Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (3): 811-819.doi: 10.13229/j.cnki.jdxbgxb.20230592

Previous Articles Next Articles

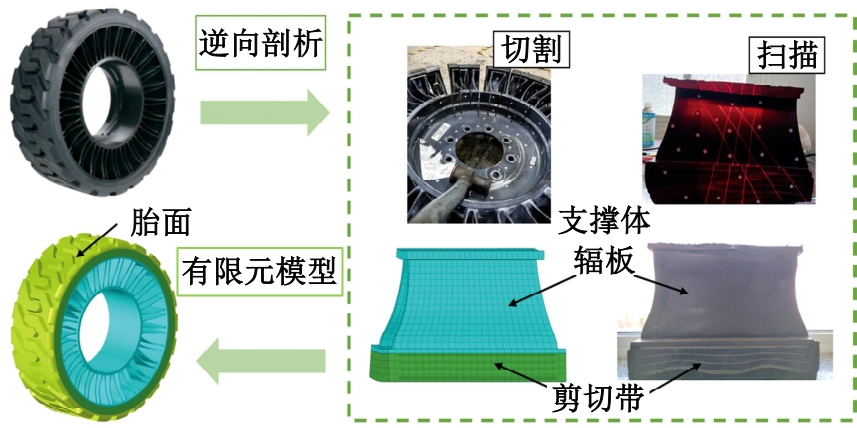

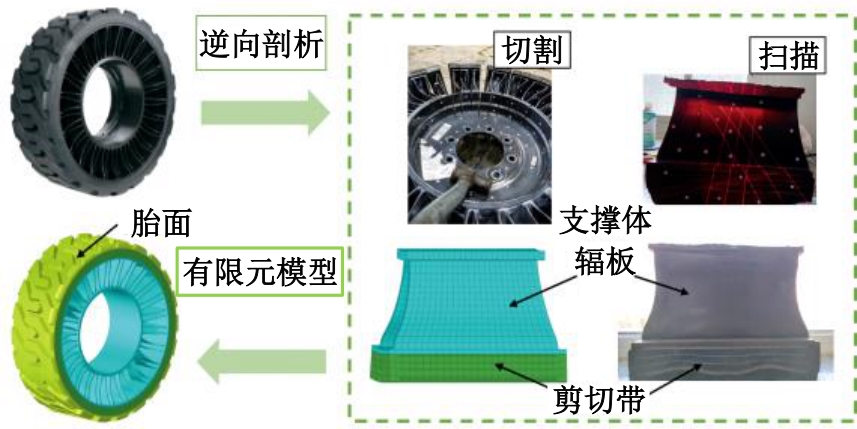

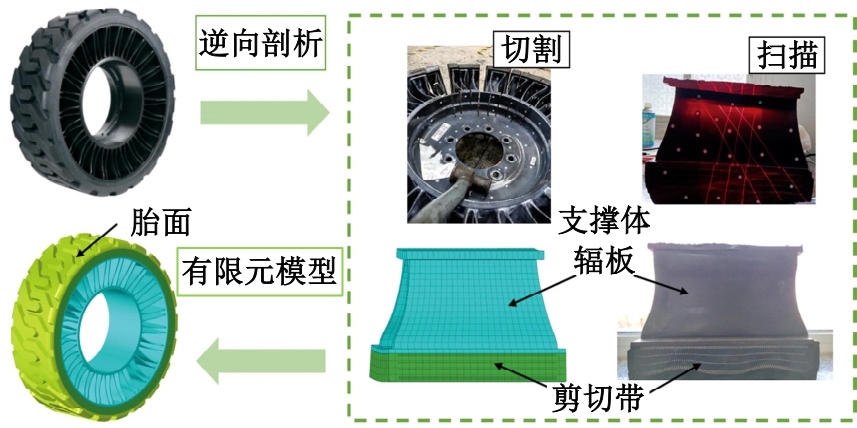

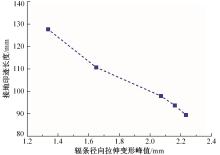

