Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (2): 434-443.doi: 10.13229/j.cnki.jdxbgxb.20230462

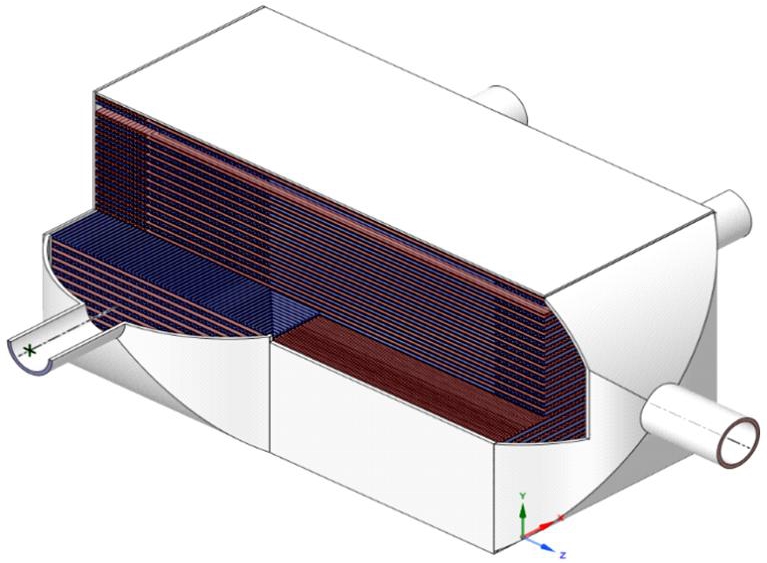

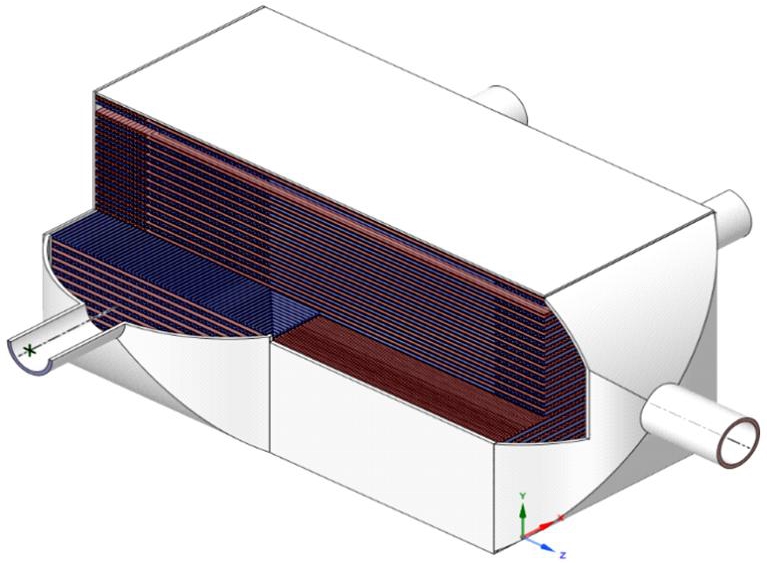

