Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (10): 3262-3273.doi: 10.13229/j.cnki.jdxbgxb.20231438

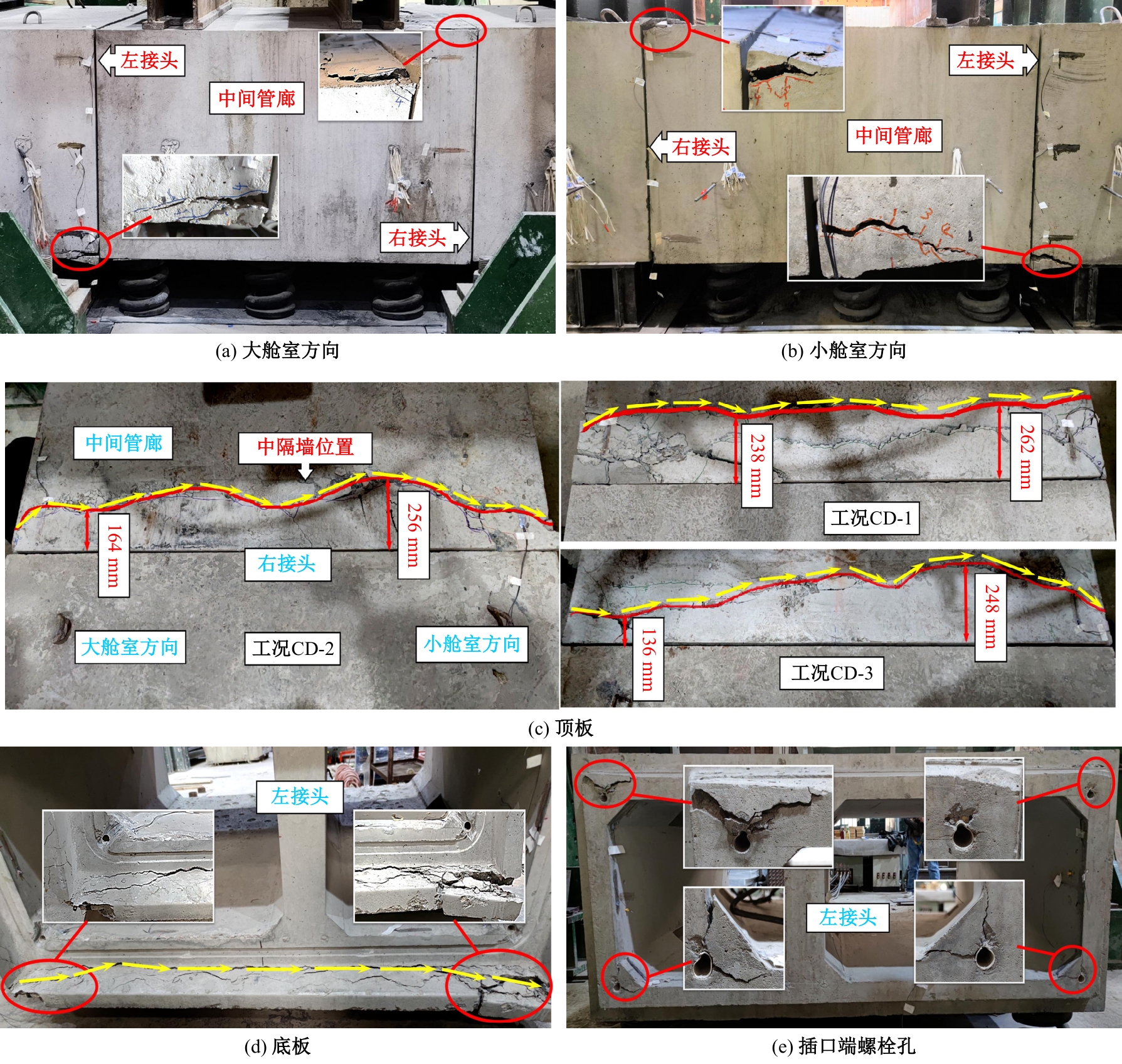

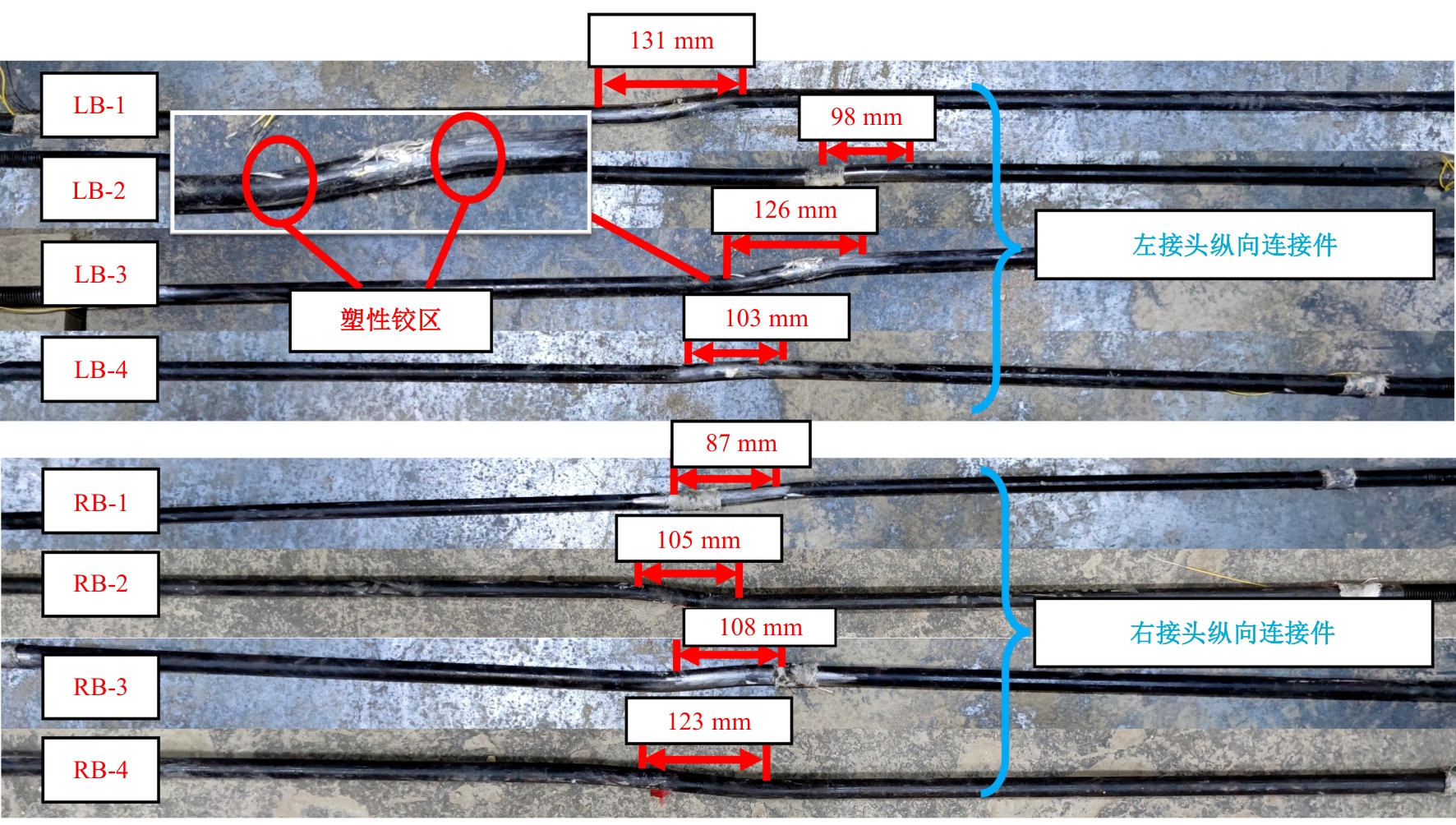

Shear deformation and failure characteristics of precast utility tunnel joints by foundation

Chao ZHANG1,2( ),Zheng-rong ZHAO1,2,You-jun XU1,2,Xu-zhi NIE1,2

),Zheng-rong ZHAO1,2,You-jun XU1,2,Xu-zhi NIE1,2

- 1.School of Civil Engineering,Inner Mongolia University of Science and Technology,Baotou 014010,China

