吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2600-2608.doi: 10.13229/j.cnki.jdxbgxb.20230724

• 交通运输工程·土木工程 • 上一篇

考虑黏结-滑移效应的UHPC梁裂缝宽度计算方法

- 兰州交通大学 土木工程学院,兰州 730070

Calculation method for crack width of UHPC beams considering bond slip effect

Yong-xin SUN( ),Peng-zhen LIN(

),Peng-zhen LIN( ),Zi-jiang YANG,Wei JI

),Zi-jiang YANG,Wei JI

- College of Civil Engineering,Lanzhou Jiaotong University,Lanzhou 730070,China

摘要:

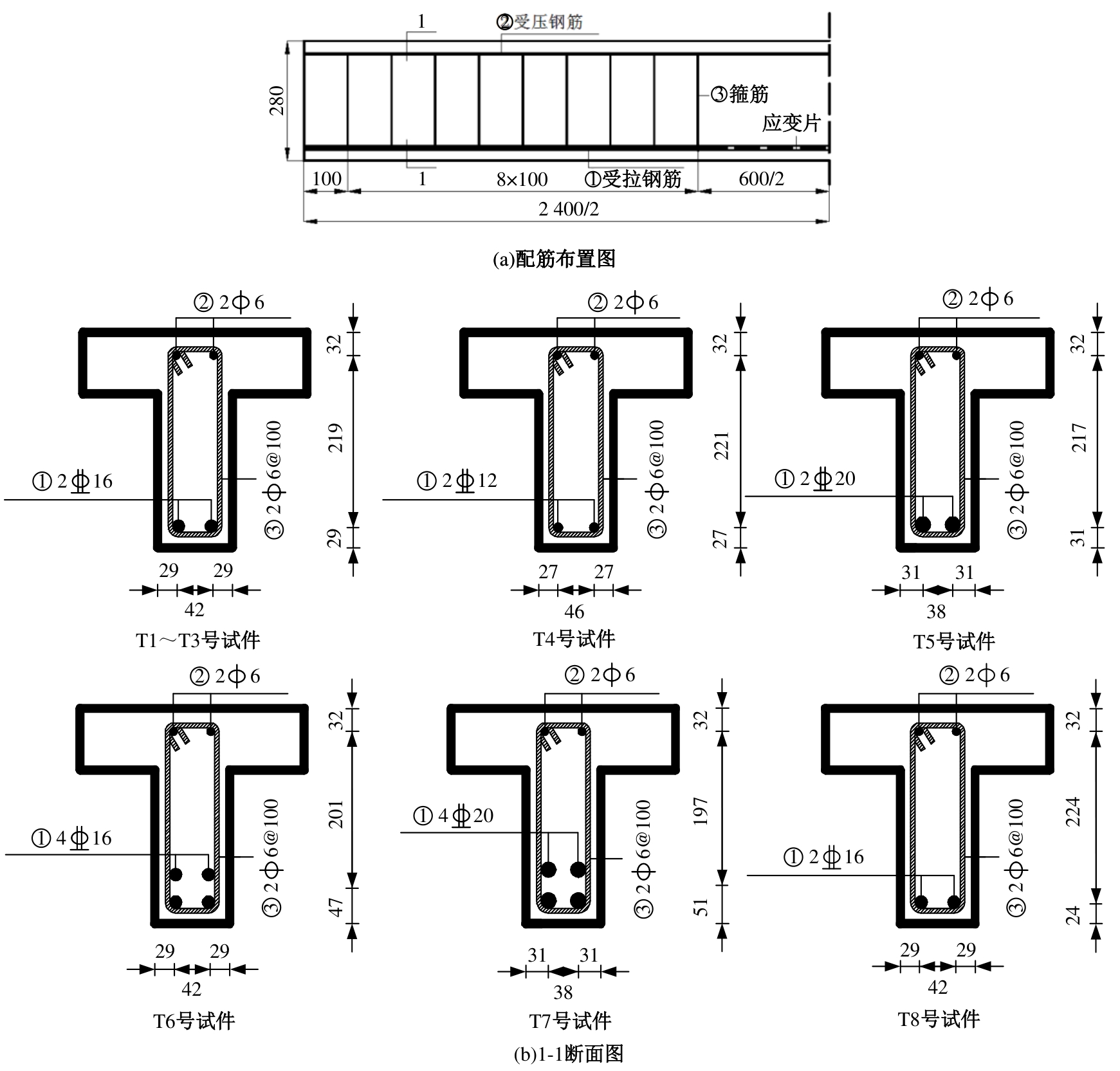

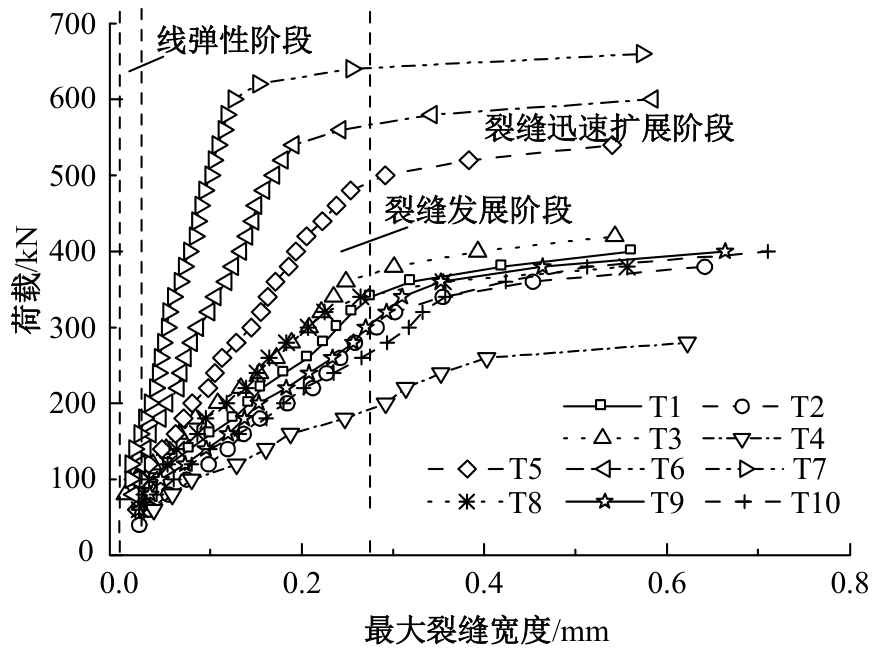

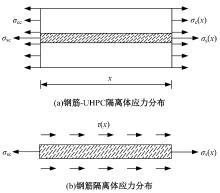

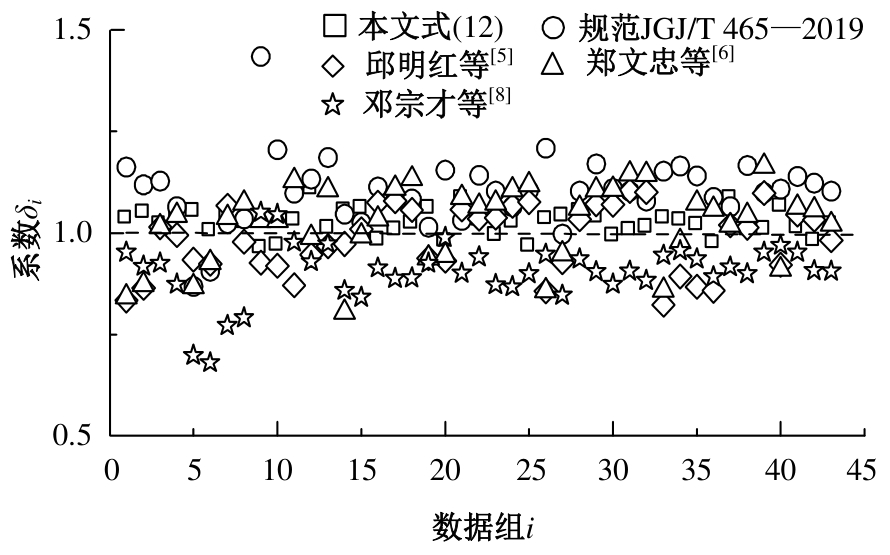

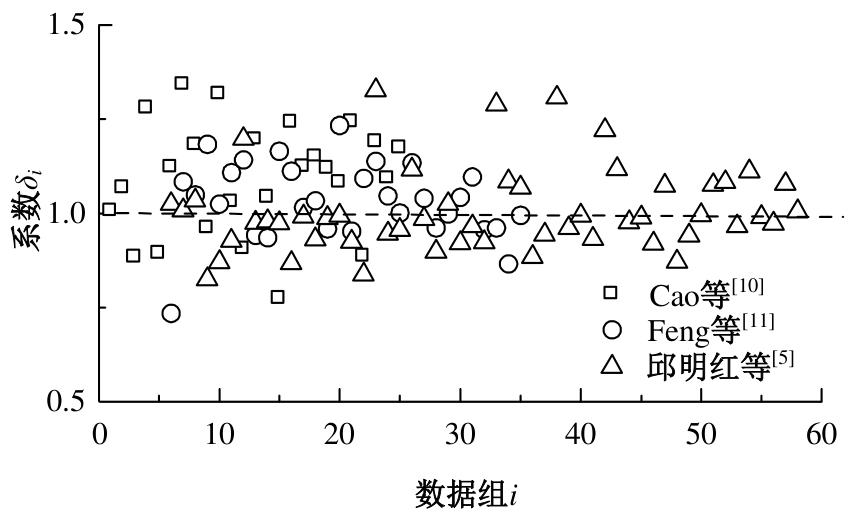

为建立适用于配筋超高性能混凝土(UHPC)梁的裂缝宽度计算公式,提出了考虑黏结-滑移效应的裂缝宽度计算方法。以钢纤维掺量、配筋率和保护层厚度为参变量,通过10片UHPC-T形截面梁的四点抗弯试验,研究了各参变量对试验梁破坏形态和最大裂缝宽度的影响规律。应用基于微元体建立的平衡与变形微分控制方程,结合考虑多影响因素的界面黏结-滑移关系,建立了配筋UHPC梁的裂缝宽度计算公式。