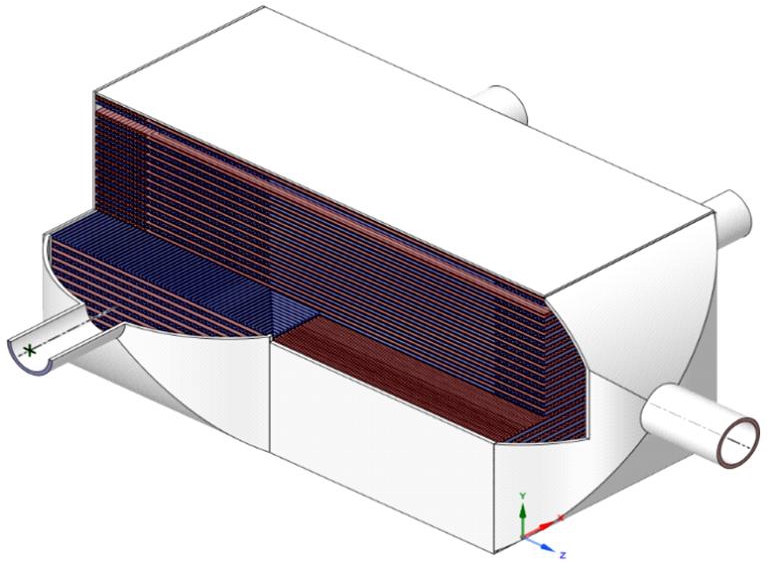

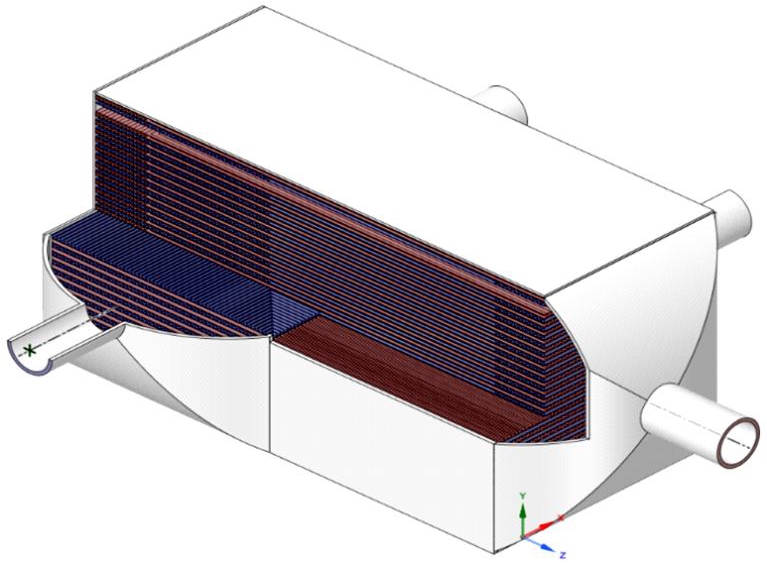

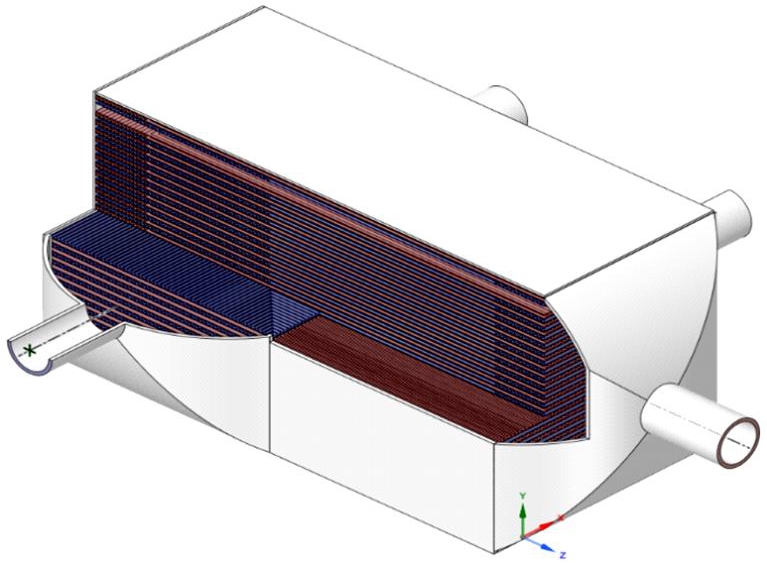

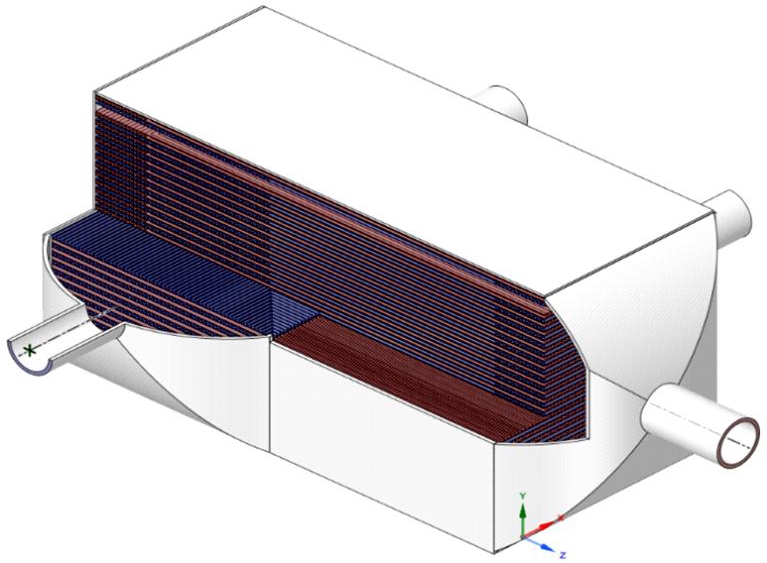

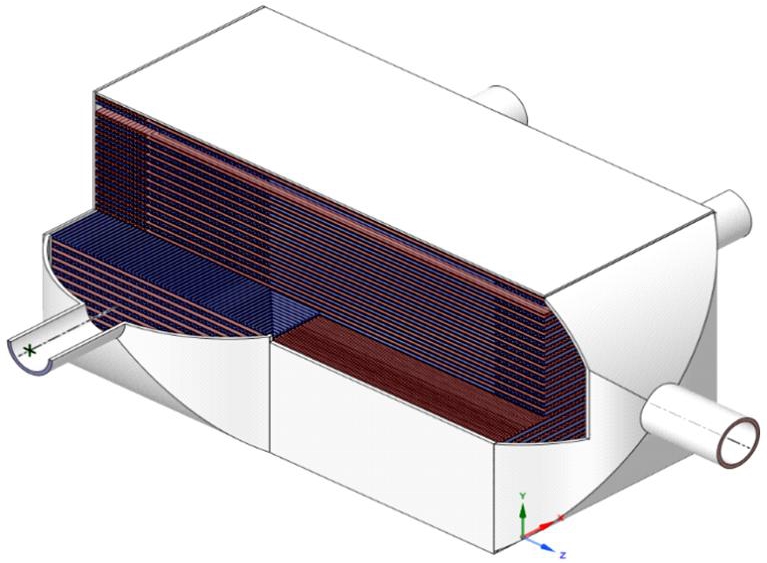

