吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1537-1547.doi: 10.13229/j.cnki.jdxbgxb.20230025

• 车辆工程·机械工程 • 上一篇

基于改进神经网络和Fluent的气液固技术的内表面处理

- 1.上海航天精密机械研究所,上海 201600

2.哈尔滨工业大学 机电工程学院,哈尔滨 150001

Internal surface treatment of gas-liquid-solid technology based on improved neural network and Fluent

Guang-bao LI1,2( ),Dong GAO2,Yong LU2,Hao PING1,Yuan-yuan ZHOU1

),Dong GAO2,Yong LU2,Hao PING1,Yuan-yuan ZHOU1

- 1.Shanghai Aerospace Precision Machinery Research Institute,Shanghai 201600,China

2.School of Mechanical and Electrical Engineering,Harbin Institute of Technology,Harbin 150001,China

摘要:

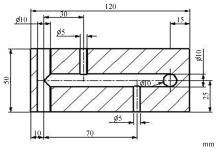

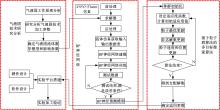

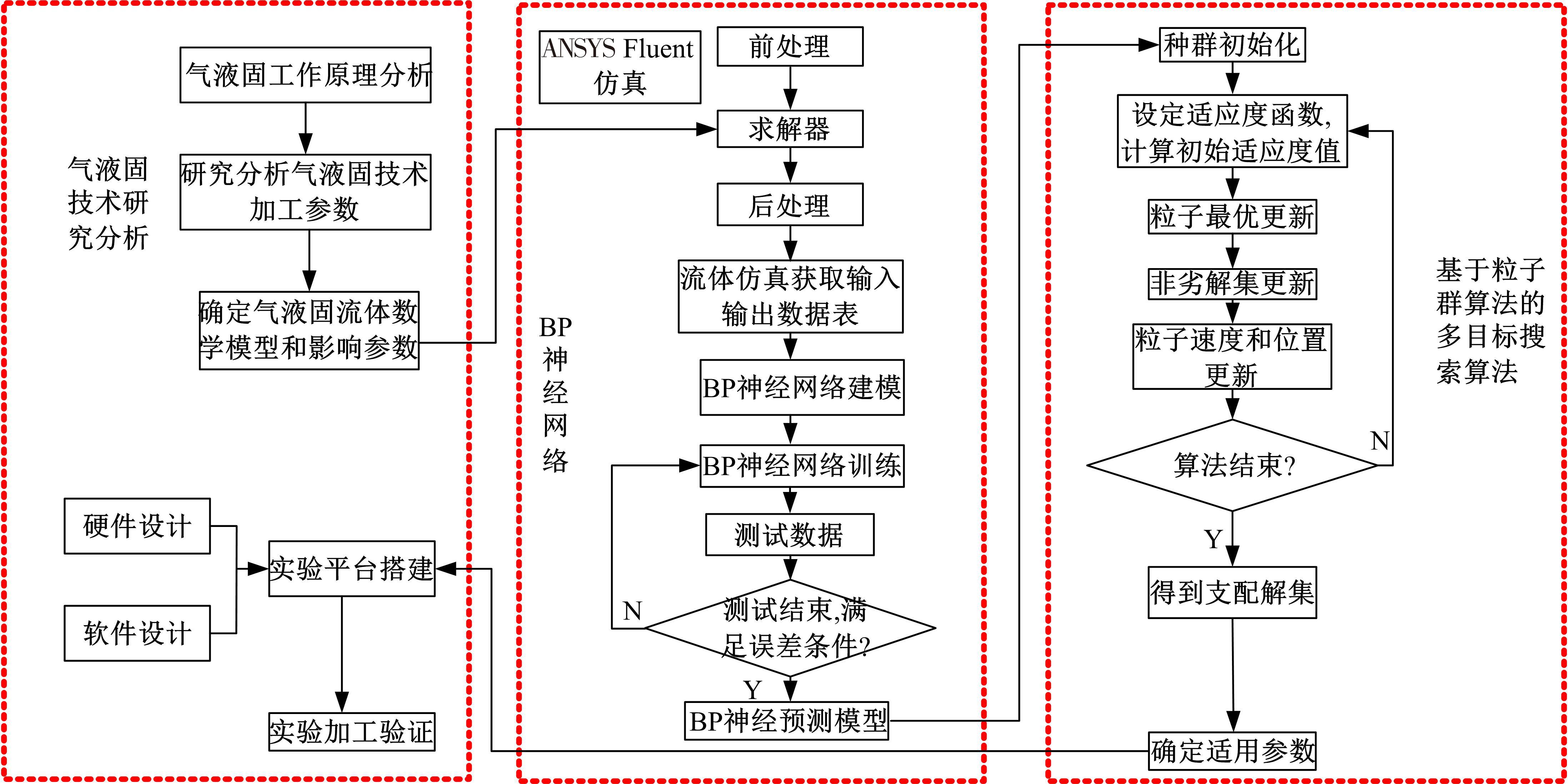

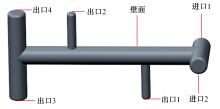

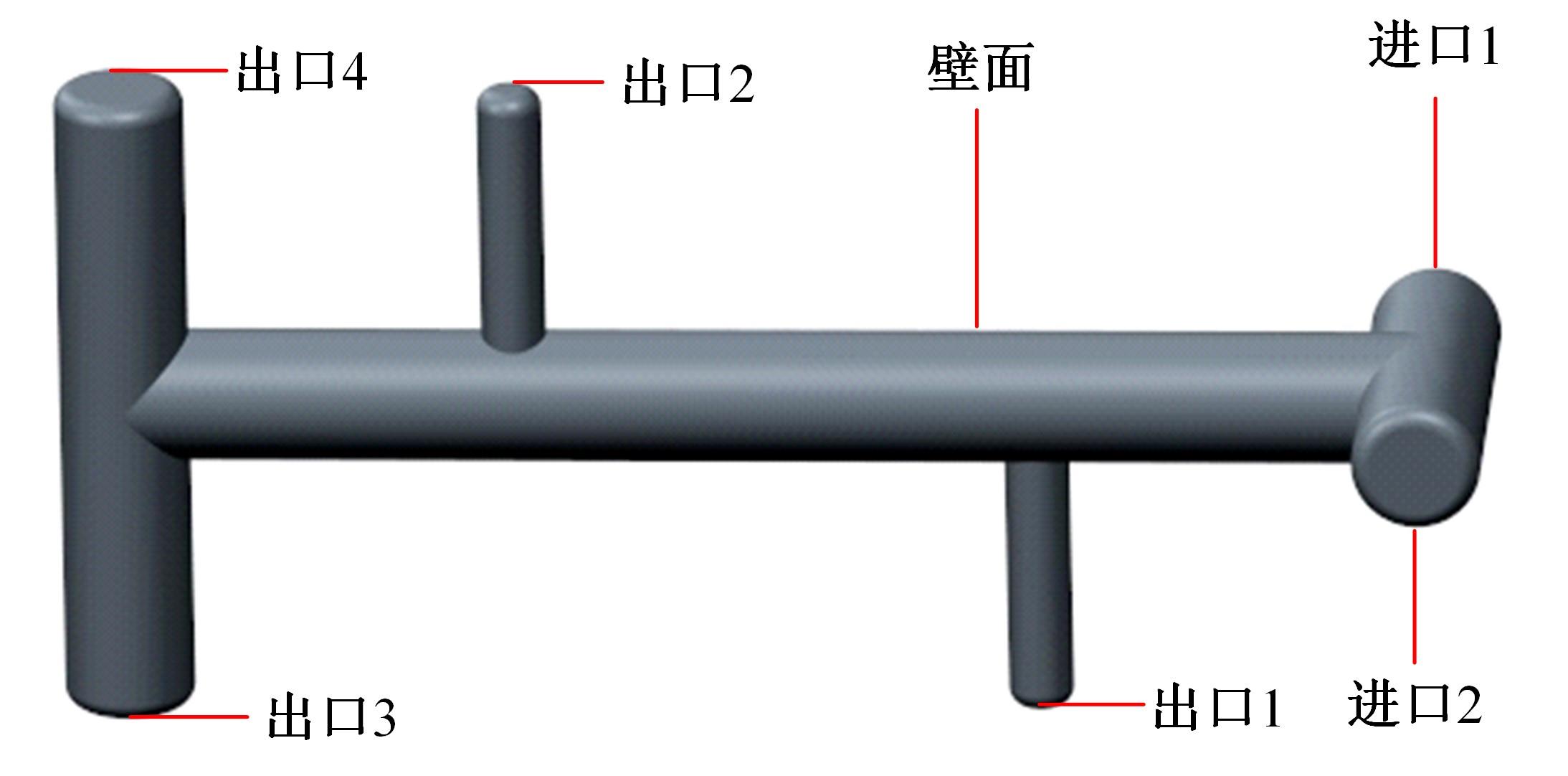

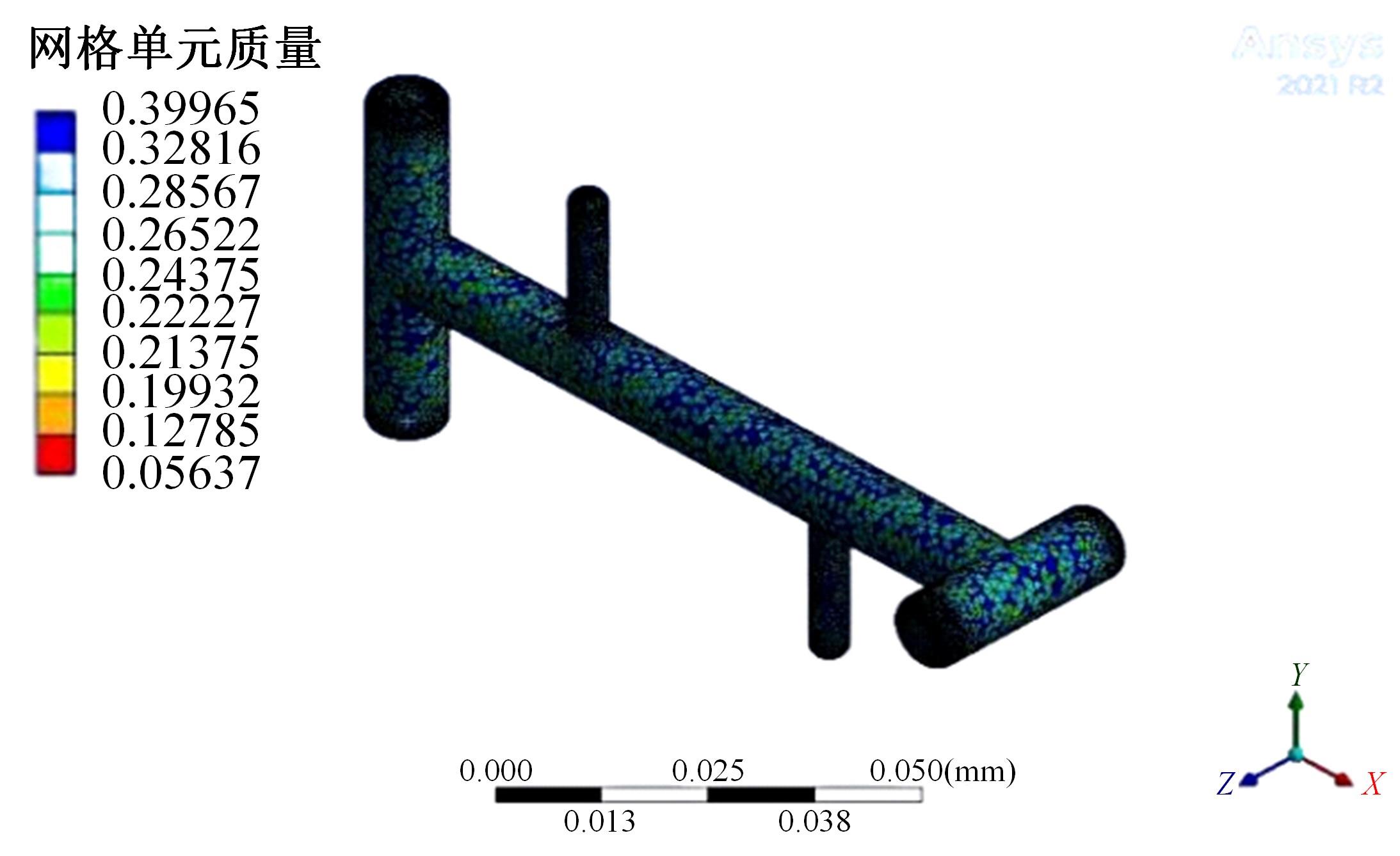

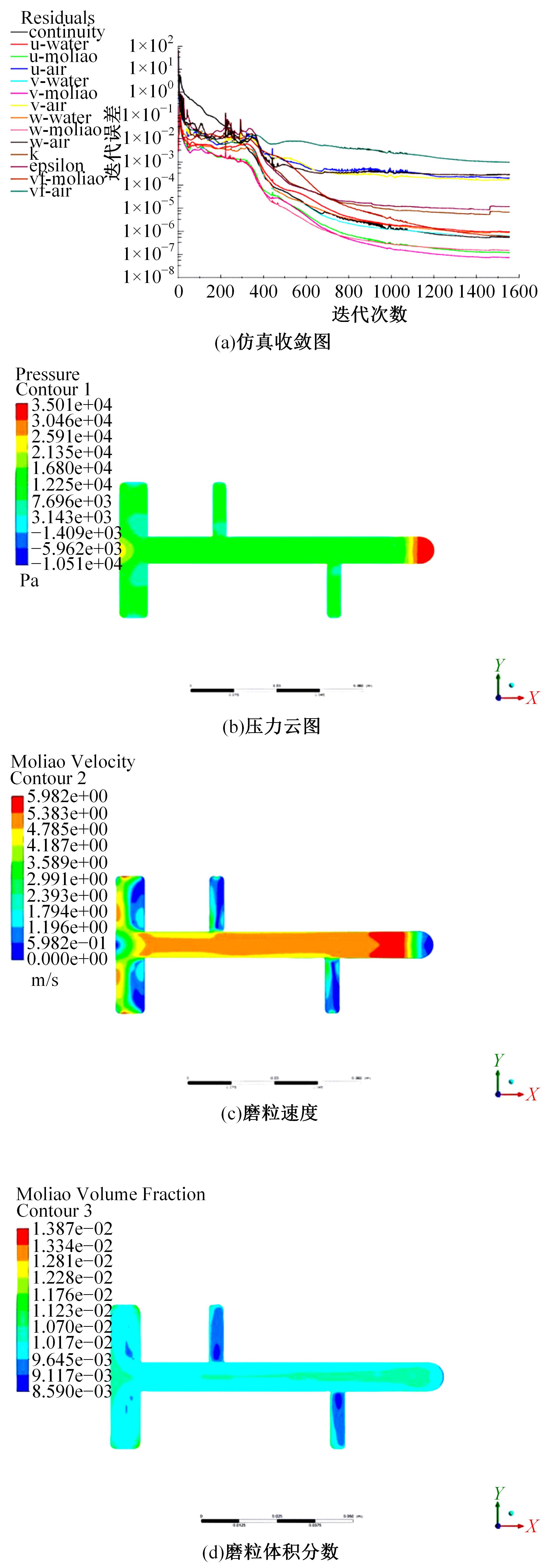

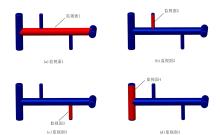

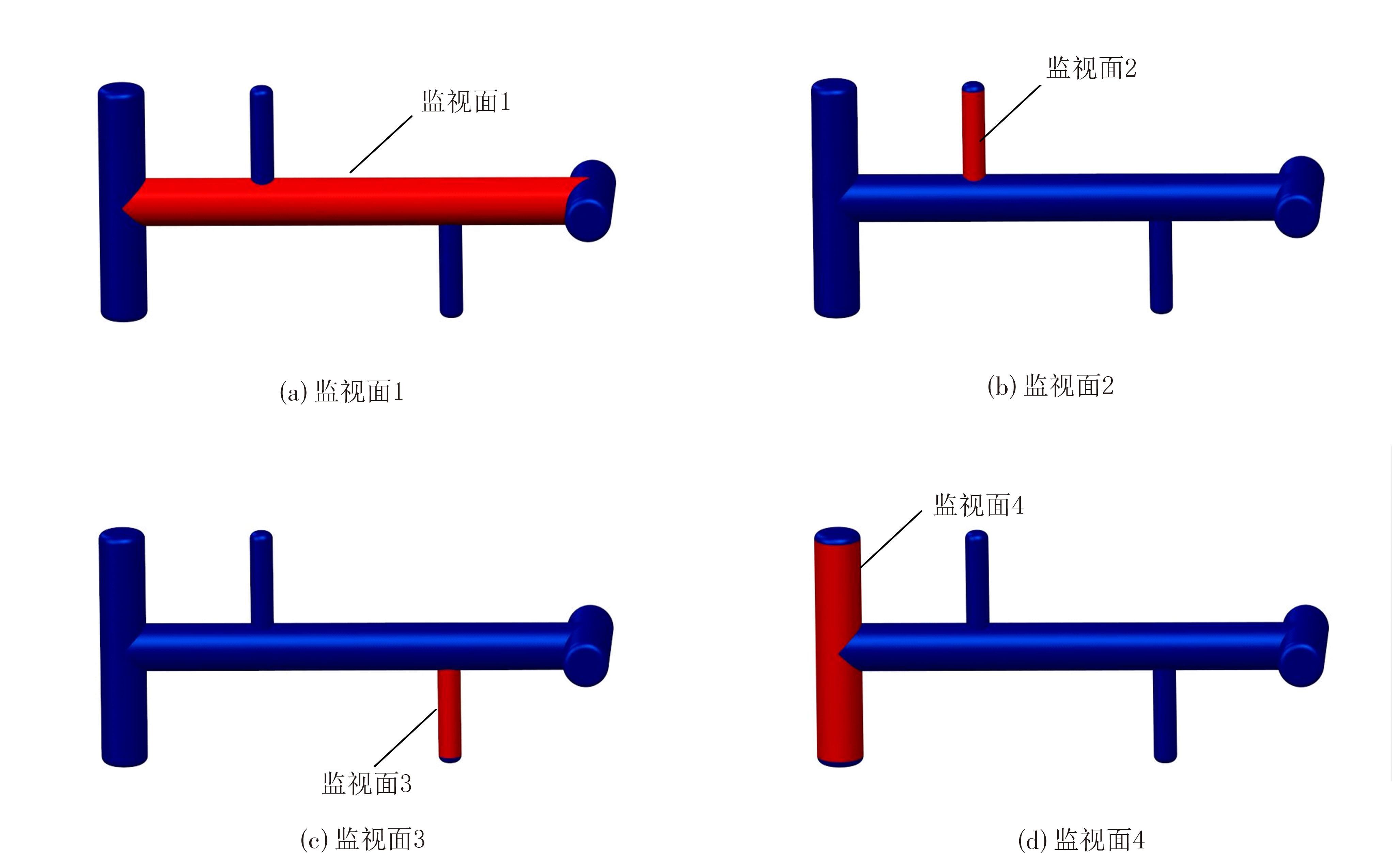

