Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (8): 2555-2569.doi: 10.13229/j.cnki.jdxbgxb.20231227

Effect of laser surface treatment on the shear strength of aluminum-aluminum bonding joints

Gui-shen YU1,2( ),Xin CHEN2(

),Xin CHEN2( ),Yue TANG2,Chun-hui ZHAO1,Ai-jia NIU1,Hui CHAI1,Jing-xin NA2

),Yue TANG2,Chun-hui ZHAO1,Ai-jia NIU1,Hui CHAI1,Jing-xin NA2

- 1.Department of System Overall Technology,North China Vehicle Research Institute,Beijing 100072,China

2.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130012,China

CLC Number:

- U463.82

| [1] | Qbau N, Nam N D, Hien N T, et al. Development of light weight high strength aluminum alloy for selective laser melting[J]. Journal of Materials Research and Technology, 2020, 9(6): 14075-14081. |

| [2] | 王登峰, 陈宏利, 那景新, 等. 单双搭接接头经高温老化后的失效对比[J]. 吉林大学学报:工学版, 2023, 53(2): 346-354. |

| Wang Deng-feng, Chen Hong-li, Na Jing-xin, et al. Failure comparison of single and double lap joints after high temperature aging[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(2): 346-354. | |

| [3] | Martínez L V, Vargas I S, Cruz G C E, et al. Studies on the influence of surface treatment type, in the effectiveness of structural adhesive bonding, for carbon fiber reinforced composites[J]. Journal of Manufacturing Processes, 2019, 39: 160-166. |

| [4] | Li G, Lei M, Liang C, et al. Improving adhesive bonding of Al alloy by laser-induced micro&ndash [J]. Nano Structures, 2022, 12(3): 12031199. |

| [5] | Guo L, Liu J, Xia H, et al. Effects of surface treatment and adhesive thickness on the shear strength of precision bonded joints[J]. Polymer Testing, 2021, 94: 107063. |

| [6] | Rudawska A, Zaleski K, Miturska I, et al. Effect of the application of different surface treatment methods on the strength of titanium alloy sheet adhesive lap joints[J]. 2019, 12(24): 12244173. |

| [7] | Min J, Wan H, Carlson B E, et al. Application of laser ablation in adhesive bonding of metallic materials: a review[J]. Optics & Laser Technology, 2020, 128: 106188. |