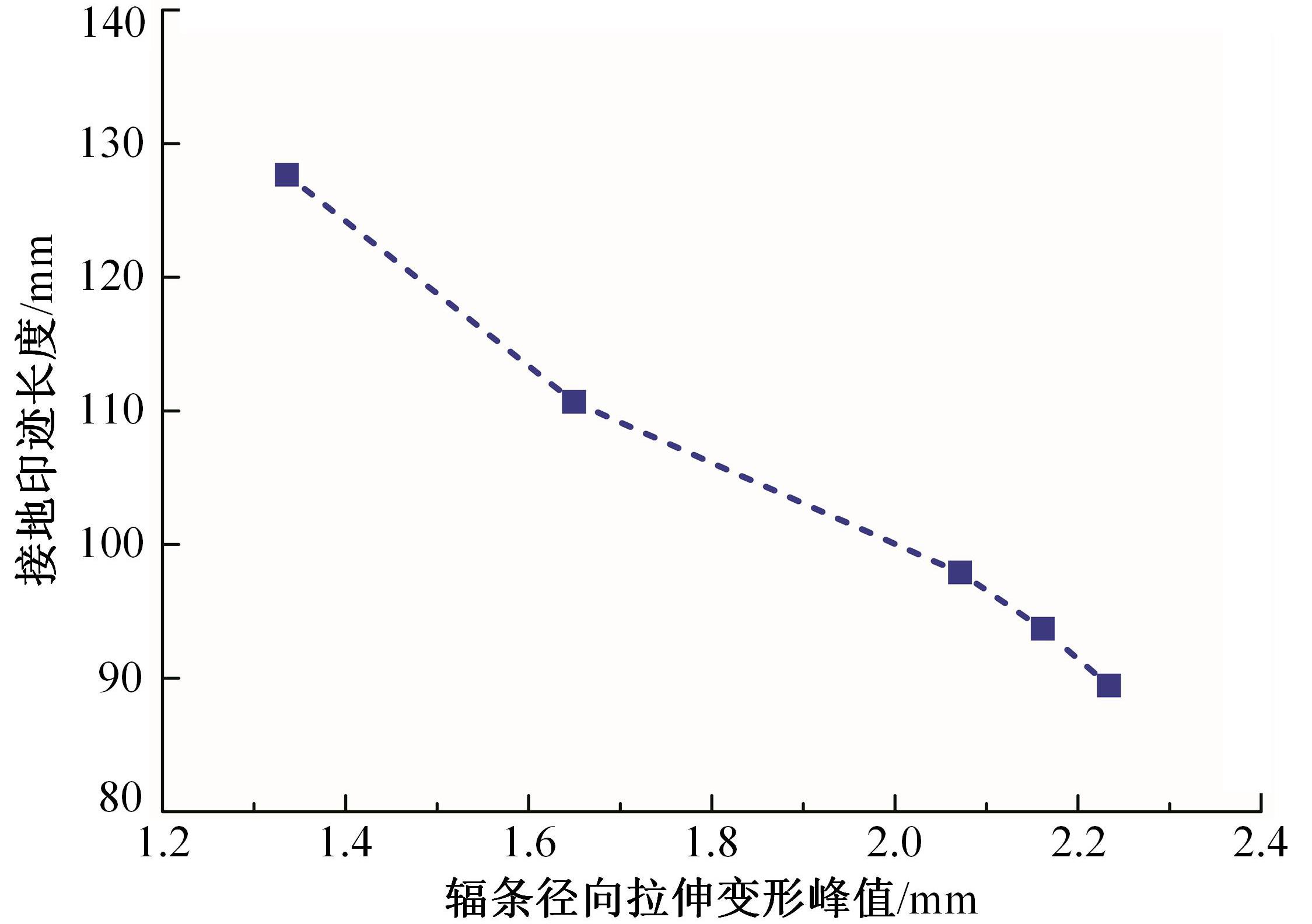

Analysis of uniform distribution characteristics of contact pressure of TWEEL tires

Dang LU( ),Xiao-fan WANG,Hai-dong WU(

),Xiao-fan WANG,Hai-dong WU( )

)

- College of Automotive Engineering,Jilin University,Changchun 130022,China

CLC Number:

