Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (2): 564-573.doi: 10.13229/j.cnki.jdxbgxb.20220449

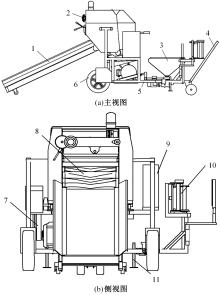

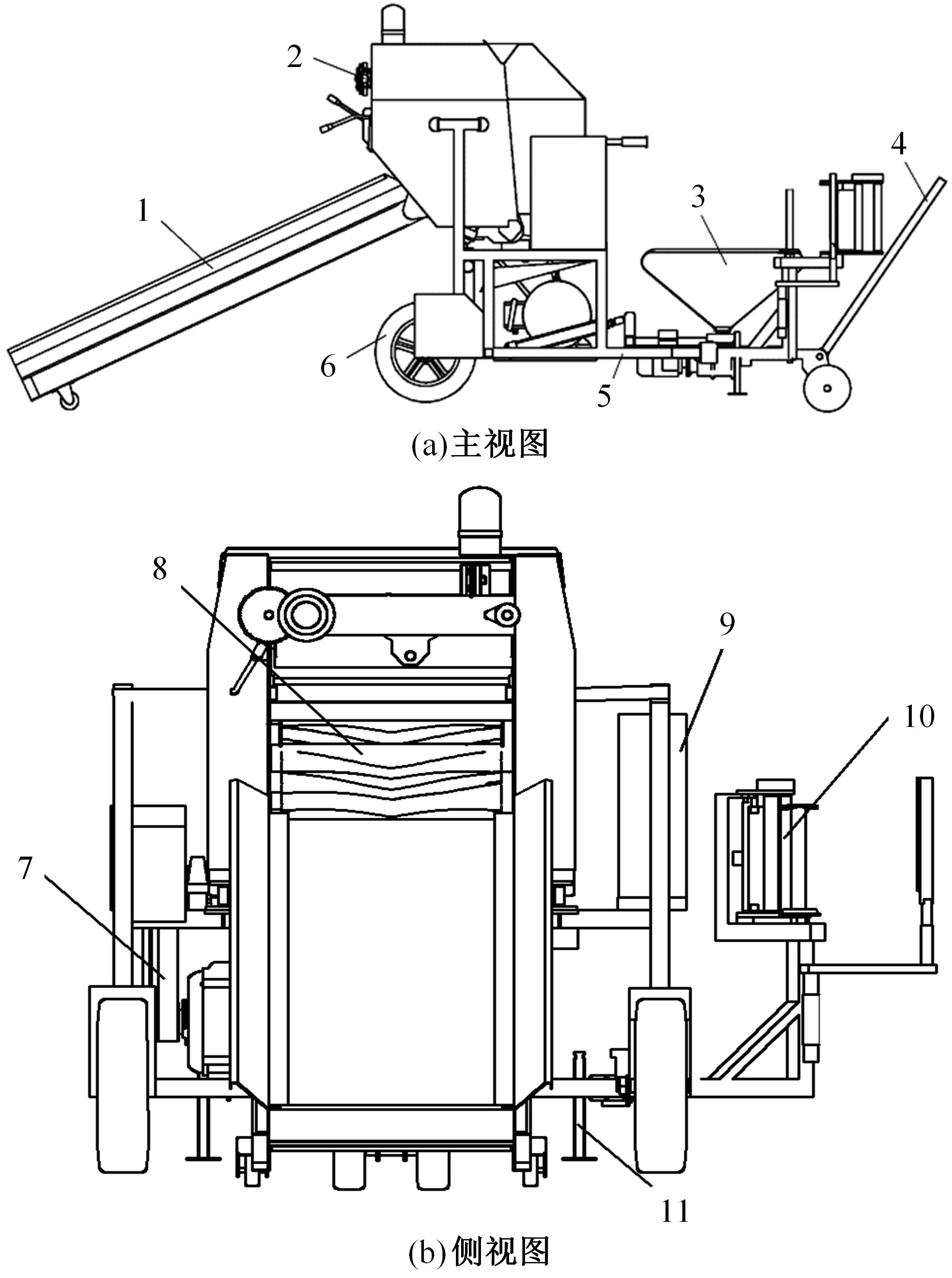

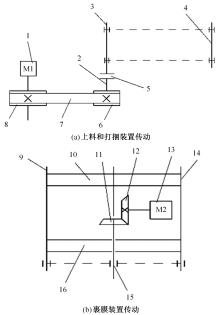