通过与试验值、文献值对比,验证了裂缝宽度计算公式的正确性与适用性。结果表明:建立的裂缝宽度计算公式能充分体现钢纤维抗拉贡献和钢筋与UHPC界面间的黏结-滑移性能影响,其计算值与试验值吻合良好,能准确计算配筋UHPC梁的裂缝宽度。

中图分类号:

- U443.32

| 1 | 朱劲松, 秦亚婷, 刘周强.预应力UHPC-NC组合梁截面优化设计[J].吉林大学学报: 工学版, 2023, 53(11): 3151-3159. |

| Zhu Jin-song, Qin Ya-ting, Liu Zhou-qiang, et al. Section optimization design of prestressed UHPC-NC composite beams[J]. Journal of Jinlin University (Engineering and Technology Edition), 2023, 53(11): 3151- 3159. | |

| 2 | 邱明红, 邵旭东, 刘琼伟,等. UHPC局部受压承载力计算方法[J].交通运输工程报, 2021, 21(4): 116-129. |

| Qiu Ming-hong, Shao Xu-dong, Liu Qiong-wei, et al. Calculation method of UHPC local compressive bearing capacity[J]. Journal of Traffic and Transportation Engineering, 2021, 21(4): 116-129. | |

| 3 | Makita T, Brühwiler E. Tensile fatigue behavior of ultra-high performance fibre reinforced concrete (UHPFRC)[J]. Materials & Structures, 2014, 47(3):475-491. |

| 4 | Qi J, Wu Z, Ma Z J, et al. Pullout behavior of straight and hooked-end steel fibres in UHPC matrix with various embedded angles[J]. Construction and Building Materials, 2018, 191: 764-774. |

| 5 | 邱明红, 邵旭东, 胡伟业, 等.钢筋UHPC受弯构件裂缝宽度计算方法研究[J].土木工程学报, 2020, 53(10): 89-98. |

| Qiu Ming-hong, Shao Xu-dong, Hu Wei-ye, et al. Calculation method for crack width of reinforced UHPC flexural components[J]. China Civil Engineering Journal, 2020, 53(10): 89-98. | |

| 6 | 郑文忠, 李莉, 卢珊珊. 钢筋活性粉末混凝土简支梁正截面受力性能试验研究[J]. 建筑结构学报, 2011, 52(6):125-134. |

| Deng Wen-zhong, Li Li, Lu Shan-shan. Experimental research on mechanical performance of normal section of reinforced reactive powder concrete beam[J]. Journal of Building Structure, 2011, 52(6): 125-134. | |

