吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (1): 1-19.doi: 10.13229/j.cnki.jdxbgxb.20230972

• 综述 •

内燃机先进燃烧模式闭环控制策略综述

- 1.哈尔滨工程大学 烟台研究生院,山东 烟台 264000

2.哈尔滨工程大学 动力与能源工程学院,哈尔滨 150001

Review of internal combustion engine advanced combustion mode control strategy

En-zhe SONG1( ),Xiao-yang LIU2,Yun LONG2,Rui LI1,Yun KE1,Chong YAO1(

),Xiao-yang LIU2,Yun LONG2,Rui LI1,Yun KE1,Chong YAO1( )

)

- 1.Yantai Research Institute,Harbin Engineering University,Yantai 264000,China

2.College of Power and Energy Engineering,Harbin Engineering University,Harbin 150001,China

摘要:

本文对先进燃烧模式的内涵和发展过程进行了总结,介绍了内燃机各种先进燃烧模式目前的研究进展,重点介绍了先进燃烧闭环控制策略及系统硬件平台组成,对机器学习在控制过程中起到的作用进行了阐述;针对先进燃烧模式发动机控制未来的发展方向进行了展望,可以为先进燃烧模式实现的相关研究提供参考。

中图分类号:

- TP182

| 1 | 郑洁, 柳存根,林忠钦.绿色船舶低碳发展趋势与应对策略[J].中国工程科学,2020,22(6):94-102. |

| Zheng-jie, Liu Cun-gen, Lin Zhong-qin. Low-carbon development of green ships and related strategies[J]. Strategic Study of CAE, 2020,22(6):94-102. | |

| 2 | Reitz R D, Ogawa H, Payri R, et al. IJER editorial: the future of the internal combustion engine[J]. International Journal of Engine Research, 2020, 21(1): 3-10. |

| 3 | 燃料灵活性是船舶过渡到未来燃料的关键[EB/OL].[2023-08-12].. |

| 4 | Yao M, Zheng Z, Liu H. Progress and recent trends in homogeneous charge compression ignition (HCCI) engines[J]. Progress in Energy And Combustion Science, 2009, 35(5): 398-437. |

| 5 | 张志强,赵福全,李理光.柴油机低温燃烧技术综述[J].汽车工程学报,2016,6(4):235-243. |

| Zhang Zhi-qiang, Zhao Fu-quan, Li Li-guang. A review on technologies of low temperature combustionfor diesel engines[J]. Chinese Journal of Automotive Engineering, 2016,6(4):235-243. | |

| 6 | Maurya R K. Characteristics and Control of Low Temperature Combustion engines[M]. Berlin: Springer, 2018. |

| 7 | Onishi S, Jo S, Shoda K, et al. Active thermo-atmosphere combustion (ATAC)—a new combustion process for internal combustion engines[C]∥SAE Technical Paper,1979-790501. |

| 8 | Thring R. Homogeneous-charge compression-ignition (HCCI) engines[C]∥SAE Technical Paper,1989-892068. |

| 9 | 李耀宗, 缪雪龙, 彭海勇. 低温燃烧技术综述[J].农业装备与车辆工程,2022,60(7):109-113, 117. |

| Li Yao-zong, Miao Xue-long, Peng Hai-yong.Review of low temperature combustion technology[J]. Agricultural Equipment & Vehicle Engineering, 2022,60(7):109-113, 117. | |

| 10 | Biswas S, Sengupta A, Kakati D, et al. The transition from conventional biodiesel combustion to RCCI with CNG/ethanol induction in CI engine: a comparative combustion analysis and relative effects on performance-emissions[J]. International Journal of Engine Research, 2023, 24(6): 2505-2522. |

| 11 | Yu L, Li Y, Li B, et al. Comparative study on gasoline hcci and dici combustion in high load range with high compression ratio for passenger cars application[J]. SAE International Journal of Fuels and Lubricants, 2017, 10(3): 710-717. |

| 12 | Najafi B, Akbarian E, Lashkarpour S M, et al. Modeling of a dual fueled diesel engine operated by a novel fuel containing glycerol triacetate additive and biodiesel using artificial neural network tuned by genetic algorithm to reduce engine emissions[J]. Energy, 2019, 168: 1128-1137. |

| 13 | Bidarvatan M, Shahbakhti M. Gray-box modeling for performance control of an HCCI engine with blended fuels[J]. Journal of Engineering for Gas Turbines and Power, 2014, 136(10): No.101510. |

| 14 | Hardy W L, Reitz R D. A study of the effects of high EGR, high equivalence ratio, and mixing time on emissions levels in a heavy-duty diesel engine for PCCI combustion[C]∥SAE Technical Paper, 2006-0026. |

| 15 | Zhang Y, Sellnau M. A computational investigation of PPCI-diffusion combustion strategy at full load in a light-duty GCI engine[J]. SAE International Journal of Advances and Current Practices in Mobility, 2021, 3(2021): 1757-1775. |

| 16 | Willems R, Willems F, Deen N, et al. Heat release rate shaping for optimal gross indicated efficiency in a heavy-duty RCCI engine fueled with E85 and diesel[J]. Fuel, 2021, 288: No.119656. |

| 17 | Pandian M M, Krishnasamy A. Homogeneous charges with direct injection strategy to achieve high efficiency and clean combustion in diesel engines[J]. SAE International Journal of Engines, 2021, 14(3): 319-334. |

| 18 | 于洋,苏万华. 多次喷射所组织的复合燃烧及其排放的影响因素[J]. 内燃机学报, 2010, 28(5): 385-392. |

| Yu Yang, Su Wan-hua. Numerical of the effects on the emissions of compound combustion using multiple flexible injections[J]. Transactions of CSICE, 2010, 28(5): 385-392. | |

| 19 | 鹿盈盈,苏万华,于文斌. 多次喷油实现清洁高效柴油预混燃烧的机理[J]. 内燃机学报, 2012, 30(2): 97-106. |

| Lu Ying-ying, Su Wan-hua, Yu Wen-bin. Mechanism of multiple injections on clean and high efficiency diesel PCCI combustion[J]. Transactions of CSICE, 2012, 30(2): 97-106. | |

