Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (4): 1220-1230.doi: 10.13229/j.cnki.jdxbgxb.20210788

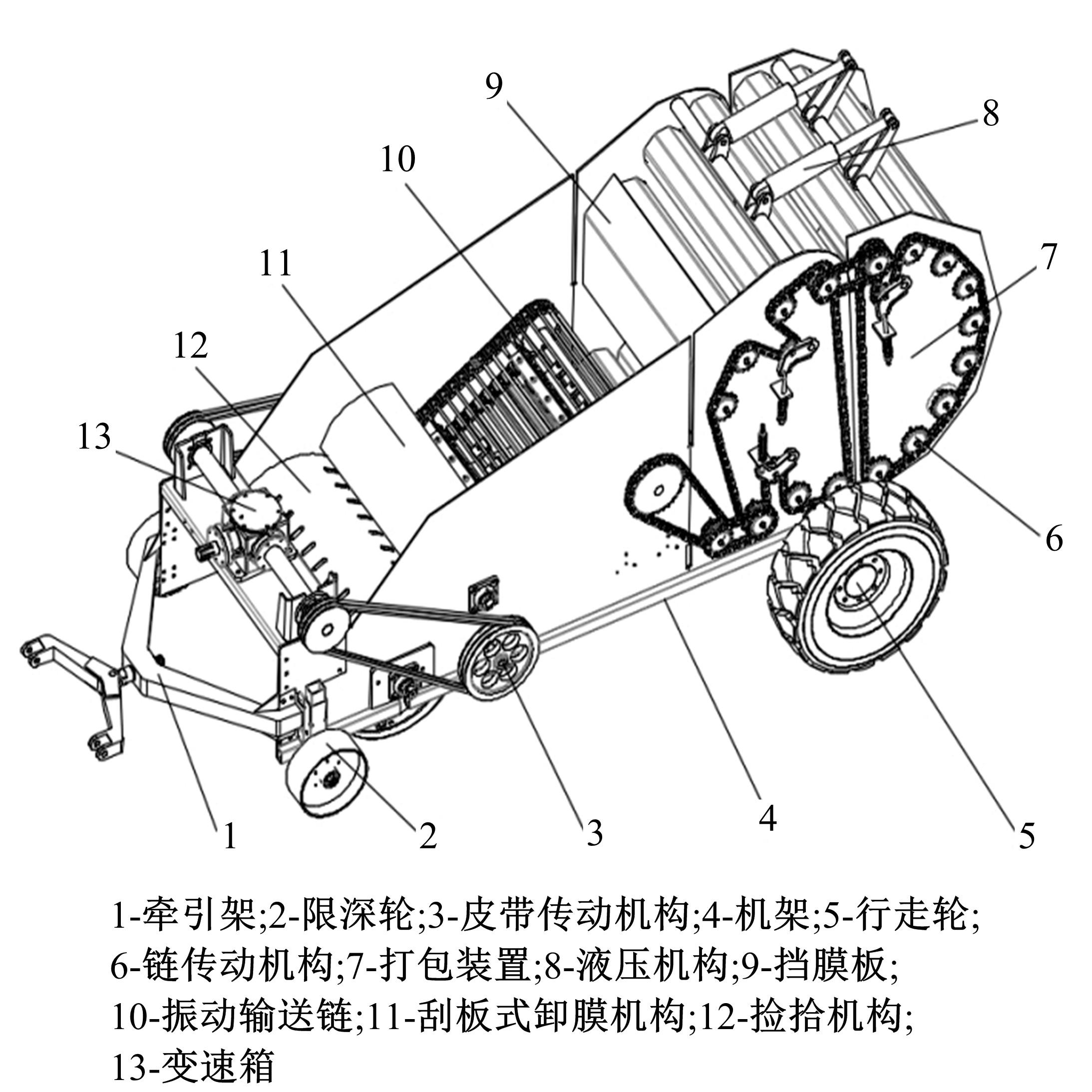

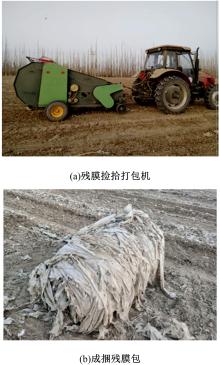

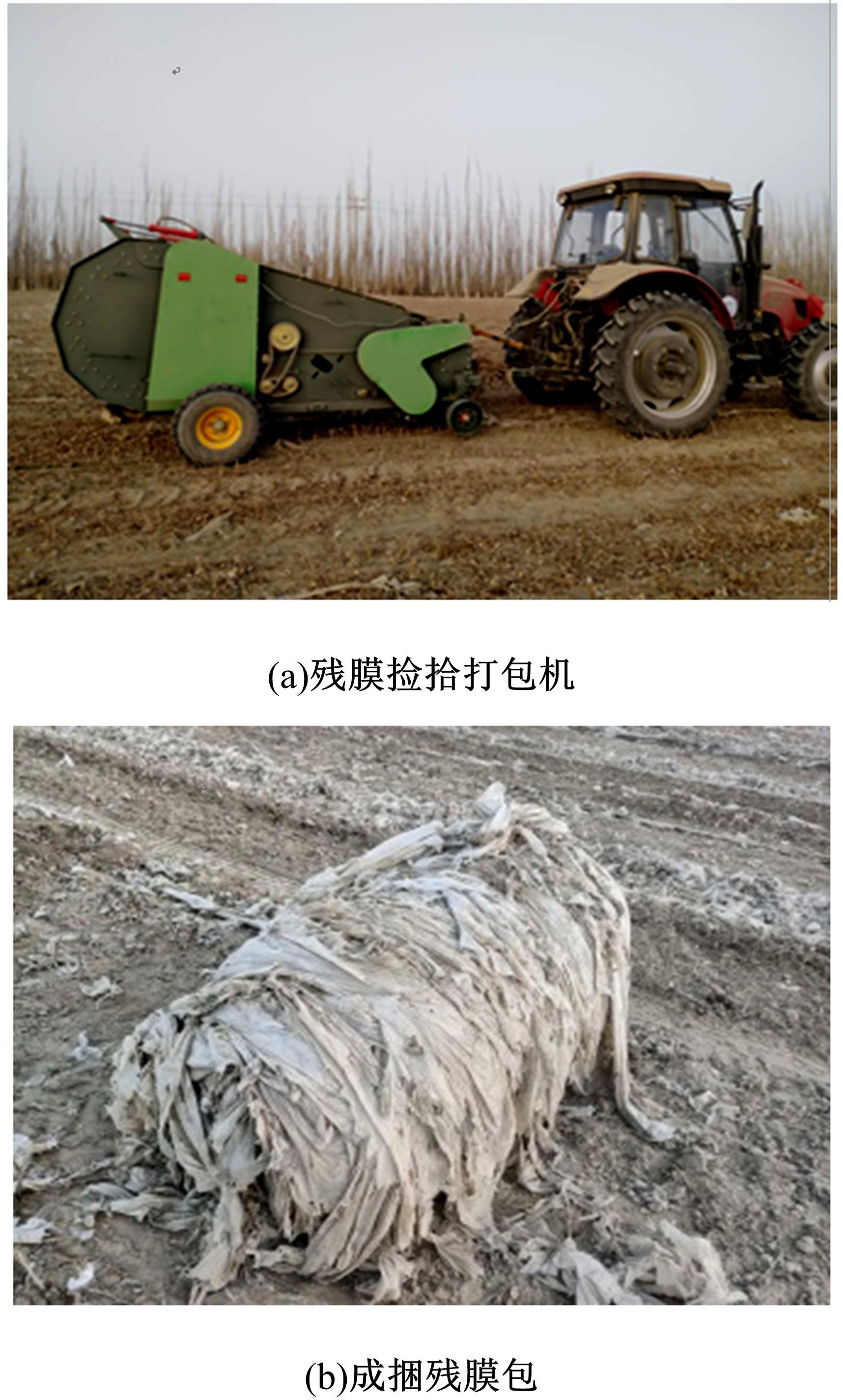

Design and test of the remaining film picking and baling machine

Xue-jun ZHANG1,2( ),Shuang HUANG1,Zeng-lu SHI1,2,Yong-liang YU3,Xin-cheng ZHOU1,Wei JIN1,2,Yong CHEN1,Jia HONG1

),Shuang HUANG1,Zeng-lu SHI1,2,Yong-liang YU3,Xin-cheng ZHOU1,Wei JIN1,2,Yong CHEN1,Jia HONG1

- 1.College of Mechanical and Electrical Engineering,Xinjiang Agricultural University,Urumqi 830052,China

2.Key Laboratory of Innovation Design laboratory,Xinjiang Agricultural Engineering Equipment,Urumqi 830052,China

3.Xinjiang Tiancheng Agricultural Machinery Manufacturing Co. Ltd. ,Tiemenguan 841007,China

CLC Number:

- S223.5

| 1 | 由佳翰,陈学庚,张本华,等.4JSM-2000型棉秆粉碎与残膜回收联合作业机的设计与试验[J].农业工程学报,2017, 33(10): 10-16. |

| You Jia-han, Chen Xue-geng, Zhang Ben-hua, et al. Design and experiment of 4JSM-2000 cotton stalk crushing and residual film recovery combined operation machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(10): 10-16. | |