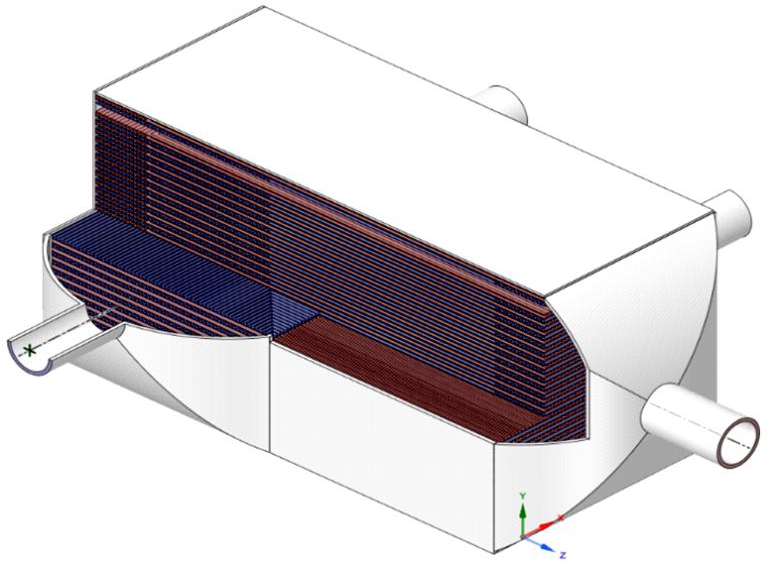

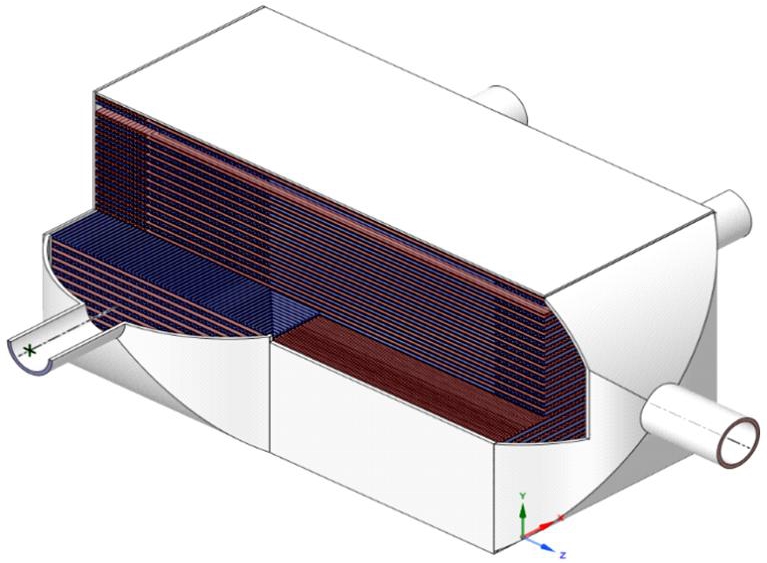

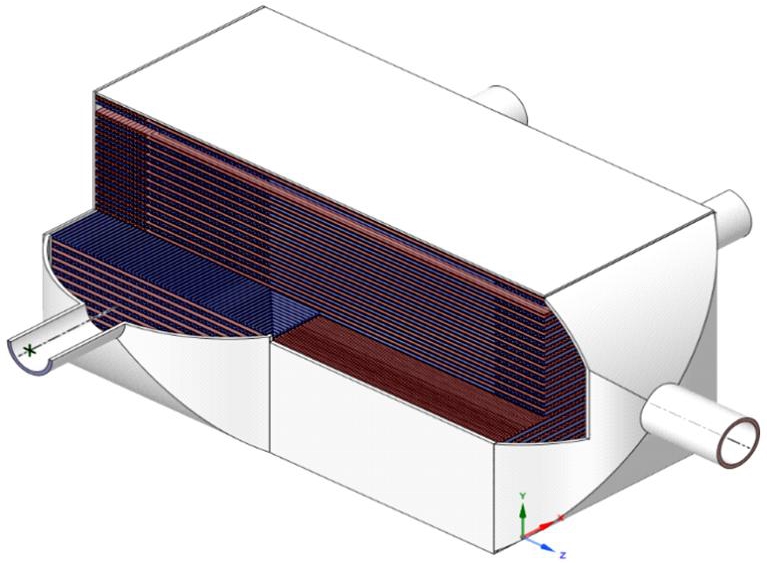

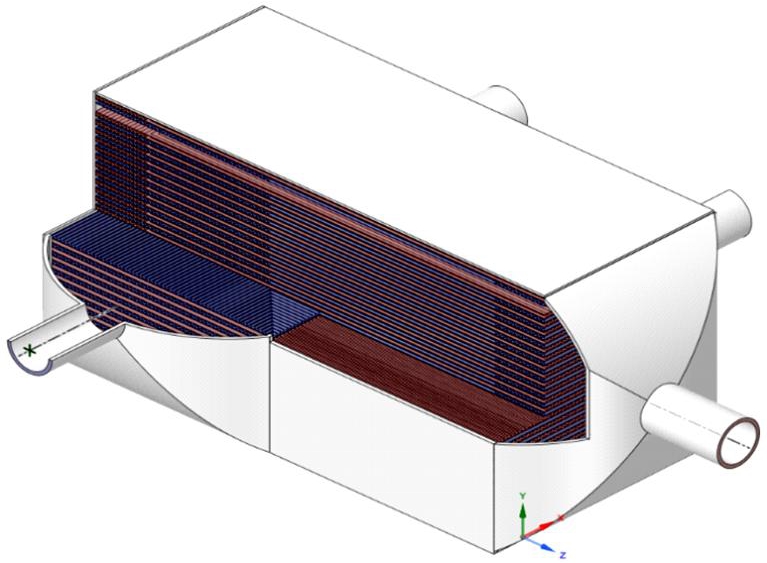