| 20 | 王辉. 多脉冲喷油模式的调制及其对柴油HCCI燃烧过程影响的研究[D]. 天津:天津大学机械工程学院, 2005. |

| Wang Hui. A study of modulation of multi-pulse injection mode and its effects on diesel HCCI combustion[D].Tianjing: College of Mechanical Engineering, Tianjin University,2005. | |

| 21 | Su W, Liu B, Wang H, et al. Effects of multi-injection mode on diesel homogeneous charge compression ignition combustion[J]. Journal of Engineering for Gas Turbines and Power, 2007, 129(1): 230-238. |

| 22 | 王辉, 苏万华, 刘斌. 基于调制多脉冲喷油模式的柴油预混合燃烧和排放特性的研究[J]. 内燃机学报, 2005 (4): 289-296. |

| Wang Hui, Su Wan-hua, Liu Bin. Study of characteristics of premixed diesel combustion and emissions based on modulated multi-pulse injection modes[J]. Transactions of CSICE, 2005 (4): 289-296. | |

| 23 | 王辉, 苏万华, 刘斌, 等. 调制多脉冲喷油策略的实现及对HCCI燃烧过程影响的研究[J]. 内燃机学报, 2005(5): 385-391. |

| Wang Hui, Su Wan-hua, Liu Bin,et al. A study of realization of modulated multi-pulse injection mode and its effects on HCCI combustion[J]. Transactions of CSICE, 2005(5): 385-391. | |

| 24 | 于文斌, 刘斌, 李洋, 等. 基于多脉冲喷射、可变增压以及推迟进气门关闭定时技术的混合燃烧控制策略[J]. 燃烧科学与技术, 2012, 18(4): 331-337. |

| Yu Wen-bin, Liu Bin, Li Yang, et al. Hybrid combustion control strategy based on technologies of multi-pulse injections,variable boost pressure and retarded intake valve closing timing in a heavy duty diesel engine[J]. Journal of Combustion Science and Technology, 2012, 18(4): 331-337. | |

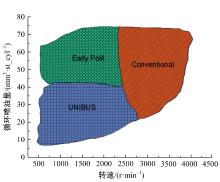

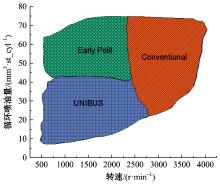

| 25 | Kimura S, Aoki O, Ogawa H,et al. New combustion concept for ultra-clean and high-efficiency small DI diesel engines[C]∥SAE Paper, 1999-3681. |

| 26 | Shuji K, Osamu A, Yasuhisa K,et al. Ultra-clean combustion technology combining a low-temperature and premixed combustion concept for meeting future emission standards[C]∥SAE Technical Paper, 2001-0200. |

| 27 | Keiji K, Takashi A, Motohiro S,et al. Combination of combustion concept and fuel property for ultra-clean DI diesel[C]∥SAE Technical Paper, 2004-1868. |

| 28 | Walter B, Gatellier B. Near zero NOx emissions and high fuel efficiency diesel engine: the NADITM concept using dual mode combustion[J]. Oil & Gas Science and Technology, 2003, 58(1): 101-114. |

| 29 | Takeda Y, Keiichi N, Keiichi N. Emission characteristics of premixed lean diesel combustion with extremely early staged fuel injection[C]∥SAE Paper, 1996-961163. |

| 30 | Nakagome K, Shimazaki N, Niimura K, et al. Combustion and emission characteristics of premixed lean diesel combustion engine[J]. SAE Transactions, 1997: 1528-1536. |

| 31 | Su W H, Lin T J, Pei Y Q. A compound technology for HCCI combustion in a di diesel engine based on the multi-pulse injection and the BUMP combustion chamber[R].SAE Technical Paper, 2003-0741. |

| 32 | Kokjohn S L, Hanson R M, Splitter D A, et al. Fuel reactivity controlled compression ignition (RCCI): a pathway to controlled high-efficiency clean combustion[J]. International Journal of Engine Research, 2011, 12: 209-226. |

| 33 | Kokjohn S L, Hanson R M, Splitter D A, et al. Experiments and modeling of dual-fuel HCCI and PCCI combustion using in-cylinder fuel blending[J]. SAE International Journal of Engines, 2010, 2(2): 24-39. |

| 34 | Sankaralingam R K, Feroskhan M, Elango M, et al. Experimental studies on premixed charge and reactivity-controlled compression ignition combustion modes using gasoline/diesel fuel combination[J]. Case Studies in Thermal Engineering, 2022, 39: No.102467. |

| 35 | Poorghasemi K, Saray R K, Ansari E, et al. Effect of diesel injection strategies on natural gasdiesel RCCI combustion characteristics in a light duty diesel engine[J]. Applied Energy, 2017, 199: 430-446. |

| 36 | 耿培林,姚春德,胡江涛,等. 柴油在甲烷氛围及在甲醇氛围下的着火燃烧特性[J]. 燃烧科学与技术, 2017, 23(4): 344-350. |

| Geng Pei-lin, Yao Chun-de, Hu Jiang-tao,et al. Ignition and combustion characteristics of diesel in premixedmethane and methanol atmosphere[J].Journal of Combustion Science and Technology, 2017, 23(4): 344-350. | |

| 37 | 任烁今. 重型发动机均质混合气引燃燃烧的试验研究和数值模拟[D].北京:清华大学车辆与运载学院, 2018. |

| Ren Shuo-jin. Experimental and numerical investigation of homogeneous charge induced ignition combustion on a heavy-duty engine[D].Beijing: School of Vehicle and Mobility, Tsinghua University, 2018. | |

| 38 | 穆林. 基于共轨系统的柴油引燃式天然气发动机控制与优化研究[D].北京: 清华大学车辆与运载学院, 2013. |

| Mu Lin. Research on control and optimazation of common rail based diesel ignited natural gas engine[D].Beijing: School of Vehicle and Mobility, Tsinghua University,2013. | |

| 39 | 李临蓬,毛斌,刘海峰,等. 多缸重型柴油机的预混低温燃烧[J]. 燃烧科学与技术, 2019, 25(1): 16-23. |

| Li Lin-peng, Mao Bin, Liu Hai-feng. Premixed low-temperature combustion in multi-cylinder heavy-duty diesel engine[J]. Journal of Combustion Science and Technology, 2019, 25(1): 16-23. | |

| 40 | 李临蓬,毛斌,郑尊清,等. 汽油、正丁醇掺混柴油对部分预混压燃的燃烧和排放影响[J]. 内燃机学报, 2020, 38(4): 289-297. |

