吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 178-187.doi: 10.13229/j.cnki.jdxbgxb20210482

• 交通运输工程·土木工程 • 上一篇

离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响

- 1.浙江大学 交通工程研究所,杭州310058

2.安徽省交通控股集团有限公司,合肥 230088

3.河北省交通规划设计院,石家庄 050011

4.公路建设与养护技术、材料及装备交通运输行业研发中心,石家庄 050011

Influence of aggregate contact characteristics on shear fatigue life of asphalt mixtures using discrete element method

Yong PENG1( ),Xiu-fang ZHANG1,Ze-yu GUO1,Xue-yuan LU2,Yan-wei LI3,4

),Xiu-fang ZHANG1,Ze-yu GUO1,Xue-yuan LU2,Yan-wei LI3,4

- 1.Institute of Transportation Engineering,Zhejiang University,Hangzhou 310058,China

2.Anhui Transportation Holding Group Co. ,Ltd. ,Hefei 230088,China

3.Hebei Provincial Communications Planning and Design Institute,Shijiazhuang 050011,China

4.Research and Development Center of Transport Industry of Technologies,Materials and Equipments of Highway Construction and Maintenance,Shijiazhuang 050011,China

摘要:

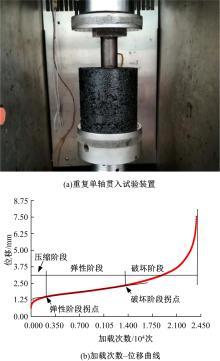

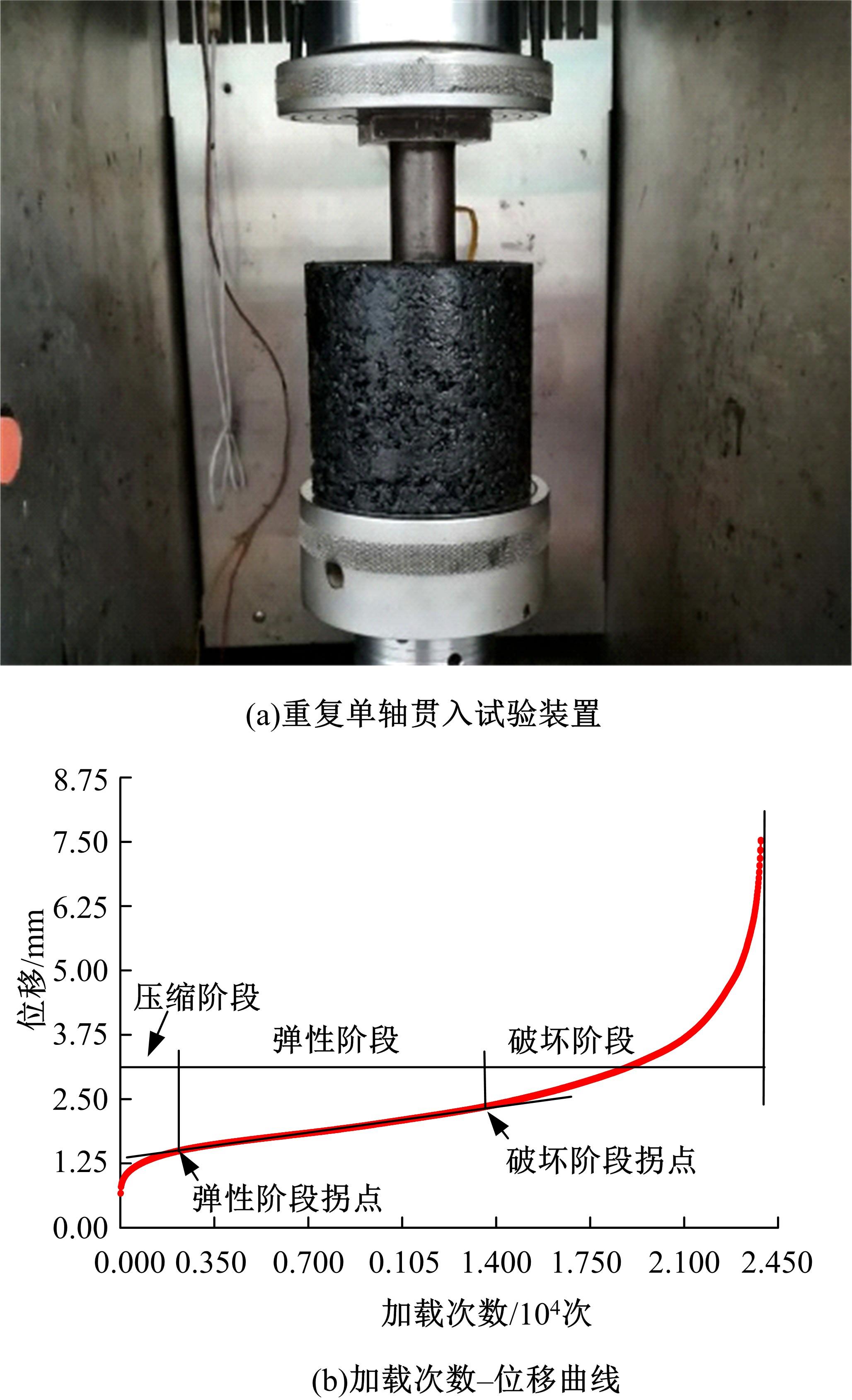

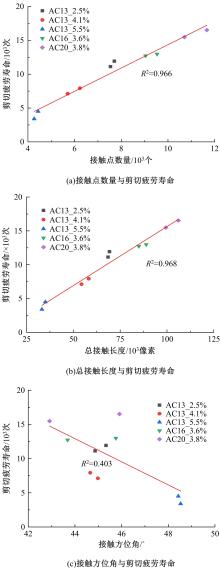

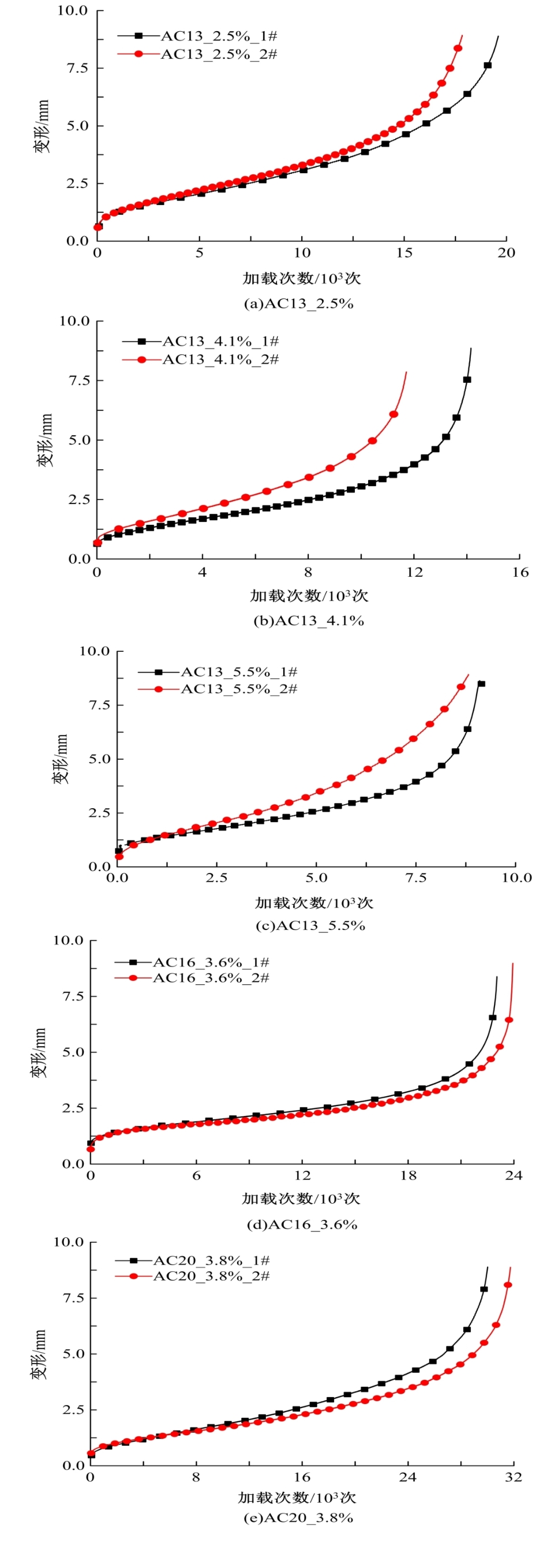

基于CT断层扫描和图像处理采集到的沥青混合料内部结构信息,采用Matlab软件编写程序获取混合料内部集料接触特性,借助颗粒流软件PFC3D建立混合料剪切疲劳试验三维离散元模型,模拟考虑损伤的沥青混合料剪切疲劳寿命,研究集料接触特性对沥青混合料剪切疲劳寿命的影响,并对模拟结果加以试验验证。研究结果表明,考虑疲劳损伤的沥青混合料剪切疲劳三维离散元法可以较好地模拟沥青混合料剪切疲劳试验,得到的剪切疲劳寿命模拟值与试验值误差较小。集料接触点和总接触长度对沥青混合料剪切疲劳寿命影响显著,集料接触点数越多,总接触长度越大,混合料的剪切疲劳寿命越大;水平截面上集料接触方位角对沥青混合料剪切疲劳寿命影响较小,其两者间相关性不明显。此外,集料粒径和空隙率对沥青混合料中集料接触特性有较大的影响。相同的试验条件下,沥青混合料内部集料接触点数和总接触长度随集料粒径的增大而增加,随空隙率的增大而减少。