2.Research Center of Urban Underground Engineering at Universities of Inner Mongolia,Baotou 014010,China

CLC Number:

- U451

| [1] | Hunt D V L, Nash D, Rogers C D F. Sustainable utility placement via multi-utility tunnels[J]. Tunnelling and Underground Space Technology incorporating Trenchless Technology Research, 2014, 39: 15-26. |

| [2] | Lin Z Z, Guo C C, Ni P P, et al. Experimental and numerical investigations into leakage behaviour of a novel prefabricated utility tunnel[J]. Tunnelling and Underground Space Technology incorporating Trenchless Technology Research,2020, 104: No. 103529. |

| [3] | Bai Y P, Zhou R, Wu J S. Hazard identification and analysis of urban utility tunnels in China[J]. Tunnelling and Underground Space Technology incorporating Trenchless Technology Research, 2020, 106: No.103584. |

| [4] | Wang T Y, Tan L X, Xie S Y, et al. Development and applications of common utility tunnels in China[J]. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 2018, 76: 92-106. |

| [5] | 梁荣柱, 林存刚, 夏唐代, 等. 考虑隧道剪切效应的基坑开挖对邻近隧道纵向变形分析[J]. 岩石力学与工程学报, 2017, 36(1): 223-233. |

| Liang Rong-zhu, Lin Cun-gang, Xia Tang-dai, et al. Analysis on the longitudinal deformation of tunnels due to pit excavation considering the tunnel shearing effect[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(1): 223-233. | |

| [6] | 梁荣柱, 曹世安, 向黎明, 等. 地表堆载作用下盾构隧道纵向受力机制试验研究[J]. 岩石力学与工程学报, 2023, 42(3): 736-747. |

| Liang Rong-zhu, Cao Shi-an, Xiang Li-ming, et al. Experimental investigation on longitudinal mechanical mechanism of shield tunnels subjected to ground surface surcharge[J]. Chinese Journal of Rock Mechanics and Engineering, 2023, 42(3): 736-747. | |

| [7] | 胡翔, 薛伟辰. 预制预应力综合管廊受力性能试验研究[J]. 土木工程学报, 2010, 43(5): 29-37. |

| Hu Xiang, Xue Wei-chen. Experimental study of mechanical properties of PPMT[J]. China Civil Engineering Journal, 2010, 43(5): 29-37. | |

| [8] | 闫鑫雨, 余村, 翟世鸿. 分片预制装配式管廊管片接头力学性能试验研究[J]. 四川建筑科学研究, 2017, 43(6): 28-31. |

| Yan Xin-yu, Yu Cun, Zhai Shi-hong. Experimental study on segment joint's mechanical properties of split type prefabricated municipal tunnel[J]. Sichuan Building Science, 2017, 43(6): 28-31. | |

| [9] | 王雪亮, 王鹏宇, 王述红, 等. 预制预应力管廊接头抗弯力学研究[J].现代隧道技术, 2021, 58(1): 134-140, 167. |

| Wang Xue-liang, Wang Peng-yu, Wang Shu-hong, et al. Study on the bending mechanics of precast prestressed utility tunnel joints[J]. Modern Tunnelling Technology, 2021, 58(1): 134-140, 167. | |

| [10] | 付伟庆, 聂长强, 李茂, 等.预制沟道缆线管廊接头受力性能研究[J].地下空间与工程学报, 2023, 19(6): 2028-2038. |

| Fu Wei-qing, Nie Chang-qiang, Li Mao, et al. Study on mechanical performance of prefabricated trench cable tunnel joint[J]. Chinese Journal of Underground Space and Engineering, 2023, 19(6): 2028-2038. | |

| [11] | Wang P Y, Wang S H, Israr M K, et al. Bending mechanics model and value of transverse joints in precast prestressed utility tunnel[J]. Journal of Asian Architecture and Building Engineering, 2020, 19(3): 203-219. |

