吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (7): 1831-1843.doi: 10.13229/j.cnki.jdxbgxb.20221159

• 车辆工程·机械工程 • 上一篇

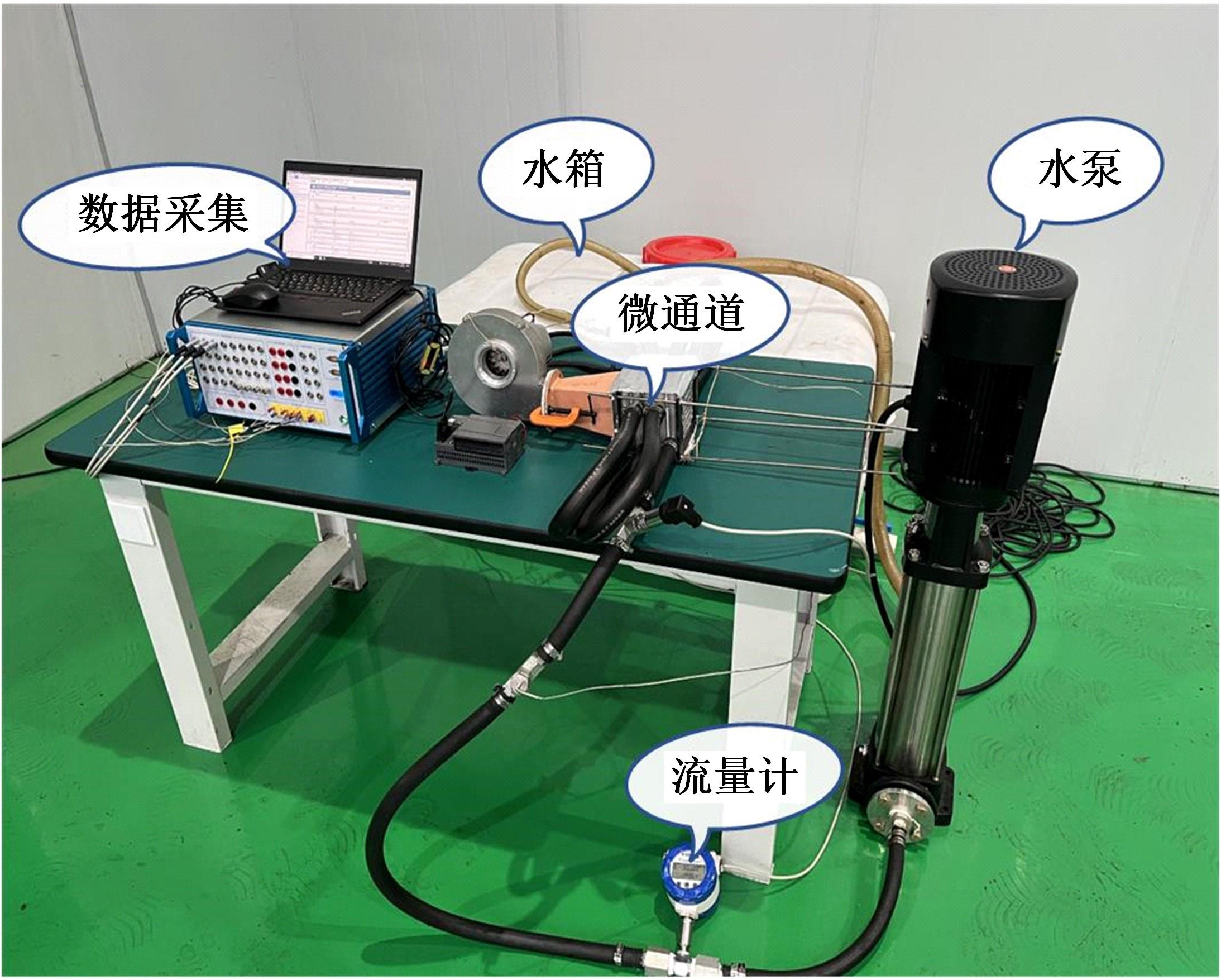

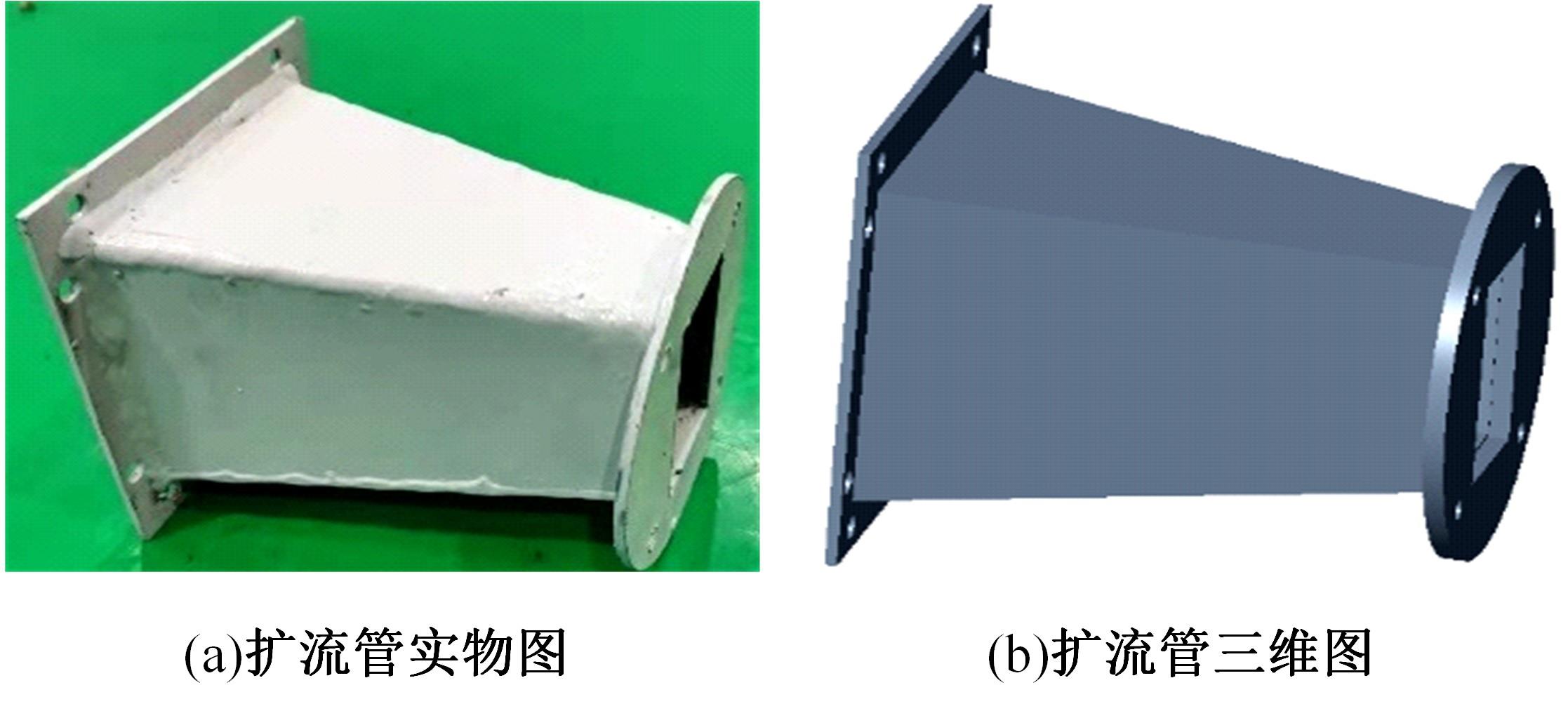

基于Fluent的散热系统扩流结构内部流场分析及优化

- 吉林大学 机械与航空航天工程学院,长春 130022

Analysis and optimization of internal flow field of diffuser structure of cooling system based on Fluent