| Li Lin-peng, Mao Bin, Zheng Zun-qing. Effect of gasoline/diesel and n-butanol/diesel blends on combustion and emissions of PPCI[J]. Transactions of CSICE, 2020, 38(4): 289-297. | |

| 41 | Manente V, Tunestal P, Johansson B, et al. Effects of ethanol and different type of gasoline fuels on partially premixed combustion from low to high load[C]∥SAE Paper, 2010-0871. |

| 42 | Manente V, Johansson B, Tunestal P. Partially premixed combustion at high load using gasoline and ethanol, a comparison with diesel[C]∥SAE Technical Paper, 2009-0944. |

| 43 | 方强. 基于喷射策略和燃料设计的压燃式发动机高效低排放燃烧模式研究[D]. 上海:上海交通大学机械工程学院, 2013. |

| Fang Qiang.Study on high-efficiency low-emission combustion modes in compression ignition engines based on injection strategy and fuel design [D]. Shanghia:College of Mechanical Engineering, Shanghai Jiao Tong University, 2013. | |

| 44 | 冀雯霞. 船用低速机燃烧排放多策略协同优化研究[D]. 上海:上海交通大学机械工程学院, 2019. |

| Ji Wen-xia. Multi-strategy collaborative optimization research on combustion emissions of marine low-speed engines [D]. Shanghai:College of Mechanical Engineering, Shanghai Jiaotong University, 2019. | |

| 45 | 曲栓, 石磊, 邓康耀. 柴油机低温燃烧闭环控制及切换过程[J]. 上海交通大学学报, 2012, 46(4): 540-544. |

| Qu Shuan, Shi Lei, Deng Kang-yao. Closed-loop control and transition process of low-temperature combustion in diesel engines[J]. Journal of Shanghai Jiao Tong University, 2012, 46(4): 540-544. | |

| 46 | 隆武强, 王一聪, 张强, 等. JCCI发动机预混合着火与燃烧过程的模拟[J]. 内燃机学报, 2014, 32(4): 302-308. |

| Long Wu-qiang, Wang Yi-cong, Zhang Qiang, et al. Simulation of premixed ignition and combustion processes in JCCI engines[J]. Transactions of CSICE, 2014, 32(4): 302-308. | |

| 47 | 隆武强,礼博,李达,等. 柴油射流控制柴油基燃料预混合气压缩着火相位的试验研究[J]. 中南大学学报:自然科学版, 2018, 49(7): 1815-1822. |

| Long Wu-qiang, Li Bo, Li Da, et al. Experimental study on compression ignition phase of diesel jet controlled diesel base fuel premixed mixture[J]. Journal of Central South University (Science and Technology), 2018, 49(7): 1815-1822. | |

| 48 | 赵国锋. 基于模型的柴油微引燃天然气发动机控制及性能优化研究[D]. 哈尔滨:哈尔滨工程大学动力与能源工程学院, 2020. |

| Zhao Guo-feng. Control and performance optimization of diesel micro-pilot ignition natural gas engines based on models[D]. Harbin: College of Power and Energy Engineering, Harbin Engineering University, 2020. | |

| 49 | 龙云. 基于模型的双燃料发动机转速控制研究[D]. 哈尔滨:哈尔滨工程大学动力与能源工程学院, 2020. |

| Long Yun. Research on speed control of dual-fuel engines based on models[D]. Harbin: College of Power and Energy Engineering, Harbin Engineering University, 2020. | |

| 50 | 王佳琦. 油气喷射对柴油/天然气双燃料发动机多模式燃烧特性影响研究[D]. 哈尔滨:哈尔滨工程大学动力与能源工程学院, 2021. |

| Wang Jia-qi. Study on the impact of oil and gas injection on the multi-mode combustion characteristics of diesel/natural gas dual-fuel engines[D]. Harbin: College of Power and Energy Engineering, Harbin Engineering University, 2021. | |

| 51 | Olsson J O, Tunestå, P, Johansson B. Closed-loop control of an HCCI engine[C]∥SAE Paper, 2001-1031. |

| 52 | Goran H, Per T, Bengt J, et al. HCCI combustion phasing with closed-loop combustion control using variable compression ratio in a multi cylinder engine[C]∥SAE Technical Paper, 2003-1830. |

| 53 | Göran H, Per T, Bengt J,et al. HCCI closed-loop combustion control using fast thermal management[C]∥SAE Technical Paper Series: SAE International, 2004-0943. |

| 54 | Pfeiffer R, Haraldsson G, Olsson J O,et al. System identification and LQG control of variable-compression HCCI engine dynamics[C]∥Proceedings of the 2004 IEEE International Conference on Control Applications, Taipei,China,2004:No.1387578 |

| 55 | Karlsson M, Ekholm K, Strandh P, et al. Closed-loop control of combustion phasing in an hcci engine using vva and variable egr[J]. Ifac Proceedings Volumes, 2006, 40: 501-508. |

| 56 | Petter S, Johan B, Rolf J, et al. Variable valve actuation for timing control of a homogeneous charge compression ignition engine[C]∥SAE Technical Paper, 2005-0147. |

| 57 | Jorques Moreno C, Stenlåås O, Tunestål P. Indicated efficiency optimization by in-cycle closed-loop combustion control of diesel engines[J]. Control Engineering Practice, 2022, 122: No.105097. |

| 58 | Zander C G, Tunesta˚l P, Stenla˚a˚s O, et al. In-cycle closed loop control of the fuel injection on a 1-cylinder heavy duty CI-Engine[C]∥Asme 2010 Internal Combustion Engine Division Fall Technical Conference, San Antonio, USA 2010: 405-414. |

| 59 | Hasegawa M, Shimasaki Y, Yamaguchi S, et al. Study on ignition timing control for diesel engines using in-cylinder pressure sensor[C]∥SAE Technical Paper, 2006-0180. |

| 60 | Thorsten S, Stefan P, Thomas K, et al. Diesel combustion control with closed-loop control of the injection strategy[C]∥SAE Technical Paper, 2008-0651. |

| 61 | Hinkelbein J, Sandikcioglu C, Pischinger S, et al. Control of the diesel combustion process via advanced closed loop combustion control and a flexible injection rate shaping tool[J]. SAE International Journal of Fuels and Lubricants, 2010, 2(2): 362-375. |