| 7 | 徐海宾, 邓宗才. UHPC梁开裂弯矩和裂缝试验[J].哈尔滨工业大学学报, 2014, 46(4): 87-92. |

| Xu Hai-bin, Deng Zong-cai. Cracking moment and crack width of ultra-high performance concrete beams[J]. Journal of Harbin Engineering University, 2014, 46(4): 87-92. | |

| 8 | 邓宗才, 肖锐, 徐海宾, 等. 高强钢筋超高性能混凝土梁的使用性能研究[J]. 哈尔滨工业大学学报, 2015, 36(10): 1335-1340. |

| Deng Zong-cai, Xiao Rui, Xu Hai-bin, et al. Serviceability research of ultra-high performance concrete beams reinforced with high strength steel bars[J]. Journal of Harbin Engineering University, 2015, 36(10): 1335-1340. | |

| 9 | Stürwald S, Fehling E. Design of reinforced UHPFRC in flexure[C]∥Proceedings of Hipermat 2012 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials. Kassel: Kassel, Germany, 2012: 443-450. |

| 10 | Cao X, Ren Y C, Zhang L, et al. Flexural behavior of ultra-high-performance concrete beams with various types of rebar[J]. Composite Structures, 2022, 292: No.115674. |

| 11 | Feng Z, Li C X, Yoo D Y, et al. Flexural and cracking behaviors of reinforced UHPC beams with various reinforcement ratios and fiber contents[J]. Engineering Structures, 2021, 248: No.113266. |

| 12 | . National addition to eurocode 2-design of concrete structures: specific rules for ultra-high performance fibre reinforced concrete [S]. |

| 13 | 程东辉, 范永萱, 王彦松. RC类活性粉末混凝土钢筋粘结滑移本构模型[J].吉林大学学报: 工学版, 2021, 51(4): 1317-1330. |

| Cheng Dong-hui, Fan Yong-xuan, Wang Yan-song. Bond-slip constitutive model of steel bars and reactive powder concrete under standard curing[J]. Journal of Jinlin University (Engineering and Technology Edition), 2021, 51(4): 1317-1330. | |

| 14 | Khaksefidi S, Ghalehnovi M, Debrito J. Bond behaviour of high-strength steel rebars in normal (NSC) and ultra-high performance concrete (UHPC)[J]. Journal of Building Engineering, 2021, 33: No.101592. |

| 15 | 邱明红, 邵旭东, 胡伟业, 等. 钢筋UHPC矩形截面受弯构件的钢筋应力简化计算[J]. 中国公路学报, 2021, 34(8): 106-117. |

| Qiu Ming-hong, Shao Xu-dong, Hu Wei-ye, et al. Simplified calculation of reinforcement stress in reinforced UHPC bending members with rectangular sections[J]. China Journal of Highway and Transport, 2021, 34(8): 106-117. | |

| 16 | 徐明雪, 梁兴文, 汪萍, 等.超高性能混凝土梁正截面受弯承载力理论研究[J].工程力学, 2019, 36(8): 70-78. |

| Xu Ming-xue, Liang Xing-wen, Wang Ping, et al. The oretical Investigation on normal section flexural capacity of UHPC beams[J]. Engineering Mechanics, 2019, 36(8): 70-78. | |

| 17 | 赵国藩, 王清湘. 钢筋混凝土构件裂缝宽度分析的应力图形和计算模式[J]. 大连工学院学报, 1984(4): 87-94. |

| Zhao Guo-fan, Wang Qing-xiang. Stress distribution and calculation formula for crack width analysis of reinforced concrete members[J]. Journal of Dalian Institute of Technology, 1984(4): 87-94. | |

| 18 | 贾方方, 安明喆, 余自若, 等. 钢筋与活性粉末混凝土黏结性能的梁式试验研究[J].铁道学报, 2012, 34(6): 83-87. |

| Jia Fang-fang, An Ming-zhe, Yu Zi-ruo, et al. Beam test of bond behavior between steel bars and reactive powder concrete[J]. Journal of the China Railway Society, 2012, 34(6): 83-87. | |

| 19 | 王景全, 戚家南, 刘加平.基于细观本构模型的UHPC梁受弯全过程分析[J].建筑结构学报, 2020, 41(9): 137-144. |

| Wang Jing-quan, Qi Jia-nan, Liu Jia-ping. Flexural analysis of UHPC beams based on a mesoscale constitutive model[J]. Journal of Building Structure, 2020, 41(9): 137-144. | |