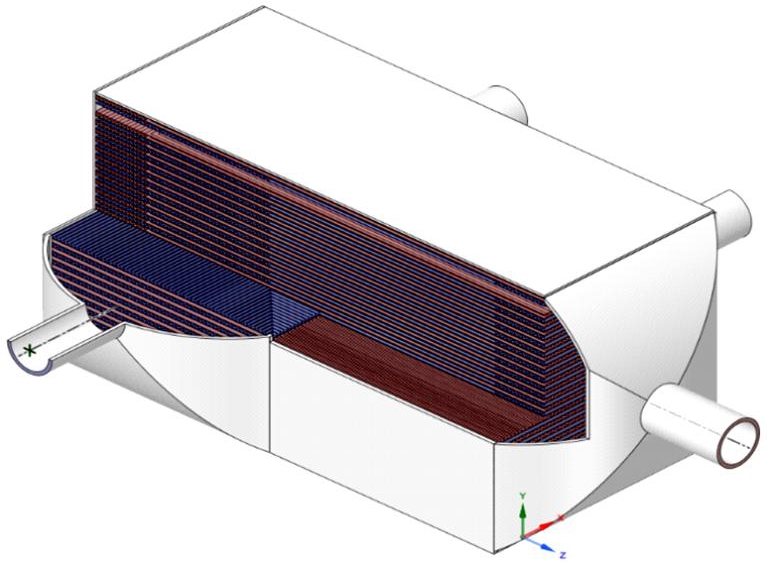

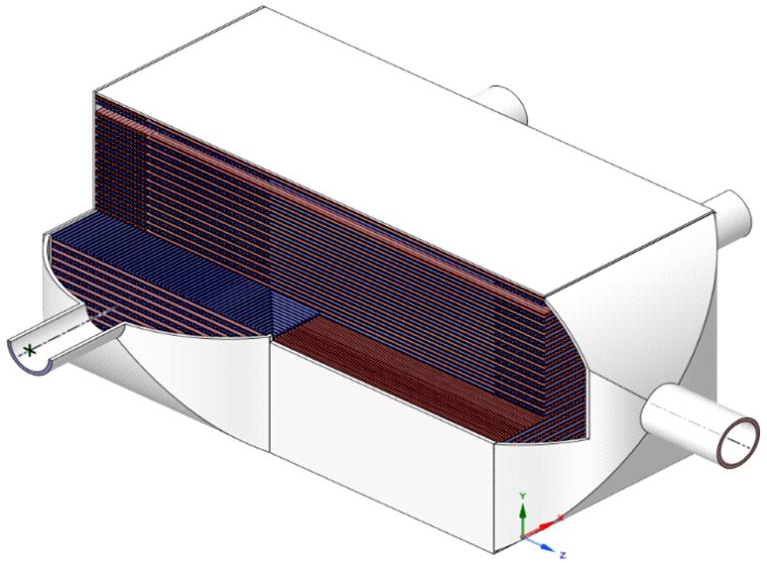

Experimental study of a combustor-coupled heat exchanger for compact SOFC system

Si-yuan LI1( ),Shu-zhan BAI1(

),Shu-zhan BAI1( ),Guo-xiang LI1,Kong-rong MA2,Wen-cong LI2,Yu-hao HAN1

),Guo-xiang LI1,Kong-rong MA2,Wen-cong LI2,Yu-hao HAN1

- 1.School of Energy and Power Engineering,Shandong University,Jinan 250061,China