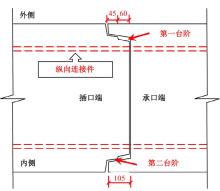

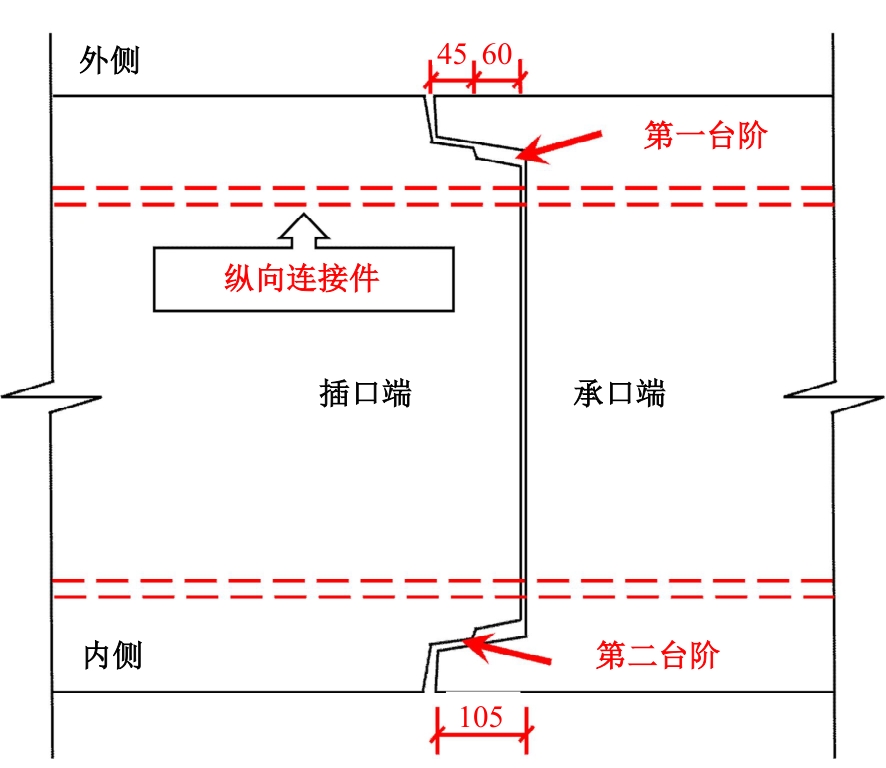

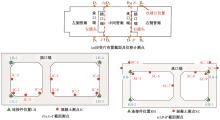

| [12] | 凌同华, 余彬, 肖南, 等. 预制拼装综合管廊承插式接头抗剪性能研究[J]. 应用基础与工程科学学报, 2023, 31(3): 741-751. |

| Ling Tong-hua, Yu Bin, Xiao Nan, et al. Shear performance of bell and spigot joint of precast utility tunnel[J]. Journal of Basic Science and Engineering, 2023, 31(3): 741-751. | |

| [13] | 凌同华, 余彬, 黄阜, 等. 预制拼装综合管廊承插式接头剪切力学性能研究[J]. 地下空间与工程学报, 2023, 19(2): 541-549. |

| Ling Tong-hua, Yu Bin, Huang Fu, et al. Shear mechanical properties of bell and spigot joint of precast utility tunnel[J]. Chinese Journal of Underground Space and Engineering, 2023, 19(2): 541-549. | |