Xin-hui LIU( ),Zhi-lin XIANG,Peng TAN,Wei CHEN,Ji-yu FENG

),Zhi-lin XIANG,Peng TAN,Wei CHEN,Ji-yu FENG

- School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

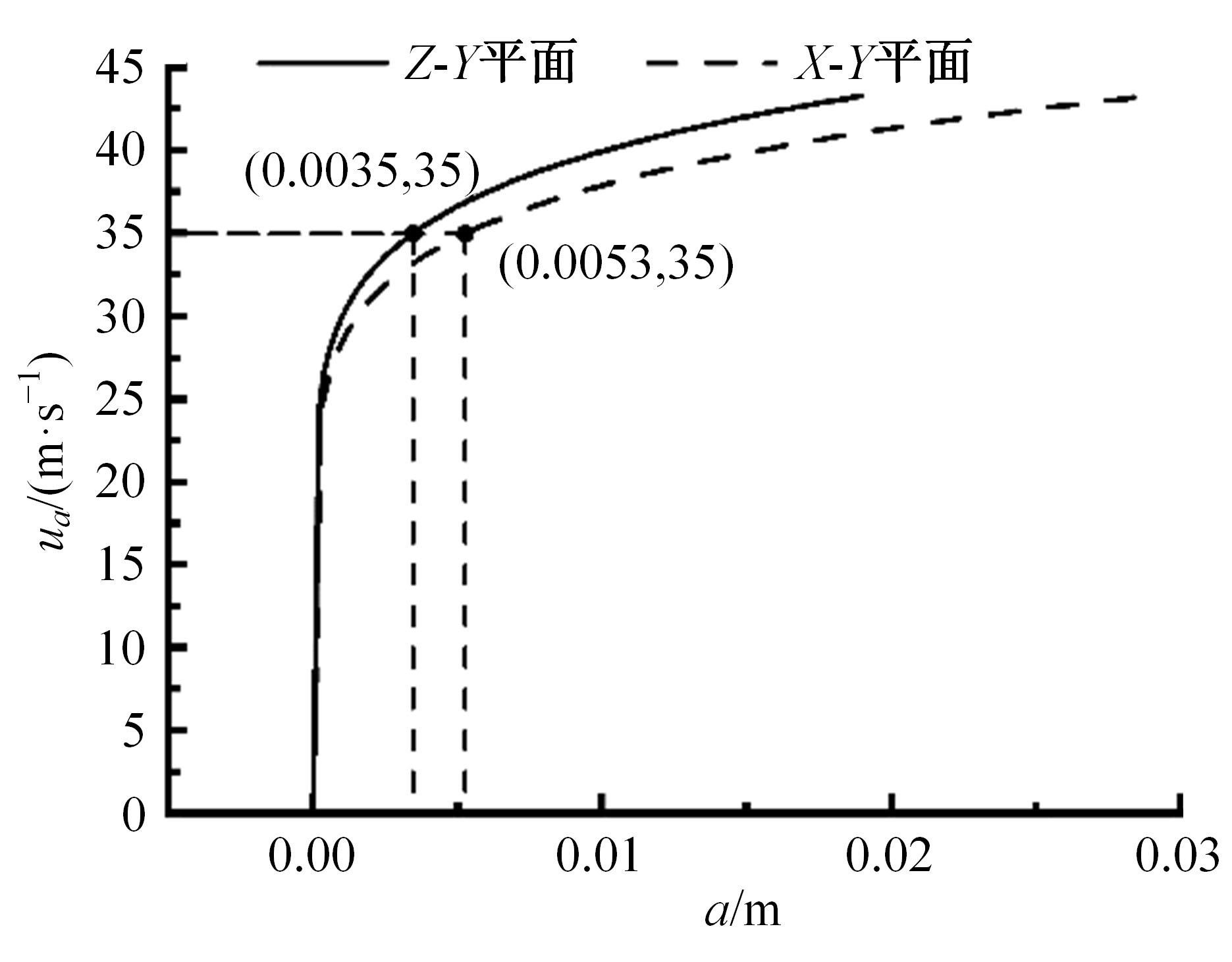

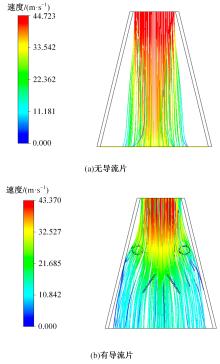

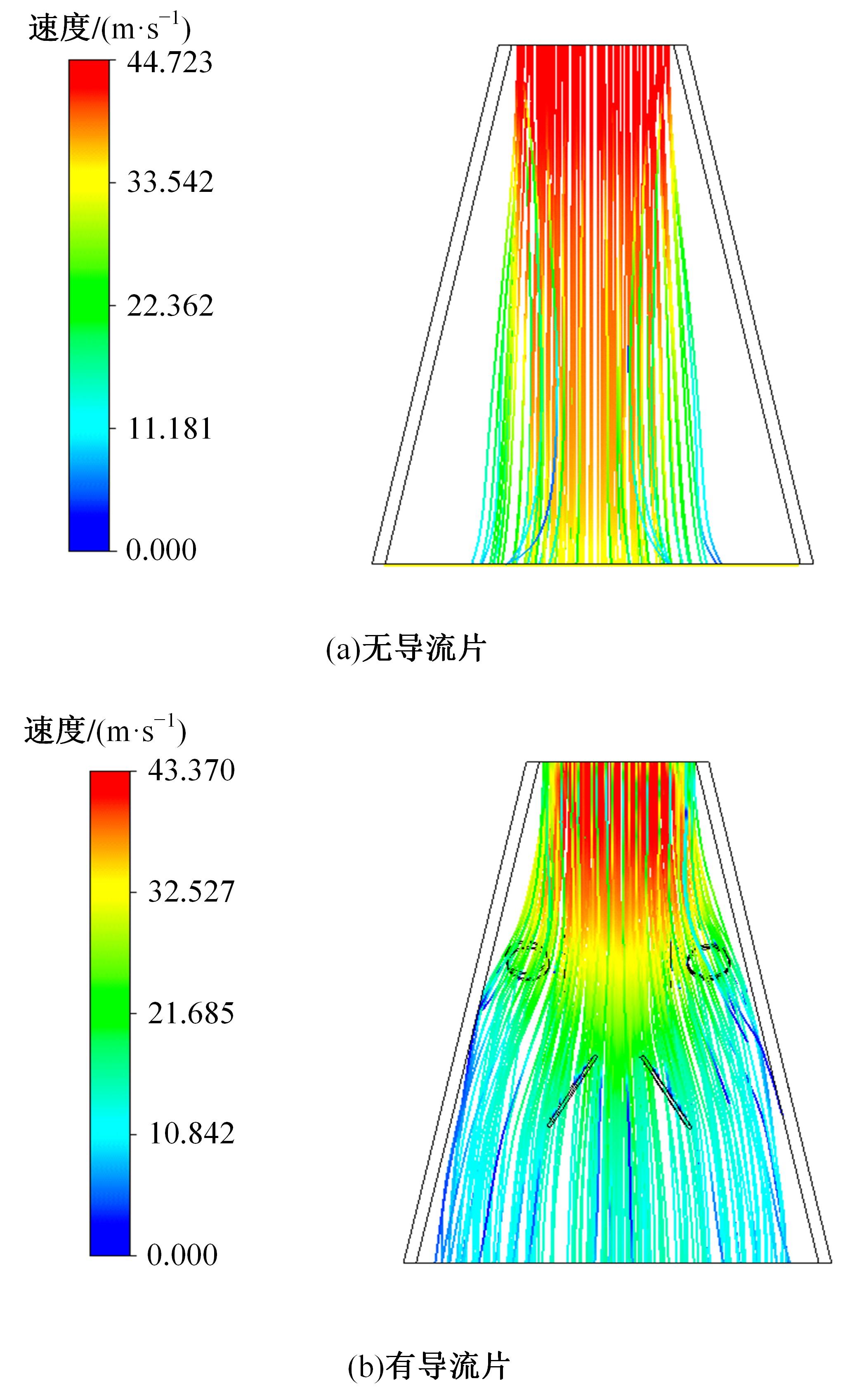

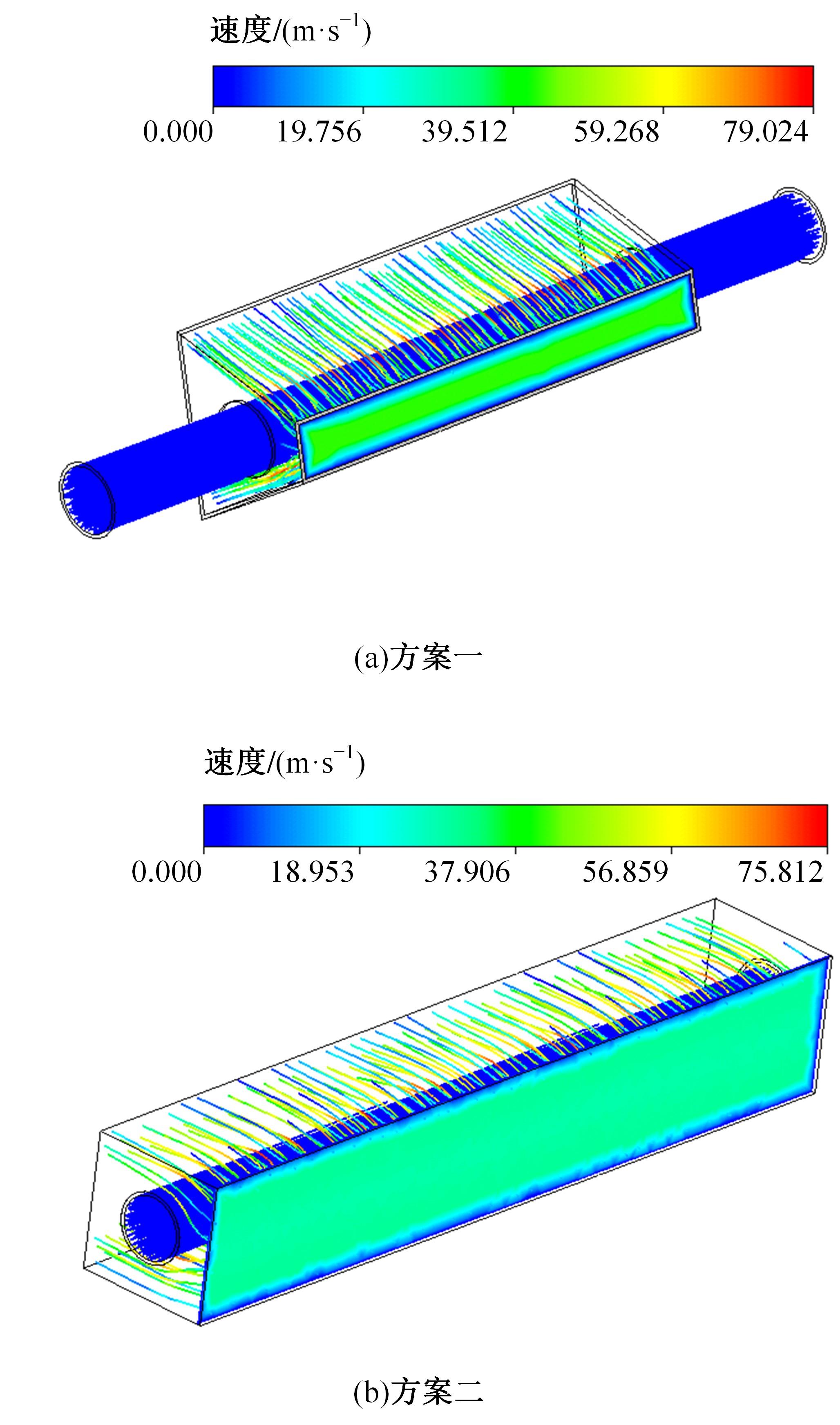

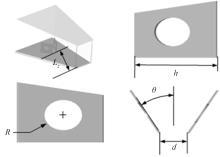

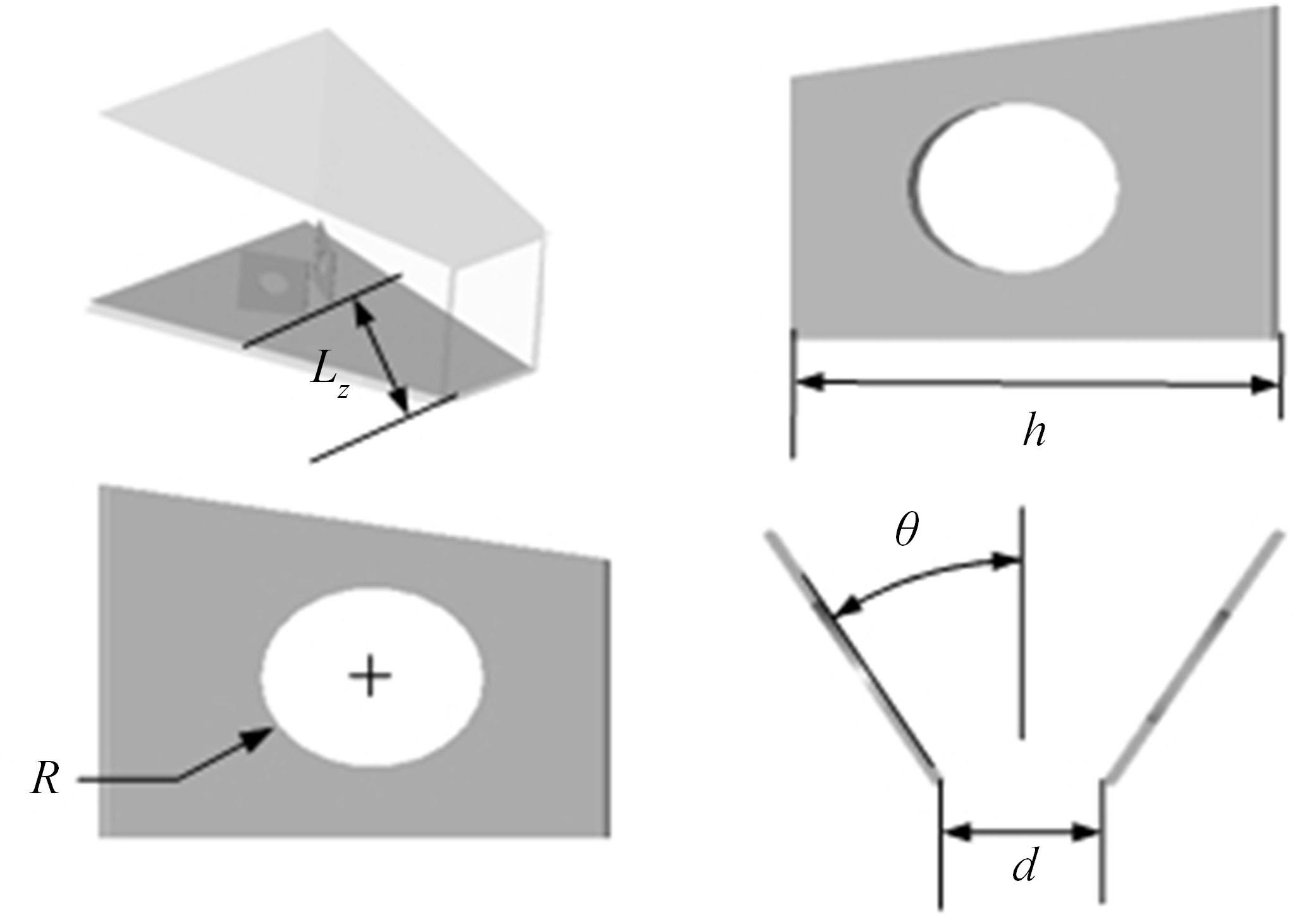

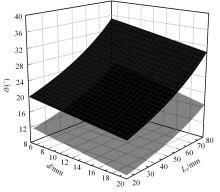