2.China National Heavy Duty Truck Group Co. ,Ltd. ,Jinan 250000,China

CLC Number:

- TK91

| 1 | Kuyper J, Schroeder H, Linnér B. The evolution of the UNFCCC[J]. Annual Review of Environment and Resources, 2018, 43(1): 343-368. |

| 2 | 王灿, 张雅欣. 碳中和愿景的实现路径与政策体系[J]. 中国环境管理, 2020, 12(6): 58-64. |

| Wang Can, Zhang Ya-xin. The path to carbon neutral vision and policy system[J]. China Environmental Management, 2020, 12(6): 58-64. | |

| 3 | Choudhury A, Chandra H, Arora A. Application of solid oxide fuel cell technology for power generation—a review[J]. Renewable & Sustainable Energy Reviews, 2013, 20: 430-442. |

| 4 | O'Hayre R P, Cha S W, Colella W, et al. Fuel Cell Fundamentals[M]. 3rd Edition. Hoboken: Wiley, 2016. |

| 5 | Zeng Z Z, Qian Y P, Zhang Y J, et al. A review of heat exchange and thermal management methods for temperature gradient reduction in solid oxide fuel cell (SOFC) stacks[J]. Applied Energy, 2020, 280: No. 115899. |

| 6 | Crosbie G M, Murray E P, Bauer D R, et al. Solid oxide fuel cells for direct oxidation of liquid hydrocarbon fuels in automotive auxiliary power units: sulfur tolerance and operation on gasoline[J]. SAE International, 2002, 111(3): 832-839. |

| 7 | Rechberger J, Kaupert A, Hagerskans J, et al. Demonstration of the first European SOFC APU on a heavy duty truck[J]. Transportation Research Procedia, 2016, 14: 3676-3685. |

| 8 | Nissan Motor Company. Nissan SOFC powered vehicle system runs on bioethanol[J]. Fuel Cells Bulletin, 2016, 2016(7): 2-3. |

| 9 | Bessekon Y, Zielke P, Hagen A, et al. Simulation of a SOFC/Battery powered vehicle[J]. International Journal of Hydrogen Energy, 2019, 44(3): 1905-1919. |

| 10 | Crosbie G M, Murray E P, Bauer D R, et al. Solid oxide fuel cells for direct oxidation of liquid hydrocarbon fuels in automotive auxiliary power units: Sulfur tolerance and operation on gasoline[C]∥SAE Technical Paper, 2002-0410. |

| 11 | Botti J J, Grieve M J, MacBain J A. Electric vehicle range extension using an SOFC APU[C]∥SAE Technical Paper, 2005-1172. |

| 12 | Bessekon Y, Zielke P, Hagen A, et al. Simulation of a SOFC/battery powered vehicle[J]. International Journal of Hydrogen Energy, 2019, 44(3): 1905-1919. |

| 13 | Yen T H, Hong W T, Huang W P, et al. Experimental investigation of 1 kW solid oxide fuel cell system with a natural gas reformer and an exhaust gas burner[J]. Journal of Power Sources, 2010, 195(5): 1454-1462. |

| 14 | Martinez A S, Brouwer J, Samuelsen G S. Comparative analysis of SOFC-GT freight locomotive fueled by natural gas and diesel with onboard reformation[J]. Applied Energy, 2015, 148: 421-438. |

| 15 | Barzi Y M, Ghassemi M, Hamedi M H. Numerical analysis of start-up operation of a tubular solid oxide fuel cell[J]. International Journal of Hydrogen Energy, 2009, 34(4): 2015-2025. |

