吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (11): 3265-3273.doi: 10.13229/j.cnki.jdxbgxb.20230009

• 交通运输工程·土木工程 • 上一篇

钢纤维与细非金属纤维混杂UHPC双向板弯曲特性

- 1.中南大学 土木工程学院,长沙 410075

2.北京工业大学 建筑工程学院,北京 100124

Bending behaviors of two-way slab of UHPC with steel fiber and micro-nonmetallic fiber

Gen-she YU1( ),Zong-cai DENG2(

),Zong-cai DENG2( )

)

- 1.School of Civil Engineering,Central South University,Changsha 410075,China

2.College of Architecture and Civil Engineering,Beijing University of Technology,Beijing 100124,China

摘要:

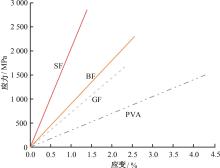

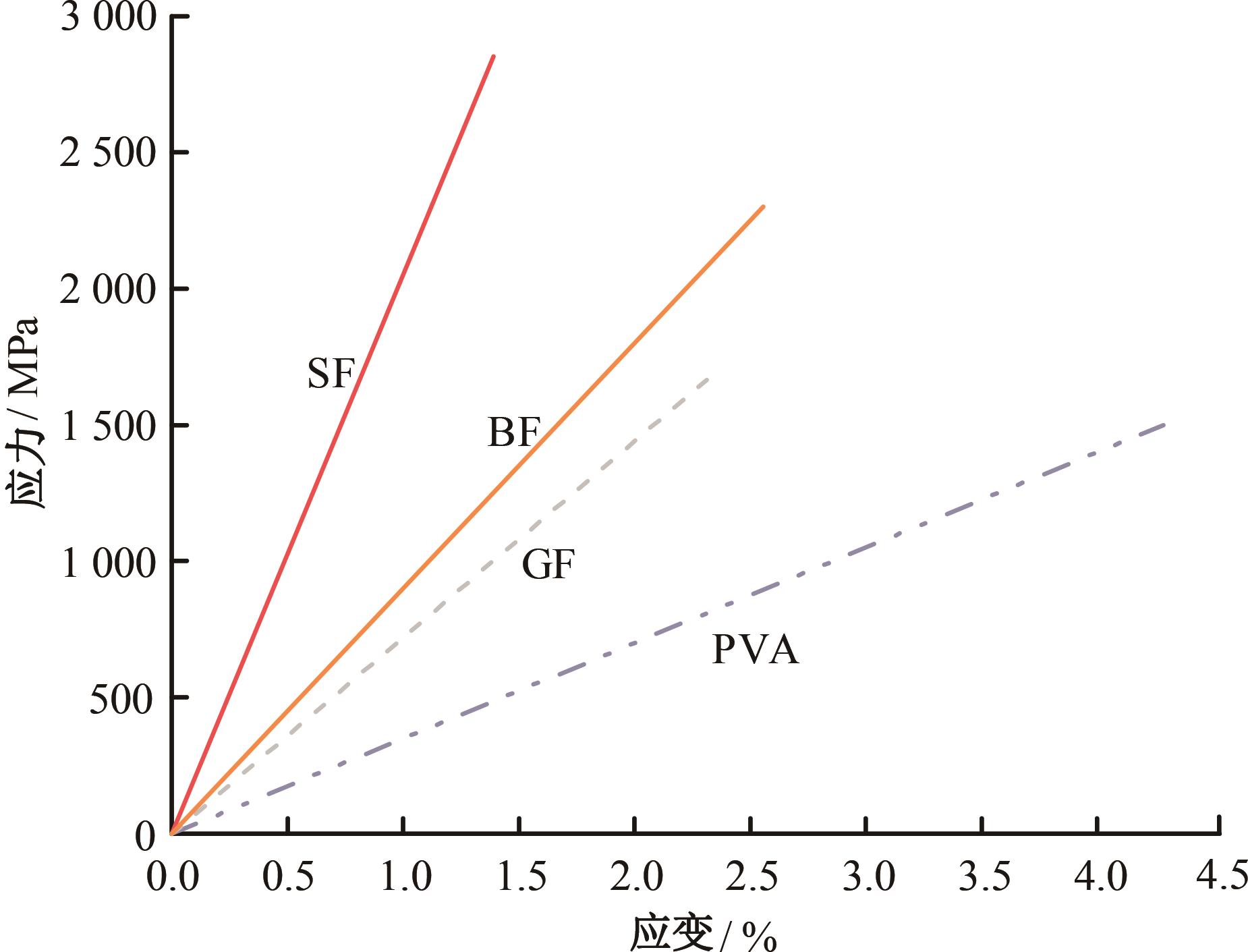

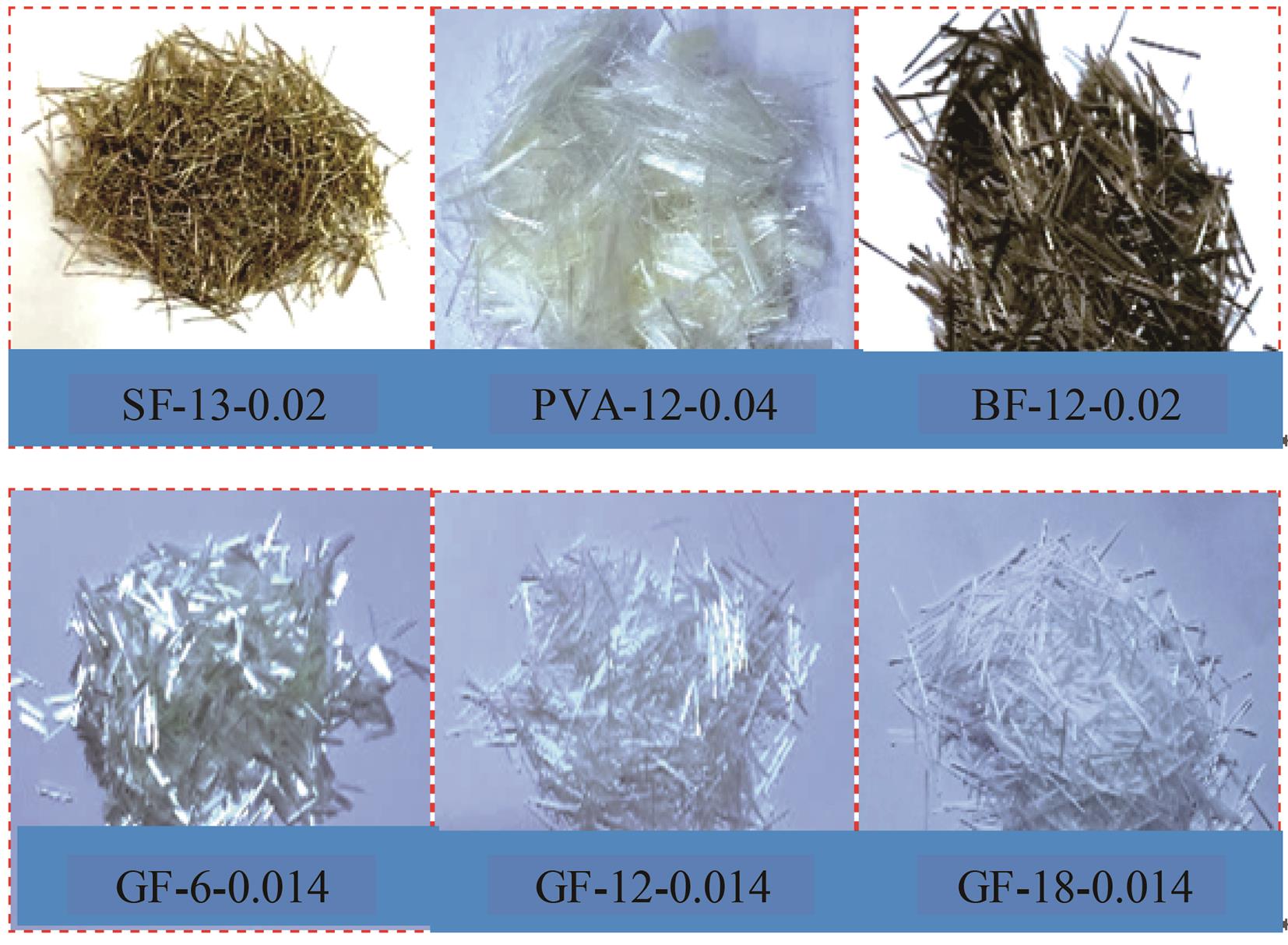

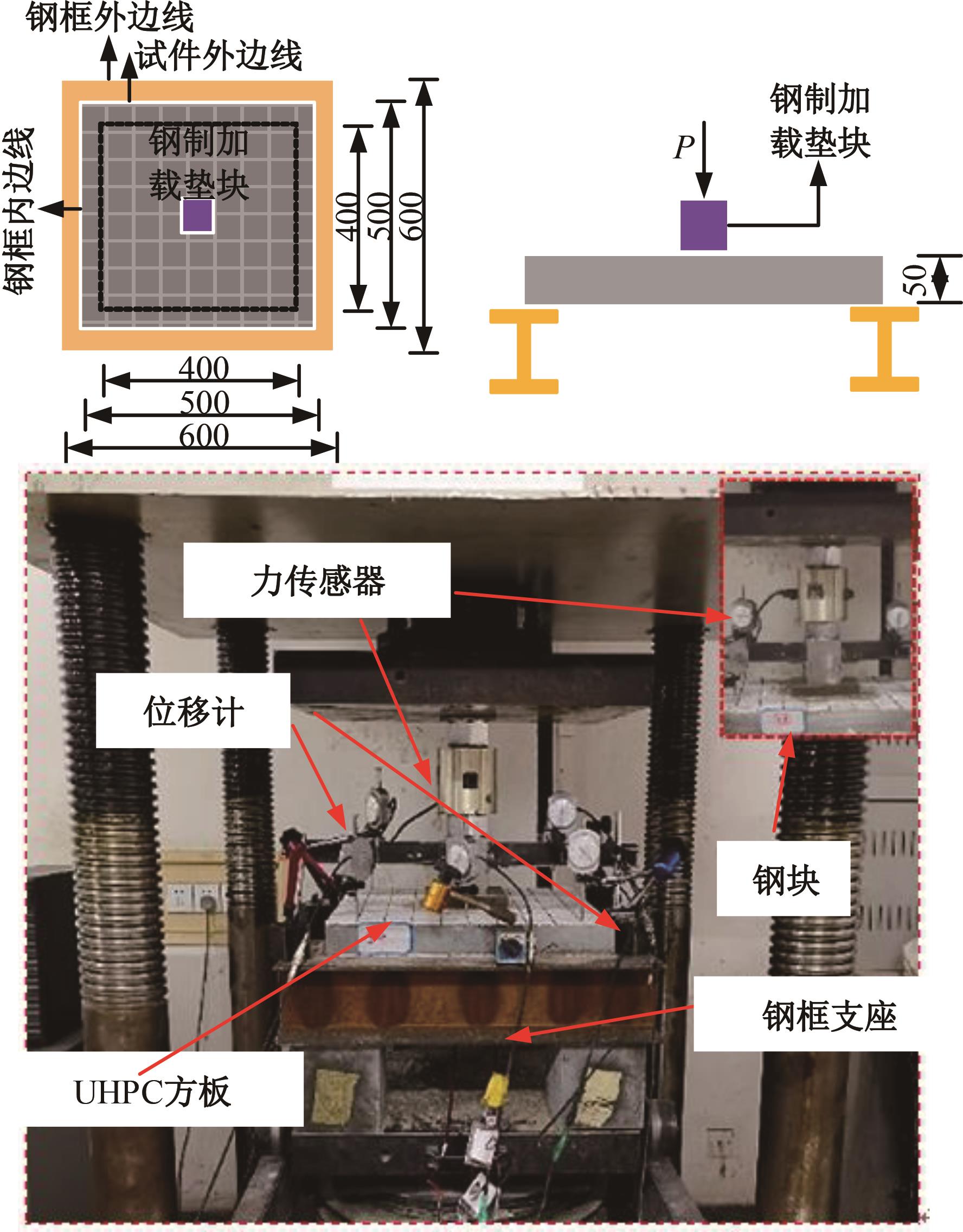

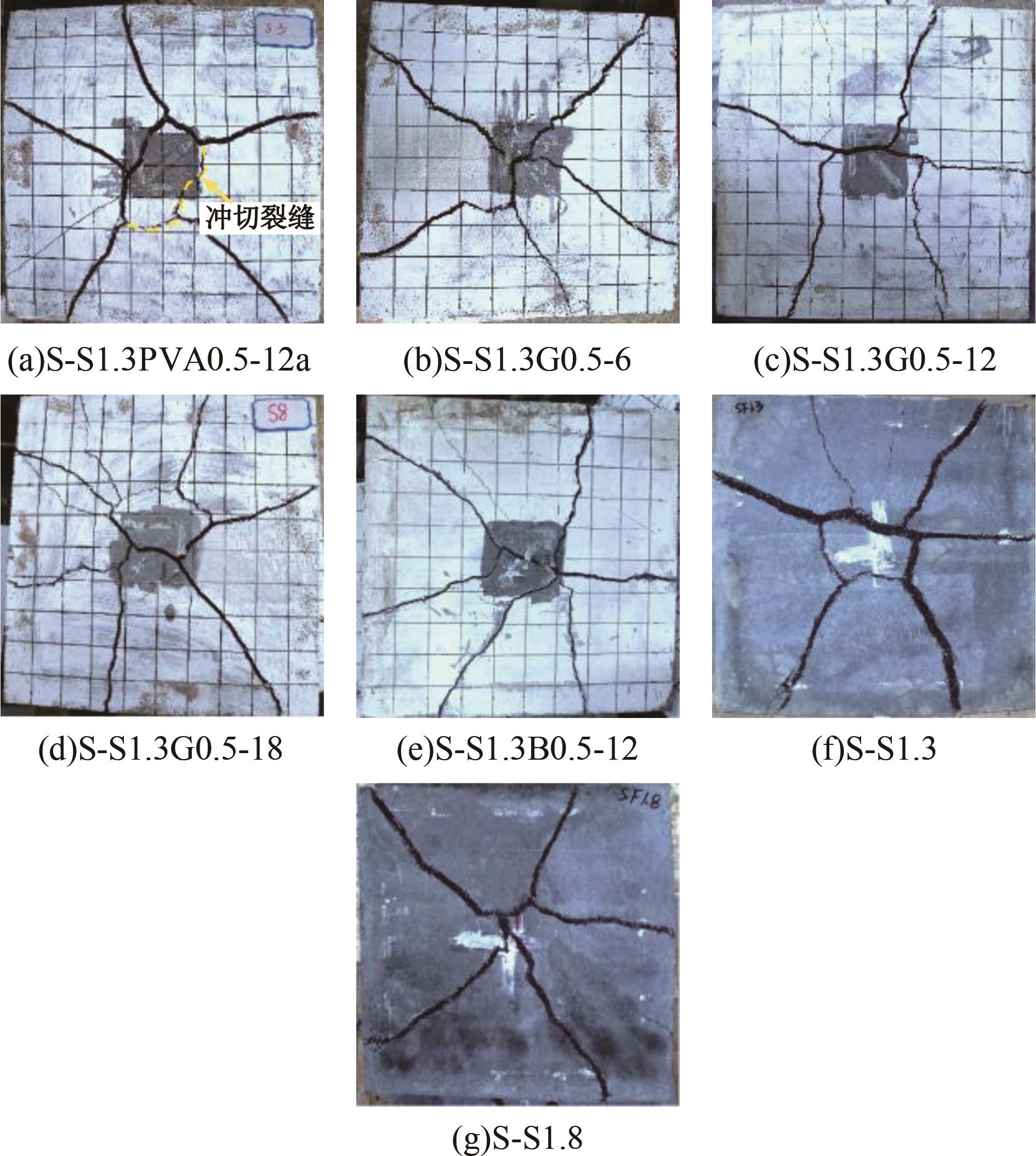

