Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (12): 3039-3048.doi: 10.13229/j.cnkj.jdxbgxb20210453

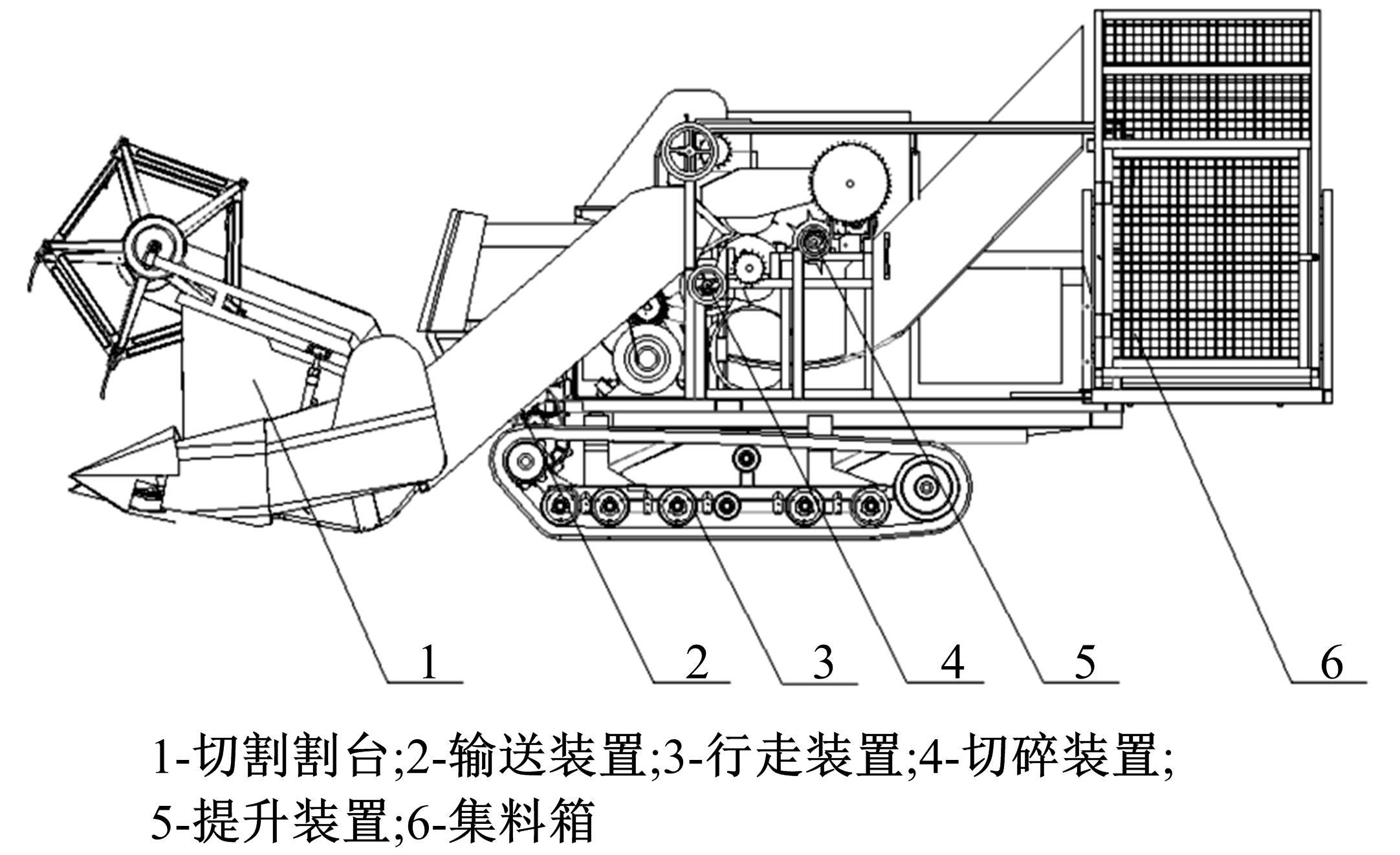

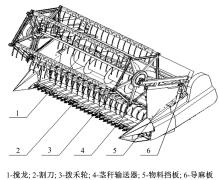

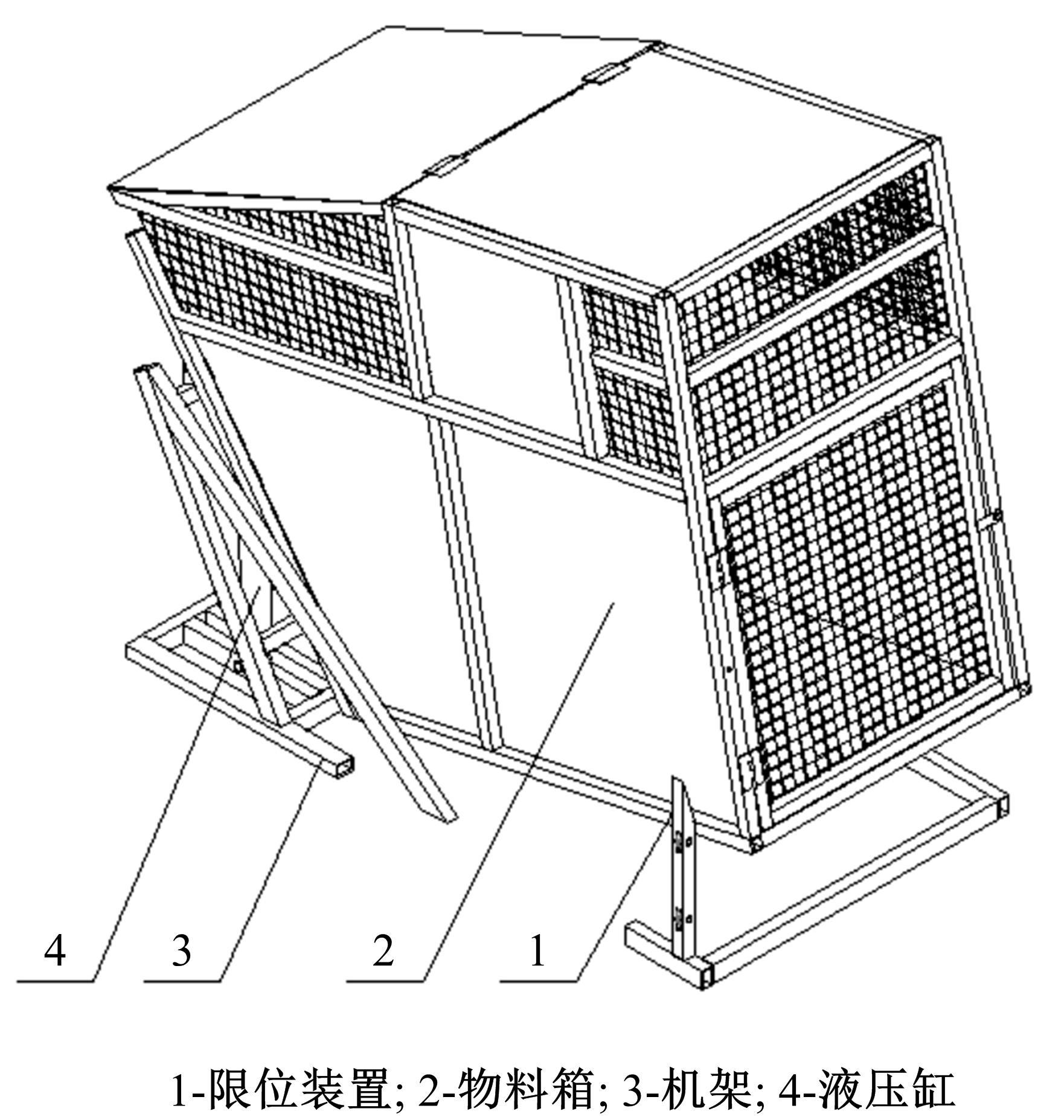

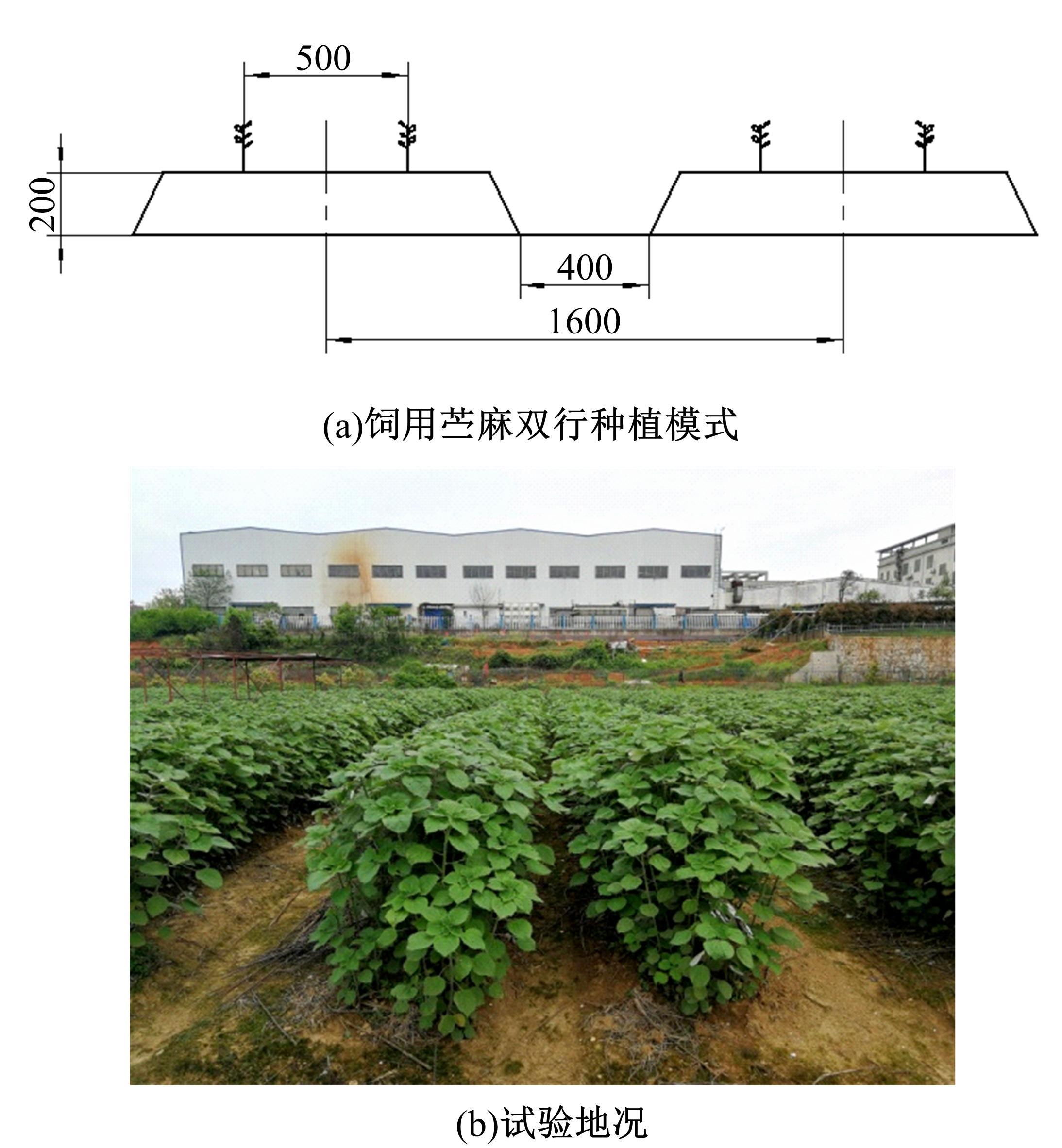

Design of 4QM⁃4.0 fibre crops green fodder combine harvester

Jia-jie LIU( ),Lan MA,Wei XIANG,Bo YAN,Qing-hua WEN,Jiang-nan LYU(

),Lan MA,Wei XIANG,Bo YAN,Qing-hua WEN,Jiang-nan LYU( )

)

- Fiber Crops Product and Processing Technology Innovation Team,Institute of Bast Fiber Crops,Chinese Academy of Agricultural Sciences,Changsha 410205,China

CLC Number:

- S232.5

| 1 | 王琴. 苎麻种质资源评价及栽培模式对其饲用价值影响研究[D]. 武汉:华中农业大学植物科学与技术学院, 2019. |

| Wang Qin. Assessment of the feeding potential and cultivation systems on feeding values of ramie germplasm resources[D]. Wuhan: College of Plant Science and Technology, Huazhong Agricultural University, 2019. | |

| 2 | 侯振平, 林谦, 蒋桂韬, 等. 不同比例青贮苎麻替代基础饲粮对朗德鹅生长性能、肠道发育、养分表观代谢率及血清生化指标的影响[J]. 动物营养学报, 2018, 30(5): 1920-1927. |