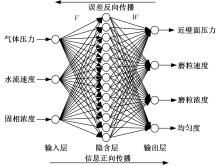

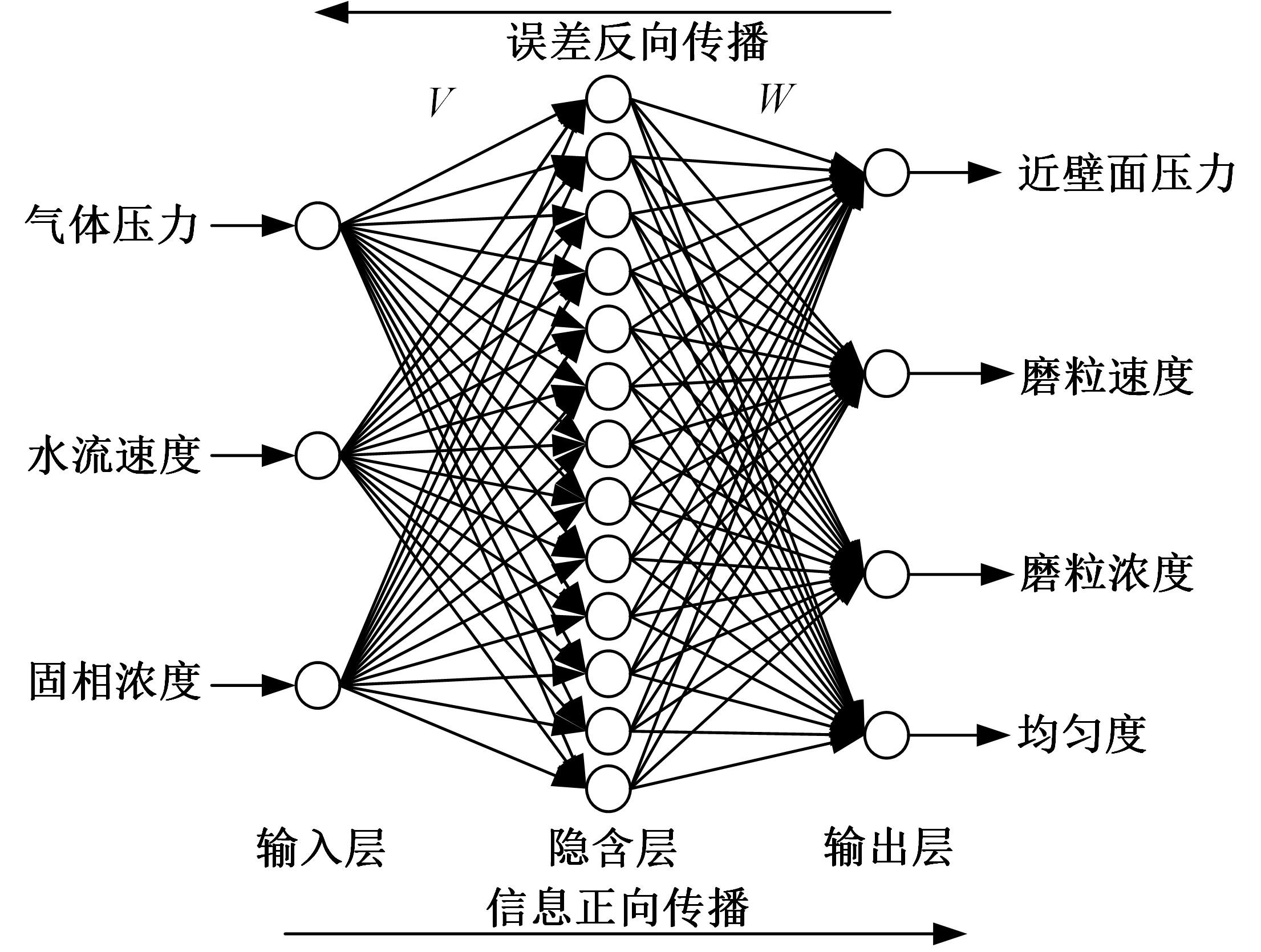

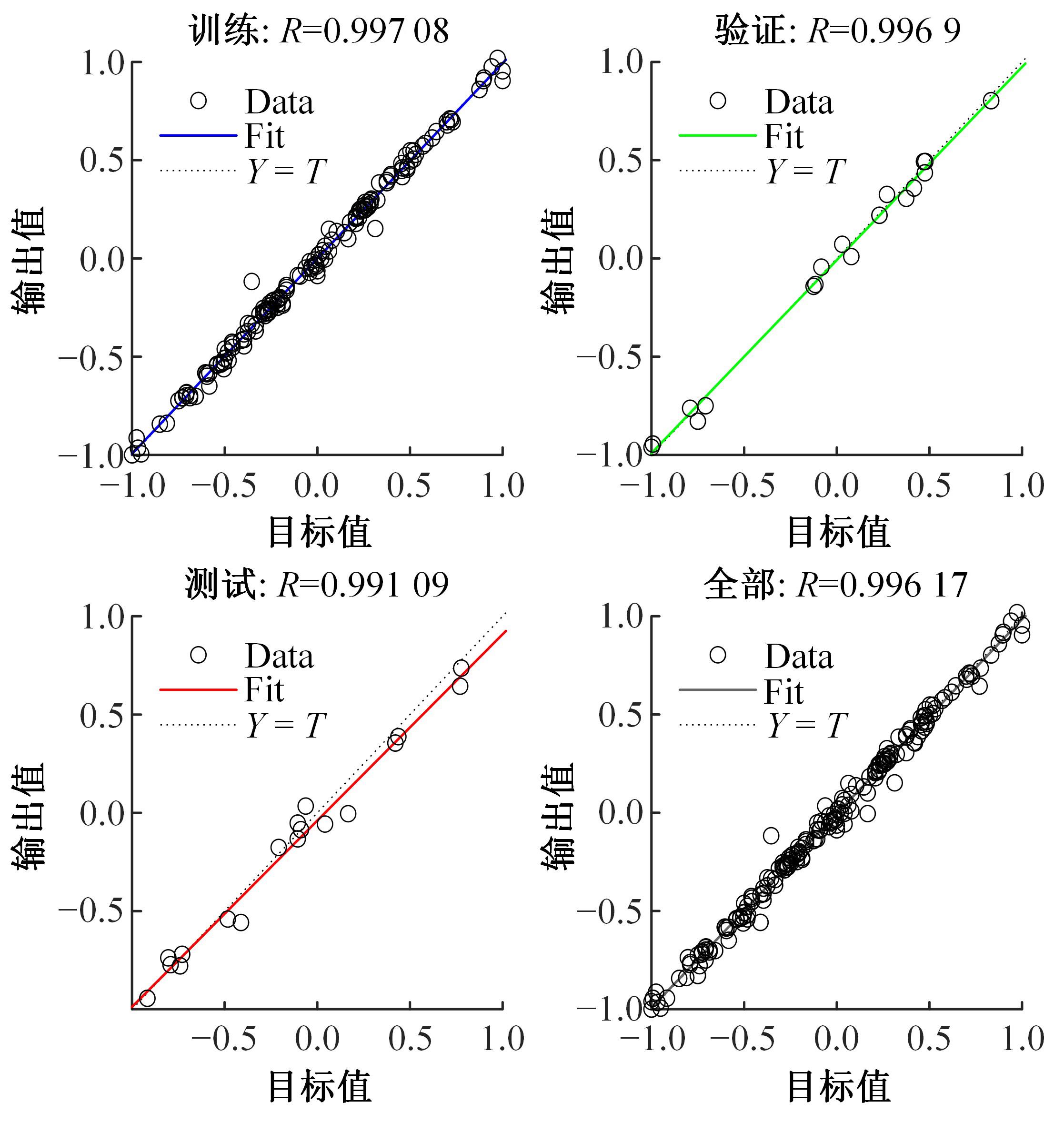

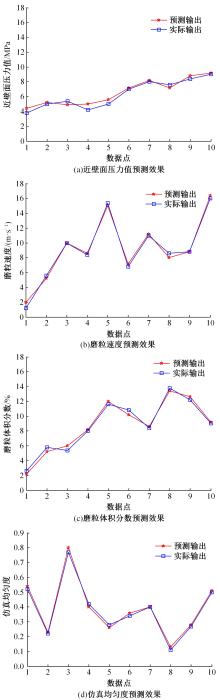

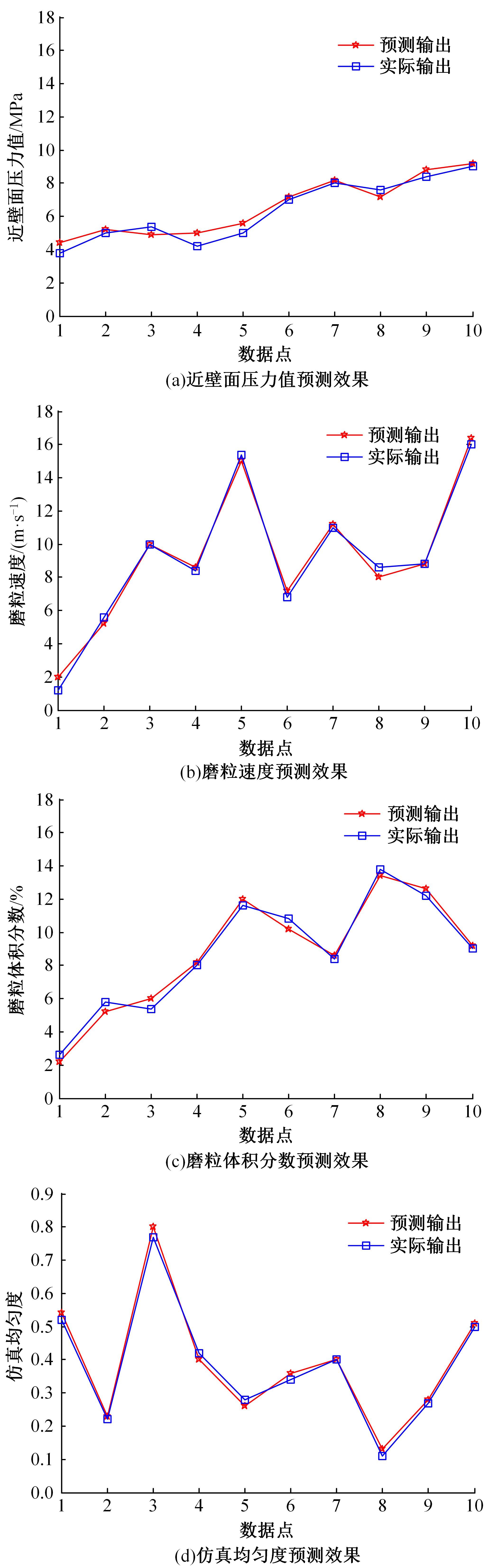

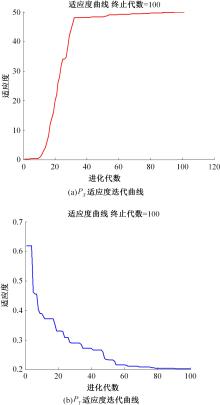

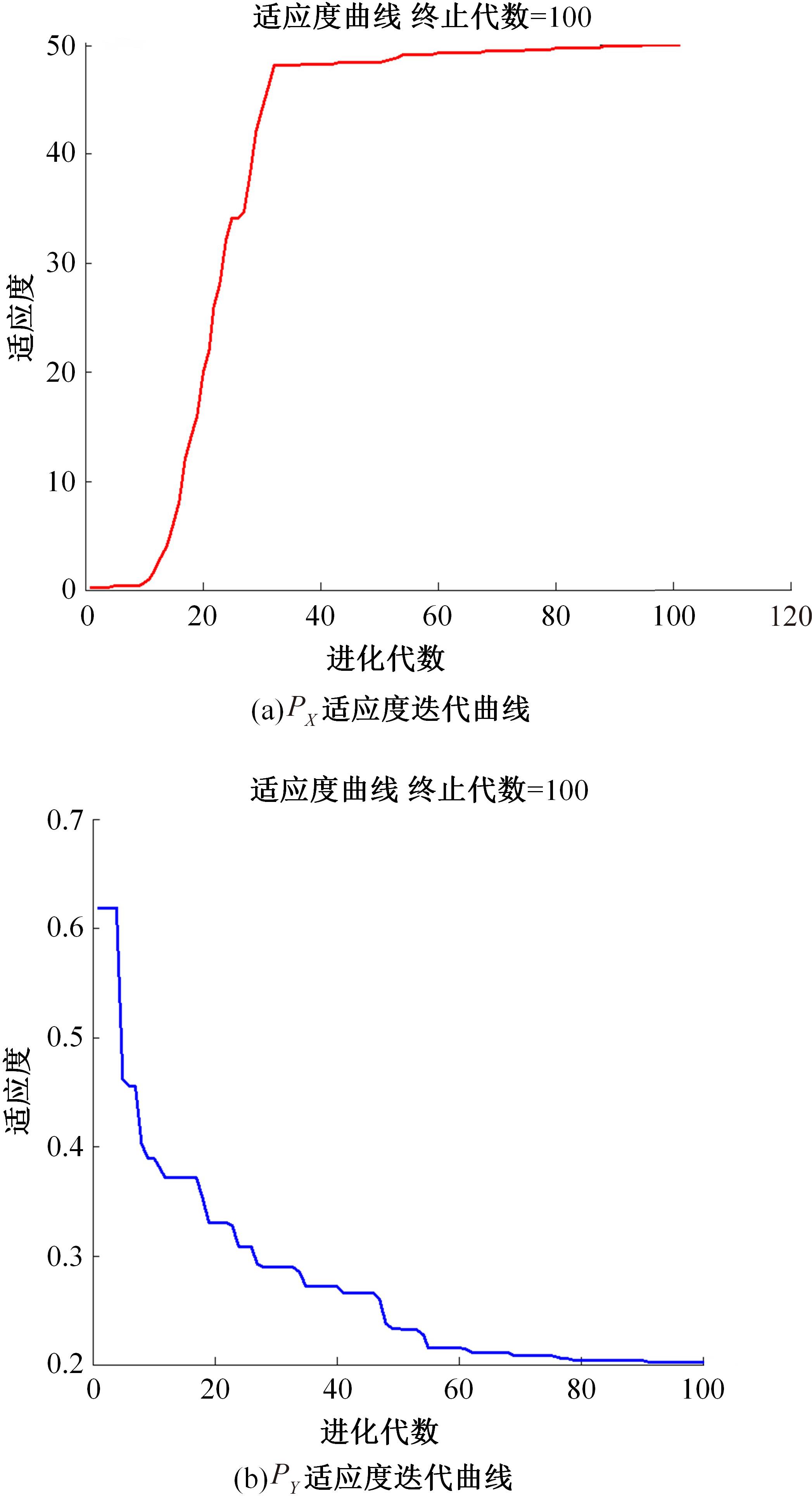

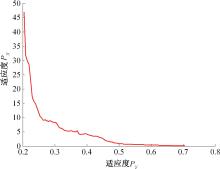

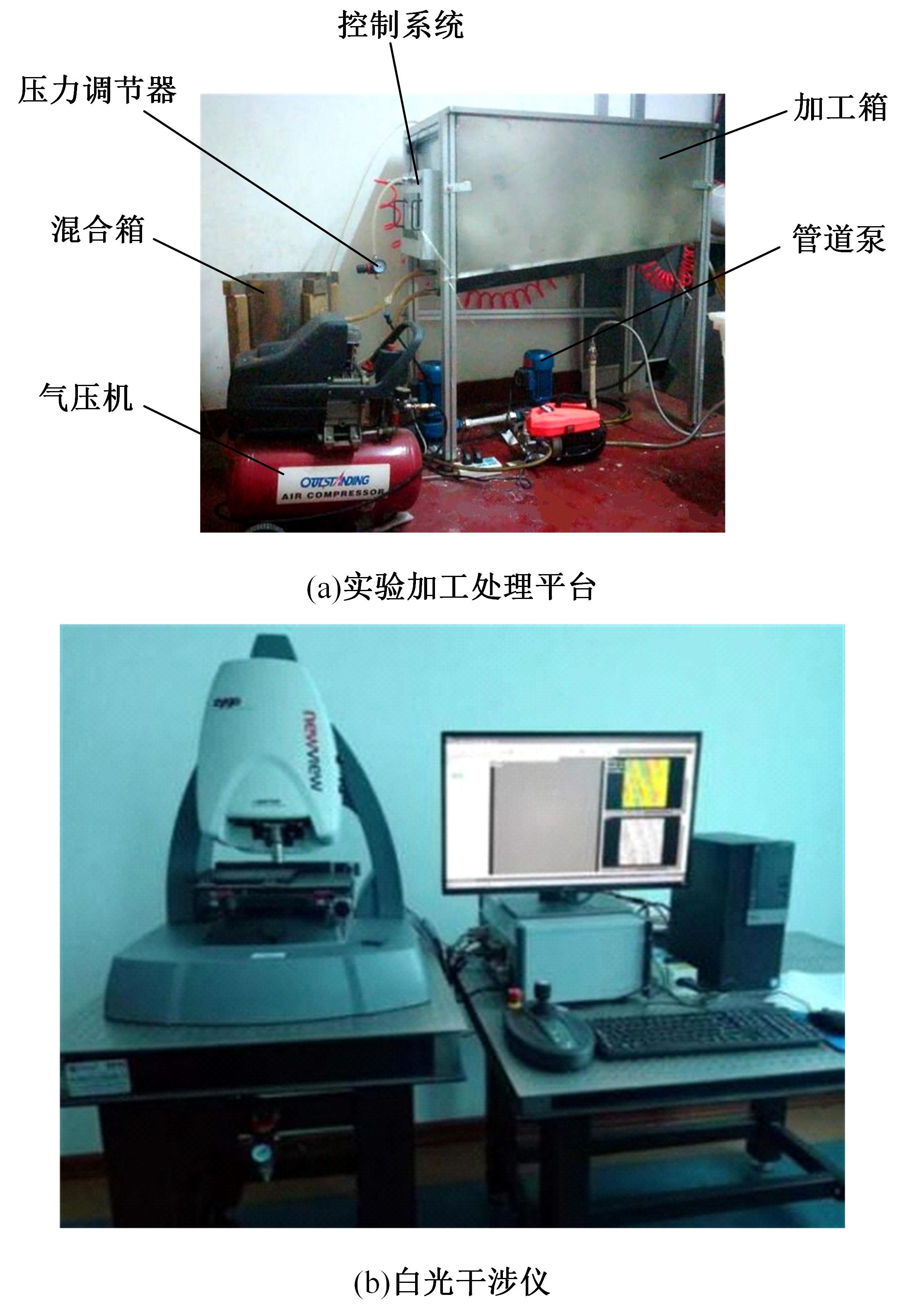

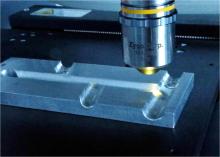

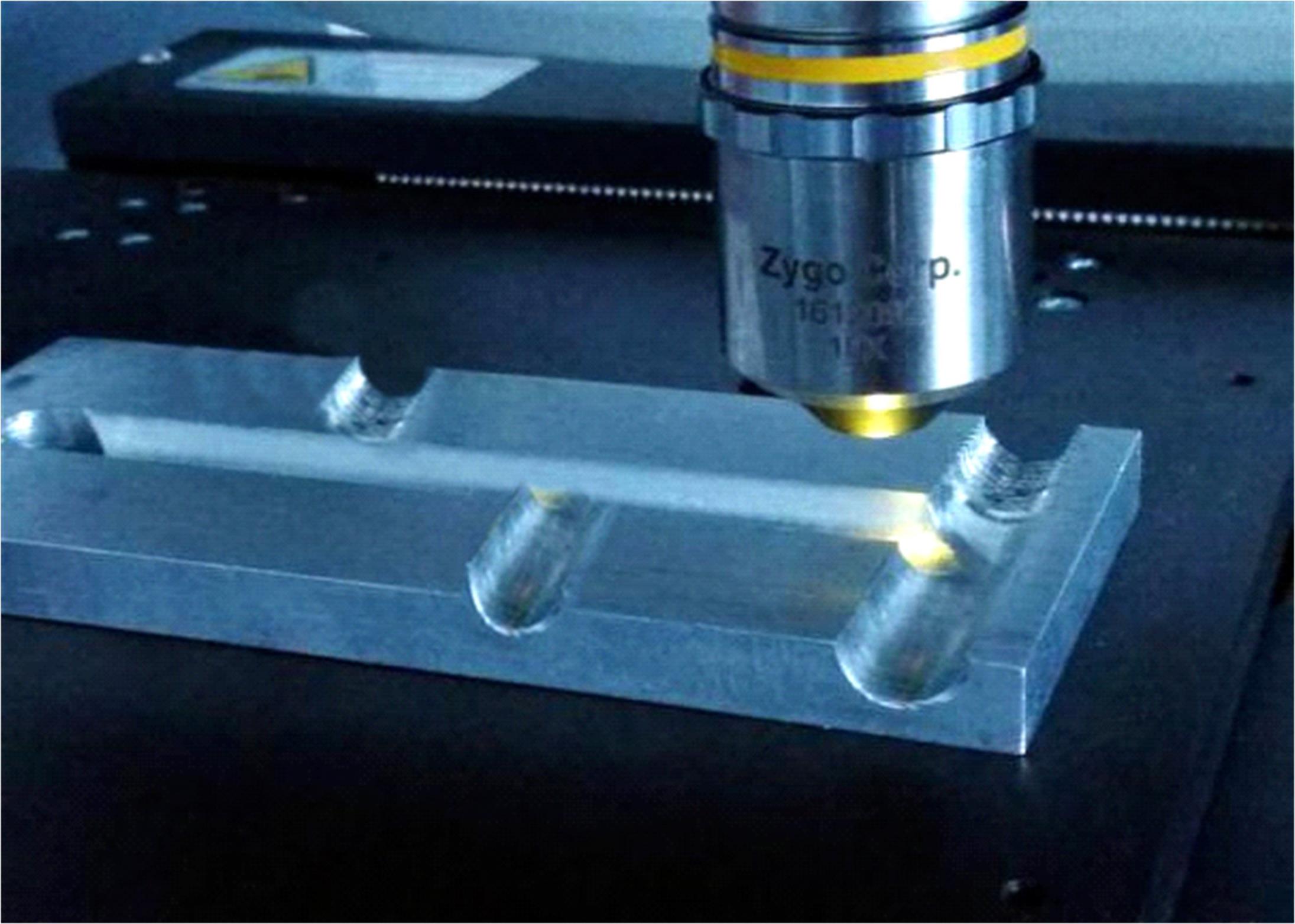

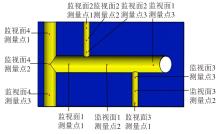