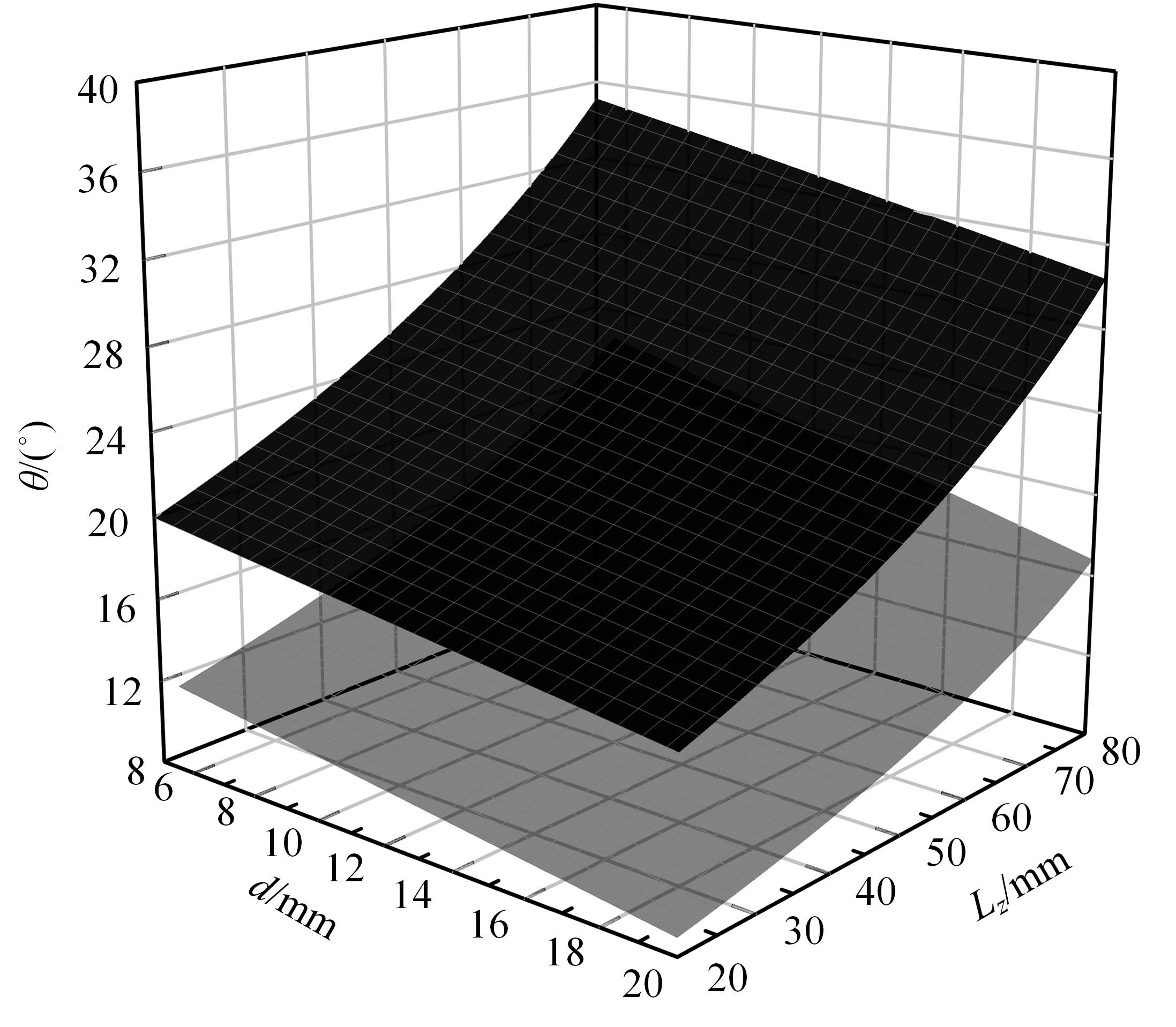

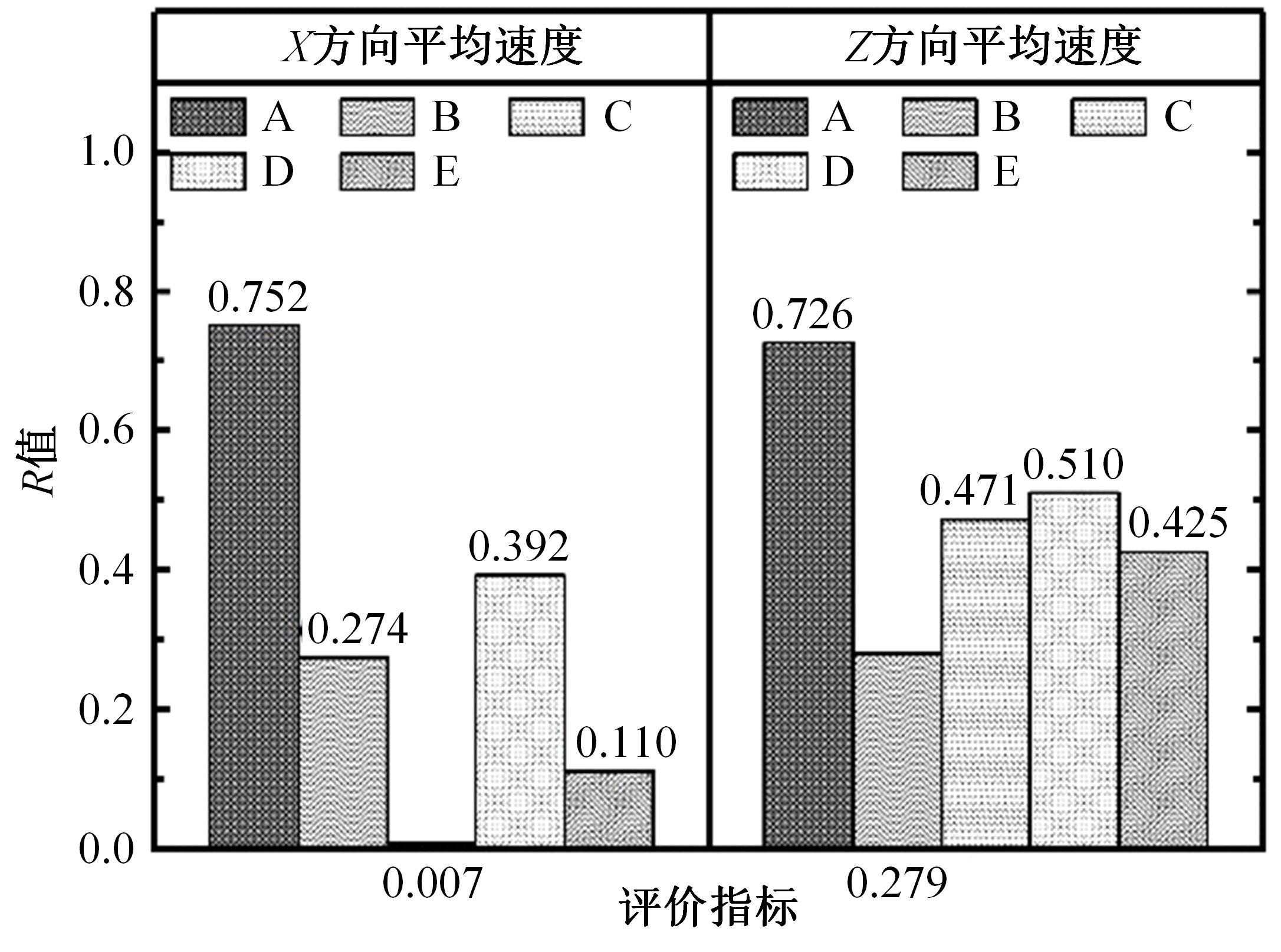

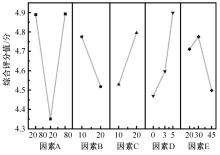

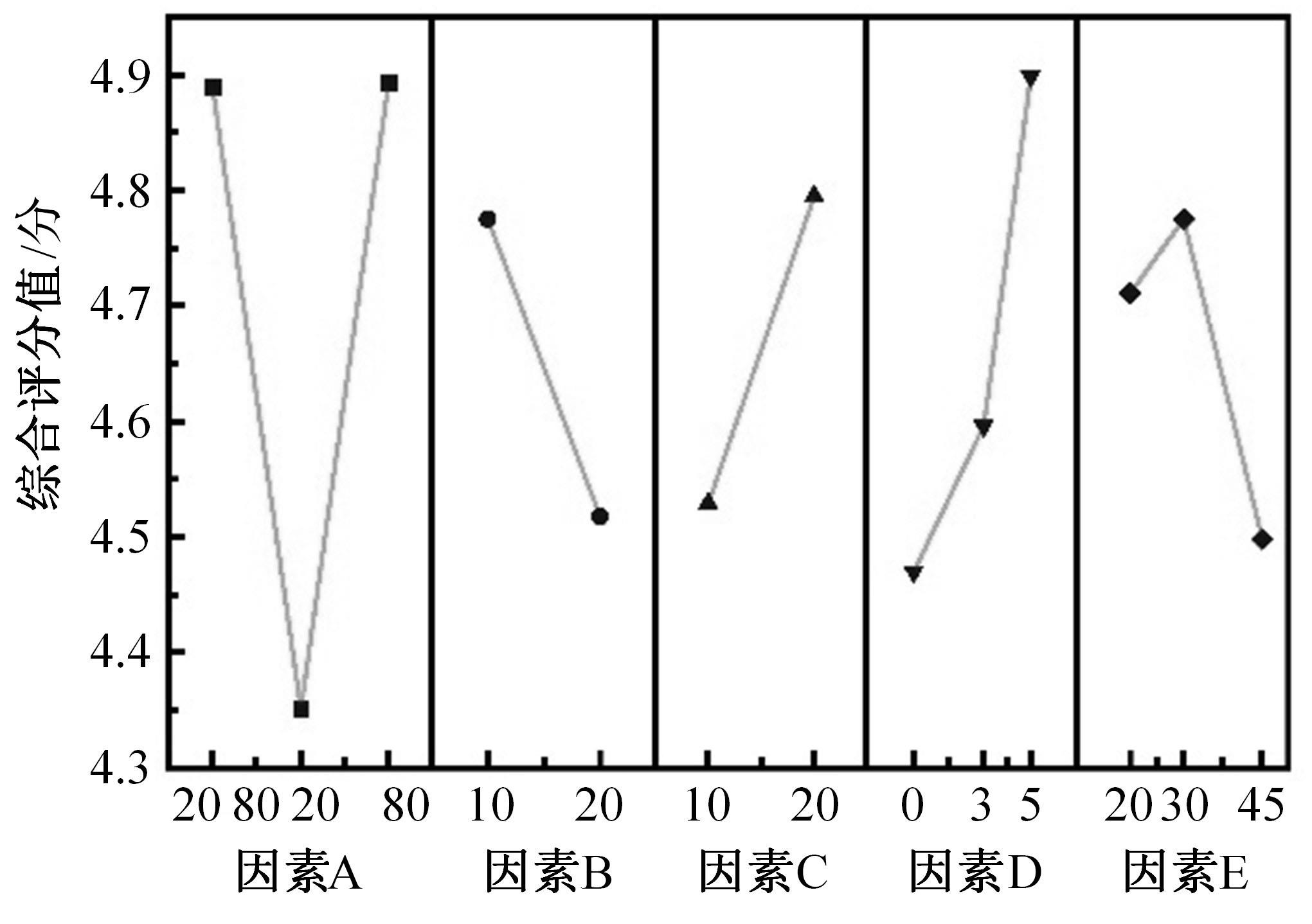

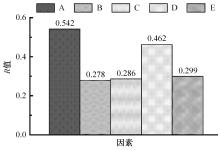

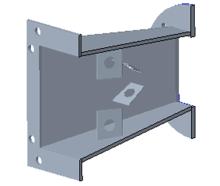

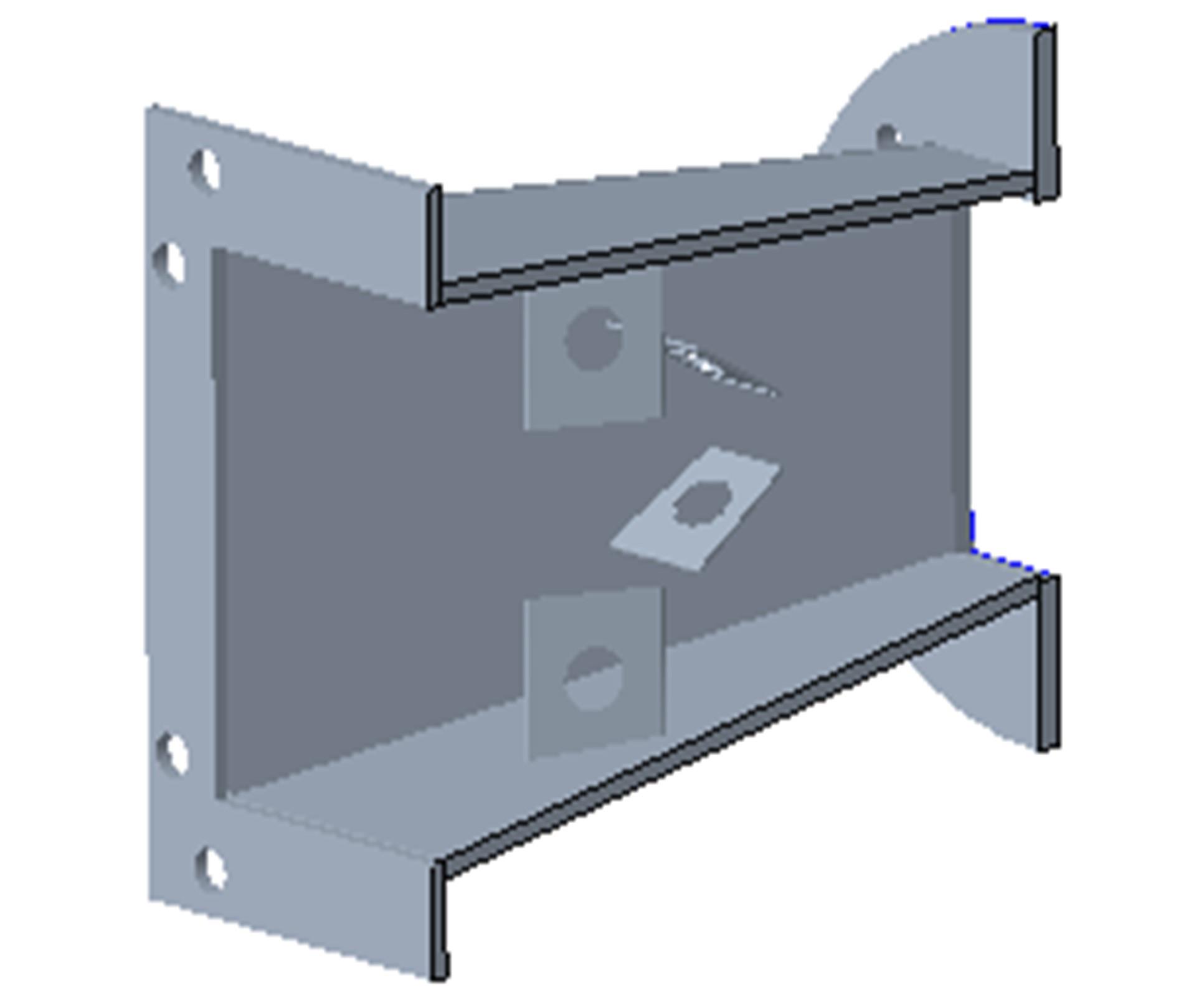

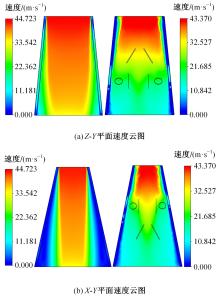

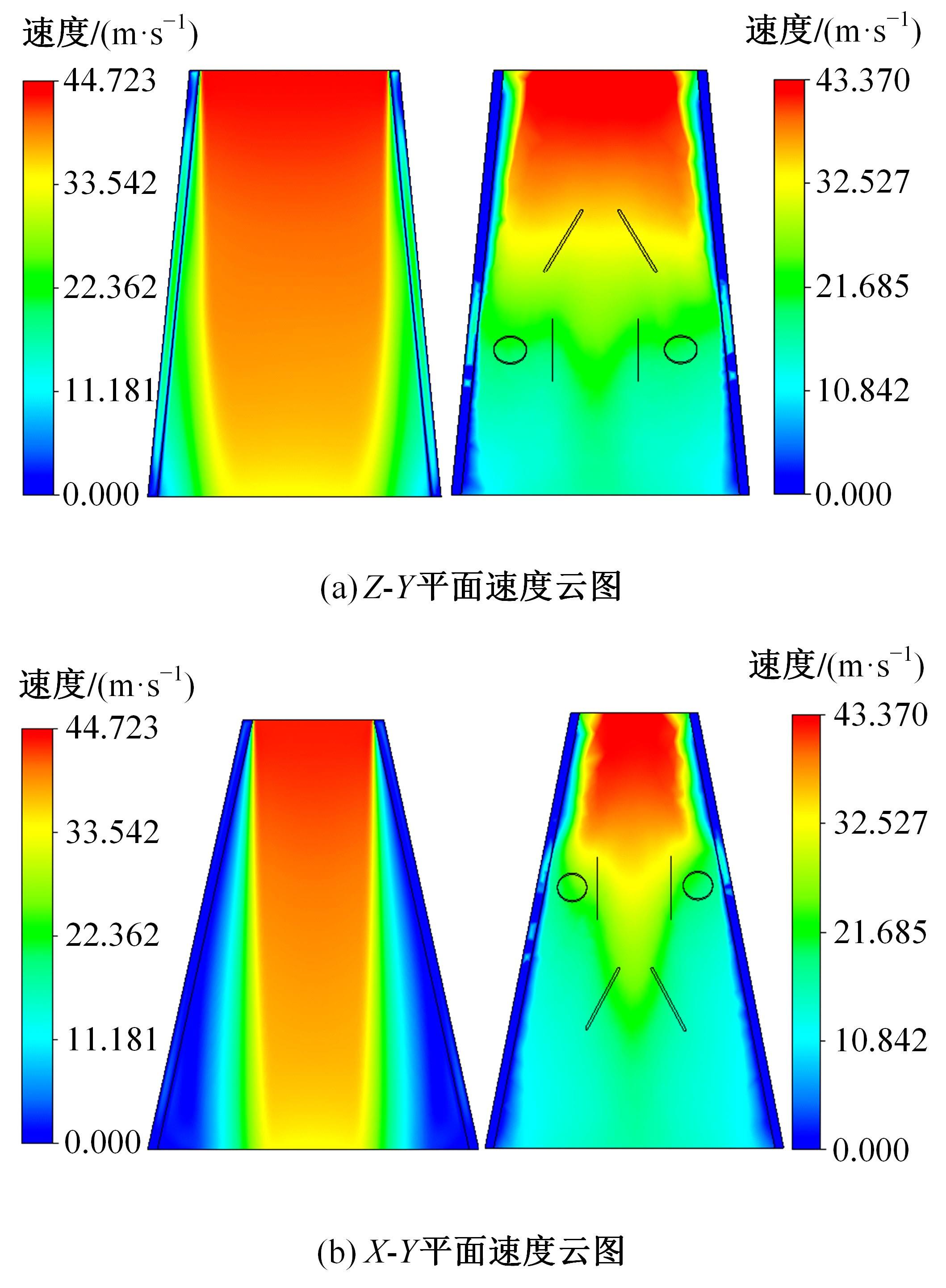

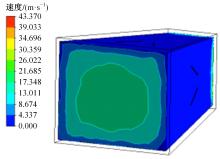

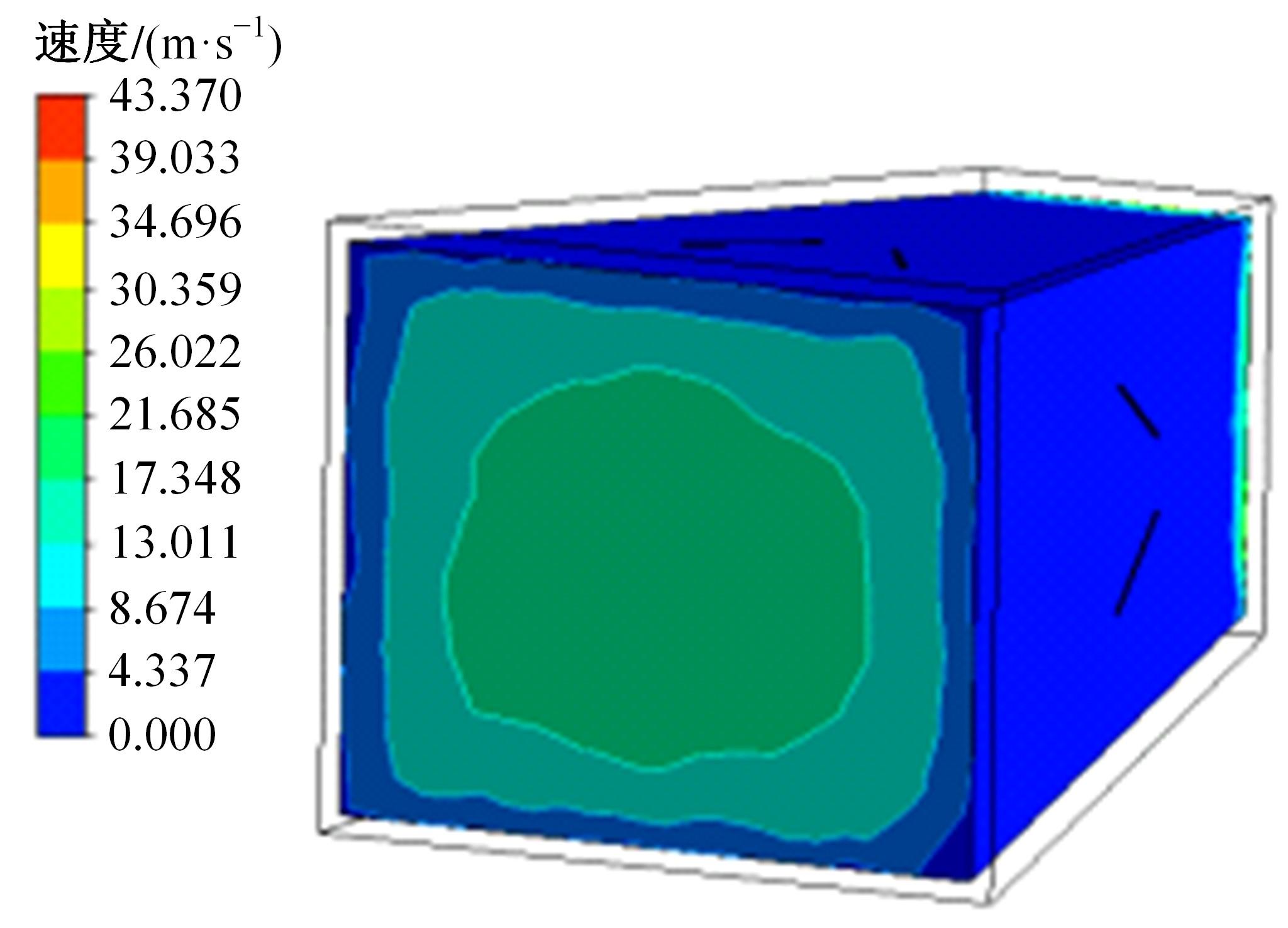

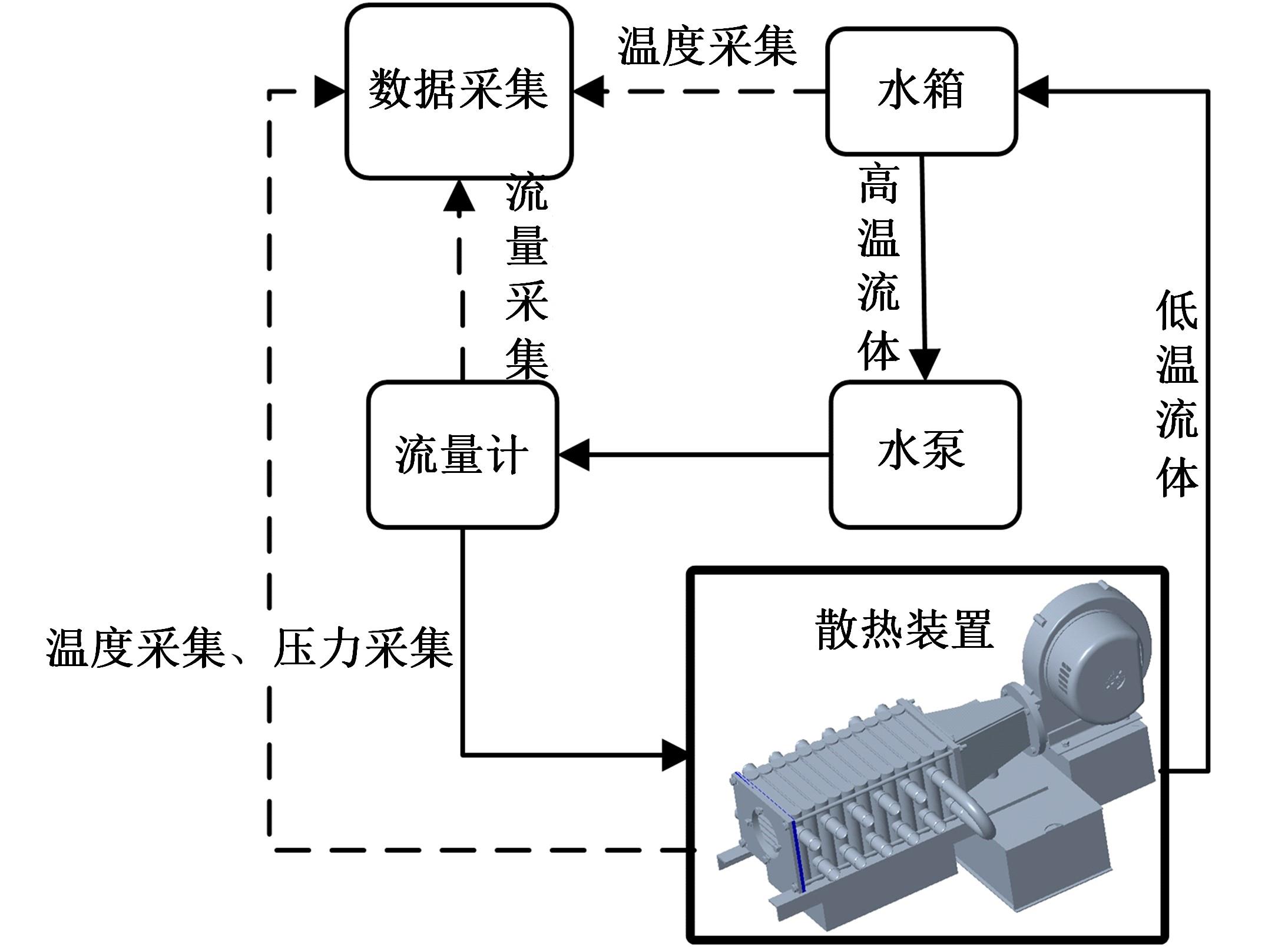