| Hou Zhen-ping, Lin Qian, Jiang Gui-tao, et al. Effects of different proportions of silage ramie instead of basal diet on growth performance, intestina development, nutrient apparent metabolic rate and serum biochemical indices of landes geese[J]. Chinese Journal of Animal Nutrition, 2018, 30(5): 1920-1927. | |

| 3 | 朱涛涛, 朱爱国, 余永廷, 等. 苎麻饲料化的研究[J]. 草业科学, 2016, 33(2): 338-347. |

| Zhu Tao-tao, Zhu Ai-guo, Yu Yong-ting, et al. Research progress of ramie for feedstuff[J]. Pratacultural Science, 2016, 33(2): 338-347. | |

| 4 | 白玉超, 郭婷, 杨瑞芳, 等.氮肥用量刈割高度对饲用苎麻产量、营养品质及败蔸的影响[J]. 草业学报, 2015, 24(12): 112-120. |

| Bai Yu-chao, Guo Ting, Yang Rui-fang, et al.Effect of nitrogen fertilization rate and cutting height on yields,nutritive values and root-rot incidence in forage ramie[J]. Acta Prataculturae Sinaca, 2015, 24(12):112-120. | |

| 5 | 白杰, 黄思齐, 李建军, 等. 红麻饲用价值的研究进展[J]. 中国麻业学,2015,37(1):30-34. |

| Bai Jie, Huang Si-qi, Li Jian-jun, et al. Research development of the value of kenaf as forage[J]. Plant Fiber Science in China, 2015, 37(1): 30-34. | |

| 6 | 唐慧娟, 白杰, 陈安国,等.不同留茬收获模式对红麻产量及营养价值的影响初探[J].中国麻业科学, 2017, 39(5): 251-256. |

| Tang Hui-juan, Bai Jie, Chen An-guo,et al.Effects of different stubble patterns on yield and nutrient composition of hibiscus cannabinus[J]. Plant Fiber Science in China, 2017, 39(5): 251-256. | |

| 7 | 刘春喜, 祝学珍, 贾昌泽, 等.红麻叶在安徽白山羊生产中的饲用价值探究[J]. 安徽科技学院学报, 2020, 34(2): 1-5. |

| Liu Chun-xi, Zhu Xue-zhen, Jia Chang-ze, et al.Study on feeding value of kenaf leaves in production of anhui white goat[J]. Journal of Anhui Science and Technology University, 2020, 34(2): 1-5. | |

| 8 | 王延周, 熊和平, 吴端钦, 等. 饲用苎麻'中饲苎1号'最佳刈割株高的研究[J]. 草地学报, 2017, 25(6): 1280-1286. |

| Wang Yan-zhou, Xiong He-ping, Wu Duan-qin,et al. Study of cutting height of the fodder ramie variety 'Zhongsizhu No.1'[J]. Acta Prataculturae Sinaca, 2017, 25(6): 1280-1286. | |

| 9 | 王延周, 喻春明, 唐守伟, 等. 纤用苎麻“中苎2号”饲草化刈割模式研究[J]. 中国麻业科学, 2017, 39(3): 120-129. |

| Wang Yan-zhou, Yu Chun-ming, Tang Shou-wei, et al. The study of cutting model of the fiber ramie variety "Zhongzhu No.2" as the forage[J]. Plant Fiber Science in China, 2017, 39(3): 120-129. | |

| 10 | 唐忠, 王红达, 李禧尧, 等. 履带式联合收割机割台结构设计及模态分析[J]. 农机化研究, 2020, 42(1): 25-30. |

| Tang Zhong, Wang Hong-da, Li Xi-yao,et al.Design and finite element analysis of header of rice combine harvester[J].Journal of Agricultural Mechanization Research, 2020, 42(1): 25-30. | |