| 20 | 周建民, 王眺, 赵勇, 等. 高强钢筋混凝土受弯构件裂缝宽度计算方法的研究[J].土木工程学报, 2010, 43(9): 69-76. |

| Zhou Jian-min, Wang Tiao, Zhao Yong, et al. Research on the calculation of crack width for RC flexural member using high-strength bars[J]. China Civil Engineering Journal, 2010, 43(9): 69-76. | |

| 21 | 孙永新, 蔺鹏臻, 杨子江, 等. 考虑多影响因素的配筋UHPC梁裂缝宽度计算方法[J].东南大学学报:自然科学版, 2023,53(4): 628-636. |

| Sun Yong-xin, Lin Peng-zhen, Yang Zi-jiang, et al. Calculation method for crack width of reinforced UHPC beams considering multiple influencing factors[J]. Journal of Southeast University (Natural Science Edition), 2023, 53(4): 628-636. |

| [1] | 朱劲松,佟欣瑶,刘晓旭. 装配式小箱梁桥超高性能混凝土免支模湿接缝抗弯性能[J]. 吉林大学学报(工学版), 2024, 54(9): 2568-2580. |

| [2] | 薛宇欣,周勇军,王业路,范凯翔,赵煜. 基于悬锤系统的简支梁桥冲击系数测试方法适用性[J]. 吉林大学学报(工学版), 2024, 54(9): 2557-2567. |

| [3] | 郭雪莲,韩万水,王涛,周恺,张修石,张书颖. 大件车通行弯桥抗倾覆稳定安全系数评估方法[J]. 吉林大学学报(工学版), 2024, 54(8): 2229-2237. |

| [4] | 肖林,魏欢博,卫星,康志锐. 钢混组合梁栓钉锈胀下混凝土板开裂行为数值分析[J]. 吉林大学学报(工学版), 2024, 54(7): 1958-1965. |

| [5] | 张春雷,邵长宇,苏庆田,戴昌源. 球扁钢肋钢纤维混凝土组合桥面板正弯矩受力性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1634-1642. |

| [6] | 张彦玲,贾云飞,贾晓远,郑旺,李运生. 装配式小箱梁桥内力横向分布系数建议公式[J]. 吉林大学学报(工学版), 2024, 54(6): 1688-1700. |

| [7] | 黄汉辉,陈康明,吴庆雄. 钢管混凝土桁式弦杆组合连续梁抗弯性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1665-1676. |

| [8] | 邵长江,崔皓蒙,漆启明,庄卫林. 近断层大跨RC轻柔拱桥纵向阻尼器减震研究[J]. 吉林大学学报(工学版), 2024, 54(5): 1355-1367. |

| [9] | 赵秋,陈鹏,赵煜炜,余澳. 台后设置拱形结构的无缝桥梁整体受力性能[J]. 吉林大学学报(工学版), 2024, 54(4): 1016-1027. |

| [10] | 张洪,朱志伟,胡天宇,龚燕峰,周建庭. 基于改进YOLOv5s的桥梁螺栓缺陷识别方法[J]. 吉林大学学报(工学版), 2024, 54(3): 749-760. |

| [11] | 韩智强,谢刚,卓亚娟,骆佐龙,李华腾. 基于车轮-桥面相干激励的大跨连续梁桥振动响应[J]. 吉林大学学报(工学版), 2024, 54(2): 436-444. |

| [12] | 杨国俊,齐亚辉,石秀名. 基于数字图像技术的桥梁裂缝检测综述[J]. 吉林大学学报(工学版), 2024, 54(2): 313-332. |

| [13] | 谭国金,欧吉,艾永明,杨润超. 基于改进DeepLabv3+模型的桥梁裂缝图像分割方法[J]. 吉林大学学报(工学版), 2024, 54(1): 173-179. |

| [14] | 龙关旭,张修石,辛公锋,王涛,杨干. 融合机器视觉的桥梁动态称重方法[J]. 吉林大学学报(工学版), 2024, 54(1): 188-197. |

| [15] | 卫星,高亚杰,康志锐,刘宇辰,赵骏铭,肖林. 低温环境下栓钉环焊缝焊接残余应力场数值模拟[J]. 吉林大学学报(工学版), 2024, 54(1): 198-208. |

|

||

16

16 16

16 16

16 12

12 20

20 16

16 20

20 16

16 16

16 16

16