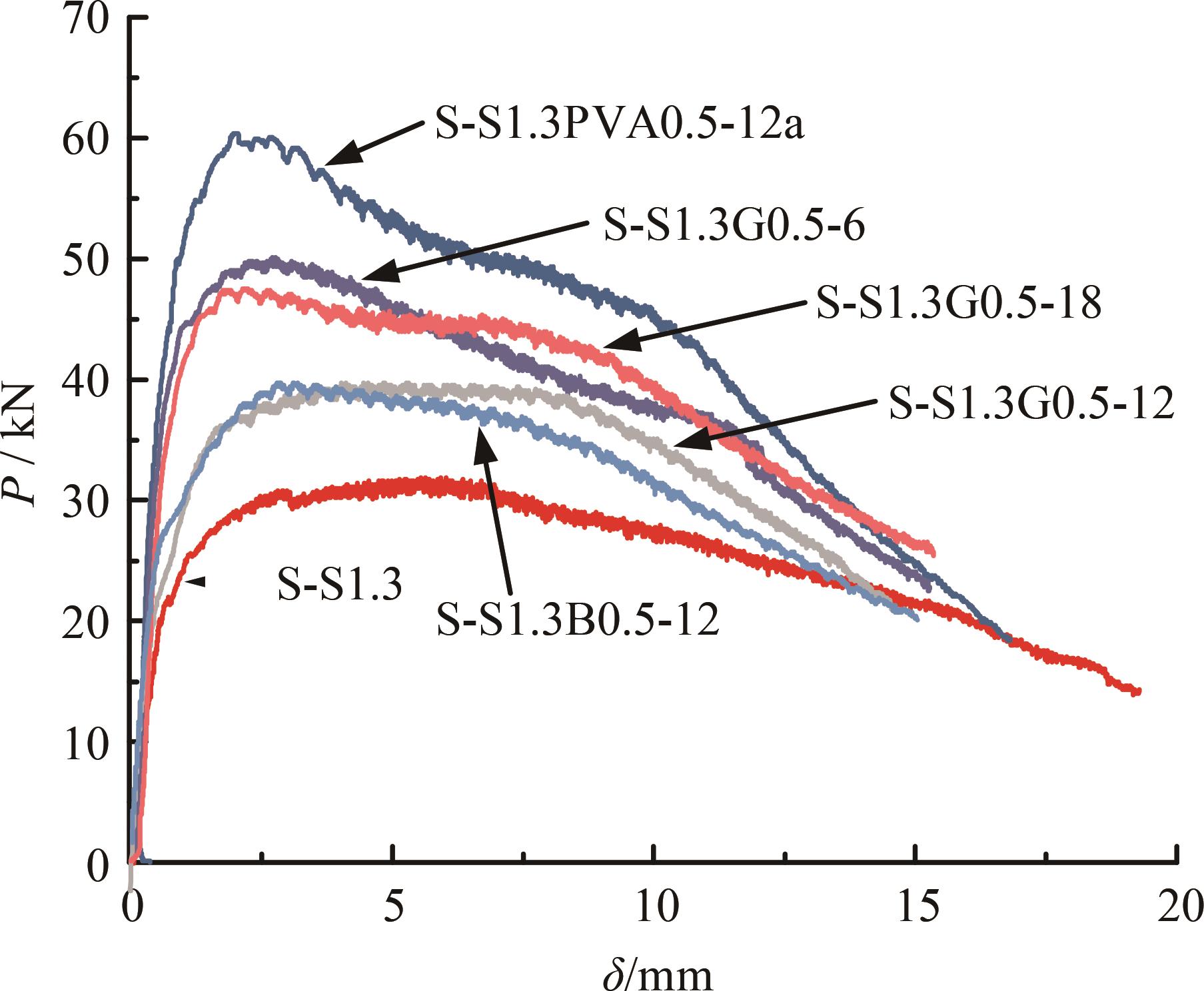

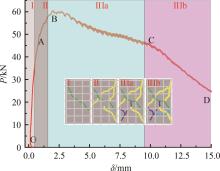

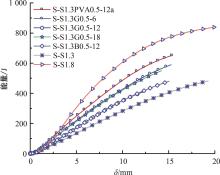

为研究混杂纤维对UHPC弯曲性能的影响,本文将钢纤维与3种新型非金属细纤维混杂,通过7组四边简支方板中心点加载试验,研究了各组试件的受力过程、破坏形态和荷载-挠度曲线,分析了混杂纤维UHPC板的初裂荷载、峰值荷载和弯曲韧性等。结果表明:混杂纤维提高了UHPC板的初裂荷载、峰值荷载、能量吸收值和变形性能;混杂纤维UHPC板的能量吸收值高于单掺1.3%钢纤维(SF);混杂纤维UHPC板的峰后韧性指标T9(5.5)、T14(8)和T19(10.5)均高于单掺1.3%SF和1.8%SF试件,混杂纤维显著提高了残余承载力和变形能力;当SF分别与聚乙烯醇纤维(PVA)、玻璃纤维(GF)和玄武岩纤维(BF)混杂,SF/PVA、SF/BF的混杂增韧效应优于SF/GF。通过能量法、硬化指数和峰后韧性指标可以全面评价混杂纤维UHPC板在不同受力阶段的增强与增韧效应。