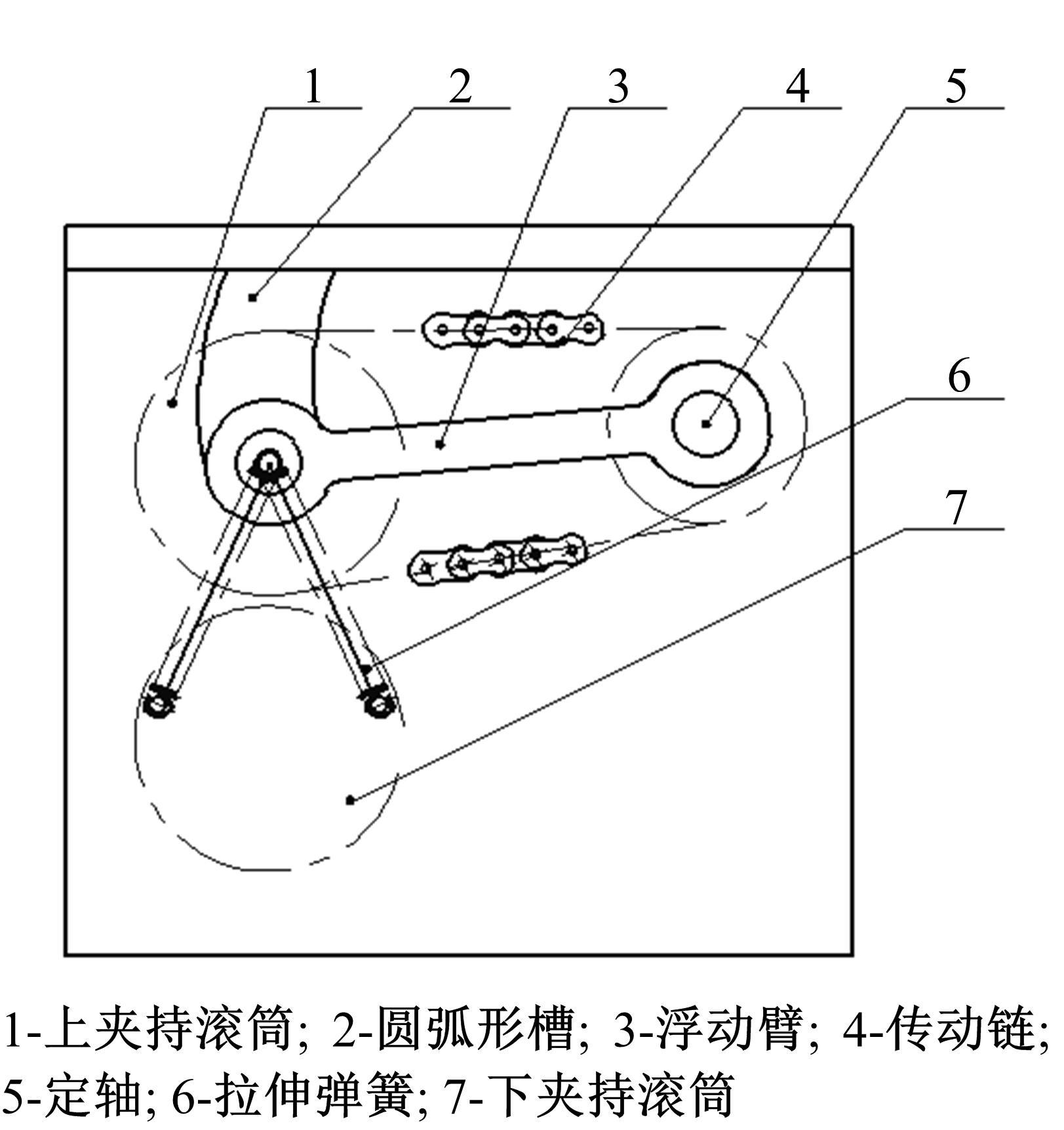

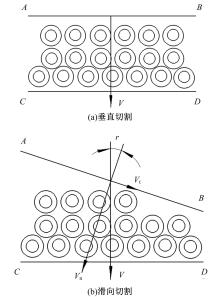

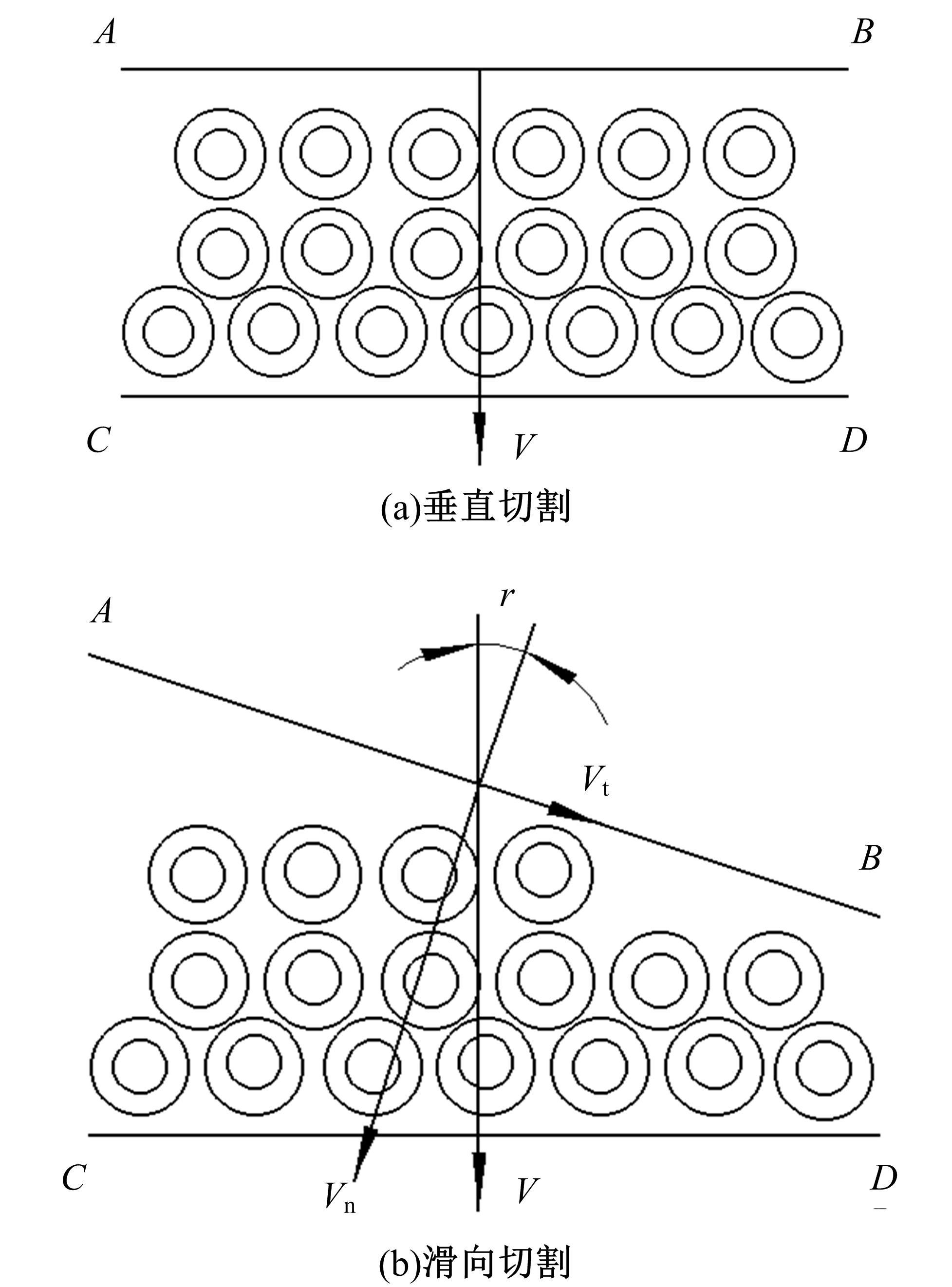

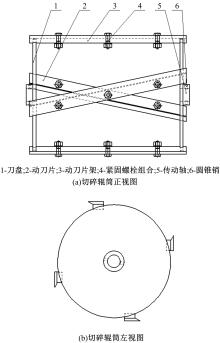

| 11 | 刘佳杰, 马兰, 向伟, 等.93QS-5.0型麻类青饲料切碎机的设计与试验[J]. 中国麻业科学, 2020,42(5): 209-218. |

| Liu Jia-jie, Ma Lan, Xiang Wei, et al.Design and experiment of 93QS-5.0 bast fiber crops green feed chopper[J]. Plant Fiber Science in China, 2020, 42(5): 209-218. | |

| 12 | 万其号. 新型自走式螺旋致密苜蓿袋装青贮装备的研制[D]. 北京: 中国农业大学工学院, 2019. |

| Wang Qi-hao. Development of new self-propelled screw densification alfalfa bag silage equipment[D]. Beijing: College of Engineering, China Agricultural University,2019. | |

| 13 | 谭敏尧. 移动式生物质粉碎成型联合机的设计与研究[D]. 哈尔滨: 东北林业大学机电工程学院,2013. |

| Tan Min-yao.Design and research of biomass mobile crushing forming joint machine[D]. Harbin: College of Mechanical and Electrical Engineering, Northeast Forestry University, 2013. | |

| 14 | 张宗玲. 新型玉米穗茎联合收获机割台的研制[D]. 北京: 中国农业大学工学院, 2018. |

| Zhang Zong-ling.Study on a new corn combine harvester header for reaping both corn stalk and spike[J].Beijing: College of Engineering,China Agricultural University, 2018. | |