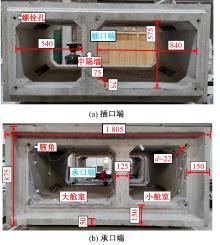

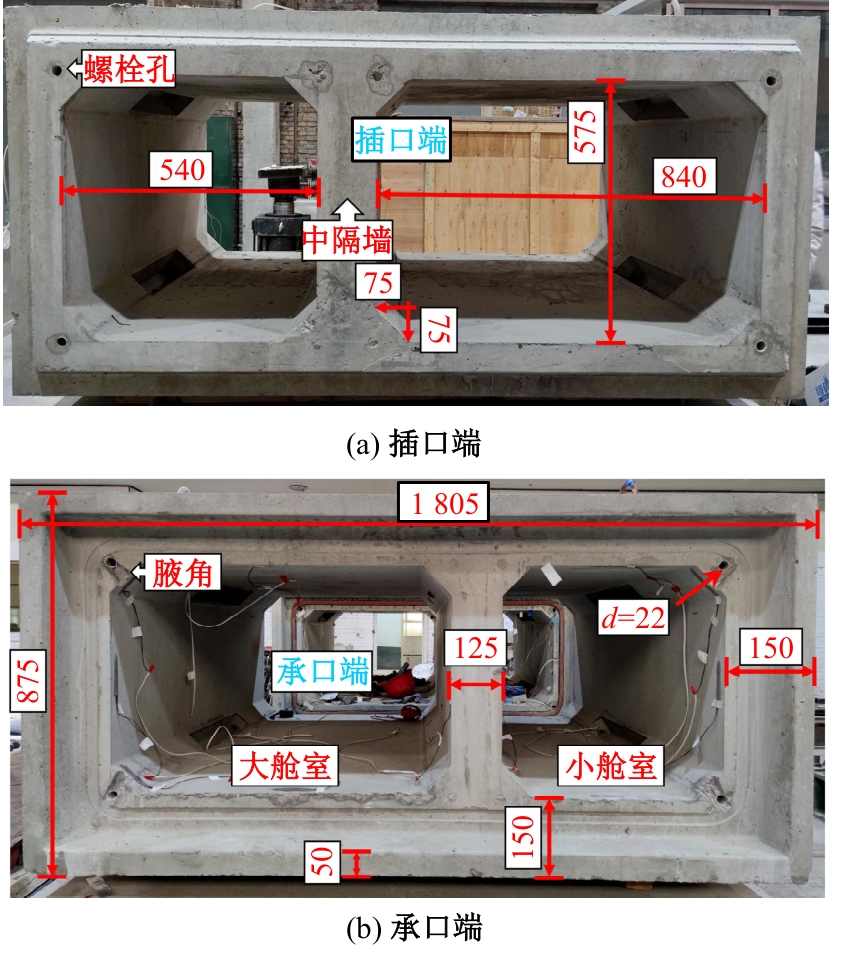

| [14] | 陈小赞, 杨灵, 张宸浩, 等.预制双舱综合管廊拼装接头力学特性数值研究[J]. 工程建设, 2018, 50(11): 8-14. |

| Chen Xiao-zan, Yang Ling, Zhang Chen-hao, et al. Numerical study on mechanical characteristics of joint of precast two-compartment utility tunnel[J]. Engineering Construction, 2018, 50(11): 8-14. | |

| [15] | 王鹏宇, 朱承金, 王述红, 等.预制管廊横向接头抗弯力学模型及取值方法[J].东北大学学报: 自然科学版, 2020, 41(5): 629-634. |

| Wang Peng-yu, Zhu Cheng-jin, Wang Shu-hong, et al. Bending mechanical model of transverse joints in precast prestressed municipal tunnel and its value method[J]. Journal of Northeastern University(Natural Science), 2020, 41(5): 629-634. | |

| [16] | 程新俊, 景立平, 崔杰, 等. 沉管隧道管节接头剪切破坏试验[J].中国公路学报, 2020, 33(4): 99-105. |

| Cheng Xin-jun, Jing Li-ping, Cui Jie, et al. Experimental failure analysis on immersed tunnel joint subjected to shear loading[J]. China Journal of Highway and Transport, 2020, 33(4): 99-105. | |

| [17] | 许有俊, 庞跃魁, 张朝, 等. 矩形顶管隧道F型承插接头剪切性能研究[J]. 浙江大学学报: 工学版, 2023, 57(5): 957-966. |

| Xu You-jun, Pang Yue-kui, Zhang Chao, et al. Shear performance of F-type socket joint in rectangular pipe jacking tunnel[J]. Journal of Zhejiang University (Engineering Science), 2023, 57(5): 957-966. | |

| [18] | 袁勇, 禹海涛, 萧文浩, 等. 沉管隧道管节接头混凝土剪力键压剪破坏试验研究[J]. 工程力学, 2017, 34(3): 149-154, 181. |

| Yuan Yong, Yu Hai-tao, Xiao Wen-hao, et al. Experimental failure analysis on concrete shear keys in immersion joint subjected to compression-shear loading[J]. Engineering Mechanics, 2017, 34(3): 149-154, 181. | |

| [19] | 赵远清, 赵怡薇, 伍云天, 等.综合管廊变形缝抗剪锚筋往复加载试验研究[J]. 土木工程学报, 2020, 53(9): 14-21. |

| Zhao Yuan-qing, Zhao Yi-wei, Wu Yun-tian, et al. Experimental study on shear anchor bars of deformation joint in utility tunnel under cyclic loading[J]. China Civil Engineering Journal, 2020, 53(9): 14-21. | |