中图分类号:

- TU375.2

| 1 | 史金华, 史才军, 欧阳雪, 等. 超高性能混凝土受压弹性模量研究进展[J]. 材料导报, 2021, 35(3): 3067-3075. |

| Shi Jin-hua, Shi Cai-jun, Ouyang Xue, et al. Compressive elastic modulus of ultra-high performance concrete : a review[J]. Materials Reports, 2021, 35(3): 3067-3075. | |

| 2 | 苏家战, 林毅焌, 陈宝春, 等. 混杂钢纤维UHPC单轴拉伸性能的混杂效应分析[J]. 南昌大学学报: 自然科学版, 2019, 41(4): 358-364. |

| Su Jia-zhan, Lin Yi-jun, Chen Bao-chun, et al. Hybrid effects of steel fibers on the uniaxial tensile properties of ultra-high performance concrete[J]. Journal of Nanchang University (Engineering & Technology), 2019, 41(4): 358-364 . | |

| 3 | 陈宝春, 林毅焌, 杨简, 等. 超高性能纤维增强混凝土中纤维作用综述[J]. 福州大学学报: 自然科学版, 2020, 48(1): 58-68. |

| Chen Bao-chun, Lin Yi-jun, Yang Jian, et al. Review on fiber function in ultra-high performance fiber reinforced concrete[J]. Journal of Fuzhou University (Natural Science Edition),2020, 48(1): 58-68. | |

| 4 | Cengiz O, Turanli L. Comparative evaluation of steel mesh, steel fibre and high-performance polypropylene fibre reinforced shotcrete in panel test[J]. Cement and Concrete Research, 2004, 34(8):1357-1364. |

| 5 | Bindiganavile V, Banthia N. Fiber reinforced dry-mix shotcrete with metakaolin[J]. Cement and Concrete Composites, 2001, 23(6): 503-514. |

| 6 | 朱如如. 混杂纤维对活性粉末混凝土性能影响的研究[D]. 哈尔滨: 哈尔滨工业大学交通科学与工程学院, 2016. |

| Zhu Ru-ru. Research on the effects of hybrid fiber on reactive powder concrete[D]. Harbin: School of Transportation Science and Engineering, Harbin Institute of Technology, 2016. | |

| 7 | 李黎, 曹明莉, 冯嘉琪. 纤维增强水泥基复合材料的纤维混杂效应研究进展[J]. 应用基础与工程科学学报, 2018, 26(4): 843-853. |

| Li Li, Cao Ming-li, Feng Jia-qi. Research progress on fiber hybrid effect in fiber reinforced cementitious composite[J]. Journal of Basic Science and Engineering, 2018, 26(4): 843-853. | |

| 8 | Galobardes I, Silva C L, Figueiredo A, et al. Alternative quality control of steel fibre reinforced sprayed concrete (SFRSC) [J]. Construction and Building Materials, 2019, 223: 1008-1015. |

| 9 | Banthia N, Gupta R. Hybrid fiber reinforced concrete(HyFRC): fiber synergy in high strength matrices[J]. Materials and Structures, 2004, 37: 707-716. |

| 10 | Bakhshi M, Barsby C, Mobasher B. Comparative evaluation of early age toughness parameters in fiber reinforced concrete[J]. Materials and Structures, 2014, 47(5): 853-872. |

| 11 | Chun B, Yoo D. Hybrid effect of macro and micro steel fibers on the pullout and tensile behaviors of ultra-high-performance concrete[J]. Composites Part B-Engineering, 2019, 162: 344-360. |