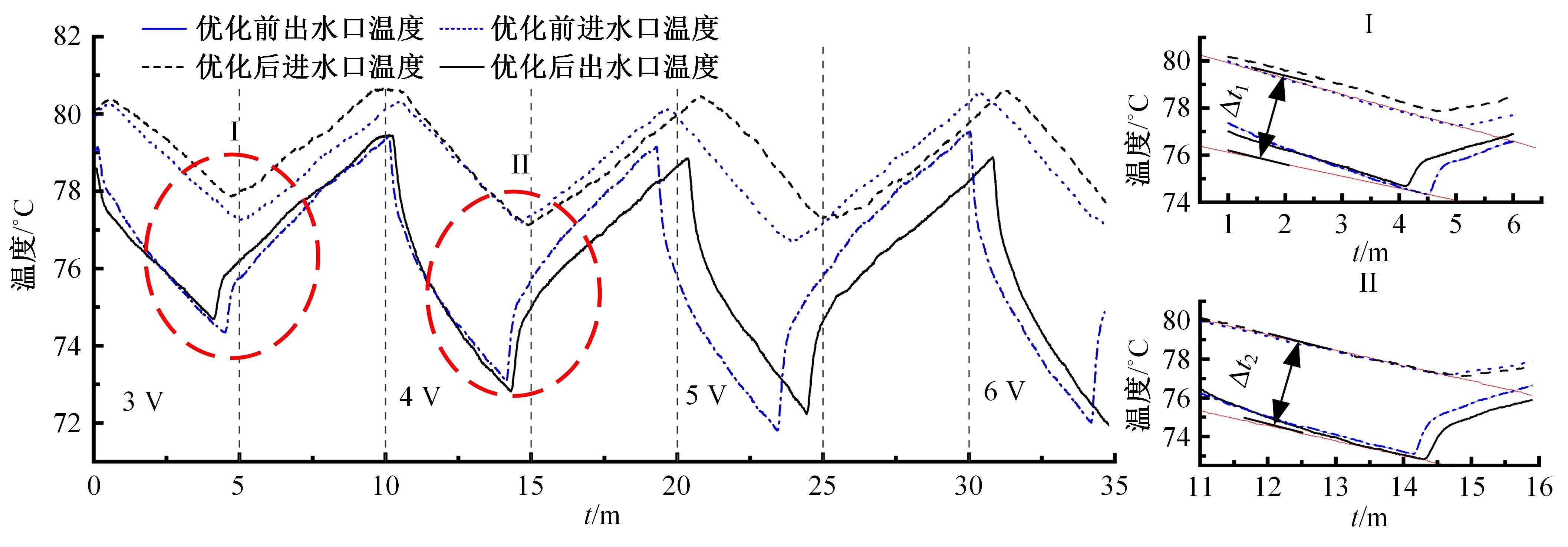

针对风冷散热系统中气体扩流不充分的问题,提出在扩流结构内部安装导流片的解决方案。利用流体动力学软件Fluent搭建了扩流结构的仿真模型并对扩流结构进行了内部流场分析,得出的结论有:流体在扩流结构的不同平面内的局部水头损失分别为3.24 m和1.21 m;在简化模型中,流体低速、大面积分布的散热效率比流体高速、小面积分布的散热效率高8%。利用正交试验研究导流片参数对散热效率的影响,结果表明,针对系统的散热效率,影响程度从大到小的排序为:导流片组距入口端的最短距离L>导流片表面孔的半径R>导流片与流速方向的倾角

中图分类号:

- TK89

| 1 | Salleh M B, Kamaruddin N M, Mohamed-Kassim Z. The effects of deflector longitudinal position and height on the power performance of a conventional Savonius turbine[J]. Energy Conversion and Management, 2020,226:No.113584. |