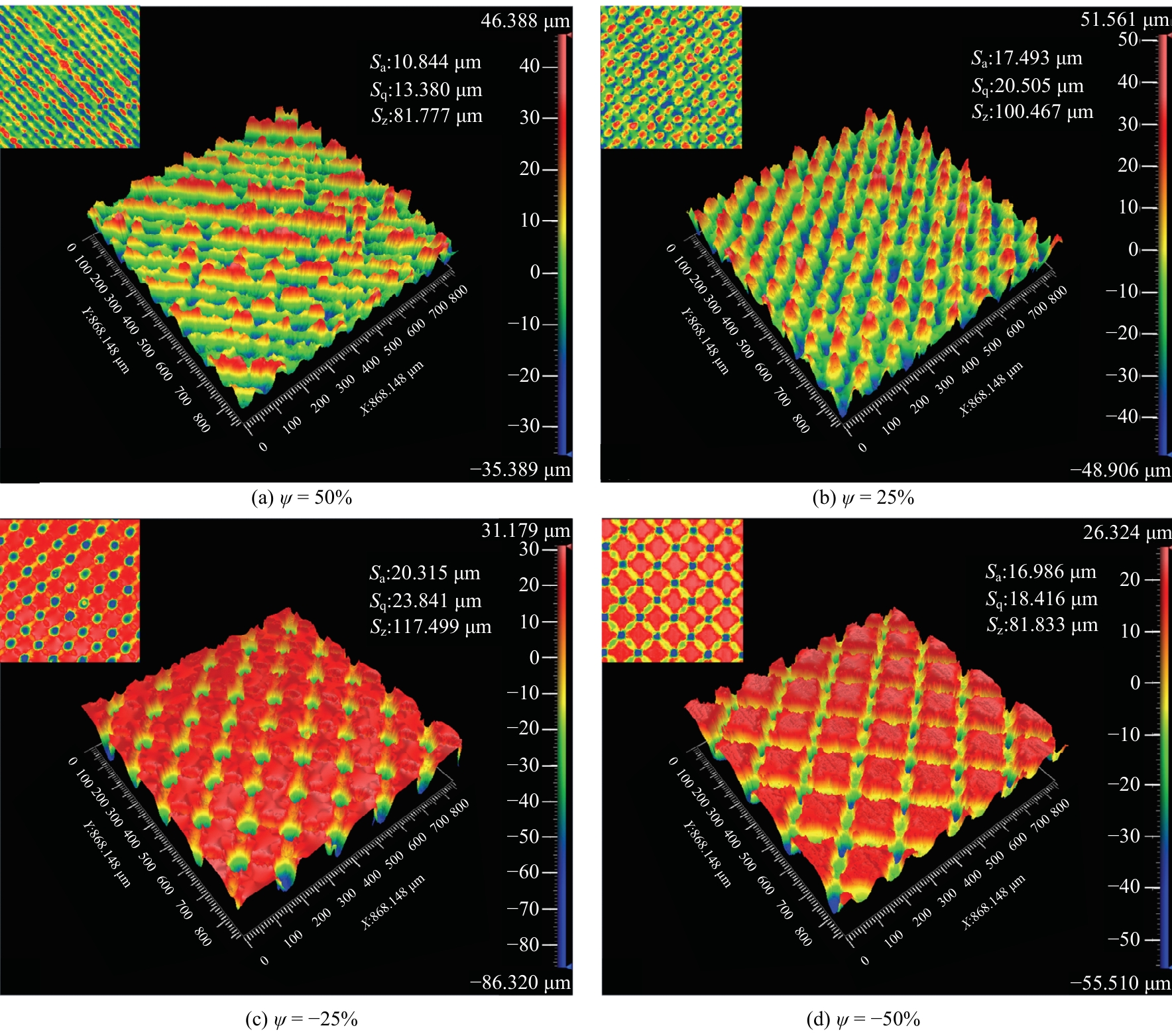

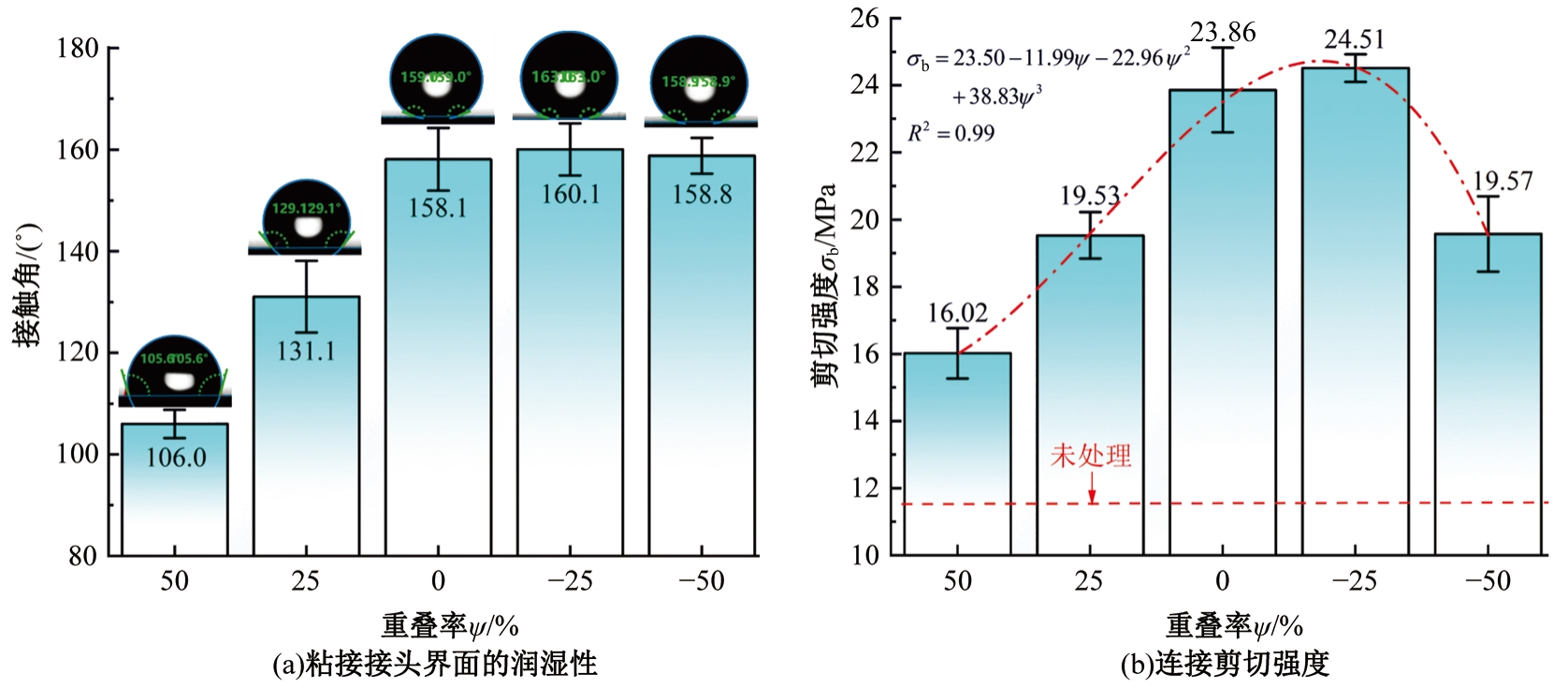

| [8] | Wan H, Min J, Lin J, et al. Effect of laser spot overlap ratio on surface characteristics and adhesive bonding strength of an Al alloy processed by nanosecond pulsed laser[J]. Journal of Manufacturing Processes, 2021, 62: 555-565. |

| [9] | Xie Y, Yang B, Lu L, et al. Shear strength of bonded joints of carbon fiber reinforced plastic (CFRP) laminates enhanced by a two-step laser surface treatment [J]. Composite Structures, 2020, 232: 111559. |

| [10] | Na J X, Mu W L, Qin G F, et al. Effect of temperature on the mechanical properties of adhesively bonded basalt FRP-aluminum alloy joints in the automotive industry[J]. International Journal of Adhesion and Adhesives, 2018, 85: 138-148. |

| [11] | Qin G, Na J, Mu W, et al. Effect of thermal cycling on the degradation of adhesively bonded CFRP/aluminum alloy joints for automobiles[J]. International Journal of Adhesion and Adhesives, 2019, 95: 102439. |