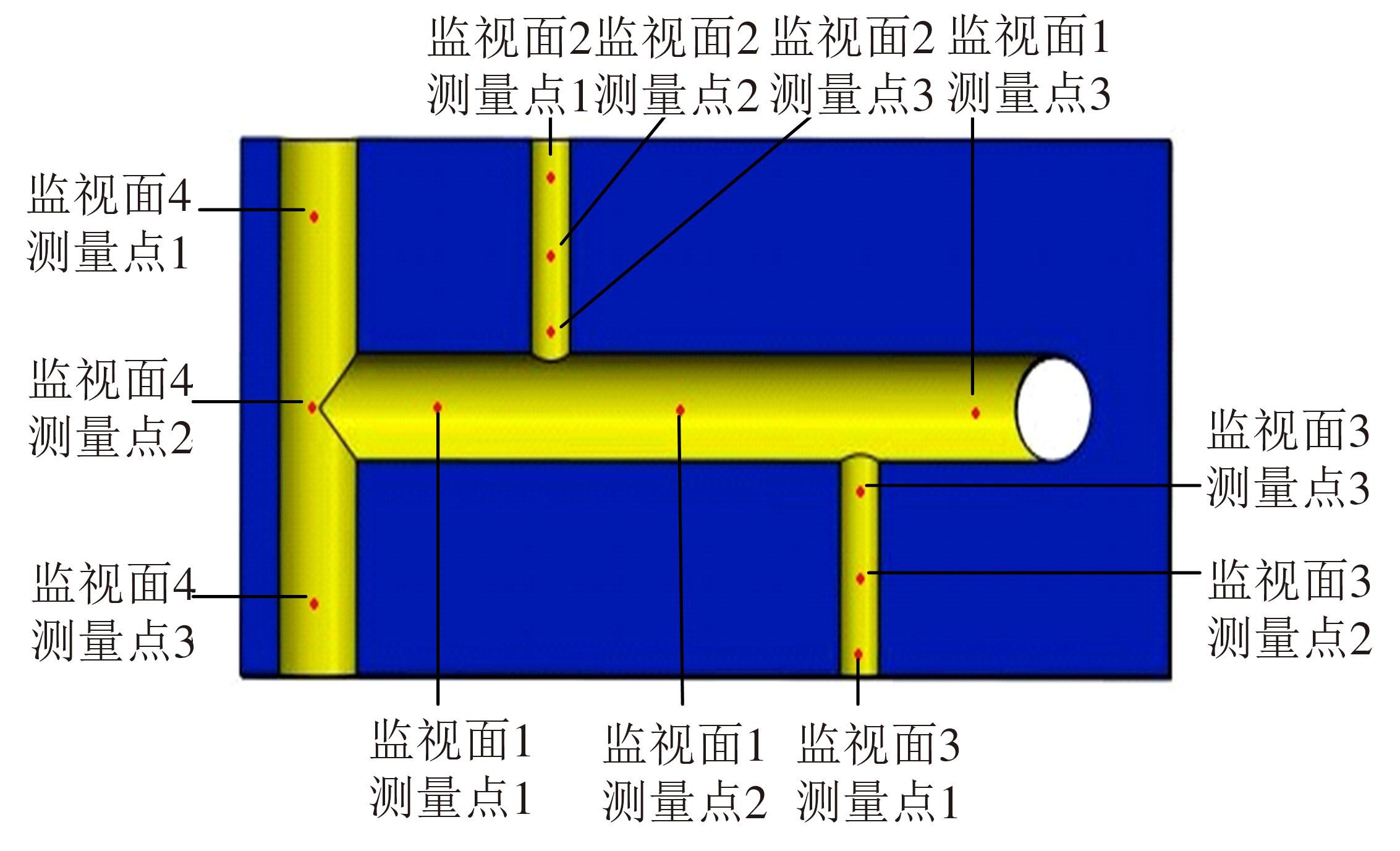

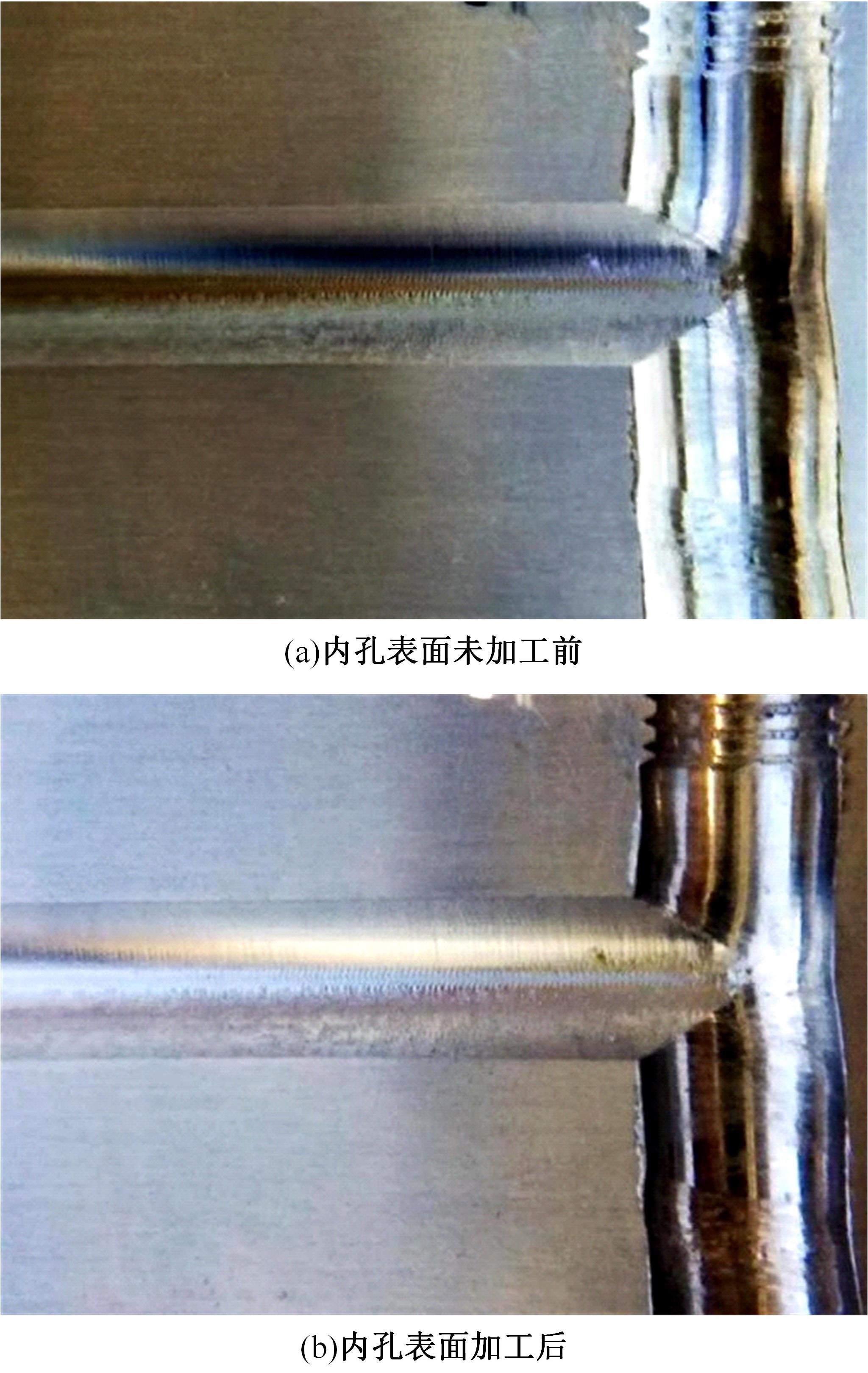

针对目前航空、航天工件内孔表面有凸起毛刺且不容易去除的问题,提出一种气液固多相流技术方法。基于Fluent数值分析对多相流下的不同气体压力、水流速度和磨粒浓度参数进行流体仿真,得到影响加工的近壁区内表面处的磨粒速度、相对压力及磨粒体积分数参数,采用MATLAB软件利用BP神经网络对各参数进行拟合,通过BP预测模型再运用PSO(粒子群算法)在支配解集中求解满足约束数学模型的气液固三相流最优输入值,基于最优输入值搭建试验平台并设计L9(33)正交试验对工件内表面进行加工,最后通过白光干涉仪测量加工前后的内孔表面精度,验证了仿真最优参数与试验加工最优参数的一致性,运用最优参数值下的气液固流体对工件内表面加工,经测量显示,内表面精度提高了75%,满足航空航天工件的应用要求。

中图分类号:

- TG664

| 1 | 王杰,李爱蓉.小波包分析识别气液固三相流流型[J].石油化工,2020(1):62-69. |

