Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (3): 650-656.doi: 10.13229/j.cnki.jdxbgxb.20220474

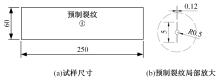

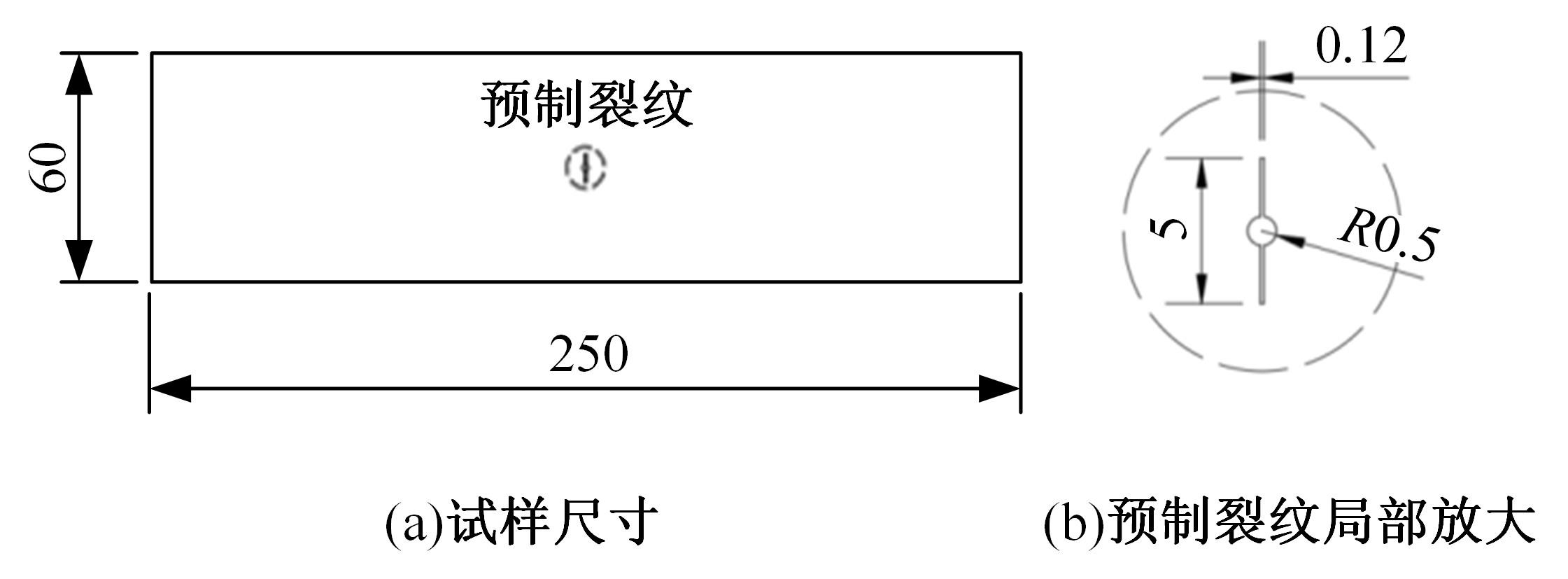

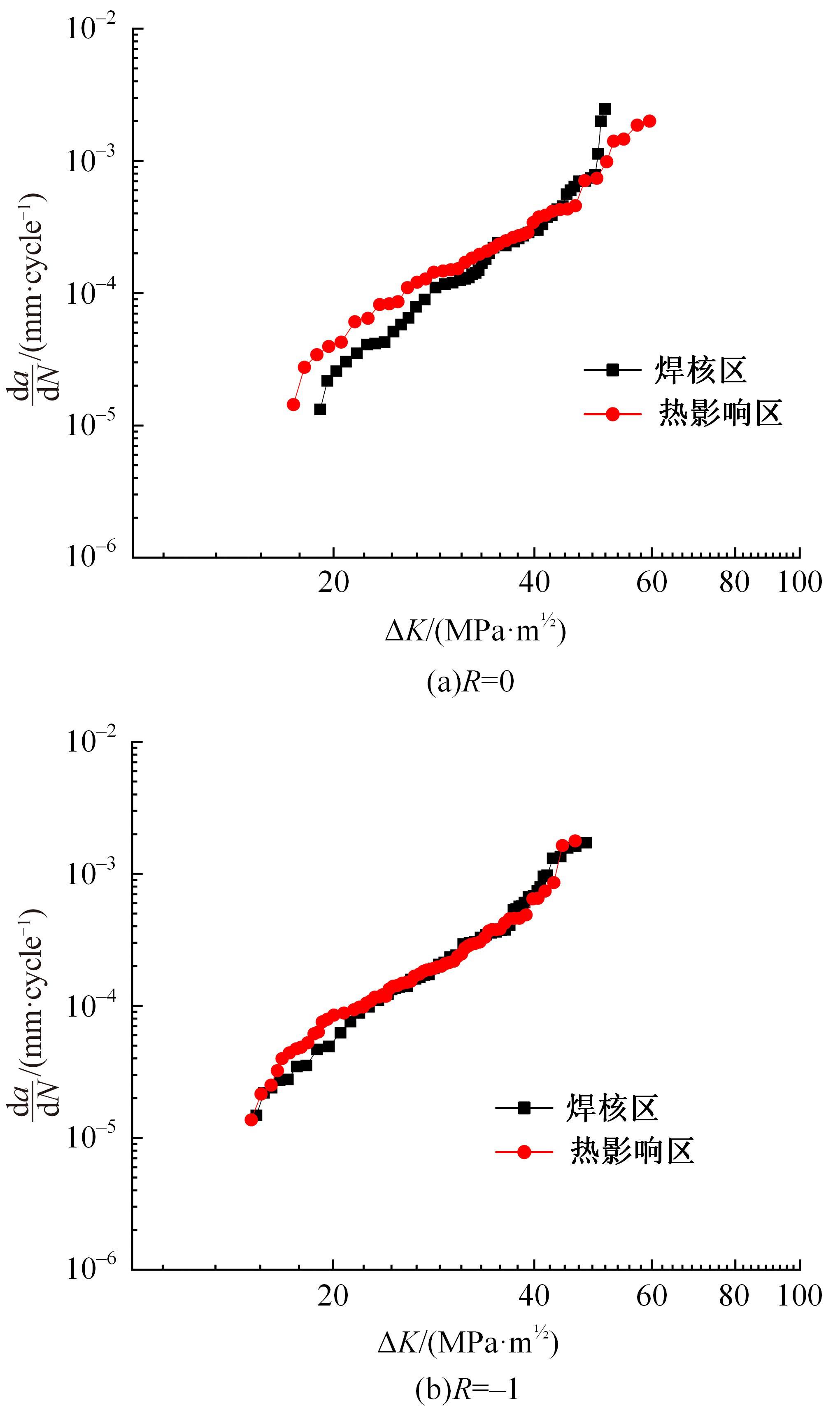

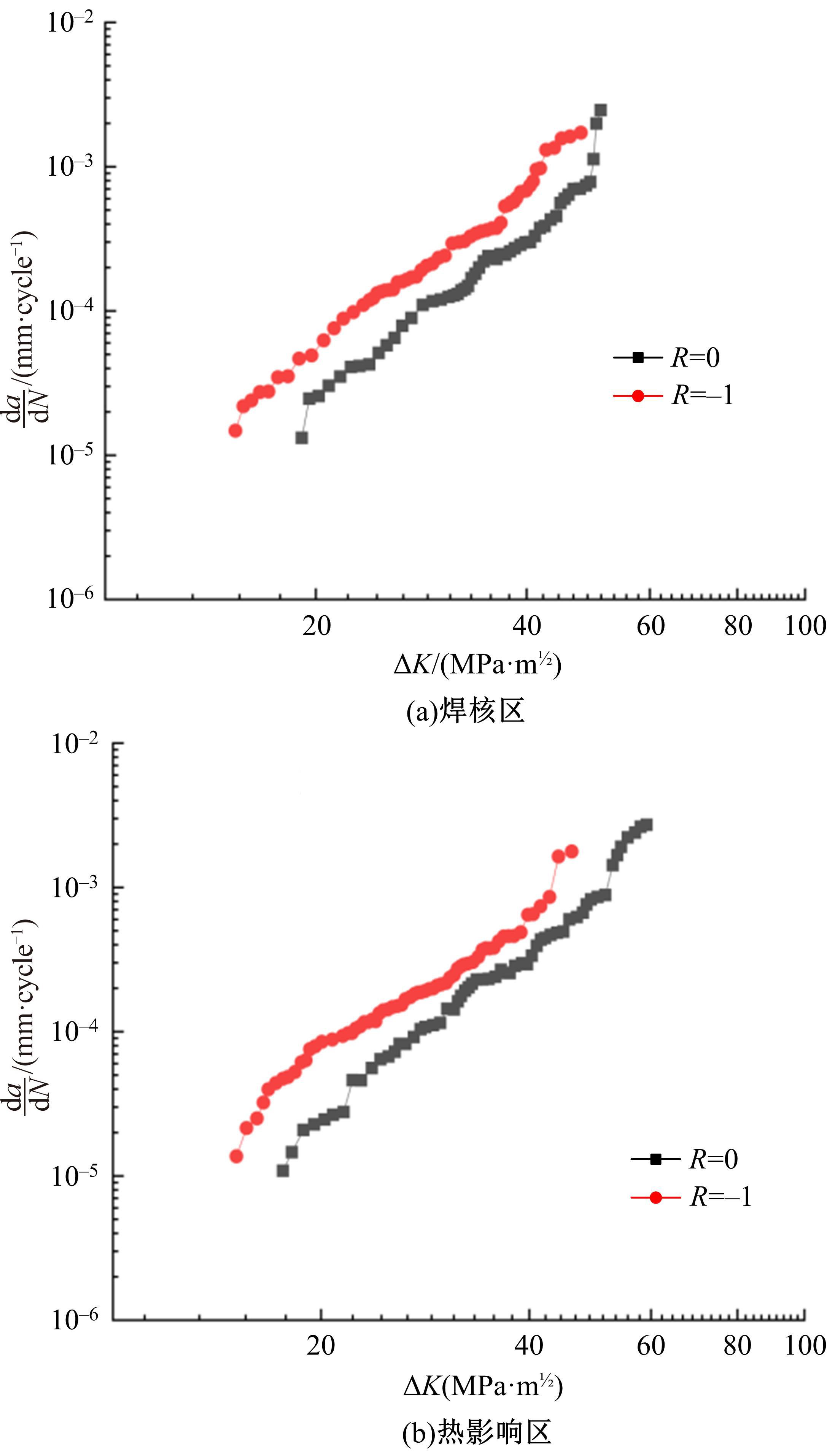

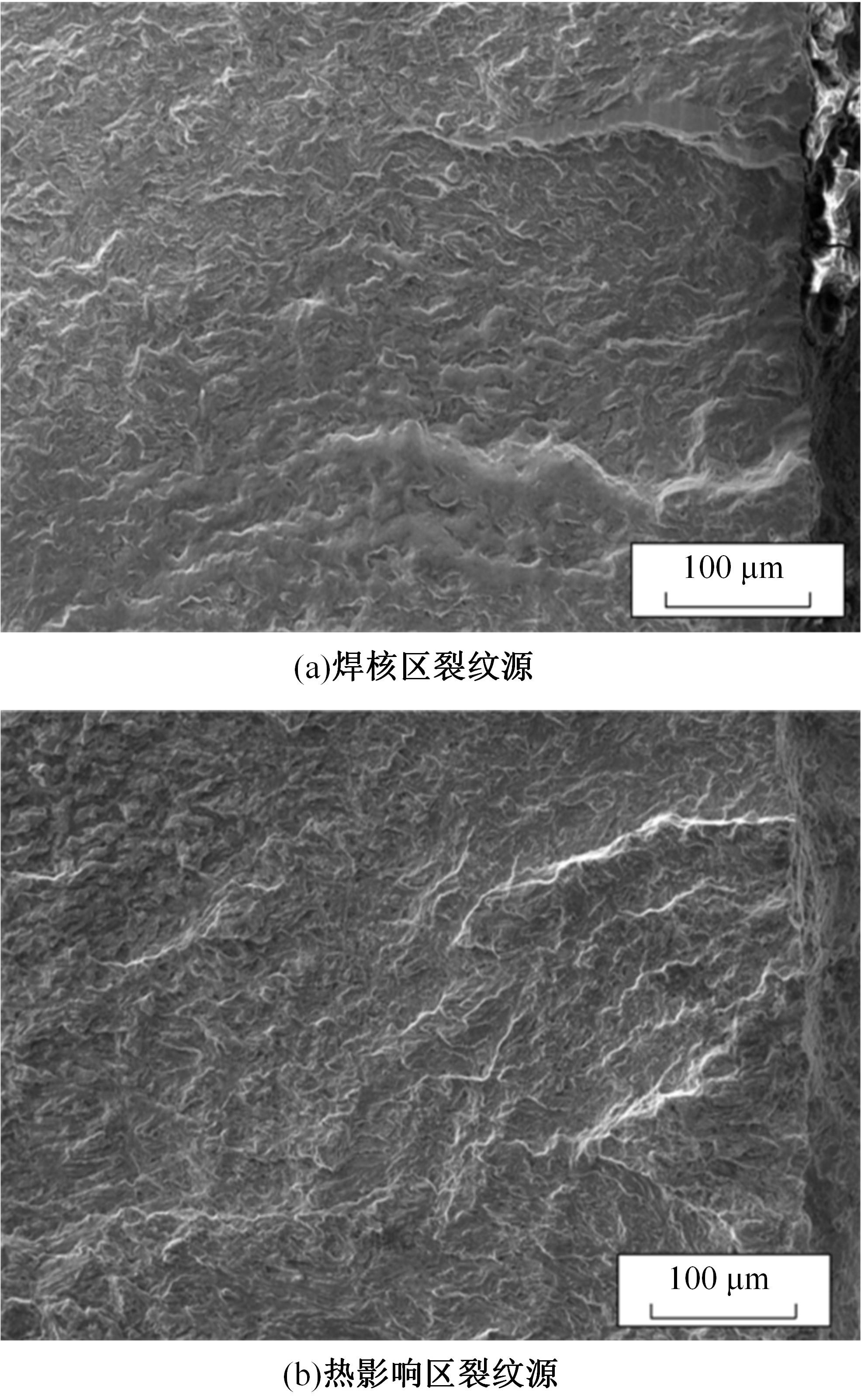