| 2 | 田辛亮,赵岩,陈学庚,等. 4JSM-2000A型棉秆粉碎及搂膜联合作业机的研制[J].农业工程学报,2018, 34(10):25-35. |

| Tian Xin-liang, Zhao Yan, Chen Xue-geng, et al. Development of 4JSM-2000A cotton stalk crushing and film coating combined operation machine[J].Transactions of the Chinese Society of Agricultural Engineering,2018, 34(10): 25-35. | |

| 3 | 国家统计局农村社会经济调查司.中国农村统计年鉴[M].北京:中国统计出版社,2020. |

| 4 | 赵岩,陈学庚,温浩军,等.农田残膜污染治理技术研究现状与展望[J].农业机械学报,2017, 48(6): 1-14. |

| Zhao Yan, Chen Xue-geng, Wen Hao-jun, et al. Research status and prospects of farmland residual film pollution treatment technology[J].Transactions of the Chinese Society of Agricultural Machinery, 2017, 48(6): 1-14. | |

| 5 | 王振华, 贺怀杰, 郑旭荣, 等. 新疆典型绿洲棉秆还田对覆膜滴灌棉田残膜分布的影响[J]. 农业工程学报,2018, 34(21): 120-127. |

| Wang Zhen-hua, He Huai-jie, Zheng Xu-rong, et al. Effectof returning cotton stalks to fields in Xinjiang typicaloasis on residual film distribution in drip irrigation cotton fields[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(21): 120-127. | |