| 62 | Srivastava V, Schaub J, Pischinger S. Advanced model-based closed-loop combustion control strategies with combustion rate shaping[J]. International Journal of Engine Research, 2023,24(8): 3688-3706. |

| 63 | Srivastava V, Schaub J, Pischinger S. Combustion rate shaping for flex-fuel applications[J]. International Journal of Engine Research, 2023, 24(5): 2091-2112. |

| 64 | Quillen K P, Viele M, Ciatti S A. Next-cycle and same-cycle cylinder pressure based control of internal combustion engines[C]∥Internal Combustion Engine Division Fall Technical Conference, San Antonio, USA, 2010: 635-645. |

| 65 | Shaver G M, Gerdes J C, Roelle M. Physics-based closed-loop control of phasing, peak pressure and work output in HCCI engines utilizing variable valve actuation[C]∥Proceedings of the 2004 American Control Conference,Boston, USA, 2004: 150-155. |

| 66 | Shaver G M, Gerdes J M, Roelle M J. Physics-based modeling and control of residual-affected HCCI engines[C]∥Proceedings of the 2004 American Control Conference, Boston, USA,2004:No.1383595. |

| 67 | Husted H, Kruger D, Fattic G, et al. Cylinder pressure-based control of pre-mixed diesel combustion[C]∥SAE Technical Paper, 2007-0773. |

| 68 | Schten K, Ripley G, Punater A, et al. Design of an automotive grade controller for in-cylinder pressure based engine control development[C]∥SAE Technical Paper, 2007-0774. |

| 69 | Kumar R, Zheng M, Asad U. Heat release based adaptive control to improve low temperature diesel engine combustion[C]∥SAE Technical Paper, 2007-0771. |

| 70 | Liebig D, Krane W, Ziman P, et al. The response of a closed loop controlled diesel engine on fuel variation[C]∥SAE Technical Paper, 2008-2471. |

| 71 | Yoon M, Lee K, Sunwoo M. A method for combustion phasing control using cylinder pressure measurement in a CRDI diesel engine[J]. Pergamon, 2007, 17(9): 469-479. |

| 72 | Seungsuk O, Daekyung K, Junsoo K. Real-time IMEP estimation for torque-based engine control using an in-cylinder pressure sensor[C]∥SAE Technical Paper, 2009-0244. |

| 73 | Willems F, Doosje E, Engels F, et al. Cylinder pressure-based control in heavy-duty EGR diesel engines using a virtual heat release and emission sensor[C]∥SAE Technical Paper, 2010-0564. |

| 74 | Huang Y, Yang F Y, Ouyang M G, et al. Optimal feedback control with in-cylinder pressure sensor under engine start conditions[C]∥SAE Technical Paper, 2011-1422. |

| 75 | 方成,杨福源,欧阳明高,等. 利用以太网的柴油机燃烧分析与控制方法研究[J]. 内燃机工程, 2017, 38(2): 19-23. |

| Fang Cheng, Yang Fu-yuan, Ouyang Ming-gao, et al. Research on combustion analysis and control method of diesel engine using ethernet[J]. Internal Combustion Engine Engineering, 2017, 38(2): 19-23. | |

| 76 | 方成,杨福源,陈林,等. 柴油机低温预混合燃烧稳定性控制方法[J]. 车用发动机, 2014 (1): 50-54. |

| Fang Cheng, Yang Fu-yuan, Chen Lin, et al. Stability control method of low-temperature premixed combustion in diesel engines[J]. Automotive Engine, 2014 (1): 50-54. | |

| 77 | 方成,杨福源,欧阳明高,等. 使用缸压信息的柴油机低温燃烧闭环控制[J]. 清华大学学报:自然科学版, 2013, 53(3): 371-377. |

| Fang Cheng, Yang Fu-yuan, Ouyang Ming-gao, et al. Closed-loop control of low-temperature combustion in diesel engines using cylinder pressure information[J]. Journal of Tsinghua University (Science and Technology), 2013, 53(3): 371-377. | |

| 78 | 曲栓. 缸内喷射CO2对柴油准均质压燃燃烧影响的研究[D]. 上海:上海交通大学机械工程学院, 2010. |

| Qu Shuan. Study on the influence of in-cylinder co2 injection on diesel homogeneous charge compression ignition combustion [D]. Shanghai: School of Mechanical Engineering, Shanghai Jiaotong University, 2010. | |

| 79 | 魏子凯. 基于缸压信号的增程式发动机燃烧相位控制[D]. 长春:吉林大学汽车工程学院, 2021. |

| Wei Zi-kai. Combustion phase control of range-extended engines based on cylinder pressure signal [D]. Changchun: College of Automotive Engineering, Jilin University, 2021. | |

| 80 | 孙万臣,刘忠长,刘巽俊,等.燃料特性对小型压燃式发动机增负荷工况燃烧及HC排放的影响[J].吉林大学学报:工学版,2005(2):131-135, 140. |

| Sun Wan-chen, Liu Zhong-chang, Liu Xun-jun, et al. Influence of fuel characteristics on combustion and HC emissions under high load conditions in small compression ignition engines[J]. Journal of Jilin University (Engineering and Technology Edition), 2005, (2): 131-135, 140. | |

| 81 | 孙士杰. 喷射参数对柴油机稳态和瞬态工况下燃烧的影响[D]. 长春:吉林大学汽车工程学院, 2014. |

| Sun Shi-jie. Influence of injection parameters on combustion in steady-state and transient conditions of diesel engines [D]. Changchun: College of Automotive Engineering, Jilin University, 2014. | |

| 82 | 佀庆涛. 基于缸压反馈的柴油发动机控制研究[D]. 长春:吉林大学机械工程学院, 2014. |

| Si Qing-tao. Study on control of diesel engines based on cylinder pressure feedback [D]. Changchun: School of Mechanical Engineering, Jilin University, 2014. | |

| 83 | 王忠恕,吴楠,许允,等. 增压直喷柴油机瞬态工况燃烧参数的变化规律[J]. 内燃机学报, 2007 (5): 385-389. |

| Wang Zhong-shu, Wu Nan, Xu Yun, et al. Variation patterns of combustion parameters in transient conditions of turbocharged direct injection diesel engines[J]. Transactions of CSICE, 2007 (5): 385-389. | |