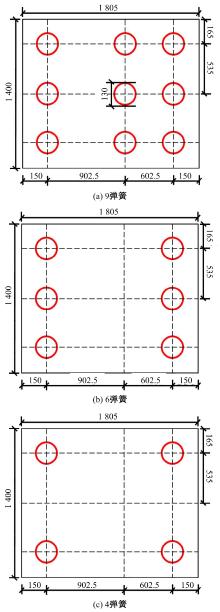

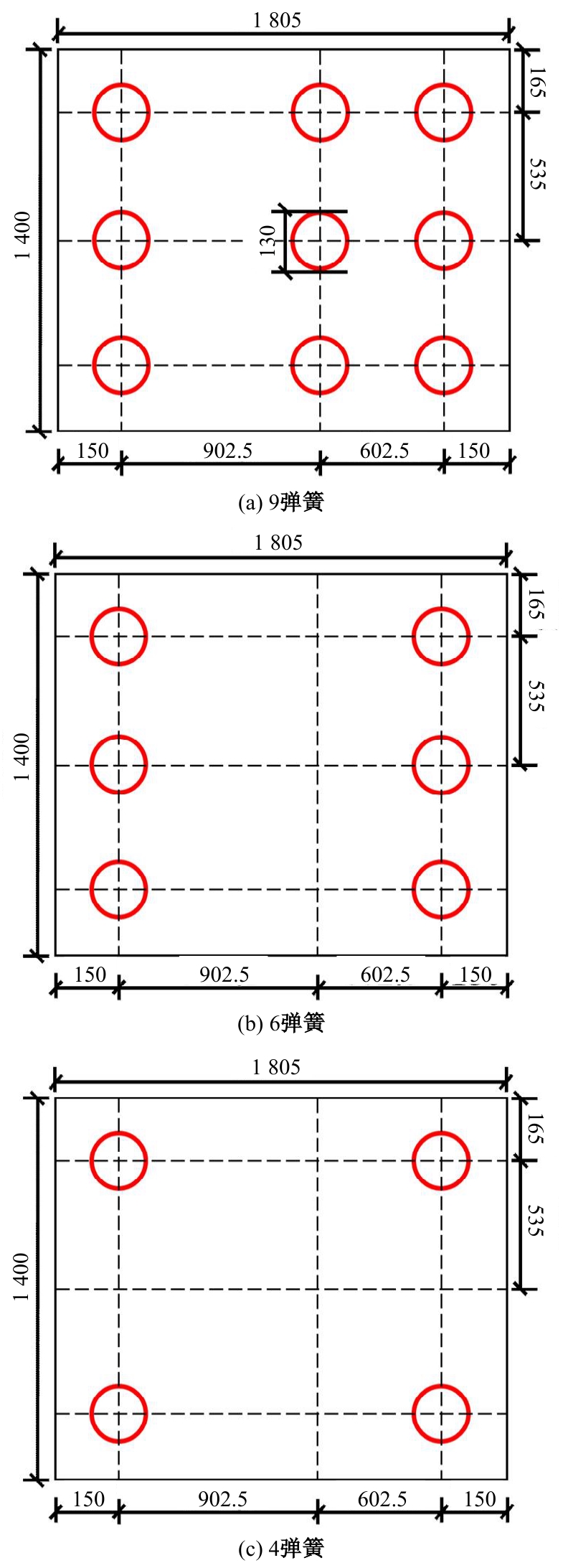

| [20] | 许成顺, 韩润波, 杜修力, 等.考虑土-结构相互作用的弹簧-地下结构体系静力推覆试验技术及其试验研究[J].建筑结构学报, 2023, 44(1): 248-258. |