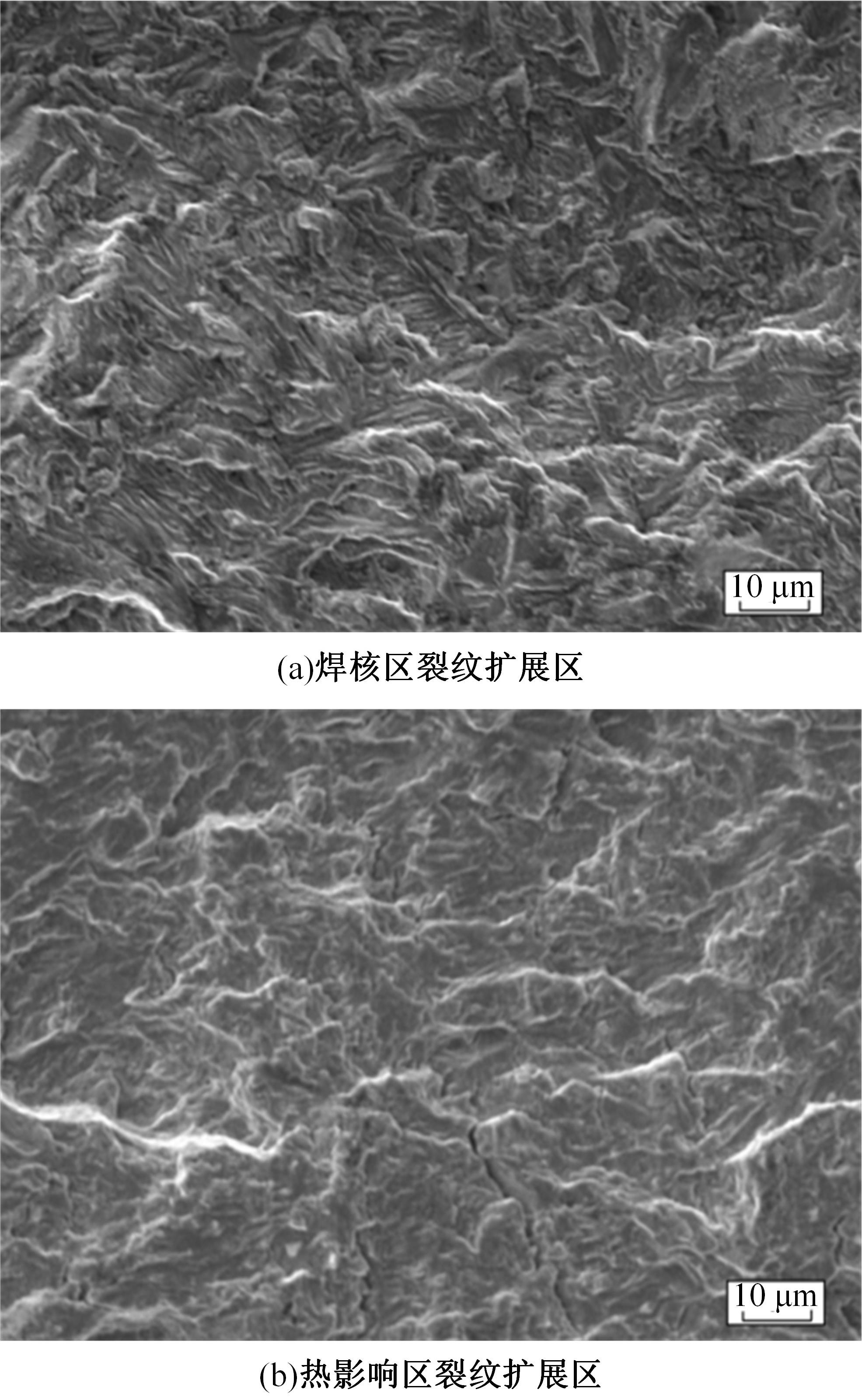

Crack growth rate of SMA490BW steel in different welding areas for bogie

Li HUI1( ),Lei JIN2,Wan-wan SONG3,Song ZHOU2(

),Lei JIN2,Wan-wan SONG3,Song ZHOU2( ),Jin-lan AN1

),Jin-lan AN1

- 1.Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process,Shenyang Aerospace University,Shenyang 110136,China

2.School of Mechanical and Electrical Engineering,Shenyang Aerospace University,Shenyang 110136,China

3.Shenyang Aircraft Corporation,Shenyang 110034,China

CLC Number:

- TG405

| 1 | 吕文阁. 基于疲劳短裂纹行为的疲劳寿命估算要疲劳与断裂[M]. 北京: 气象工业出版社, 2002. |

| 2 | Hariharan K, Prakash R V, Sathya P M. Weighted error criterion to evaluate strain-fatigue life prediction methods[J]. International Journal of Fatigue, 2011, 33(5): 727-734. |

| 3 | 杨新华,陈传尧. 疲劳与断裂[M]. 武汉: 华中科技大学出版社, 2018. |

| 4 | 何柏林, 叶斌, 邓海鹏, 等. 转向架用SMA490BW钢焊接接头超高周疲劳性能[J]. 焊接学报, 2019, 40(2): 31-37, 162. |

| He Bo-lin, Ye Bin, Deng Hai-peng, et al. Very high cycle fatigue properties of SMA490BW steel welded joints for train bogie[J]. Transactions of the China Welding Institution, 2019, 40(2): 31-37, 162. | |

| 5 | 李余江, 史春元, 胡文浩, 等. 焊后处理对转向架SMA490BW钢焊接接头疲劳性能的影响[J]. 焊接技术, 2016, 45(11): 79-83. |

| Li Yu-jiang, Shi Chun-yuan, Hu Wen-hao, et al. Influence of post-weld treatment on fatigue properties of welded joints of bogie SMA490BW steel[J]. Welding Technology,2016, 45(11): 79-83. | |

| 6 | 王志杰,齐芳娟,林松,等.焊补对SMA490BW焊接接头疲劳性能的影响[J]. 焊接学报, 2015, 36(5): 109-112, 118. |

| Wang Zhi-jie, Qi Fang-juan, Lin Song, et al. Effect of repair welding on fatigue properties of SMA490BWsteel welded joints[J]. Transactions of the China Welding Institution, 2015, 36(5): 109-112, 118. | |

| 7 | 张成竹, 陈辉, 蔡创, 等. 激光清洗对SMA490BW钢接头表面应力及腐蚀的影响[J]. 焊接学报,2020, 41(11): 89-96, 102. |

| Zhang Cheng-zhu, Chen Hui, Cai Chuang, et al. Effect of laser cleaning on surface stress and corrosion of SMA490BW steel welded joint[J]. Transactions of the China Welding Institution, 2020, 41(11): 89-96, 102. | |

| 8 | 罗开玉, 邢月华, 柴卿锋, 等. 激光冲击强化对2Cr13不锈钢腐蚀疲劳性能的影响[J]. 吉林大学学报: 工学版, 2019, 49(3): 850-858. |

| Luo Kai-yu, Xing Yue-hua, Chai Qing-feng, et al. Effects of laser shock peening on corrosion fatigue behaviour of 2Cr13 stainless steel[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(3): 850-858. | |

| 9 | 谢旭, 吴向阳, 张志毅, 等. 焊接工艺对SMA490BW耐候钢接头腐蚀行为的影响[J]. 表面技术, 2018, 47(10): 256-261. |

| Xie Xu, Wu Xiang-yang, Zhang Zhi-yi, et al. Effects of welding processes on corrosion behavior of SMA490BW weathering steel joints[J]. Surface Technology, 2018, 47(10): 256-261. | |

| 10 | 崔坤强, 吴向阳, 张志毅, 等. SMA490BW耐候钢及其焊接接头的盐雾腐蚀行为[J].热加工工艺,2018,47(13):68-71. |

| Cui Kun-qiang, Wu Xiang-yang, Zhang Zhi-yi, et al. Salt fog corrosion behavior of SMA490BW weathering steel and its welded joints[J]. Hot Working Technology, 2018, 47(13): 68-71. | |

| 11 | 许良, 黄国栋, 回丽, 等. 转向架用SMA490BW钢的疲劳裂纹扩展行为研究[J]. 热加工工艺, 2022(10): 1-5. |

| Xu Liang, Huang Guo-dong, Hui Li, et al. Research on fatigue crack propagation behavior of SMA490BW steel for bogie[J]. Hot Working Technology, 2022(10): 1-5. | |

| 12 | Paris P C, Erdogan F. A critical analysis of crack propagation laws[J]. Journal of Basic Engineering, ASME, 1963, 84(4): 528-534. |

| 13 | Paris P C, Gomez M P, Anderson W P. A Rational analytic theory of fatigue[J]. The Trend in Engineering, 1961, 13(1): 9-14. |