| 84 | 刘思品. 基于缸压的柴油机燃烧闭环控制[D].武汉:华中科技大学能源与动力工程学院, 2019. |

| Liu Si-pin. Closed-loop control of diesel engine combustion based on cylinder pressure [D]. Wuhan: School of Energy and Power Engineering, Huazhong University of Science and Technology, 2019. | |

| 85 | 曹银波,白云,张志永,等. 基于离子电流的HCCI燃烧相位闭环控制[J]. 燃烧科学与技术, 2013, 19(2): 135-140. |

| Cao Yin-bo, Bai Yun, Zhang Zhi-yong, et al. Closed-loop control of HCCI combustion phase based on ion current[J]. Combustion Science and Technology, 2013, 19(2): 135-140. | |

| 86 | 王小说,安士杰,周磊,等. 基于缸压的闭环控制燃烧参数仿真研究[J]. 小型内燃机与车辆技术, 2018, 47(3): 5-9. |

| Wang Xiao-shuo, An Shi-jie, Zhou Lei, et al. Simulation study on closed-loop control of combustion parameters based on cylinder pressure[J]. Small Internal Combustion Engines and Vehicle Technology, 2018, 47(3): 5-9. | |

| 87 | 刘晓阳,姚崇,王睿,等. 船用柴油机燃烧过程控制策略设计及仿真验证[J]. 内燃机学报, 2021, 39(3): 209-216. |

| Liu Xiao-yang, Yao Chong, Wang Rui, et al. Design and simulation verification of combustion process control strategies for marine diesel engines[J]. Transactions of CSICE, 2021, 39(3): 209-216. | |

| 88 | 张俊. 柴油机燃烧闭环控制实时仿真技术研究[D]. 哈尔滨:哈尔滨工程大学动力与能源工程学院, 2020. |

| Zhang Jun. Research on real-time simulation technology for closed-loop combustion control of diesel engines [D]. Harbin: College of Power and Energy Engineering, Harbin Engineering University, 2020. | |

| 89 | 唐俊,余永华,王勤鹏,等. 船用中速柴油机缸压闭环控制技术仿真研究[J]. 内燃机工程, 2019, 40(1): 72-78. |

| Tang Jun, Yu Yong-hua, Wang Qin-peng, et al. Simulation study on cylinder pressure closed-loop control technology for marine medium-speed diesel engines[J]. Internal Combustion Engine Engineering, 2019, 40(1): 72-78. | |

| 90 | 余永华,沈叶磊,王勤鹏,等. 船用低速柴油机缸压闭环控制硬件在环仿真技术研究[J]. 内燃机工程, 2019, 40(5): 86-92. |

| Yu Yong-hua, Shen Ye-lei, Wang Qin-peng, et al. Hardware-in-the-loop simulation technology research on cylinder pressure closed-loop control for marine low-speed diesel engines[J]. Internal Combustion Engine Engineering, 2019, 40(5): 86-92. | |

| 91 | 欧顺华,余永华,胡闹,等. 基于缸压的船用柴油机燃烧闭环控制策略研究[J]. 内燃机工程, 2020, 41(6): 29-35. |

| Shun-hua Ou, Yu Yong-hua, Hu Nao, et al. Research on closed-loop combustion control strategy for marine diesel engines based on cylinder pressure[J]. Internal Combustion Engine Engineering, 2020, 41(6): 29-35. | |

| 92 | Proc H Y. A New Generation of Engine Combustion[M].New York: Editions Technip,2001. |

| 93 | 黄颖. 面向柴油机燃烧闭环控制的新一代控制平台研究及应用[D]. 北京:清华大学车辆与运载学院, 2010. |

| Huang Ying. Research and application of a new generation control platform for closed-loop combustion control of diesel engines[D]. Beijing: School of Vehicle and Mobility,Tsinghua University, 2010. | |

| 94 | 姚昌晟. 混合发动机燃烧模式优化及控制研究[D]. 北京:清华大学车辆与运载学院, 2019. |

| Yao Chang-sheng. Research on combustion mode optimization and control of hybrid engines[D]. Beijing: School of Vehicle and Mobility, Tsinghua University, 2019. | |

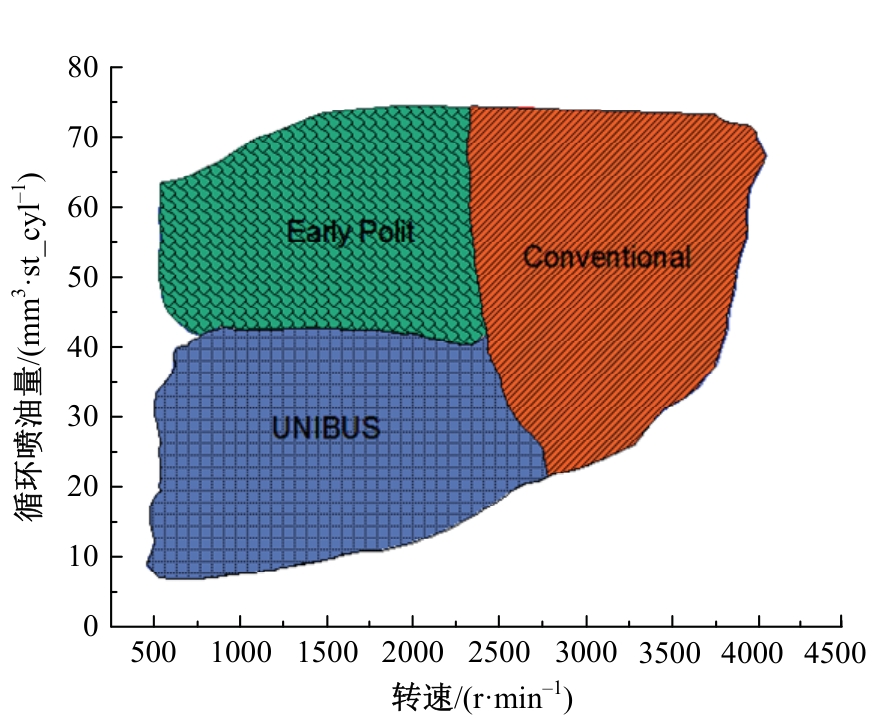

| 95 | 王金力. 基于燃烧闭环控制的灵活燃料发动机燃烧控制研究[D]. 北京:清华大学车辆与运载学院, 2015. |

| Wang Jin-li. Research on combustion control of flexible fuel engines based on closed-loop control[D]. Beijing: School of Vehicle and Mobility, Tsinghua University, 2015. | |