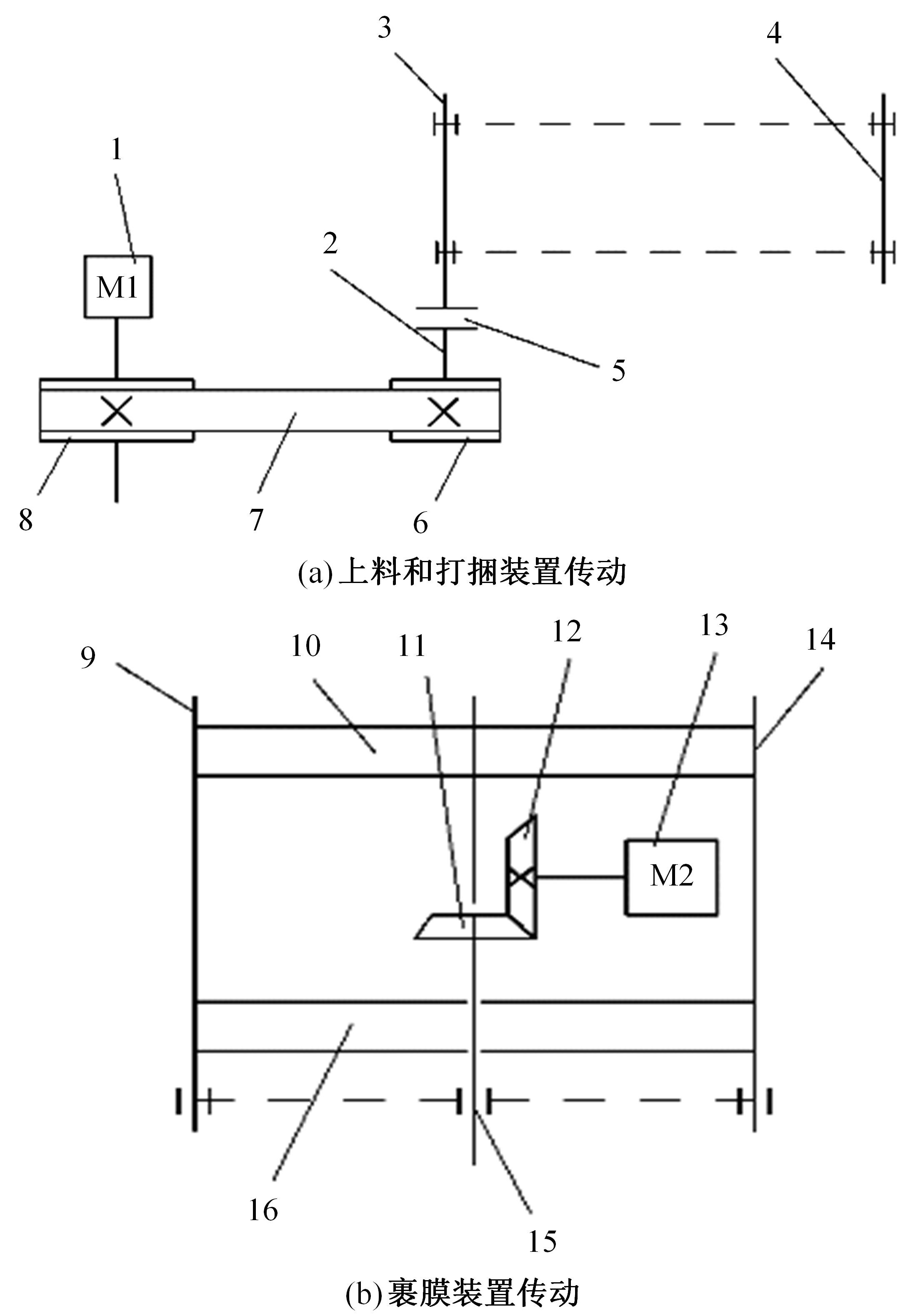

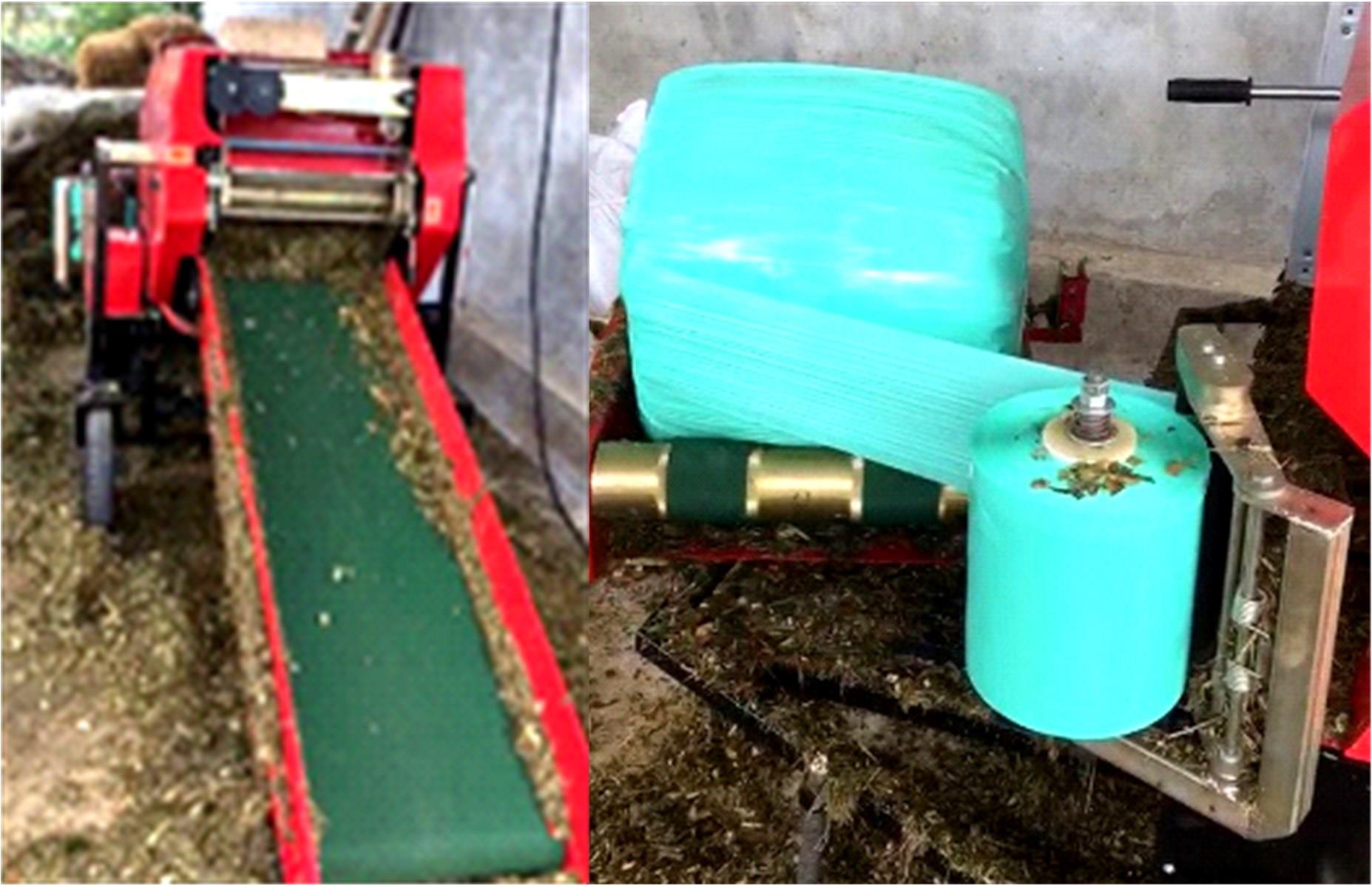

Design and experiment of silage baling and wrapping machine with electric driving

Bin FENG1( ),Tao ZHANG1,2(

),Tao ZHANG1,2( ),Tao LIANG2,Ying ZHANG2,Xing-long TANG2,Guan-ping WANG1

),Tao LIANG2,Ying ZHANG2,Xing-long TANG2,Guan-ping WANG1

- 1.College of Electromechanical Engineering,Gansu Agricultural University,Lanzhou 730070,China

2.Chongqing Academy of Agricultural Sciences,Chongqing 401329,China

CLC Number:

- S817.1

| 1 | 梁荣庆,钟波,蒙贺伟,等. 4QJ-3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报:工学版, 2021, 51(5): 1887-1896. |

| Liang Rong-qing, Zhong Bo, Meng He-wei, et al.Development of 4QJ-3 type picking and cutting platform for silage oat[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(5): 1887-1896. | |

| 2 | Toruk F, Gonulol E. Effects of particle length on alfalfa baled silage quality and color under different storage conditions[J]. Bulgarian Journal of Agricultural Science, 2011, 17(4): 451-455. |

| 3 | 杨牧. 农作物秸秆、黑麦草与豆科牧草混合青贮发酵品质的研究[D]. 南京: 南京农业大学草业学院, 2015. |

| Yang Mu. Effect of ensiling straw and grass in different proportion with legumes on fermentation quality[D]. Nanjing: College of Agro-Grassland Science, Nanjing Agricultural University, 2015. | |

| 4 | 巴隆业. 方草捆捡拾压捆机压捆室设计及有限元分析[D]. 呼和浩特: 内蒙古农业大学机电工程学院, 2013. |

| Ba Long-ye. Square hay baler design and baling room finite element analysis based on ANSYS[D]. Huhehaote: College of Mechanical and Electrical Engineering, Inner Mongolia Agricultural University, 2013. | |

| 5 | Toruk F, Gonulol E. Effects of particle length on alfalfa baled silage quality and color under different storage conditions[J]. Bulgarian Journal of Agricultural Science, 2011, 17(4): 451-455. |

| 6 | 白彦福. 甘肃饲用甜高粱青贮发酵品质、瘤胃降解特性及加工工艺[D]. 兰州: 兰州大学草地农业科技学院, 2017. |

| Bai Yan-fu. Fermentation quality, rumen degradation characteristics and processing technology of sweet sorghum silage in gansu province[D]. Lanzhou: College of Pastoral Agriculture Science and Technology, Lanzhou University, 2017. | |

| 7 | Savoie P, Tremblay D, Trembleay G F, et al. Effecr of length of cut on quality of stack silage and milk production[J]. Canadian Journal of Animal Science, 1992, 72(2): 253-263. |

| 8 | 包攀攀,吕江南,王加跃,等. 青贮饲料收获机械的发展现状与对策[J]. 粮食与饲料工业, 2018(1): 42-45. |

| Bao Pan-pan, Lv Jiang-nan, Wang Jia-yue, et al. Research progress and suggestions on harvesting machine for silage fodder[J]. Cereal & Feed Industry, 2018(1): 42-45. | |

| 9 | 梁荣庆,张翠英,任冬梅,等. 玉米青贮收获机械的应用及发展趋势[J]. 农业装备与车辆工程, 2016, 54(2): 17-21. |

| Liang Rong-qing, Zhang Cui-ying, Dong-mei Reng, et al. Application and development trend of corn silage harvest machinery[J]. Agricultural Equipment & Vehicle Engineering, 2016, 54(2): 17-21. | |

| 10 | 闵令强,张军强,梁荣庆,等. 青贮饲料收获贮存模式及机械设备概述[J]. 中国农机化学报, 2018, 39(8): 62-66, 75. |

| Min Ling-qiang, Zhang Jun-qiang, Liang Rong-qing, et al. Overview of harvesting and storage modes of silage and related mechanical equipment[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(8): 62-66, 75. | |

| 11 | 陈美舟,徐广飞,宋志才,等.全株青贮玉米径向局部压缩特性试验[J]. 吉林大学学报:工学版, 2021, 51(1): 1-9. |

| Chen Mei-zhou, Xu Guang-fei, Song Zhi-cai, et al. Experimental study of radial partial compression characteristics of whole silage corn[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(1): 1-9. | |

| 12 | 王国富. 青贮稻杆圆捆打捆机的设计与试验研究[D]. 哈尔滨: 东北农业大学工程学院, 2019. |

| Wang Guo-fu. Design and experimental study of round baler for silage rice straw[D]. Harbin: College of Engineering, Northeast Agricultural University, 2019. | |

| 13 | 西北工业大学机械原理及机械零件教研室. 机械设计[M]. 北京: 高等教育出版社, 2006. |

| 14 | 王伟,格根图,刘兴波,等. 压缩密度对天然牧草青贮养分含量的影响[J]. 草原与草业, 2018, 30(3): 43-49. |

| Wang Wei, Ge Gen-tu, Liu Xing-bo, et al. Effect of compressing density on nutritional quality of natural grass silage[J]. Grassland and Prataculture, 2018, 30(3): 43-49. | |

| 15 | 北京起重运输机械研究所. DTⅡ(A)型带式输送机设计手册[M]. 北京: 冶金工业出版社, 2003. |

| 16 | . 圆草捆打捆机 [S]. |

| 17 | . 玉米饲草青贮技术规程 [S]. |

| 18 | 战长江. 自走式秸秆收获打捆机的研制[J]. 新疆农机化, 2013(4): 9-10. |

| Zhan Chang-jiang. Development of self-propelled straw harvest baling machine[J]. Xinjiang Agricultural Mechanization, 2013(4): 9-10. | |