| Wang Jie, Li Ai-rong. Identification of gas-liquid-solid three-phase flow pattern by wavelet packet analysis[J]. Petrochemical Industry, 2020(1):62-69. | |

| 2 | 辛亚男,张建文,姜爱国.一种新型螺旋内槽管的气液固三相流数值模拟研究[J].计算力学学报,2018(2):238-248. |

| Xin Ya-nan, Zhang Jian-wen, Jiang Ai-guo. Numerical simulation of gas-liquid-solid three-phase flow of a new type of spiral inner groove tube[J]. Journal of Computational Mechanics, 2018(2):238-248. | |

| 3 | 黄豆豆,计时鸣,陈国达,等.气液固三相湍流环境中气泡破裂对SiC颗粒的影响研究[J].机电工程,2017,34(9):965-970. |

| Huang Dou-dou,Timing, Chen Guo-da,et al. Study on the influence of bubble burst on SiC particles in gas-liquid-solid three-phase turbulent environment[J]. Electromechanical Engineering, 2017,34(9):965-970. | |

| 4 | 杨建.水力空化气液固三相磨粒流抛光工具及系统研究[D].杭州:浙江工业大学机械工程学院,2019. |

| Yang Jian. Study on polishing tools and systems of hydraulic cavitation gas-liquid-solid three-phase abrasive flow[D]. Hangzhou:College of Mechanical Engineering,Zhejiang University of Technology, 2019. | |

| 5 | 胡焰.基于气液固混合的磨料射流加工系统及实验研究[D].南京:南京航空航天大学机电学院,2019. |

| Hu Yan. Abrasive jet machining system and experimental study based on gas-liquid-solid mixing[D].Nanjing: School of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, 2019. | |

| 6 | 李瑞光,丁宇亭,杨增辉,等.航天伺服阀阀套相交孔磨粒流工艺技术研究[J].液压气动与密封,2022,42(7):109-112. |

| Li Rui-guang, Ding Yu-ting, Yang Zeng-hui,et al. Study on abrasive flow technology of intersecting hole of aerospace servo valve sleeve[J]. Hydraulic Pneumatic and Sealing, 2022,42(7):109-112. | |