| 14 | 韦龙, 王时越, 刘国寿, 等. 不同应力比下ADB610钢疲劳裂纹扩展速率的试验研究[J]. 机械强度, 2016, 38(1): 64-68. |

| Wei Long, Wang Shi-yue, Liu Guo-shou, et al. Experiment study on crack growth rate of ADB610 steel under different stress ratios[J]. Journal of Mechanical Strength, 2016, 38(1): 64-68. | |

| 15 | Elber W. Fatigue crack closure under cyclic tension[J]. Engineering Fracture Mechanics, 1971, 2: 37-45. |

| 16 | Ismonov S, Daniewicz S R. Simulation and comparison of several crack closure assessment methodologies using three-dimensional finite element analysis[J]. International Journal of Fatigue, 2010, 32(8): 1322-1329. |

| [1] | Zhi-jun YANG,Chi ZHANG,Guan-xin HUANG. Mechanical model of rigid⁃flexible coupling positioning stage based on floating coordinate method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 385-393. |

| [2] | Lin-rong SHI,Wu-yun ZHAO. Design and test of rolling spoon type flaxes precision hole sower for caraway in northwest cold and arid agricultural region [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2706-2717. |

| [3] | Bo-sen CHAI,Guang-yi WANG,Dong YAN,Guo-ren ZHU,Jin ZHANG,Heng-sheng LYU. Numerical simulation of cavitation in torque converter and analysis of its influence on performance [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2236-2244. |

| [4] | Guo-hui CHEN,Ye-yin XU,Ying-hou JIAO. Meshing stiffness calculation and vibration analysis of helical gear considering deflection [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1902-1910. |

| [5] | Li-juan YU,Yang AN,Jia-long HE,Guo-fa LI,Sheng-xu WANG. Research progress and development trend of extrapolation method in electromechanical equipment load spectrum [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 941-953. |

| [6] | Jian WANG,Wei YU,Bin WANG. Effects of methanol substitution percent on combustion and emission of diesel engines under plateau condition [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 954-963. |

| [7] | Sheng LI,Jia ZHU,De-hui HUANG,Cun-fu CHEN,Hong-qing FEI,Wei FENG,Xing-jun HU. Structural parameters optimization of louver fins of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 998-1006. |

| [8] | Bo-sen CHAI,Dong YAN,Guang-yi WANG,Wen-jie ZUO. Three-dimensional vortex characteristic analysis and simulation evaluation of peach cavity hydrodynamic coupling under braking condition [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3045-3055. |

| [9] | Zhen SONG,Jie LIU. Time series prediction algorithm of vibration frequency of rotating machinery [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1764-1769. |

| [10] | Ling ZHU,Qiu-cheng WANG. New energy vehicle drive system coordinated control method under spatial geometric constraints [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1509-1514. |

| [11] | Zhao-hui JIN,Le-qi GU,Wei HONG,Fang-xi XIE,Tian YOU. Analysis on pressure fluctuation of hydraulic variable valve actuation [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 773-780. |

| [12] | Guo-fa LI,Yan-bo WANG,Jia-long HE,Ji-li WANG. Research progress and development trend of health assessment of electromechanical equipment [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 267-279. |

| [13] | Lei WANG,Bing-han HUANG,Jia-hui CONG,Li HUI,Song ZHOU,Yong-zhen XU. Effect of ultrasonic impact on fatigue performance of friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2542-2548. |

| [14] | Xing-jun HU,Jing-long ZHANG,Li XIN,Yu-fei LUO,Jing-yu WANG,Tian-ming YU. Investigation on influence of cooling tube structure and airflow speed on cold side performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1557-1564. |

| [15] | Yong-ying TAN,Shan-zhen YI,Da-bing XUE,Xiao-ming WANG,Lei YUAN. Weight adaptive control for trotting gait of load-carrying quadruped walking vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1506-1517. |

|

||