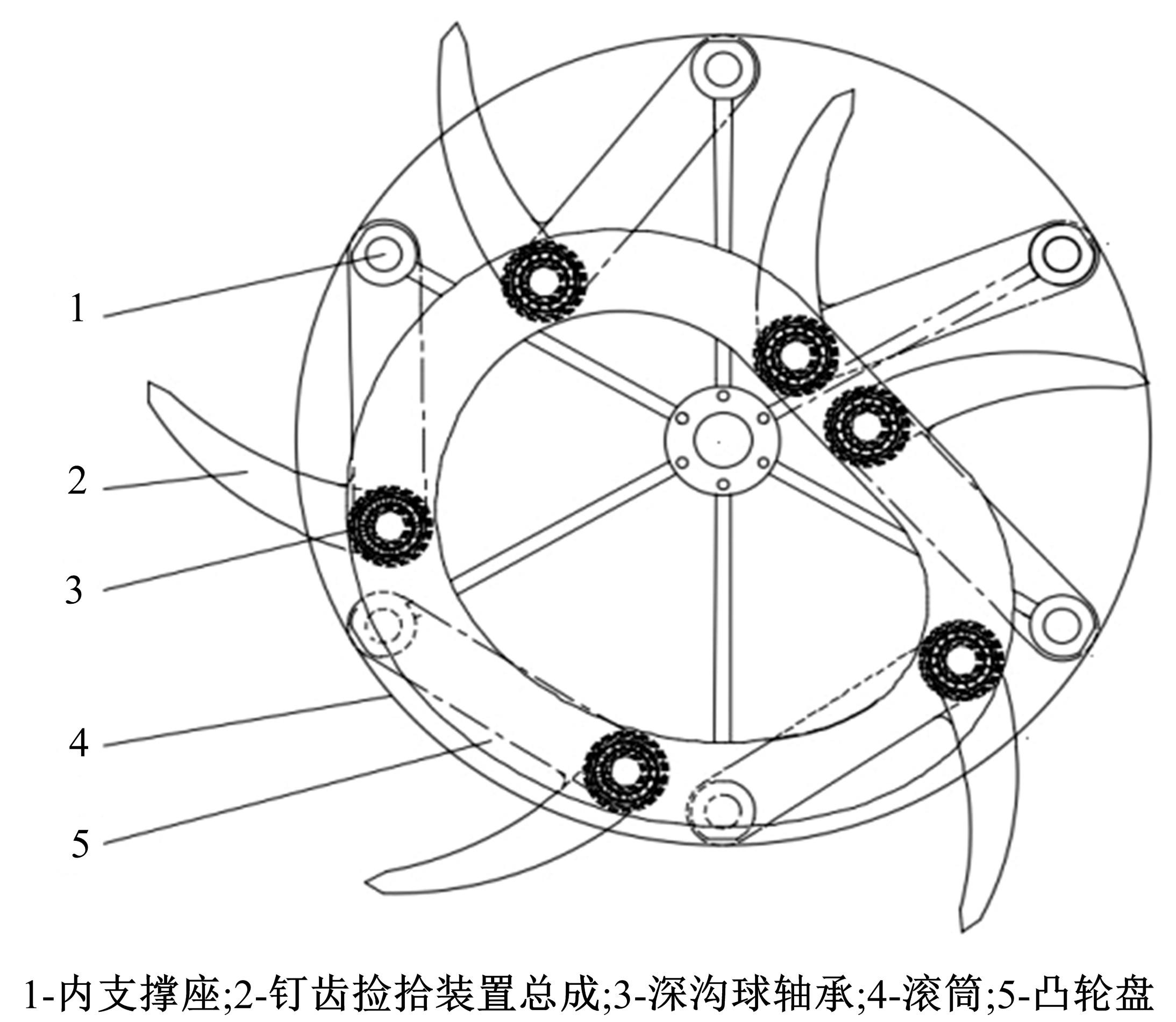

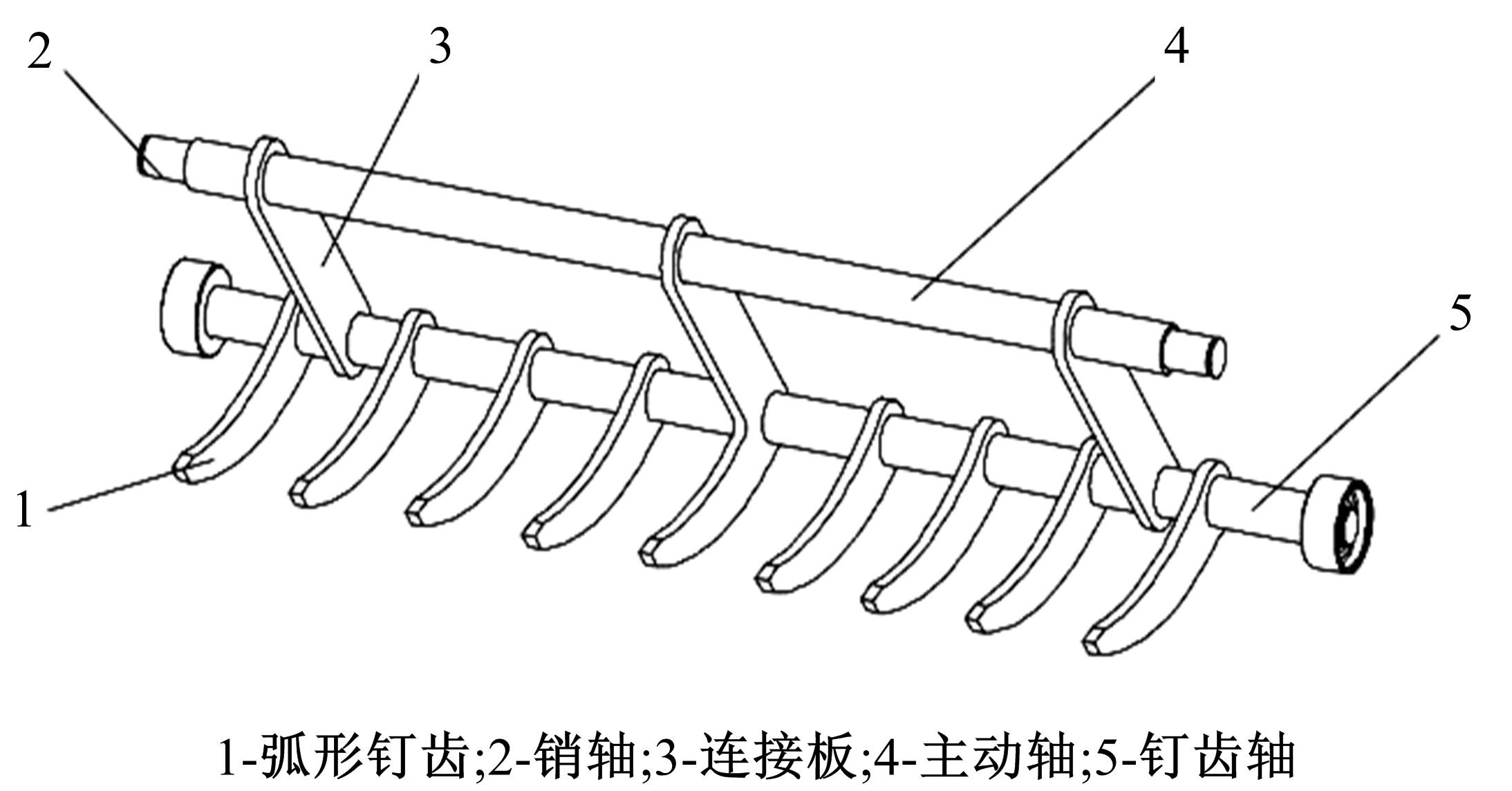

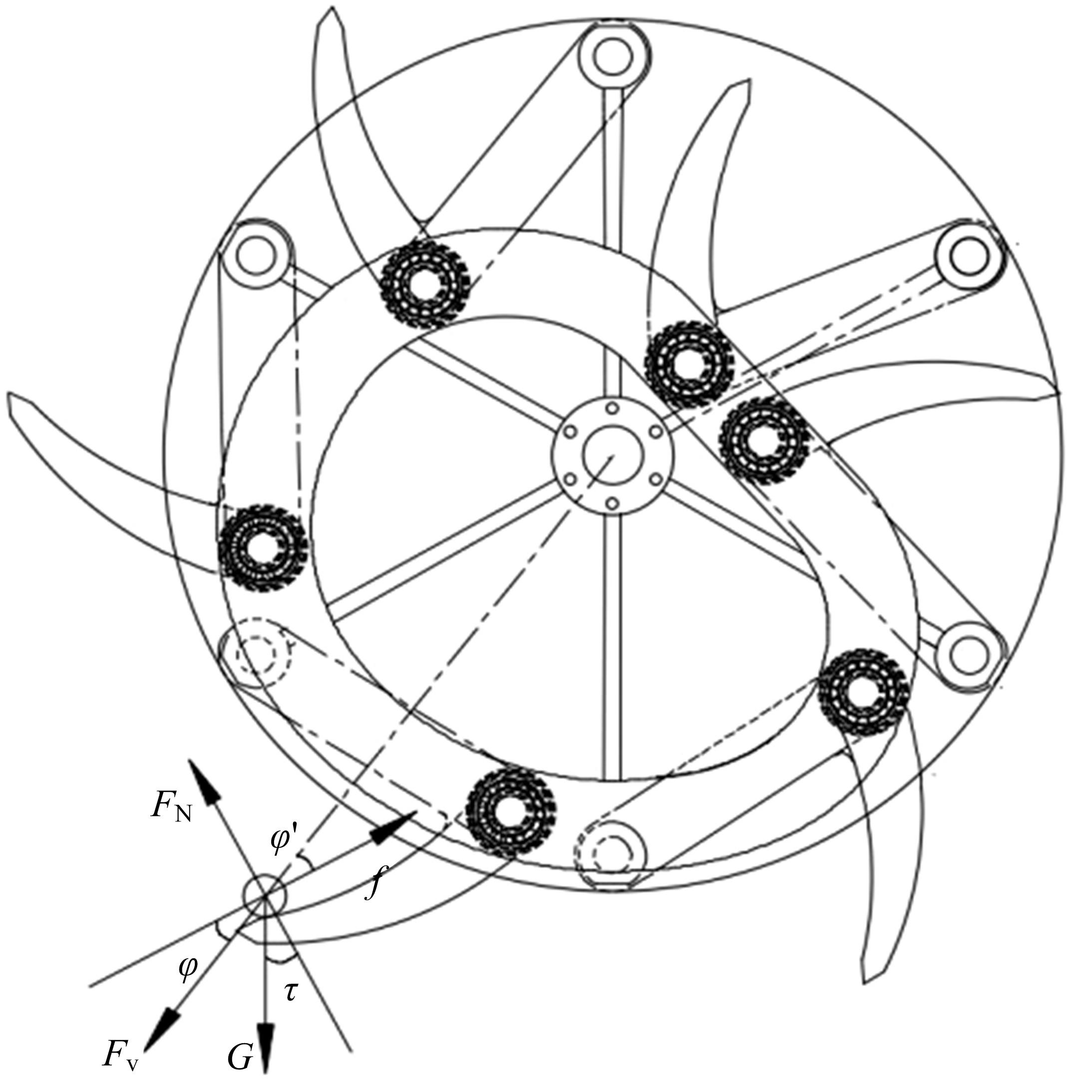

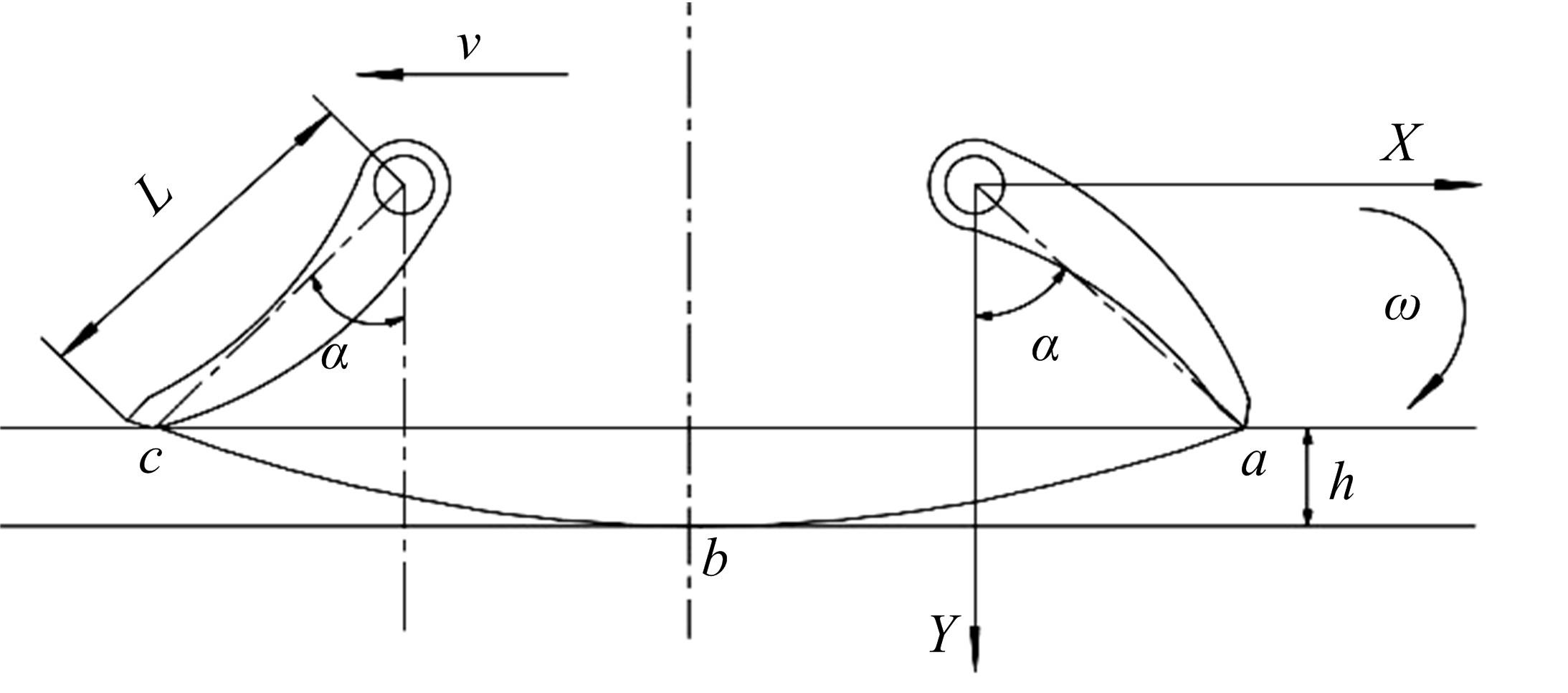

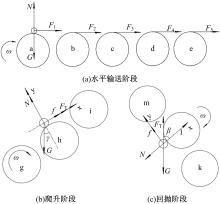

| 6 | 史增录,唐学鹏,甄军,等.钉齿式残膜捡拾机构运动仿真分析及性能试验[J].农业工程学报,2019, 35(4): 64-71. |

| Shi Zeng-lu, Tang Xue-peng, Zhen Jun, et al. Motion simulation analysis and performance test of nail-tooth residual film pickup mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019,35(4): 64-71. | |