- U463.34

| 1 | Kim K, Kim D M. Contact pressure of non-pneumatic tires with hexagonal lattice spokes[C]∥SAE Technical Paper, 2011-0099. |

| 2 | Cesbron J, Anfosso-Ledee F, Duhamel D, et al. Experimental study of tyre/road contact forces in rolling conditions for noise prediction[J]. Journal of Sound and Vibration, 2009, 320(1-2): 125-144. |

| 3 | Rhyne T B, Thompson R H, Cron S M, et al. Non-pneumatic tire 4[P]. United States Patent :720119,2007-04-10. |

| 4 | Cron S M, Pompier J P, Rhyne T B, et al. Non-pneumatic tire[P]. United States Patent: 7418988, 2008-09-02. |

| 5 | Rhyne T B, Cron S M. Development of a non-pneumatic wheel[J]. Tire Science and Technology, 2006, 34(3): 150-169. |

| 6 | Manesh A, Tercha M, Anderson B, et al. Tension-based non-pneumatic tire[P]. United States:8176957, 2012-02-07. |

| 7 | Manesh A, Tercha M J, Meliska B, et al. Tension-based non-pneumatic tire[P]. United States: 8176957, 2012-05-15. |

| 8 | 赵又群, 付宏勋, 林棻, 等. 非充气车轮及其力学特性研究进展[J].江苏大学学报:自然科学版,2016,37(6): 621-627. |

| Zhao You-qun, Fu Hong-xun, Lin Fen, et al. Advancement of non-pneumatic wheels and mechanical characteristics[J]. Journal of Jiangsu University (Natural Science Edition), 2016, 37(6): 621-627. | |

| 9 | Corporation Bridgestone. Non-pneumatic tire [P]. Janpan: 078538, 2013-10-22. |

| 10 | 赵颖, 宋胜, 李建重, 等. 新型负泊松比非充气轮胎设计及性能分析[J].南京理工大学学报,2021, 45(6):751-760. |

| Zhao Ying, Song Sheng, Li Jian-chong, et al. Structural design and performance analysis on novel airless tire with negative Poisson´s ratio characteristic[J]. Journal of Nanjing University of Science and Technology, 2021, 45(6): 751-760. | |

| 11 | Gasmi A, Joseph P F, Rhyne T B, et al. Closed-form solution of a shear deformable, extensional ring in contact between two rigid surfaces[J]. International Journal of Solids and Structures, 2011, 48(5): 843-853. |

| 12 | Veeramurthy M. Modeling, finite element analysis, and optimization of non-pneumatic tire (NPT) for the minimization of rolling resistance[D]. Clemson: The Graduate School, Clemson University, 2011. |

| 13 | Veeramurthy M, Ju J, Thompson L L, et al. Optimisation of geometry and material properties of a non-pneumatic tyre for reducing rolling resistance[J]. International Journal of Vehicle Design, 2014, 66(2): 193-216. |

| 14 | Aboul-Yazid A M, Emam M A A, Shaaban S, et al. Effect of spokes structures on characteristics performance of non-pneumatic tires[J]. International Journal of Automotive and Mechanical Engineering, 2015, 11(1):2212-2223. |

| 15 | Hryciow Z, Jackowski J, Żmuda M. The influence of non-pneumatic tyre structure on its operational properties[J]. International Journal of Automotive and Mechanical Engineering, 2020, 17(3): 8168-8178. |

| 16 | 付宏勋, 赵又群, 林棻, 等. 机械弹性车轮稳态侧偏特性的理论与试验分析[J].浙江大学学报:工学版,2017, 51(2): 344-349. |

| Fu Hong-xun, Zhao You-qun, Lin Fen, et al. Theoretical and experimental analysis on steady‑state cornering properties of mechanical elastic wheel[J]. Journal of Zhejiang University (Engineering Science), 2017, 51(2): 344-349. | |

| 17 | 臧利国, 赵又群, 李波, 等. 机械弹性车轮提高轮胎耐磨性和抓地性分析[J]. 农业工程学报, 2014, 30(12): 56-63. |

| Zang Li-guo, Zhao You-qun, Li Bo, et al. Mechanical elastic wheel improving road holding and wear resistance of tire[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(12): 56-63. | |