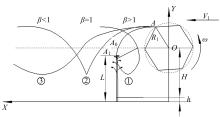

| 15 | 徐秀英, 张维强, 杨和梅, 等. 小型牧草收获机双动切割装置设计与运动分析[J]. 农业工程学报, 2011, 27(7): 156-161. |

| Xu Xiu-ying, Zhang Wei-qiang, Yang He-mei, et al. Design and kinematic analysis of double-acting cutting device of walk-type pasture reaper[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(7): 156-161. | |

| 16 | 康峰, 仝思源, 张汉石, 等. 苹果枝条往复式切割剪枝参数分析与试验[J]. 农业工程学报, 2020, 36(16): 9-16. |

| Kang Feng, Tong Si-yuan, Zhang Han-shi,et al.Analysis and experiments of reciprocating cutting parameters for apple tree branches[J].Transactions of the Chinese Society of Agricultural Engineering,2020,36(16):9-16. | |

| 17 | 赵艳忠, 王运兴, 刘海涛, 等. 带状深松灭茬机灭茬部件设计与试验[J]. 农业机械学报, 2018, 49(3): 94-103. |

| Zhao Yan-zhong, Wang Yun-xing, Liu Hai-tao,et al.Design and test of stubble-breaking components on strip subsoiling and stubble-breaking machine[J]. Transactions of the Chinese Society of Agricultural Machinery, 2018, 49(3): 94-103. | |