| 7 | 蒋德莉, 陈学庚, 颜利民, 等. 随动式残膜回收机清杂系统作业参数优化[J]. 农业工程学报, 2019, 35(19): 1-10. |

| Jiang De-li, Chen Xue-geng, Yan Li-min, et al. Optimization of operating parameters of cleaning system of follow-up residual film recovery machine[J].Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(19): 1-10. | |

| 8 | 罗凯,袁盼盼,靳伟,等.链筛式耕层残膜回收机设计与工作参数优化试验[J].农业工程学报,2018, 34(19): 19-27. |

| Luo Kai, Yuan Pan-pan, Jin Wei, et al. Design of chain screen type plough layer residual film recovery machine and optimization experiment of working parameters[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(19): 19-27. | |

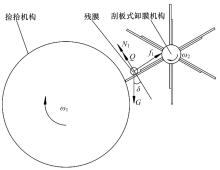

| 9 | 唐永飞,赵永满,王吉奎,等.夹指链式残膜回收机脱膜装置设计与试验[J].农业工程学报,2020, 36(13): 11-19. |

| Tang Yong-fei, Zhao Yong-man, Wang Ji-kui, et al. Design and test of stripping device of finger chain type residual film recovery machine[J].Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(13): 11-19. | |

| 10 | 彭强吉,李成松,康建明,等.气力式圆筒筛膜杂分离机改进设计与试验[J].农业机械学报,2020, 51(8): 126-135. |

| Peng Qiang-ji, Li Cheng-song, Kang Jian-ming, et al.Improved design and test of pneumatic cylindrical sieve membrane separator[J].Transactions of the Chinese Society of Agricultural Machinery, 2020, 51(8): 126-135. | |

| 11 | 田辛亮,赵岩,陈学庚,等.棉秆粉碎与搂膜联合作业机关键部件设计与试验[J].甘肃农业大学学报,2019, 54(4): 190-198. |

| Tian Xin-liang, Zhao Yan, Chen Xue-geng, et al. Design and test of key components of the combined operation machine for cotton stalk crushing and film coating[J] .Journal of Gansu Agricultural University,2019,54(4): 190-198. | |