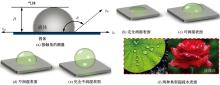

| [12] | Barthlott W, Neinhuis C. Purity of the sacred lotus, or escape from contamination in biological surfaces [J]. Planta, 1997, 202(1): 1-8. |

| [13] | Andarabi A A, Shelesh N K, Chakherlou T N. The effect of laser surface structuring patterns on the interfacial resistance of aluminum joints bonded with epoxy adhesive[J]. International Journal of Adhesion and Adhesives, 2022, 114: 103101. |

| [14] | Fan Z, Wang R, Mei X, et al. Microstructure evolution in yttria stabilized zirconia during laser hybrid induction modification [J]. Journal of Alloys and Compounds, 2019, 810: 151898. |

| [15] | Guo S, Carlson B, Hector L, et al. Increasing strength and fracture toughness of AA7075-T6 adhesively-bonded joints with laser ablation[J]. Journal of Materials Processing Technology, 2018, 259: 368-379. |

| [16] | Feng Z, Zhao H, Tan C, et al. Nanosecond laser ablation for improving the strength of CFRTP and aluminum alloy adhesively bonded joints[J]. Composite Structures, 2021, 274: 114369. |

| [1] | Jin-wu GAO,Shao-long SUN,Shun-yao WANG,Bing-zhao GAO. Speed fluctuation suppression strategy of range extender based on motor torque compensation [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(8): 2475-2486. |

| [2] | Liang FAN,Wen ZENG,Qiang WEN,Fu-yu ZHAO,Ying-ming XU. Vibration characteristics of prefabricated steel-concrete composite beam bridges with clustered grouping bolt connection and analysis of vehicle-bridge coupling [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(7): 2354-2364. |

| [3] | Mei-xia JIA,Jian-jun HU,Feng XIAO. Multi⁃physics simulation method of vehicle motor under varying working conditions based on multi⁃software combination [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1862-1872. |

| [4] | Xue-wei SONG,Ze-ping YU,Yang XIAO,De-ping WANG,Quan YUAN,Xin-zhuo LI,Jia-wen ZHENG. Research progress on the performance changes of lithium⁃ion batteries after aging [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1817-1833. |

| [5] | Chun XIAO,Zi-chun YI,Bing-yin ZHOU,Shao-rui ZHANG. Fuzzy energy management strategy of fuel cell electric vehicle based on improved pigeon⁃inspired optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1873-1882. |

| [6] | Zhen YANG,Rui-ping ZHENG,Zhe GONG. Highway infrastructure performance and traffic state prediction on road network [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1973-1983. |

| [7] | An-shun ZHANG,Wei FU,Jun-hui ZHANG,Feng GAO. Shear properties and stress-strain relationships characterization of Changsha compacted clay [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1604-1616. |

| [8] | Dang LU,Yan-ru SUO,Yu-hang SUN,Hai-dong WU. Estimation of tire camber and sideslip combined mechanical characteristics based on dimensionless expression [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1516-1524. |

| [9] | Wei-dong LI,Cao-yuan MA,Hao SHI,Heng CAO. An automatic driving decision control algorithm based on hierarchical reinforcement learning [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1798-1805. |

| [10] | Zhen-hai GAO,Cheng-yuan ZHENG,Rui ZHAO. Review of active safety verification and validation for autonomous vehicles in real and virtual scenarios [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1142-1162. |

| [11] | Tao ZHANG,Huang-da LIN,Zhong-jun YU. Real-time rolling optimization control method for gearshift of hybrid electric vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1215-1224. |

| [12] | Dang LU,Xiao-fan WANG,Hai-dong WU. Analysis of uniform distribution characteristics of contact pressure of TWEEL tires [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 811-819. |

| [13] | Chang-long ZHAO,Chen MA,Jun-bao YANG,Qin-xiang ZHAO,Xiao-yu JIA,Hong-nan MA. Influence of pre⁃set surface texture on laser cladding of 316L coatings [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 899-911. |

| [14] | Jun-long QU,Wen-ku SHI,Sheng-yi XUAN,Zhi-yong CHEN. Parameter design method of multiple dynamic vibration absorbers for suppressing multi-frequency resonance of automotive powertrain [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 444-455. |

| [15] | Xin CHEN,Xiang-yuan ZHANG,Zi-tao WU,Gui-shen YU,Li-fei YANG. Effect of process sequence on tensile shear properties of PFSSW joints for automotive aluminum sheets [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 468-475. |

|

||