanical and Electrical Engineering, Kunming University of Science and Technology, 2022. | |

| 22 | Esteves P M, Mazzinghy D B, Galery R, et al. Predictive modelling of vertical stirred mills liner wear using vibration signature analysis[J/OL].[2022-11-02]. |

| [1] | 刘昕晖,相志霖,谭鹏,陈伟,冯吉宇. 基于Fluent的散热系统扩流结构内部流场分析及优化[J]. 吉林大学学报(工学版), 2024, 54(7): 1831-1843. |

| [2] | 李光保,高栋,路勇,平昊,周愿愿. 基于改进神经网络和Fluent的气液固技术的内表面处理[J]. 吉林大学学报(工学版), 2024, 54(6): 1537-1547. |

| [3] | 赵晓康,胡哲,牛振兴,张久鹏,裴建中,温永. 基于非均质模型的水稳碎石材料细观开裂行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1258-1266. |

| [4] | 刘元义,于圣洁,胥备,王宪良,宋发成. 基于离散元的设施农业就地翻土犁的研究与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1153-1165. |

| [5] | 李义,吕晨阳,梁继才,梁策. 不规则Y形铝型材多点拉弯成形截面变形分析[J]. 吉林大学学报(工学版), 2024, 54(1): 105-113. |

| [6] | 司春棣,崔亚宁,许忠印,凡涛涛. 层间粘结失效后桥面沥青铺装层细观力学行为分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1719-1728. |

| [7] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [8] | 彭勇,章秀芳,郭泽宇,陆学元,李彦伟. 离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响[J]. 吉林大学学报(工学版), 2023, 53(1): 178-187. |

| [9] | 王同建,杨书伟,谭晓丹,陈晋市,刘同文,职振领. 基于DEM⁃MBD联合仿真的液压挖掘机作业性能分析[J]. 吉林大学学报(工学版), 2022, 52(4): 811-818. |

| [10] | 耿端阳,孙延成,牟孝栋,张国栋,姜慧新,朱俊科. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 693-702. |

| [11] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [12] | 李建平,边永亮,杨欣,王鹏飞,李昕昊,薛春林. 果园多风机风送喷雾机作业参数优化与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2474-2485. |

| [13] | 金文明,梁田,梁策,李义,李俊涛,梁继才. 工艺参数对汽车防护梁绕弯成形的截面变形影响[J]. 吉林大学学报(工学版), 2021, 51(4): 1182-1189. |

| [14] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [15] | 狄胜同,贾超,乔卫国,李康,童凯. 橡胶集料混凝土细观损伤特性的加载速率效应[J]. 吉林大学学报(工学版), 2019, 49(6): 1900-1910. |

|

||