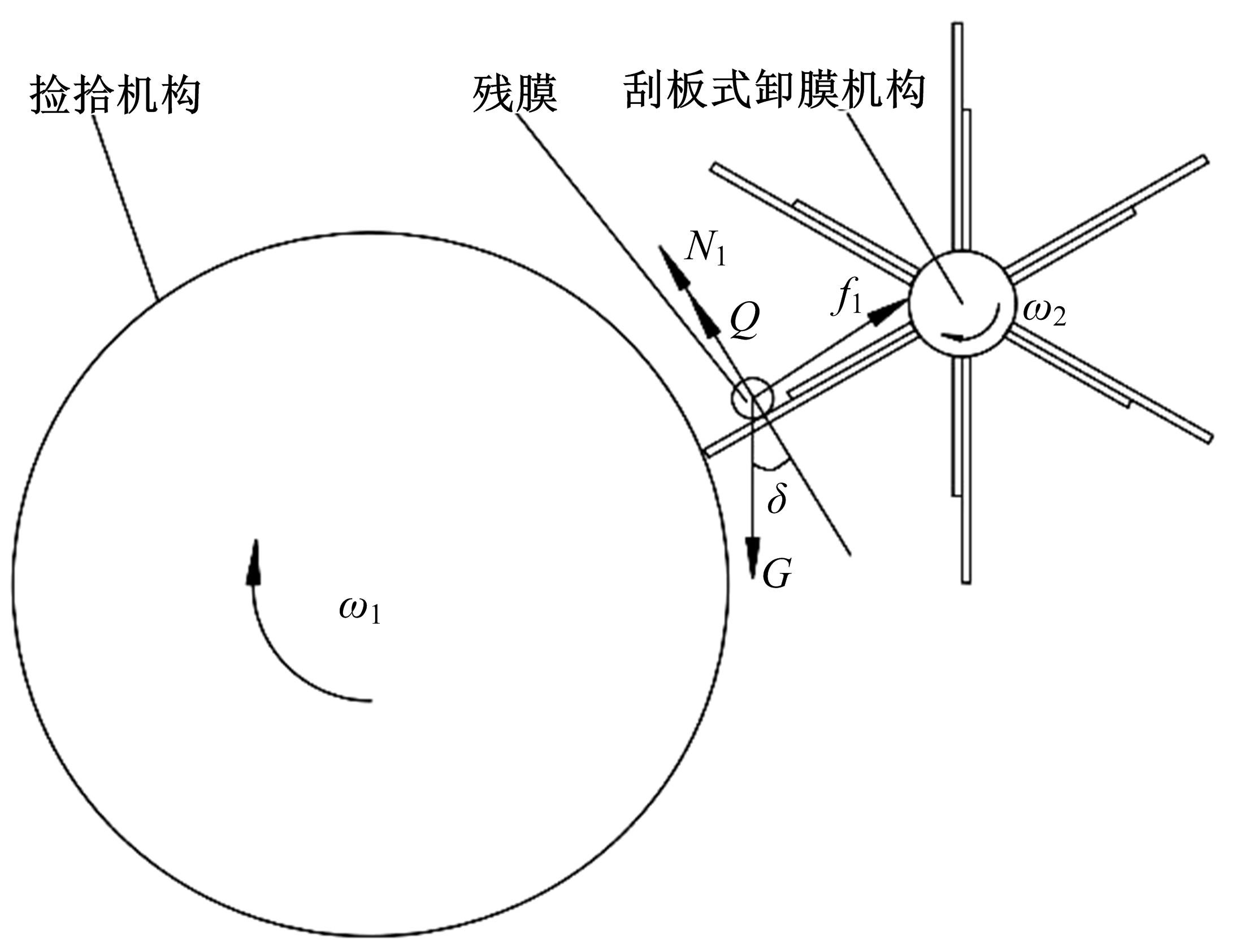

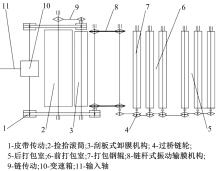

| 12 | 赵岩,郑炫,陈学庚,等.CMJY-1500型农田残膜捡拾打包联合作业机设计与试验[J].农业工程学报,2017, 33(5): 1-9. |

| Zhao Yan, Zheng Xuan, Chen Xue-geng, et al. Design and test of CMJY-1500 farmland residual film picking and packing combined operation machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(5): 1-9. | |

| 13 | 谢建华,唐炜,曹肆林,等.齿链复合式残膜回收机设计与试验[J]. 农业工程学报,2020, 36(1): 11-19. |

| Xie Jian-hua, Tang Wei, Cao Si-lin, et al. Design and experiment of tooth chain compound residual film recovery machine[J].Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(1): 11-19. | |

| 14 | 牛琪,纪超,赵岩,等.集条残膜打包机捡拾清理装置设计与试验[J].农业机械学报,2017, 48(5): 101-107. |

| Niu Qi, Ji Chao, Zhao Yan, et al. Design and test of the picking and cleaning device of the strip residual film baler[J].Transactions of the Chinese Society of Agricultural Machinery, 2017, 48(5): 101-107. | |

| 15 | 严伟,胡志超,吴努,等.铲筛式残膜回收机输膜机构参数优化与试验[J].农业工程学报, 2017, 33(1): 17-24. |

| Yan Wei, Hu Zhi-chao, Wu Nu, et al. Optimization and experiment on parameters of film conveying mechanism of shovel-screen residual film recovery machine[J].Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(1): 17-24. | |

| 16 | 谢建华,张凤贤,陈学庚,等.弧形齿滚扎式残膜回收机的设计及参数优化[J]. 农业工程学报,2019, 35(11): 26-37. |

| Xie Jian-hua, Zhang Feng-xian, Chen Xue-geng, et al. Design and parameter optimization of arc-tooth rolling-type residual film recovery machine[J]. Transactions of the Chinese Society of Agricultural Engineering,2019, 35(11): 26-37. | |

| 17 | 郭博,贺敬良,王德成,等.秸秆打捆机研究现状及发展趋势[J].农机化研究,2018, 40(1): 264-268. |

| Guo Bo, He Jing-liang, Wang De-cheng, et al. Research status and development trend of straw baler[J].Journalof Agricultural Mechanization Research, 2018, 40(1): 264-268. | |

| 18 | 操子夫.圆捆秸秆打捆机工作参数的试验研究[D]. 长春: 吉林农业大学工程技术学院, 2016. |

| Cao Zi-fu. Experimental research on working parameters of round straw baler[D]. Changchun: College of Engineering and Technology, Jilin Agricultural University,2016. | |

| 19 | 徐俊.9YG-2200型圆捆打捆机改进设计研究[D].哈尔滨: 东北农业大学工程学院,2017. |

| Xu Jun. Research on the improved design of 9YG-2200 round baler[D]. Harbin: College of Engineering, Northeast Agricultural University, 2017. | |

| 20 | 王春光.钢辊外卷式圆捆机结构与原理[J].农业机械,2008, 50(34): 43-45. |

| Wang Chun-guang.Structure and principle of steel roll outer-coiling round baler[J]. Agricultural Machinery, 2008, 50(34): 43-45. | |