| 96 | 方成. 基于缸压信息的压燃发动机燃烧模式识别与反馈控制研究[D]. 北京:清华大学车辆与运载学院, 2015. |

| Fang Cheng. Research on combustion mode recognition and feedback control of compression ignition engines based on cylinder pressure information[D]. Beijing: School of Vehicle and Mobility, Tsinghua University, 2015. | |

| 97 | Fang C, Yang F Y, Ouyang M G, et al. Combustion mode switching control in a HCCI diesel engine[J]. Applied Energy, 2013, 110: 190-200. |

| 98 | 张昊,范钦灏,王巍,等. 基于强化学习的多燃烧模式混合动力能量管理策略[J]. 汽车工程, 2021, 43(5): 683-691. |

| Zhang Hao, Fan Qin-hao, Wang Wei,et al. Reinforcement learning based energy management strategy for hybrid electric vehicles using multi⁃mode combustion[J].Automotive Engineering,2021, 43(5): 683-691. | |

| 99 | 李坤颖. 柴油/天然气双燃料发动机燃烧策略的研 究[D]. 广州:华南理工大学机械与汽车工程学院, |

| 2016 | |

| Li Kun-ying. Research on combustion strategy for diesel/natural gas dual fuel engine[D].Guangzhou:School of Mechanical and Automotive Engineering,South China University of Technology, 2016. | |

| 100 | Roelle M J, Shaver G M, Gerdes J C. Tackling the transition: a multi-mode combustion model of SI and HCCI for mode transition control[C]∥Asme International Mechanical Engineering Congress and Exposition,Anaheim,USA, 2004: 329-336. |

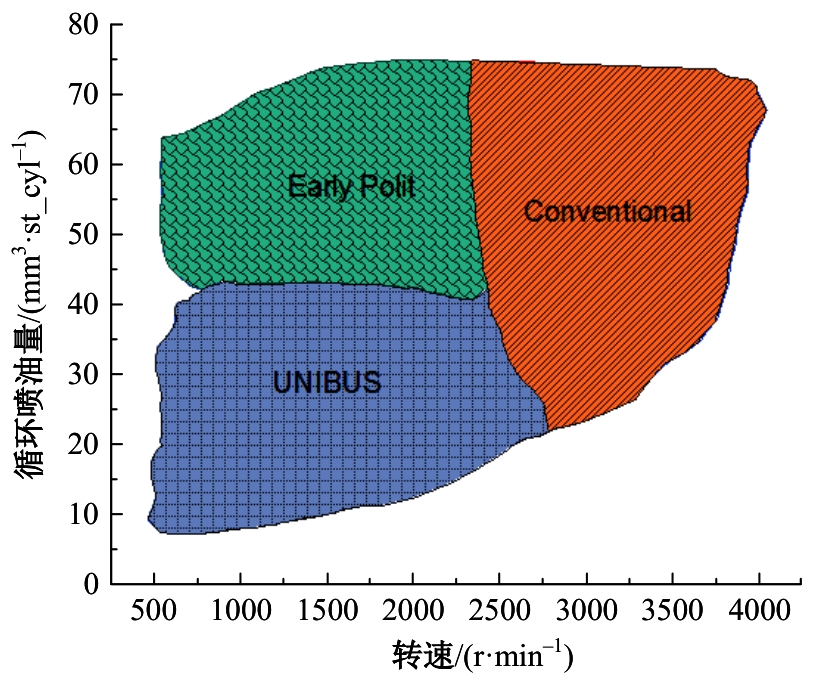

| 101 | Fang C, Ouyang M G, Tunestal P, et al. Closed-loop combustion phase control for multiple combustion modes by multiple injections in a compression ignition engine fueled by gasoline-diesel mixture[J]. Applied Energy, 2018, 231: 816-825. |

| 102 | Nieman D E, Morris A P, Neely G D, et al. Utilizing multiple combustion modes to increase efficiency and achieve full load dual-fuel operation in a heavy-duty engine[C]∥SAE Technical Paper, 2019-1157. |

| 103 | Guardiola C, Pla B, Bares P, et al. Closed-loop control of a dual-fuel engine working with different combustion modes using in-cylinder pressure feedback[J]. International Journal of Engine Research, 2020, 21(3): 484-496. |

| 104 | Batool S, Naber J, Shahbakhti M. Closed-loop predictive control of a multi-mode engine including homogeneous charge compression ignition, partially premixed charge compression ignition, and reactivity controlled compression ignition modes[C]∥SAE Paper, 2022-0003. |

| 105 | Martin J, Boehman A. Mapping the combustion modes of a dual-fuel compression ignition engine[J]. International Journal of Engine Research, 2021, 23: 1453-1474. |

| 106 | Fredrik A, Hans-Erik Å, Bengt E, et al. Control of HCCI during engine transients by aid of variable valve timings through the use of model based non-linear compensation[C]∥SAE Technical Paper, 2005-0131. |

| 107 | Olsson J O, Pfeiffer R, Tunestål P, et al. Closed-loop system identification of an HCCI engine[J]. Ifac Proceedings Volumes, 2004, 37(22): 239-244. |

| 108 | Strandh P, Bengtsson J, Johansson R, et al. Cycle-to-cycle control of a dual-fuel HCCI engine[C]∥SAE Technical Paper, 2004-0941. |

| 109 | Aulin H, Johansson T, Tunestål P, et al. Control of a turbo charged NVO HCCI engine using a model based approach[J]. Ifac Proceedings Volumes, 2009, 42: 79-86. |

| 110 | Anders W, Hsien-Hsin L, Christian G J, et al. Control of exhaust recompression HCCI using hybrid model predictive control[C]∥Proceedings of the 2011 American Control Conference,San Francisco, USA, 2011:No.5990920. |

| 111 | Anders W, Kent E, Per T, et al. Physics-based model predictive control of HCCI combustion phasing using fast thermal management and VVA[J]. IEEE Transactions on Control Systems Technology, 2012, 20(3): 688-699. |