| 19 | 肖章,刘亮东,王光辉,等. 基于PLC的青贮圆草捆打捆机控制系统设计[J]. 中国农业大学学报, 2013, 18(6): 175-179. |

| Xiao Zhang, Liu Liang-dong, Wang Guang-hui, et al. Control system design of silage round baler based on PLC[J]. Journal of China Agricultural University, 2013, 18(6): 175-179. | |

| 20 | 张泽璞,段宝成,陶桂香,等. 打捆试验台设计与试验[J]. 农机化研究, 2019, 41(9): 152-156. |

| Zhang Ze-pu, Duan Bao-cheng, Tao Gui-xiang, et al. Design and test of bale rig[J]. Journal of Agricultural Mechanization Research, 2019, 41(9): 152-156. | |

| 21 | 李耀明,成铖,徐立章. 4L-4.0型稻麦联合收获打捆复式作业机设计与试验[J]. 农业工程学报, 2016, 32(23): 29-35. |

| Li Yao-ming, Cheng Cheng, Xu Li-zhang. Design and experiment of baler for 4L-4.0 combine harvester of rice and wheat[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(23): 29-35. |

| [1] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [2] | Xiao HAN,Xian-zhang LING,Shuang TIAN,Sheng-yi CONG. Analysis and control of mud spillover in high⁃speed railway ballast⁃track subgrade caused by grouting [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 506-515. |

| [3] | Zhi-jun YANG,Chi ZHANG,Guan-xin HUANG. Mechanical model of rigid⁃flexible coupling positioning stage based on floating coordinate method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 385-393. |

| [4] | Rui-jie SHI,Fei DAI,Wu-yun ZHAO,Fa-rong YANG,Feng-wei ZHANG,Yi-ming ZHAO,Hao QU,Tian-fu WANG,Jun-hai GUO. Design and experiments of self⁃propelled quinoa combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2686-2694. |

| [5] | Shu-pei ZHANG,Ming-yue XIA,Wei ZHANG,Zhao CHEN,Yi-xiang CHEN. Impact dynamic modeling and simulation for ball joint with clearance considering nonlinear stiffness [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2227-2235. |

| [6] | Tao MA,Yuan MA,Xiao-ming HUANG. Optimal combination of key parameters of intelligent compaction based on multiple nonlinear regression [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2067-2077. |

| [7] | Jue LI,An-shun ZHANG,Jun-hui ZHANG,Jun-feng QIAN. Model testing and numerical analysis of dynamic response of graded crushed rock base structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1782-1789. |

| [8] | Si-lin CAO,Jian-hua XIE,Yu-xin YANG,Yong-rui LIU,Yong-tao LU,Bo SUN. Design and experiment of side row cotton straw returning and residual film recovery combined machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1514-1528. |

| [9] | Jiu-yi LI,Feng-jun ZHOU,Jian-hua LIU,Yun-hou SUN,Jing-zhong ZHU,Ming-kun QIU. Modified IWAN model of helical threaded connector imposed to torsional load [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1305-1314. |

| [10] | Yong ZHANG,Feng-zhao MAO,Shui-chang LIU,Qing-yu WANG,Shen-gong PAN,Guang-sheng ZENG. Optimization on distortion grid of vehicle external flow field based on Laplacian Algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1289-1296. |

| [11] | Xue-jun ZHANG,Shuang HUANG,Zeng-lu SHI,Yong-liang YU,Xin-cheng ZHOU,Wei JIN,Yong CHEN,Jia HONG. Design and test of the remaining film picking and baling machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1220-1230. |

| [12] | Hai-bin WEI,Zi-peng MA,Hai-peng BI,Han-tao LIU,Shuan-ye HAN. Conductive rubber composite pavement paving technology based on mechanical response analysis method [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 531-537. |

| [13] | Ce LIANG,Fu-lei HUANG,Ji-cai LIANG,Yi LI. Numerical simulation on deformation of protective beam with “日”-shaped section during rotary draw bending [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3397-3403. |

| [14] | Ming-gen ZENG,Yu WU,Qing-tian SU. Experimental studies on cracking behavior of steel fiber reinforced concrete slab in negative moment region of orthotropic composite bridge deck [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3176-3185. |

| [15] | Guo-qiang DUN,Wen-hui LIU,Xing-peng WU,Ning MAO,Wen-yi JI,Hong-yan MA. Simulation optimization and experiment of screw extrusion precision fertilizer ejector [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 3026-3037. |

|

||