中图分类号:

- U414

| 1 | 英红,王锦河,张宏,等. 基于图像的AC20型混合料集料接触分布变异性[J]. 同济大学学报:自然科学版,2011,39(3):359-364. |

| Ying Hong, Wang Jin-he, Zhang Hong, et al. Variation of aggregate contacts distribution in AC20 HMA based on digital image processing[J]. Journal of Tongji University (Natural Science), 2011, 39(3): 359-364. | |

| 2 | Coenen A R, Kutay M E, Sefidmazgi N R, et al. Aggregate structure characterisation of asphalt mixtures using two-dimensional image analysis[J]. Road Materials and Pavement Design, 2012, 13(3): 433-454. |

| 3 | 张东,黄晓明,赵永利. 沥青玛蹄脂混合料矿料骨架构成及其接触特性[J]. 吉林大学学报:工学版,2015,45(2):394-399. |

| Zhang Dong, Huang Xiao-ming, Zhao Yong-li. Aggregate skeleton composition of stone mastic asphalt and its contact properties[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(2): 394-399. | |

| 4 | 谭忆秋,邢超,任俊达,等. 基于颗粒堆积理论的沥青混合料细观结构特性研究[J]. 中国公路学报,2017,30(7):1-8. |

| Tan Yi-qiu, Xing Chao, Ren Jun-da, et al. Research on mesostructured characteristics of asphalt mixture based on particle packing theory[J]. China Journal of Highway and Transport, 2017, 30(7): 1-8. | |

| 5 | Cai X, Wu K, Huang W. Study on the optimal compaction effort of asphalt mixture based on the distribution of contact points of coarse aggregates[J]. Road Materials and Pavement Design, 2021, 22(7): 1594-1615. |

| 6 | Brahmajaree N, Kanitpong K, Sawangsuriya A. Investigation on internal structural properties of asphalt mixtures subjected to loading using image analysis[J]. International Journal of Pavement Engineering, 2022, 23(1): 107-120. |

| 7 | Samer D, Eyad M, Fouad B. Evaluation of asphalt mix stability using compaction properties and aggregate structure analysis[J]. International Journal of Pavement Engineering, 2003, 4(2): 87-103. |

| 8 | Li P, Su J, Ma S, et al. Effect of aggregate contact condition on skeleton stability in asphalt mixture[J]. International Journal of Pavement Engineering, 2020, 21(2): 196-202. |

| 9 | Sefidmazgi N R, Tashman L, Bahia H. Internal structure characterization of asphalt mixtures for rutting performance using imaging analysis[J]. Road Materials and Pavement Design, 2012, 13(1): 21-37. |

| 10 | Masad E, Muhunthan B, Shashidhar N . et al. Quantifying laboratory compaction effects on the internal structure of asphalt concrete[J]. Transportation Research Record, 1999, 1681(1): 179-185. |

| 11 | 王端宜,黎侃,蔡旭. 基于集料接触特性的沥青混合料抗车辙性能评价[J]. 华南理工大学学报:自然科学版,2012,40(11):121-126, 154. |

| Wang Duan-yi, Li Kan, Cai Xu. Evaluation of rutting resistance of asphalt mixture based on aggregate contact characteristics[J]. Journal of South China University of Technology (Natural Science Edition), 2012, 40(11): 121-126, 154. | |

| 12 | Ling C, Bahia H. Modelling of aggregates' contact mechanics to study roles of binders and aggregates in asphalt mixtures rutting[J]. Road Materials and Pavement Design, 2020, 21(3): 720-736. |

| 13 | Cai X, Wu K H, Huang W K, et al. Study on the correlation between aggregate skeleton characteristics and rutting performance of asphalt mixture[J]. Construction & Building Materials, 2018, 179: 294-301. |

| 14 | 毕玉峰,孙立军. 沥青混合料抗剪试验方法研究[J]. 同济大学学报自:然科学版,2005,33(8):1036-1040. |

| Bi Yu-feng, Sun Li-jun. Research on test method of asphalt mixture's shearing properties[J]. Journal of Tongji University (Natural Science), 2005, 33(8): 1036-1040. | |

| 15 | 邵显智. 沥青混合料抗剪性能影响因素及剪切疲劳试验研究[D]. 上海:同济大学交通运输学院,2005. |

| Shao Xian-zhi. Study on influence factors and fatigue experiment about shear properties of asphalt mixtures[D]. Shanghai: College of Transportation Engineering, Tongji University, 2005. | |