| 112 | Johan B, Petter S, Rolf J, et al. Model predictive control of homogeneous charge compression ignition (HCCI) engine dynamics[C]∥ 2006 IEEE International Conference on Control Applications, Munich, Germany,2006:1675-1680. |

| 113 | Karlsson M, Ekholm K, Strandh P, et al. Multiple-input multiple-output model predictive control of a diesel engine[J]. Ifac Proceedings Volumes, 2010, 43: 131-136. |

| 114 | Moreno C J, Stenlaas O, Tunestal P. FPGA implementation of in-cycle closed-loop combustion control methods[C]∥SAE Technical Paper, 2021-0024. |

| 115 | Muric K, Stenlaas O, Tunestal P, et al. A study on in-cycle control of NO x using injection strategy with a fast cylinder pressure based emission model as feedback[C]∥SAE Technical Paper, 2013-2603. |

| 116 | Shaver G M, Roelle M J, Caton P A, et al. A physics-based approach to the control of homogeneous charge compression ignition engines with variable valve actuation[J]. International Journal of Engine Research, 2005, 6: 361-375. |

| 117 | Raut A, Bidarvatan M, Borhan H, et al. Model predictive control of an RCCI engine[C]∥2018 Annual American Control Conference (ACC), Milwaukee, USA, 2018: No.8431172. |

| 118 | Bidarvatan M, Kothari D, Shahbakhti M. Integrated cycle-to-cycle control of exhaust gas temperature, load, and combustion phasing in an HCCI engine[C]∥2015 American Control Conference (ACC),Chicago, USA,2015: No.7170703. |

| 119 | Bidarvatan M, Thakkar V, Shahbakhti M. Grey-box modeling and control of HCCI engine emissions[C]∥2014 American Control Conference, Portland,USA, 2014: 837-842. |

| 120 | Mehran-Bidarvatan-Mahdi S. Model-based control of combustion phasing in an HCCI engine[J]. SAE International, 2012, 5(3): 1163-1176. |

| 121 | Erik H, Jacob L, Shyam J, et al. Reducing cyclic variability while regulating combustion phasing in a four-cylinder HCCI engine[J]. IEEE Transactions on Control Systems Technology, 2014, 22: 1190-1197. |

| 122 | Bidarvatan M, Shahbakhti M. Two-input two-output control of blended fuel HCCI engines[C]∥SAE Technical Paper, 2013-1663. |

| 123 | Bidarvatan M, Shahbakhti M, Jazayeri S A, et al. Cycle-to-cycle modeling and sliding mode control of blended-fuel HCCI engine[J]. Control Engineering Practice, 2014, 24: 79-91. |

| 124 | Ravi N, Liao H H, Jungkunz A F, et al. Modeling and control of an exhaust recompression HCCI engine using split injection[J]. Journal of Dynamic Systems, Measurement, and Control, 2011,1(134):No.011016-2. |

| 125 | Raut A, Irdmousa B K, Shahbakhti M. Dynamic modeling and model predictive control of an RCCI engine[J]. Control Engineering Practice, 2018, 81: 129-144. |

| 126 | Yin L H, Turesson G, Tunestal P, et al. Model predictive control of an advanced multiple cylinder engine with partially premixed combustion concept[J]. IEEE/ASME Transactions on Mechatronics, 2020, 25(2): 804-814. |

| 127 | Widd A, Liao H H, Gerdes J C, et al. Hybrid model predictive control of exhaust recompression hcci[J]. Asian Journal of Control, 2013, 16: 370-381. |

| 128 | Kekik B, Akar M. Model predictive control of diesel engine air path with actuator delays[J]. Ifac Papersonline, 2019, 52(18): 150-155. |

| 129 | Fathi M, Jahanian O, Shahbakhti M. Modeling and controller design architecture for cycle-by-cycle combustion control of homogeneous charge compression ignition (HCCI) engines-a comprehensive review[J]. Energy Conversion and Management, 2017, 139: 1-19. |

| 130 | Bengtsson J, Strandh P, Johansson R, et al. Hybrid control of homogeneous charge compression ignition (HCCI) engine dynamics[J]. International Journal of Control, 2006, 79(5): 422-448. |

| 131 | Janakiraman V M, Nguyen X L, Assanis D. An ELM based predictive control method for HCCI engines[J]. Engineering Applications of Artificial Intelligence, 2016, 48: 106-118. |

| 132 | Ebrahimi K, Koch C R B. Real-time control of HCCI engine using model predictive control[C]∥2018 Annual American Control Conference (ACC),Milwaukee,USA, 2018: No. 8431211. |

| 133 | Zhang L, Zheng T, Ma Y, et al. Combustion timing control of HCCI engine based on NNPC and Elman‐NN model under complex conditions[J]. Asian Journal of Control, 2023, 25(2): 1115-1129. |

| 134 | 李顶根,王迪.基于模型预测控制的废气循环HCCI发动机的多变量控制[J].汽车安全与节能学报,2012,3(4):381-389. |

| Li Ding-gen, Wang Di. Model predictive control of multivariable control for exhaust gas recirculation HCCI engines[J]. Journal of Automotive Safety and Energy, 2012, 3(4): 381-389. | |

| 135 | Zheng M, Tan Y Y, Reader G T, et al. Prompt heat release analysis to improve diesel low temperature combustion[C]∥SAE Technical Paper, 2009-1883. |

| 136 | Chung J, Min K, Oh S, et al. In-cylinder pressure based real-time combustion control for reduction of combustion dispersions in light-duty diesel engines[J]. Applied Thermal Engineering, 2016, 99: 1183-1189. |

| 137 | Beaumont A, Lemieux J, Battiston P, et al. Design of a rapid prototyping engine management system for development of combustion feedback control technology[C]∥SAE Technical Paper, 2006-0611. |

| 138 | Arora J K, Shahbakhti M. Real-time closed-loop control of a light-duty RCCI engine during transient operations[C]∥SAE Technical Paper, 2017-0767. |

| 139 | Bastian L, Stefan P, Maximilian W, et al. A study on in-cycle combustion control for gasoline controlled autoignition[C]∥SAE Technical Paper, 2016-0754. |

| 140 | Schiefer D, Maennel R, Nardoni W. Advantages of diesel engine control using in-cylinder pressure information for closed loop control[C]∥SAE Paper, 2003-0364. |