| 18 | 赵又群, 杜现斌, 林棻, 等. 侧倾角对机械弹性车轮刚度及接地特性的影响[J]. 兵工学报, 2018, 39(3):444-450. |

| Zhao You-qun, Du Xian-bin, Lin Fen, et al. Influence of camber angle on stiffness and grounding characteristics of non-pneumatic mechanical elastic wheel[J]. Acta Armamentarii, 2018, 39(3): 444-450. | |

| 19 | 周勇, 王鑫伟, 孙亚飞,等. 压电复合材料层合板弯曲变形及脱粘损伤的有限元分析[J]. 吉林大学学报:工学版, 2004, 34(2): 180-184. |

| Zhou Yong, Wang Xin-wei, Sun Ya-fei, et al. Finite element analyses for piezoelectric laminated plate in bending and actuator debonding[J]. Journal of Jilin University (Engineering and Technology Edition), 2004, 34(2): 180-184. | |

| 20 | 沈观林, 胡更开, 刘彬. 复合材料力学[M]. 2版. 北京: 清华大学出版社, 2013. |

| [1] | Jun-long QU,Wen-ku SHI,Sheng-yi XUAN,Zhi-yong CHEN. Parameter design method of multiple dynamic vibration absorbers for suppressing multi-frequency resonance of automotive powertrain [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 444-455. |

| [2] | Xin CHEN,Xiang-yuan ZHANG,Zi-tao WU,Gui-shen YU,Li-fei YANG. Effect of process sequence on tensile shear properties of PFSSW joints for automotive aluminum sheets [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 468-475. |

| [3] | Hong-yu HU,Zheng-guang ZHANG,You QU,Mu-yu CAI,Fei GAO,Zhen-hai GAO. Driver behavior recognition method based on dual-branch and deformable convolutional neural networks [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 93-104. |

| [4] | Jun-nian WANG,Yu-jing CAO,Zhi-ren LUO,Kai-xuan LI,Wen-bo ZHAO,Ying-yi MENG. Online detection algorithm of road water depth based on binocular vision [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 175-184. |

| [5] | Cao TAN,Hao-xin REN,Wen-qing GE,Ya-dong SONG,Jia-yu LU. Improved active disturbance rejection control for hydraulic vibration stages based on the direct-drive valve [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 84-92. |

| [6] | Shou-tao LI,Lu YANG,Ru-yi QU,Peng-peng SUN,Ding-li YU. Slip rate control method based on model predictive control [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2687-2696. |

| [7] | Liang WU,Yi-fan GU,Biao XING,Fang-wu MA,Li-wei NI,Wei-wei JIA. Steering four-wheel distributed integrated control method based on LQR [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2414-2422. |

| [8] | Yu-hai WANG,Xiao-zhi LI,Xing-kun LI. Predictive energy saving algorithm for hybrid electric truck under high-speed condition [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2121-2129. |

| [9] | Sheng CHANG,Hong-fei LIU,Nai-wei ZOU. H∞ loop shaping robust control of vehicle tracking on variable curvature curve [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2141-2148. |

| [10] | Jian-ze LIU,Jiang LIU,Min LI,Xin-jie ZHANG. Vehicle speed decoupling road identification method based on least squares [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1821-1830. |

| [11] | Jian-xiao ZHENG,Wen-bo WANG,Jin-song LIU,Li-ming ZHOU,Yu LI. Moisture-electro-mechanical coupling smoothed finite element method based on asymptotic homogenization [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1876-1886. |

| [12] | Xian-yi XIE,Ming-jun ZHANG,Li-sheng JIN,Bin ZHOU,Tao HU,Yu-fei BAI. Artificial bee colony trajectory planning algorithm for intelligent vehicles considering comfortable [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1570-1581. |

| [13] | Ling HUANG,Zuan CUI,Feng YOU,Pei-xin HONG,Hao-chuan ZHONG,Yi-xuan ZENG. Vehicle trajectory prediction model for multi-vehicle interaction scenario [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1188-1195. |

| [14] | Hong-yan GUO,Lian-bing WANG,Xu ZHAO,Qi-kun DAI. Joint estimation of vehicle mass and road slope considering lateral motion [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1175-1187. |

| [15] | Yu-kai LU,Shuai-ke YUAN,Shu-sheng XIONG,Shao-peng ZHU,Ning ZHANG. High precision detection system for automotive paint defects [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1205-1213. |

|

||