| 2 | 胡兴军,张靖龙,罗雨霏. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报:工学版, 2021, 51(6):1933-1942. |

| Hu Xing-jun, Zhang Jing-long, Luo Yu-fei. Investigation on influence of cooling tube structure and airflow speed on cold side performance of air⁃cooled charge air cooler[J]. Journal of Jilin University: (Engineering Edition), 2021, 51 (6):1933-1942. | |

| 3 | 张长天,刘景源. 导流片结构参数对四通道环形进气先进旋涡燃烧室性能影响[J]. 航空工程进展,2021,12(4): 138-146. |

| Zhang Chang-tian, Liu Jing-yuan. Effect of deflector structural parameters on the performance of four channel annular inlet advanced vortex combustor[J]. Progress of Aeronautical Engineering, 2021, 12 (4):138-146. | |

| 4 | 阴继翔,王涛,易文杰. 导流板倾角对“V”型直接空冷单元空气流动与换热特性的影响[J]. 热科学与技术, 2021, 20(5):424-430. |

| Yin Ji-xiang, Wang Tao, Yi Wen-jie. Effect of deflector inclination on air flow and heat transfer characteristics of "V" direct air cooling unit[J]. Thermal Science and Technology, 2021, 20 (5):424-430. | |

| 5 | 刘飞,赵一凡,牛卫箭. 发动机进气系统结构优化设计与仿真研究[J]. 机械设计,2020, 37(7):80-86. |

| Liu Fei, Zhao Yi-fan, Niu Wei-jian. Structural optimization design and Simulation of engine intake system[J]. Mechanical Design, 2020, 37(7):80-86. | |

| 6 | Huang X, Lin C, Kong Y. Effects of geometric structures of air deflectors on thermo-flow performances of air-cooled condenser[J]. International Journal of Heat & Mass Transfer, 2018, 118:1022-1039. |