| 16 | 代安娜,许林峰,税安泽. 固体氧化物燃料电池的研究与进展[J]. 硅酸盐通报, 2015, 34(): 234-238. |

| Dai An-na, Xu Lin-feng, Shui An-ze. Research and progress of solid oxide fuel cells[J]. Guisuanyan Tongbao, 2015, 34(Sup.1): 234-238. | |

| 17 | Ghang T G, Lee S M, Ahn K Y, et al. An experimental study on the reaction characteristics of a coupled reactor with a catalytic combustor and a steam reformer for SOFC systems[J]. International Journal of Hydrogen Energy, 2012, 37(4): 3234-3241. |

| 18 | Shekhawat D, Berry D A, Gardner T H, et al. Effects of fuel cell anode recycle on catalytic fuel reforming[J]. Journal of Power Sources, 2007, 168(2): 477-483. |

| 19 | 杨博然, 陈志光, 秦朝葵. 固体氧化物燃料电池(SOFC)外围热管理系统研究进展[J]. 城市燃气, 2019, 2019(3): 4-10. |

| Yang Bo-ran, Chen Zhi-guang, Qin Zhao-kui. Research progress on the peripheral thermal management system of solid oxide fuel cell (SOFC)[J]. City Gas, 2019, 2019(3): 4-10. | |

| 20 | Baek S, Kim Y, Bae J. Effect of anode-off gas recirculation at solid oxide fuel cell system[C]∥ ASME 2008 6th International Conference on Fuel Cell Science, Engineering and Technology, Denver, USA, 2008: 645-651. |

| 21 | Dietrich R U, Oelze J, Lindermeir A, et al. Efficiency gain of solid oxide fuel cell systems by using anode off-gas recycle-results for a small scale propane driven unit[J]. Journal of Power Sources, 2011, 196(17): 7152-7160. |

| 22 | Yu S, Hong D J, Lee Y D, et al. Development of a catalytic combustor for a stationary fuel cell power generation system[J]. Renewable Energy, 2010, 35(5): 1083-1090. |

| 23 | Park J, Lim H, Rhee G H, et al. Catalyst filled heat exchanger for hydrogen liquefaction[J]. International Journal of Heat & Mass Transfer, 2021, 170: No.121007. |

| 24 | 韦小雄, 张淑文, 唐萍, 等. 铝制板翅式换热器导流结构优化设计[J]. 化工设备与管道, 2011, 48(1): 13-16. |

| Wei Xiao-xiong, Zhang Shu-wen, Tang Ping, et al. Optimal design of inflow structure of aluminum plate-fin heat exchanger[J]. Chemical Equipment and Piping, 2011, 48(1):13-16. | |

| 25 | Kim J, Myung C, Lee K. Exhaust emissions and conversion efficiency of catalytic converter for an ethanol‐fueled spark ignition engine[J]. Biofuels, Bioproducts & Biorefining, 2019, 13(5): 1211-1223. |

| 26 | Venkataraman V, Pacek A W, Steinberger W R. Thermal integration of SOFC and plate heat exchanger desorber[J]. ECS Transactions, 2015, 68(1):No. 068010221. |

| 27 | 骆潮明, 李艳霞, 刘中良, 等. 低浓度甲烷在微小燃烧器中的催化燃烧实验[J]. 化工学报, 2015, 66(): 216-221. |

| Luo Chao-ming, Li Yan-xia, Liu Zhong-liang, et al. Experimental catalytic combustion of low concentration methane in a tiny burner[J]. Journal of Chemical Industry and Engineering, China, 2015, 66(Sup.1): 216-221. | |

| 28 | Leah R T, Bone A, Hammer E, et al. Development progress on the ceres power steel cell technology platform: further progress towards commercialization[J]. ECS Transactions, 2017, 78(1): 87-95. |