| 21 | 李东,赵武云,辛尚龙,等.膜面清洁打捆自卸式残膜回收机的设计[J]. 中国农业大学学报,2020, 25(11): 117-125. |

| Li Dong, Zhao Wu-yun, Xin Shang-long, et al. Design of a self-unloading residual film recovery machine for film surface cleaning and bundling[J]. Journal of China Agricultural University, 2020, 25(11): 117-125. | |

| 22 | 王国富.青贮稻秆圆捆打捆机的设计与试验研究[D]. 哈尔滨: 东北农业大学工程学院,2019. |

| Wang Guo-fu. Design and experimental research of silage rice straw round baler[D]. Harbin: College of Engineering, Northeast Agricultural University, 2019. | |

| 23 | 江志国.钢辊式卷捆机构中钢辊对稻秆导送性能影响的试验研究[D].哈尔滨: 东北农业大学工程学院,2018. |

| Jiang Zhi-guo. Experiment on influence of conveying performance of steel-roll on rice straw in steel-roll baling mechanism[D]. Harbin: Colleg of Engineering,Northeast Agricultural University,2018. | |

| 24 | . 残地膜回收机 [S]. |

| 25 | . 圆草捆打捆机试验方法 [S]. |

| 26 | 张海春,张丽,蒋永新,等.棉田地膜回收打捆机关键参数设计及试验研究[J]. 中国农机化学报,2017, 38(5): 28-31. |

| Zhang Hai-chun, Zhang Li, Jiang Yong-xin, et al. Design and experimental research on key parameters of cotton field film recycling baler[J].Chinese Journal of Agricultural Machinery Chemistry, 2017, 38(5): 28-31. |

| [1] | Rui-jie SHI,Fei DAI,Wu-yun ZHAO,Xiao-long LIU,Jiang-fei QU,Feng-wei ZHANG. Optimization and experiment of operation parameters of hilly area flax combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2746-2755. |

| [2] | Ya-jun ZHOU,Da-yu LI,Yan CHEN,Shu-jie WANG. Effect of irradiation treatment on storage quality of spiced beef in different packaging [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1548-1556. |

| [3] | Ji-cheng HUANG,Cheng SHEN,Ai-min JI,Xian-wang LI,Bin ZHANG,Kun-peng TIAN,Hao-lu LIU. Optimization of cutting⁃conveying key working parameters of hemp harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 772-780. |

| [4] | Xin-xin LI,Da-yu LI,Zi-rui ZHAO,Ya-jun ZHOU. Effect of low⁃temperature plasma treatment power on storage quality of spiced beef [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1934-1940. |

| [5] | Xue-shen CHEN,Tao CHEN,Tao WU,Xu MA,Ling-chao ZENG,Lin-tao CHEN. Design and experiment on harvester for winter planting potato of straw coverage [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 749-757. |

| [6] | LIU Kui, LIU San-yang. Mobile data collecting algorithm based on mixed sink strategy in WSNs [J]. 吉林大学学报(工学版), 2015, 45(5): 1680-1687. |

| [7] | SUN Xiao-dong,QUAN Ai-juan, LI Yong. New frequency estimation method for harmonic signal submerged in complex noise background [J]. 吉林大学学报(工学版), 2015, 45(2): 653-657. |

| [8] | ZHOU Yuan, HOU Chun-ping. Quality of multi-view 3D video transmission in error-prone networks [J]. 吉林大学学报(工学版), 2013, 43(增刊1): 419-423. |

| [9] | CHEN Wan-zhong, SUN Bao-feng, GAO Ren-jie, LEI Jun. Pattern recognition of human arm motion based on neural network ensemble method [J]. 吉林大学学报(工学版), 2013, 43(增刊1): 69-73. |

| [10] | WU Wen, MENG Xiang-ru, LIU Yun-jiang, HUO Xing-lin. Modeling and quantification of network survivability based on continuous time Markov [J]. 吉林大学学报(工学版), 2013, 43(05): 1395-1400. |

| [11] | WANG Huan, LEI Zhen-ming, CHEN Lu-ying. Distribution of cellular data network traffic volumes per cell in unit time [J]. 吉林大学学报(工学版), 2013, 43(01): 233-238. |

| [12] | CHENG Fang, TAO Hui, ZHANG Zhi-zhong, PEI Er-rong. Low delay algorithm for DTN networks based on packet exchange [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 392-395. |

| [13] | MA Zhong-su, GAO Yu-peng, NIU Yan-qing, CHEN Shan-shan. Thermodynamic properties of the soy protein isolate and chitosan blend film [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 470-474. |

| [14] | ZHONG Yu-lin, WEN Xu-hui, LIU Jun, LIU Zhi-hong. Development of IGBT-based intelligent power module for electric vehicle [J]. 吉林大学学报(工学版), 2011, 41(增刊2): 316-320. |

| [15] | LI Qing-hua, YUAN Zhi, WANG Chang-hong, WEN Fan. On the robust H∞ control of discrete networked control systems [J]. 吉林大学学报(工学版), 2011, 41(05): 1426-1432. |

|

||