| 7 | 计时鸣,曹慧强,赵军,等.三相磨粒流文丘里管结构空化辅助抛光机理与试验[J].农业工程学报,2018,34(16):71-79. |

| Timing, Cao Hui-qiang, Zhao Jun,et al. Cavitation-assisted polishing mechanism and experiment of three-phase abrasive flow venturi tube structure[J]. Journal of Agricultural Engineering, 2018,34(16):71-79. | |

| 8 | 王景坡,宋超,凌洋,等.多通管接头磨粒流光整均匀性研究[J].表面技术,2022,(4):299-307. |

| Wang Jing-po, Song Chao, Ling Yang,et al. Study on abrasive particle polishing uniformity of multi-port pipe joints[J]. Surface Technology, 2022(4):299-307. | |

| 9 | 李晓波,魏武,才冬涛,等.基于磨粒流技术的阀块内孔道光整加工[J].金属加工(冷加工),2022(3):20-24. |

| Li Xiao-bo, Wei Wu, Cai Dong-tao,et al. Finishing of inner bore of valve block based on abrasive flow technology[J]. Metalworking (Cold Working), 2022(3):20-24. | |

| 10 | 王卫东.自激振荡脉冲空化射流喷嘴多目标优化研究[D].秦皇岛:燕山大学机械工程学院,2021. |

| Wang Wei-dong. Study on multi-objective optimization of self-excited oscillation pulsed cavitation jet nozzle[D]. Qinghuangd:School of Mechanical Engineering, Yanshan University, 2021. | |

| 11 | 褚聪,戴勇,沈明,等.基于Fluent仿真的强约束磨粒射流抛光特性[J].表面技术,2016(6):198-204. |

| Chu Cong, Dai Yong, Shen Ming,et al. The polishing characteristics of strongly constrained abrasive jet based on Fluent simulation[J]. Surface Technology, 2016(6):198-204. | |

| 12 | 刘江,黄晓斌,何吕,等.基于Fluent的喷油嘴倒锥孔磨粒流加工数值模拟[J].机械制造与自动化,2021,50(2):40-42, 50. |

| Liu Jiang, Huang Xiao-bin, He Lyu,et al. Numerical simulation of abrasive flow machining in the inverted cone hole of fuel injector based on Fluent[J]. Machinery Manufacturing and Automation, 2021,50(2):40-42, 50. | |

| 13 | 李研彪,陈强,张利.钛合金薄壁曲面液态金属-磨粒流加工仿真与试验研究[J].机械工程学报,2021(23):220-231. |

| Li Yan-biao, Chen Qiang, Zhang Li. Simulation and experimental study on liquid metal-abrasive flow machining of titanium alloy thin-walled curved surface[J]. Journal of Mechanical Engineering, 2021(23):220-231. | |

| 14 | 刘洋,李俊烨,苏宁宁,等.磨粒流抛光弯管的数值模拟与试验优化[J].机械设计与制造,2021(7):137-140. |

| Liu Yang, Li Jun-ye, Su Ning-ning,et al. Numerical simulation and experimental optimization of abrasive flow polishing bend[J]. Mechanical Design and Manufacturing, 2021(7):137-140. | |

| 15 | 计时鸣,葛江勤,谭大鹏,等.三相磨粒流抛光及其气泡溃灭分布特性[J].光学精密工程,2018(2):388-398. |

| Timing, Ge Jiang-qin, Tan Da-peng,et al. Three-phase abrasive flow polishing and bubble collapse distribution characteristics[J]. Optical Precision Engineering, 2018(2):388-398. | |

| 16 | 姚燕生,周瑞根,张成林,等.增材制造复杂金属构件表面抛光技术[J].航空学报,2022(4):244-256. |

| Yao Yan-sheng, Zhou Rui-gen, Zhang Cheng-lin,et al. Surface polishing technology of complex metal components manufactured by additives[J]. Acta Aeronautical, 2022(4):244-256. | |

| 17 | 李光保.基于三相流技术的零件内表面毛刺处理的系统研究[D].哈尔滨:哈尔滨工业大学机电工程学院,2019. |

| Li Guang-bao. Systematic research on burr treatment of parts inner surface based on three-phase flow technology[D]. Harbin:School of Mechanical and Electrical Engineering, Harbin Institute of Technology, 2019. | |

| 18 | 张方东.磨料流加工工件表面粗糙度研究[J].现代制造技术与装备,2020,56(10):162-163. |

| Zhang Fang-dong. Study on the surface roughness of abrasive flow machining workpiece[J]. Modern Manufacturing Technology and Equipment, 2020,56(10):162-163. |

| [1] | 黄玲,崔躜,游峰,洪佩鑫,钟浩川,曾译萱. 适用于多车交互场景的车辆轨迹预测模型[J]. 吉林大学学报(工学版), 2024, 54(5): 1188-1195. |

| [2] | 张西广,张龙飞,马钰锡,樊银亭. 基于密度峰值的海量云数据模糊聚类算法设计[J]. 吉林大学学报(工学版), 2024, 54(5): 1401-1406. |

| [3] | 陈涛,周志刚,雷楠南. 粒子群算法下汽车机械式自动变速系统参数多目标优化[J]. 吉林大学学报(工学版), 2024, 54(5): 1214-1220. |

| [4] | 夏超,王梦佳,朱剑月,杨志刚. 基于分层卷积自编码器的钝体湍流流场降阶分析[J]. 吉林大学学报(工学版), 2024, 54(4): 874-882. |

| [5] | 刘元义,于圣洁,胥备,王宪良,宋发成. 基于离散元的设施农业就地翻土犁的研究与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1153-1165. |

| [6] | 杨国俊,齐亚辉,石秀名. 基于数字图像技术的桥梁裂缝检测综述[J]. 吉林大学学报(工学版), 2024, 54(2): 313-332. |

| [7] | 高海龙,徐一博,刘坤,李春阳,卢晓煜. 基于多源数据融合的高速公路路网短时交通流参数实时预测[J]. 吉林大学学报(工学版), 2024, 54(1): 155-161. |

| [8] | 李义,吕晨阳,梁继才,梁策. 不规则Y形铝型材多点拉弯成形截面变形分析[J]. 吉林大学学报(工学版), 2024, 54(1): 105-113. |

| [9] | 李爽,林子瑞,叶松,刘旭,赵吉松. 运载火箭推力下降时入轨能力评估与轨迹重构方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2245-2253. |

| [10] | 车翔玖,徐欢,潘明阳,刘全乐. 生物医学命名实体识别的两阶段学习算法[J]. 吉林大学学报(工学版), 2023, 53(8): 2380-2387. |

| [11] | 刘鹏举. 基于深度神经网络的物联网安全态势自动辨识算法设计[J]. 吉林大学学报(工学版), 2023, 53(7): 2121-2126. |

| [12] | 吕锋,李念,冯壮壮,张杨航. 面向用户的个性化产品服务系统协同过滤推介方法[J]. 吉林大学学报(工学版), 2023, 53(7): 1935-1942. |

| [13] | 李岩,张久鹏,陈子璇,黄果敬,王培. 基于PCA-PSO-SVM的沥青路面使用性能评价[J]. 吉林大学学报(工学版), 2023, 53(6): 1729-1735. |

| [14] | 刘洋,刘吉成. 基于大数据与粒子群的清洁能源协同优化调度方法[J]. 吉林大学学报(工学版), 2023, 53(5): 1443-1448. |

| [15] | 刘培勇,董洁,谢罗峰,朱杨洋,殷国富. 基于多支路卷积神经网络的磁瓦表面缺陷检测算法[J]. 吉林大学学报(工学版), 2023, 53(5): 1449-1457. |

|

||