| 29 | Leah R T, Bone A, Lankin M, et al. Ceres power steel cell technology: rapid progress towards a truly commercially viable SOFC[J]. ECS Transactions, 2015, 68(1): No.068010095. |

| 30 | He J, Yang Z Q, Ding C L, et al. Methane dehydrogenation and oxidation process over Ni-based bimetallic catalysts[J]. Fuel, 2018, 226: 400-409. |

| [1] | Cao TAN,Hao-xin REN,Wen-qing GE,Ya-dong SONG,Jia-yu LU. Improved active disturbance rejection control for hydraulic vibration stages based on the direct-drive valve [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 84-92. |

| [2] | Yu-dai WANG,Bin WANG,Fu-sheng MIAO,Nan MA. Freezing and expansion response of lined channels under changes in hydrothermal coupling [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 256-268. |

| [3] | Wei-song YANG,An ZHANG,Wei-xiao XU,Hai-sheng LI,Ke DU. Seismic performance of stiffness enhanced metal coupling beam damper [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2469-2483. |

| [4] | Lei SHANG,Ping YANG,Xiang-guo YANG,Jian-xin PAN,Jun YANG,Meng-ru ZHANG. Temperature control of proton exchange membrane fuel cell thermal management system based on APSO-BP-PID control strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2401-2413. |

| [5] | Jian-xiao ZHENG,Wen-bo WANG,Jin-song LIU,Li-ming ZHOU,Yu LI. Moisture-electro-mechanical coupling smoothed finite element method based on asymptotic homogenization [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1876-1886. |

| [6] | Ya-ning CUI,Chun-di SI,Tao-tao FAN,Fei WANG. Analysis on crack propagation of asphalt bridge deck pavement under water-force coupling action [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1988-1996. |

| [7] | Jian-ze LIU,Jiang LIU,Min LI,Xin-jie ZHANG. Vehicle speed decoupling road identification method based on least squares [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1821-1830. |

| [8] | Hong-zhi WANG,Ting-ting WANG,Miao-miao LAN,Shuo XU. A novel sliding mode control strategy of multi-motor for robot arm based on position tracking [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1443-1458. |

| [9] | Tong-tong WAN,Hai-nian WANG,Wen-hua ZHENG,Po-nan FENG,Yu CHEN,Chen ZHANG. Thermal contraction deformation behavior of asphalt mixture overlay with coordination of unbound aggregate layer [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1045-1057. |

| [10] | Zhi-qiang HAN,Gang XIE,Ya-juan ZHUO,Zuo-long LUO,Hua-teng LI. Vibration response of continuous girder bridge based on wheel⁃deck coherent excitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 436-444. |

| [11] | Zhi-jun YANG,Chi ZHANG,Guan-xin HUANG. Mechanical model of rigid⁃flexible coupling positioning stage based on floating coordinate method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 385-393. |

| [12] | Tian-hao WANG,Bo LI,Quan-yi YU,Lin-lin XU,Guo-qiang JIA,Shan-shan GUAN. Uncertainty quantification of electric vehicle's wireless power transfer efficiency based on sparse polynomial chaos expansion method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3433-3442. |

| [13] | Lei ZHANG,Zi-mu LI,Yong-yao YAN,Fei DOU,Hong-jie LIU. Brake control algorithm for virtually coupled trains based on multi vehicle cooperation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 3027-3036. |

| [14] | Jian-qing BU,Zhi-bo GUO,Ji-ren ZHANG,Jing-chuan XUN,Xiao-ming HUANG. Finite element analysis method for mechanical properties of steel⁃concrete composite beam bridges with multiple damages [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1621-1637. |

| [15] | Jing-fu JIN,Xin-ju DONG,Zhi-cheng JIA,Kang WANG,Lian-bin HE,Meng ZOU,Ying-chun QI. Optimization of the tread plate-spring structure of flexible metal wheel with plate-spring [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 964-972. |

|

||