| 7 | Fatahian E, Ismail F, Ishak M, et al. An innovative deflector system for drag-type Savonius turbine using a rotating cylinder for performance improvement[J]. Energy Conversion and Management, 2022, 257:No.115453. |

| 8 | 李永业,庞雅琦,宋晓腾. 导流条安放角度对管道车间断面螺旋流流速特性的影响[J]. 农业工程学报, 2021, 37(5):87-94. |

| Li Yong-ye, Pang Ya-qi, Xiao-teng Somg. Influence of setting angle for guide bar on velocity characteristics of spiral flow in cross-sections between piped carriages[J]. Journal of Agricultural Engineering, 2021, 37(5):87-94. | |

| 9 | 李雪亮,伍钒,王田天,等. 列车空调出风口导流板高度对冷凝风量影响研究[J]. 空气动力学学报,2022(6):155-162. |

| Li Xue-liang, Wu Fan, Wang Tian-tian, et al. Influence of deflector height on condensing air flux of high-speed train air conditioner[J]. Journal of Aerodynamics,2022,(6): 155-162. | |

| 10 | 毛小雨,沙雨宁,陶雨霖,等. ANSYS在流体动力学分析中的应用[J]. 广东化工, 2021,48(1):30-31. |

| Mao Xiao-yu, Sha Yu-ning, Tao Yu-lin. Application of ANSYS in fluid dynamics analysis[J]. Guangdong Chemical Industry, 2021, 48(1):30-31. | |

| 11 | 龙天渝,童思陈. 流体力学[M]. 重庆:重庆大学出版社, 2018. |

| 12 | 余建祖. 换热器原理与设计[M]. 北京:北京航空航天大学出版社, 2006. |

| 13 | Wang H F, Zhou Y, Zou C,et al. Aerodynamic drag reduction of an Ahmed body based on deflectors[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2016, 148: 34-44. |

| 14 | 胡煜,刘烁玲,宋淑然. 基于Fluent的风送式喷雾机导流片仿真分析[J]. 现代农业装备,2021,42(5):28-35. |

| Hu Yu, Liu Shuo-ling, Song Shu-ran. Simulation and analysis of flow guide plate of air spray machine based on fluent[J]. Modern Agricultural Equipment, 2021, 42(5): 28-35. | |

| 15 | 董小杏. 基于CFD除霜风道结构分析及优化设计[J]. 机械,2018,45(12):26-28. |

| Dong Xiao-xing. Analysis and optimization design of defrosting duct structure based on CFD[J]. Machinery, 2018, 45 (12): 26-28. | |

| 16 | 敬文博,吴刚,范金永. 空调风道设计影响因素[J]. 汽车实用技术, 2016,27(7):86-88. |

| Jing Wen-bo, Wu Gang, Fan Jin-yong. Influencing factor of air conditioning duct design[J]. Automotive Practical Technology, 2016(7): 86-88. | |

| 17 | 吴雪良,陈伟健,唐清生. 全域风空调出风形态PIV试验和热舒适性研究[C]∥2021年中国家用电器技术大会论文集,中国合肥,2021:565-571. |

| Wu Xue-liang, Chen Wei-jian, Tang Qing-sheng. PIV test and thermal comfort study on outlet shape of full area air conditioning[C]∥ Proceedings of the 2021 China Household Appliance Technology Conference,Hefei,China, 2021: 565-571. | |

| 18 | 楚德见,刘云,郑涛. 基于CFD数值模拟的风道优化设计分析[C]∥2021年中国家用电器技术大会论文集,中国合肥,2021:1782-1786. |

| Chu De-jian, Liu Yun, Zheng Tao. Optimization design analysis of air duct based on CFD numerical simulation[C]∥ Proceedings of the 2021 China Household Appliance Technology Conference, Hefei,China,2021:1782-1786. | |

| 19 | Lorenzini-Gutierrez D, Hernandez-Guerrero A, Luviano-Ortiz J L, et al. Numerical and experimental analysis of heat transfer enhancement in a grooved channel with curved flow deflectors[J]. Applied Thermal Engineering, 2015, 75:800-808. |

| 20 | Raymond J P, Va Nn Inathan M. Feedback stabilization of a 3D fluid flow by shape deformations of an obstacle[J]. ESAIM Control Optimisation and Calculus of Variations, 2021,27(1):No.65. |

| 21 | 李忠范,高文森. 应用数理统计[M]. 北京:高等教育出版社, 2009. |

| 22 | 吴希. 三种权重赋权法的比较分析[J]. 中国集体经济,2016,34:73-74. |

| Wu Xi. Comparative analysis of three weighting methods[J]. China's Collective Economy, 2016, 34: 73-74. | |

| 23 | 王帅. 装载机两种冷却系统热特性对比分析及优化研究[D].长春: 吉林大学机械与航空航天工程学院,2018. |

| Wang Shuai. Thermal characteristics comparison and optimization of two kinds of cooling systems for loaders[D]. Changchun:School of Mechanical and Aerospace Engineering, Jilin University, 2018. |

| [1] | 李光保,高栋,路勇,平昊,周愿愿. 基于改进神经网络和Fluent的气液固技术的内表面处理[J]. 吉林大学学报(工学版), 2024, 54(6): 1537-1547. |

| [2] | 刘元义,于圣洁,胥备,王宪良,宋发成. 基于离散元的设施农业就地翻土犁的研究与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1153-1165. |

| [3] | 李义,吕晨阳,梁继才,梁策. 不规则Y形铝型材多点拉弯成形截面变形分析[J]. 吉林大学学报(工学版), 2024, 54(1): 105-113. |

| [4] | 李建平,边永亮,杨欣,王鹏飞,李昕昊,薛春林. 果园多风机风送喷雾机作业参数优化与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2474-2485. |

| [5] | 金文明,梁田,梁策,李义,李俊涛,梁继才. 工艺参数对汽车防护梁绕弯成形的截面变形影响[J]. 吉林大学学报(工学版), 2021, 51(4): 1182-1189. |

| [6] | 钱志辉, 周亮, 任雷, 任露泉. 具有仿生距下关节和跖趾关节的完全被动步行机[J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [7] | 孙博华, 邓伟文, 朱冰, 吴坚, 王姗姗. 基于反应式行为的车辆运动意图辨识[J]. 吉林大学学报(工学版), 2018, 48(1): 36-43. |

| [8] | 张泽星, 陈国迎, 宗长富. 基于灵敏度分析的EPS转向性能试验客观评价指标[J]. 吉林大学学报(工学版), 2015, 45(4): 1043-1048. |

| [9] | 齐龙, 谭祖庭, 马旭, 陈国锐, 谢俊锋, 邝健霞. 气动振动式匀种装置工作参数的优化及试验[J]. 吉林大学学报(工学版), 2014, 44(6): 1684-1691. |

| [10] | 郑雪莲,李显生,任园园,杨猛. 瞬时液体冲击对汽车罐车侧倾稳定性的影响[J]. 吉林大学学报(工学版), 2014, 44(3): 625-630. |

| [11] | 董立春1,韩志武2,吕尤2,牛士超2,马荣峰2,任露泉2. 凹坑型仿生形态环块样件耐磨性能[J]. 吉林大学学报(工学版), 2011, 41(6): 1659-1663. |

| [12] | 韦大川, 王云鹏, 李世武, 孙文财, 杨志发. 橡胶粉/SBS复合改性沥青吸声系数试验[J]. 吉林大学学报(工学版), 2010, 40(增刊): 199-0203. |

| [13] | 任丽丽, 周江, 佟金. 烯基琥珀酸酐表面改性淀粉膜羟基取代度的影响因素[J]. 吉林大学学报(工学版), 2010, 40(06): 1624-1628. |

| [14] | 高峰;黄河;任露泉 . 新疆岩蜥三元耦合耐冲蚀磨损特性及其仿生试验[J]. 吉林大学学报(工学版), 2008, 38(03): 586-0590. |

| [15] | 王京春,陈丽莉,任露泉,谷松涛,丛茜 . 仿生注射器针头减阻试验研究[J]. 吉林大学学报(工学版), 2008, 38(02): 379-0382. |

|

||