| 141 | Ou S, Yu Y, Yang J. Study on the closed-loop combustion control for a diesel engine by using a dynamic-target online prediction model[J]. Control Engineering Practice, 2022, 125: No.105226. |

| 142 | 胡松,王贺春,孙永瑞,等. 增压柴油机零维预测燃烧模型建模方法[J]. 内燃机学报, 2016, 34(4): 311-318. |

| Hu Song, Wang He-chun, Sun Yong-rui, et al. Modeling method of zero-dimensional predictive combustion model for turbocharged diesel engines[J]. Transactions of CSICE, 2016, 34(4): 311-318. | |

| 143 | Yoon M, Lee K, Sunwoo M, et al. Cylinder pressure based combustion phasing control of a CRDI diesel engine[C]∥SAE Technical Paper, 2007-0772. |

| 144 | Beasley M, Cornwell R, Fussey P, et al. Reducing diesel emissions dispersion by coordinated combustion feedback control[C]∥SAE Technical Paper, 2006-0186. |

| 145 | Hülser H, Neunteufl K, Roduner C, et al. EmIQ: intelligent combustion and control for Tier2 Bin5 diesel engines[C]∥SAE Paper, 2006-1146. |

| 146 | 周能辉,谢辉,赵华,等. 汽油HCCI发动机实时控制系统的开发[J]. 中国机械工程, 2009, 20(8): 970-974. |

| Zhou Neng-hui, Xie Hui, Zhao Hua, et al. Development of real-time control system for gasoline HCCI engine[J]. Chinese Journal of Mechanical Engineering, 2009, 20(8): 970-974. | |

| 147 | 胡建村,金江善,王锋,等. 船用柴油机燃烧闭环控制用缸压信号实时采集技术[J]. 舰船科学技术, 2021, 43(17): 142-146. |

| Hu Jian-cun, Jin Jiang-shan, Wang Feng, et al. Real-time cylinder pressure signal acquisition technology for closed-loop combustion control of marine diesel engines[J]. Journal of Ship Science and Technology, 2021, 43(17): 142-146. | |

| 148 | Mariani V C, Och S H, Coelho H D S, et al. Pressure prediction of a spark ignition single cylinder engine using optimized extreme learning machine models[J]. Applied Energy, 2019, 249: 204-221. |

| 149 | Whitmore S A, Zelesnik E M. Attenuated chamber-pressure signal reconstruction using maximum-likelihood estimation and optimal deconvolution[J]. Journal of Spacecraft and Rockets, 2021, 58(3): 798-812. |

| 150 | Ali S A, Saraswati S. Reconstruction of cylinder pressure using crankshaft speed fluctuations[C]∥2015 International Conference on Industrial Instrumentation and Control (ICIC),Pune, India,2015: No.7150785. |

| 151 | Bennett C, Dunne J F, Trimby S, et al. Engine cylinder pressure reconstruction using crank kinematics and recurrently-trained neural networks[J]. Mechanical Systems and Signal Processing, 2017, 85: 126-145. |

| [1] | 高永强,周士谦,齐龙,尹迁齐,黄雪涛,张佳兴. 自激振荡喷嘴流动特性对近嘴区射流雾化的影响[J]. 吉林大学学报(工学版), 2024, 54(6): 1512-1518. |

| [2] | 李晓娜,解方喜,赵靖华,刘宇,孙耀. 内部废气耦合点火对甲醇燃烧和排放的影响[J]. 吉林大学学报(工学版), 2024, 54(3): 631-640. |

| [3] | 周遊,洪伟,解方喜,刘宇,宫洵,李小平. 气门控制策略对无节气门发动机性能的影响[J]. 吉林大学学报(工学版), 2024, 54(1): 55-65. |

| [4] | 吕德淋,周超,韩东. 汽油/丁醇燃料燃烧动力学简化机理的构建和验证[J]. 吉林大学学报(工学版), 2023, 53(5): 1264-1271. |

| [5] | 徐振军,张瑞凤,陈嘉祥,张晓慧,密晓光,陈杰,陈林. 回热对低温大质流密度实验系统能耗影响[J]. 吉林大学学报(工学版), 2023, 53(4): 1133-1138. |

| [6] | 杨子荣,李岩,冀雪峰,刘芳,郝冬. 质子交换膜燃料电池运行工况参数敏感性分析[J]. 吉林大学学报(工学版), 2022, 52(9): 1971-1981. |

| [7] | 徐振军,王浩,赵开元,郝博轶,李清清,王常浩. 复合太阳能的燃气机热泵热力学性能[J]. 吉林大学学报(工学版), 2022, 52(8): 1759-1763. |

| [8] | 秦静,郑德,裴毅强,吕永,苏庆鹏,王膺博. 基于PSO-GPR的发动机性能与排放预测方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1489-1498. |

| [9] | 赵同宾,吴宜胜,段耀宗,黄震,韩东. RP-3航空煤油的润滑特性和改善措施[J]. 吉林大学学报(工学版), 2022, 52(3): 533-540. |

| [10] | 徐振军,王浩,王银成,张诺,陈孟,李清清. 微通道低温换热器流动传热性能[J]. 吉林大学学报(工学版), 2022, 52(10): 2294-2299. |

| [11] | 潘凤文,弓栋梁,高莹,徐明伟,麻斌. 基于锂离子电池线性化模型的电流传感器故障诊断[J]. 吉林大学学报(工学版), 2021, 51(2): 435-441. |

| [12] | 祖象欢,杨传雷,王贺春,王银燕. 船用柴油机废气再循环性能评估及应用[J]. 吉林大学学报(工学版), 2019, 49(3): 805-815. |

| [13] | 杨帅, 冯志炜, 赵治国, 周毅. 不同米勒循环方式对柴油机工作过程影响的一维模拟分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1444-1454. |

| [14] | 唐志刚, 张力, 尚会超, 吕晓惠, 陈曦, 郑仁蔚. 电热塞点火微型内燃机燃烧特性及残余废气对其的影响[J]. 吉林大学学报(工学版), 2017, 47(3): 811-818. |

| [15] | 解方喜, 于泽洋, 刘思楠, 曹晓峰, 贾贵起, 洪伟. 喷射压力对燃油喷雾和油气混合特性的影响[J]. 吉林大学学报(工学版), 2013, 43(06): 1504-1509. |

|

||