| 12 | Wu Z M, Shi C J, He W, et al. Uniaxial compression behavior of ultra-high performance concrete with hybrid steel fiber[J]. Journal of Materials in Civil Engineering, 2016, 28: 0601601712. |

| 13 | Kang S T, Choi J I, Koh K T, et al. Hybrid effects of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete[J]. Composite Structures, 2016, 145: 37-42. |

| 14 | 沈荣熹, 王璋水, 崔玉忠. 纤维增强水泥与纤维增强混凝土[M]. 北京: 化学工业出版社, 2006. |

| 15 | Nemkumar B, Trottier J F. Test methods for flexural toughness characterization of fiber reinforced concrete: some concerns and a proposition[J]. ACI Materials Journal, 2018, 92(1): 48-57. |

| 16 | 邓宗才, 曲玖玲, 刘国平. 粗聚烯烃纤维混凝土圆板弯曲韧性和表征方法[J]. 建筑材料学报, 2015, 18(1): 7-11. |

| Deng Zong-cai, Qu Jiu-ling, Liu Guo-ping. Flexural toughness and its characterization of a new kind of macro-polyolefin fiber reinforced concrete plate[J]. Journal of Building Materials, 2015, 18(1): 7-11. |

| [1] | 周宇,李萌,狄生奎,石贤增,陈东. 变截面两铰拱推力影响线解析解及损伤识别应用[J]. 吉林大学学报(工学版), 2025, 55(2): 664-672. |

| [2] | 王羽岱,王斌,苗福生,马楠. 水热耦合变化下衬砌渠道冻胀响应[J]. 吉林大学学报(工学版), 2025, 55(1): 256-268. |

| [3] | 姜浩,赵正文. 玄武岩纤维网格水泥基复合材料加固RC梁抗剪性能试验[J]. 吉林大学学报(工学版), 2025, 55(1): 211-220. |

| [4] | 韦芳芳,李丽萍,徐庆鹏,赵有正,杨晶晶. 受火双钢板-混凝土组合剪力墙加固后抗震性能试验[J]. 吉林大学学报(工学版), 2025, 55(1): 230-244. |

| [5] | 孙永新,蔺鹏臻,杨子江,冀伟. 考虑黏结-滑移效应的UHPC梁裂缝宽度计算方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2600-2608. |

| [6] | 朱劲松,佟欣瑶,刘晓旭. 装配式小箱梁桥超高性能混凝土免支模湿接缝抗弯性能[J]. 吉林大学学报(工学版), 2024, 54(9): 2568-2580. |

| [7] | 赵金全,周龙,丁永刚,朱熔基. 螺旋箍筋-波纹管浆锚连接锚固性能试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2484-2494. |

| [8] | 杨伟松,张安,许卫晓,李海生,杜轲. 刚度增强型金属连梁阻尼器的抗震性能[J]. 吉林大学学报(工学版), 2024, 54(9): 2469-2483. |

| [9] | 阎奇武,邹忠亮. 减震结构阻尼器优化布置混合算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2267-2274. |

| [10] | 姜封国,周玉明,白丽丽,梁爽. 改进磷虾群算法及其在结构优化中的应用[J]. 吉林大学学报(工学版), 2024, 54(8): 2256-2266. |

| [11] | 张广泰,周乘孝,刘诗拓. 盐渍土环境下纤维锂渣混凝土柱恢复力模型[J]. 吉林大学学报(工学版), 2024, 54(7): 1944-1957. |

| [12] | 刁延松,任义建,杨元强,赵凌云,刘秀丽,刘芸. 带有摩擦耗能组件的可更换钢梁柱拼接节点抗震性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1643-1656. |

| [13] | 樊学平,刘月飞. 基于改进高斯混合粒子滤波新算法的桥梁极值应力动态预测[J]. 吉林大学学报(工学版), 2024, 54(4): 1038-1044. |

| [14] | 刘一凡,缪志伟,申晨,耿祥东. 基于蒙特卡罗法的不均匀锈蚀钢筋力学性能评估[J]. 吉林大学学报(工学版), 2024, 54(4): 1007-1015. |

| [15] | 樊学平,周衡,刘月飞. 基于Gaussian Copula-贝叶斯动态模型的桥梁构件时变可靠性分析[J]. 吉林大学学报(工学版), 2024, 54(2): 485-493. |

|

||