| Xu Cheng-shun, Han Run-bo, Du Xiu-li, et al. Static pushover test technology and experimental study of spring-underground structure system considering soil-structure interaction[J]. Journal of Building Structures, 2023, 44(1): 248-258. | |

| [21] | 张迪, 徐幼建, 廖少明, 等. 盾构隧道凹凸榫-斜螺栓形式环缝径向顺剪抗剪刚度研究[J]. 隧道建设, 2023, 43(2): 228-239. |

| Zhang Di, Xu You-Jian, Liao Shao-ming, et al. Radial shear stiffness of circumferential joint along shear direction with concave-convex tenon and diagonal bolt in shield tunnel[J]. Tunnel Construction, 2023, 43(2): 228-239. |

| [1] | Hao ZHANG,Yi-yan CHEN,Jun-yu YE,Ju-can DONG,Qiu ZHAO. Experiment on bending-torsional performance of super- span box girders with corrugated steel webs [J]. Journal of Jilin University(Engineering and Technology Edition), 2026, 56(1): 209-218. |

| [2] | Hong-zhe ZHANG,Yu-xin JIA,Yong-jie BAO,Yu-xing YANG. Stiffness prediction model of thermoplastic composites-metal bonded-riveted hybrid joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2026, 56(1): 131-139. |

| [3] | Ling LI,Zhi-wen JIANG,Dong-hao MIAO,Miao-xia XIE,Fu-an CHENG. Stiffness characteristics of bolt connection of composite laminates under secondary bending [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(8): 2520-2529. |

| [4] | Fang-xu WANG,Shi-zhong LIU,Xia-lin YANG,Ning JIANG,Xin-yi LIU,Chi MA. Calculation method of deflection of composite box beam with considering the deformation of the steel truss web [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(8): 2619-2629. |

| [5] | Lian-lian ZHANG,Wei GUO,Feng LIU. Detection of mixed attribute features of multi-source heterogeneous data in software defined IoT [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(8): 2746-2752. |

| [6] | Gui-shen YU,Xin CHEN,Yue TANG,Chun-hui ZHAO,Ai-jia NIU,Hui CHAI,Jing-xin NA. Effect of laser surface treatment on the shear strength of aluminum-aluminum bonding joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(8): 2555-2569. |

| [7] | Shun-sheng ZHANG,Long DU,Wen-qin WANG. Low probability of interception radar waveform design based on joint coding of complementary phase and discrete chaotic frequency [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(7): 2434-2443. |

| [8] | You-sheng DENG,Zhi-gang YAO,Ya-feng GONG,Zhong-ju FENG,Long LI,Ke-qin ZHANG. Model test and calculating analysis on vertical bearing mechanism of slotted pile [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(7): 2308-2319. |

| [9] | Mei-xia JIA,Jian-jun HU,Feng XIAO. Multi⁃physics simulation method of vehicle motor under varying working conditions based on multi⁃software combination [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1862-1872. |

| [10] | Ling LI,Hui-tao TIAN,Dong-hao MIAO,Miao-xia XIE,Fu-an CHENG. Analysis of relaxation characteristics of multi-bolted connections under the transverse cyclic load [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1525-1535. |

| [11] | Mi ZHOU,Xing-wang TIAN,Guo-qiang ZHU,Lei MA. Direct shear strength of UHPC wet joints in precast piers [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(12): 3928-3941. |

| [12] | Fu-cheng ZHOU,Yuan-hai ZHANG,Yan-hong WEI. Transverse bending moment analysis considering the influence of the distortion warping stress distribution range of the corrugated steel webs [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(11): 3498-3506. |

| [13] | Lai-wei JIANG,Ce WANG,Hong-yu YANG. Review of multi-object tracking based on deep learning [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(11): 3429-3445. |

| [14] | Li-hong HAN,Yong-guo LIU. Sshear performance of cold-formed thin-wall composite steel walls with different sections [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(10): 3221-3227. |

| [15] | Hao JIANG,Zheng-wen ZHAO. Experiment on shear performance of RC beams strengthened with basalt fiber grid cement-based composites [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 211-220. |

|

||