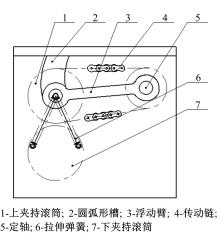

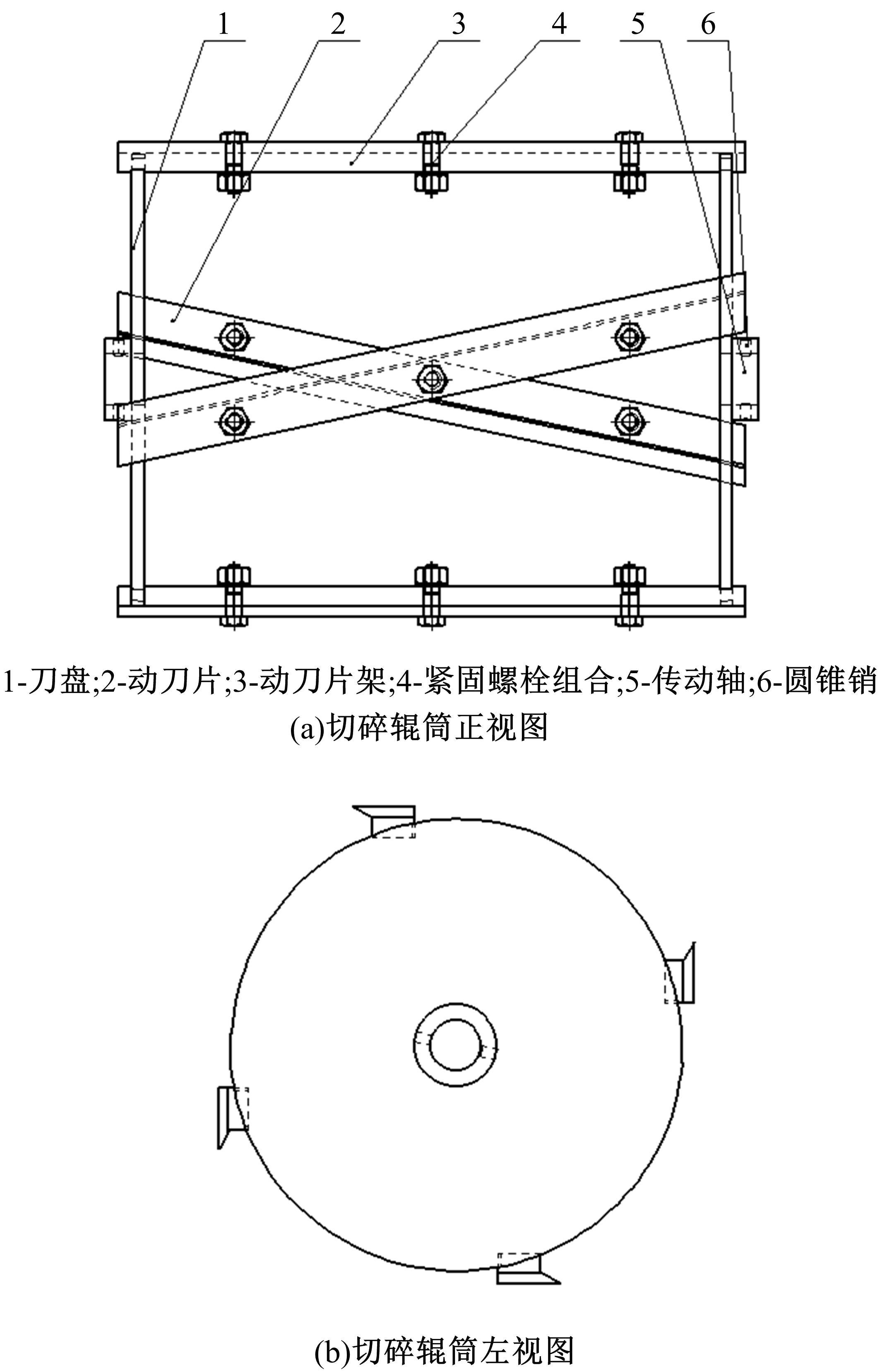

| 18 | 廖培旺, 刘凯凯, 陈明江, 等. 滚筒式棉秆铡切机构的设计与试验[J]. 中国农业大学学报, 2018, 23(9): 131-138. |

| Liao Pei-wang, Liu Kai-kai, Chen Ming-jiang,et al.Design and experiment of roller type cotton stalk cutting mechanism[J]. Journal of China Agricultural University, 2018, 23(9): 131-138. | |

| 19 | DG/T052—2019. 青饲料收获机 [S]. |

| 20 | 李晓康,张家瑞,韩少平,等. 9QZL-1.8自走式青贮玉米联合收获机设计与试验[J].中国农机化学报, 2020, 41(8): 1-6, 19. |

| Li Xiao-kang, Zhang Jia-rui, Han Shao-ping,et al.Design and test of 9QZL-1.8 tracked self-propelled silage corn combine harvester[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(8): 1-6, 19. | |

| 卷终 |

| [1] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

| [2] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [3] | Bai-gong ZENG,Kui-liang LI,Jin YE,Li-li REN,Jaloliddin Rashidov,Ming ZHANG. Design and experiment of harvesting device for industrialized production line of Shanghaiqing [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2756-2764. |

| [4] | Rui-jie SHI,Fei DAI,Wu-yun ZHAO,Xiao-long LIU,Jiang-fei QU,Feng-wei ZHANG. Optimization and experiment of operation parameters of hilly area flax combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2746-2755. |

| [5] | Xing-yu WAN,Qing-xi LIAO,Ya-jun JIANG,Yi-yin SHAN,Yu ZHOU,Yi-tao LIAO. Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. |

| [6] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU. Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2486-2500. |

| [7] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [8] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [9] | Zhao XUE,Jun FU,Zhi CHEN,Feng-de WANG,Shao-ping HAN,Lu-quan REN. Optimization experiment on parameters of chopping device of forage maize harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. |

| [10] | Jun FU,Yi-chen ZHANG,Chao CHENG,Zhi CHEN,Xin-long TANG,Lu-quan REN. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 730-738. |

| [11] | Chao CHENG,Jun FU,Fu-ping HAO,Zhi CHEN,De-yi ZHOU,Lu-quan REN. Effect of motion parameters of cleaning screen on corn cob blocking law [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 351-360. |

| [12] | Chao CHENG,Jun FU,Xin⁃long TANG,Zhi CHEN,Lu⁃quan REN. Effects of vibration mode on interface adhesion law of rice threshed mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1228-1235. |

| [13] | FU Jun,QIAN Zhi-hui,YIN Wei,WANG Jia-jia,REN Lu-quan. Experimental study of friction and tensile properties of wheat [J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

| [14] |

Li Jie,Yan Chu-liang,Yang Fang-fei .

Dynamic simulation and parameter optimization of the combine harvester vibration sieve [J]. 吉林大学学报(工学版), 2006, 36(05): 701-0704. |

|