| 16 | Peng Y, Gao H, Lu X, et al. Micromechanical discrete element modeling of asphalt mixture shear fatigue performance[J]. Journal of Materials in Civil Engineering, 2020, 32(7):No.04020183. |

| 17 | 杨宇亮. 沥青混合料细观结构的分析系统[D]. 上海:同济大学交通运输工程学院,2003. |

| Yang Yu-liang. Sub-microstructure analysis system of asphalt concrete (MASAC)[D]. Shanghai: College of Transportation Engineering, Tongji University, 2003. | |

| 18 | 蔡旭,王端宜,黎侃,等. 基于散体力学的沥青混合料剪切模量预估[J]. 中国公路学报,2013,26(6):38-46. |

| Cai Xu, Wang Duan-yi, Li Kan, et al. Prediction of shear modulus of asphalt mixtures based on granular mechanics[J]. China Journal of Highway and Transport, 2013, 26(6): 38-46. | |

| 19 | Itasca Consulting Group. Particle Flow Code in Three-dimensions (PFC3D) Manual (version 3.1)[M].Minneapolis: Itasca Consulting Group, 2004. |

| 20 | Dai Q. Micromechanical modeling of constitutive and damage behavior of heterogeneous asphalt materials[D]. Kingston: University of Rhode Island, 2004. |

| 21 | You Z, Adhikari S, Dai Q. Three-dimensional discrete element models for asphalt mixtures[J]. Journal of Engineering Mechanics, 2008, 134(12):1053-1063. |

| 22 | 张垚. 基于PFC3D的沥青混合料虚拟试验研究[D]. 南京:东南大学交通学院,2015. |

| Zhang Yao. Virtual tests of asphalt mixture based on PFC3D[D]. Nanjing: College of Transportation, Southeast University, 2015. | |

| 23 | 曾梦澜,李洁,黄冰,等. 基于常规试验数据的沥青劲度模量一般公式表达[J]. 中南公路工程,2004(1):45-50, 58. |

| Zeng Meng-lan, Li Jie, Huang Bing, et al. A general formulation for stiffness modulus of asphalt binders using routine test data[J]. Central South Highway Engineering, 2004(1): 45-50, 58. | |

| 24 | 严明星,王金昌. 沥青混合料蠕变柔量与松弛模量的转换关系研究[J]. 公路交通技术,2016,32(5):28-31. |

| Yan Ming-xing, Wang Jin-chang. Study on conversion between creep compliance and relaxation modulus of asphalt mixture[J]. Technology of Highway and Transport, 2016, 32(5): 28-31. |

| [1] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [2] | 周正峰,于晓涛,陶雅乐,郑茂,颜川奇. 基于灰色关联分析的树脂与弹性体高黏沥青高温性能评价[J]. 吉林大学学报(工学版), 2023, 53(7): 2078-2088. |

| [3] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [4] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [5] | 郑睢宁,何锐,路天宇,徐紫祎,陈华鑫. RET/胶粉复合改性沥青制备及其混合料性能评价[J]. 吉林大学学报(工学版), 2023, 53(5): 1381-1389. |

| [6] | 关博文,邸文锦,王发平,吴佳育,张硕文,贾治勋. 干湿循环与交变荷载作用下混凝土硫酸盐侵蚀损伤[J]. 吉林大学学报(工学版), 2023, 53(4): 1112-1121. |

| [7] | 杨帆,李琛琛,李盛,刘海伦. 温缩作用下双层连续配筋混凝土路面配筋率设计参数对比分析[J]. 吉林大学学报(工学版), 2023, 53(4): 1122-1132. |

| [8] | 魏海斌,马子鹏,毕海鹏,刘汉涛,韩栓业. 基于力学响应分析方法的导电橡胶复合路面铺装技术[J]. 吉林大学学报(工学版), 2023, 53(2): 531-537. |

| [9] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [10] | 郭庆林,刘强,吴春利,李黎丽,李懿明,刘富春. 导电沥青及混合料裂缝局部温度场及愈合效果[J]. 吉林大学学报(工学版), 2022, 52(6): 1386-1393. |

| [11] | 何兆益,李金凤,周文,官志桃. 多孔沥青混合料的动态模量及其预估模型[J]. 吉林大学学报(工学版), 2022, 52(6): 1375-1385. |

| [12] | 时成林,王勇,吴春利,宋文祝. 路堤挡土墙主动土压力计算方法修正[J]. 吉林大学学报(工学版), 2022, 52(6): 1394-1403. |

| [13] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [14] | 耿端阳,孙延成,牟孝栋,张国栋,姜慧新,朱俊科. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 693-702. |

| [15] | 夏全平,高江平,罗浩原,张其功,李志杰,杨飞. 用于高模量沥青砼的复合改性硬质沥青低温性能[J]. 吉林大学学报(工学版), 2022, 52(3): 541-549. |

|

||