Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (4): 1123-1141.doi: 10.13229/j.cnki.jdxbgxb.20240176

Research progress on influencing factors and material removal models for free abrasive machining

Chun-lei HE( ),Dong-yang LI,Cheng-zu REN

),Dong-yang LI,Cheng-zu REN

- School of Mechanical Engineering,Tianjin University,Tianjin 300354,China

CLC Number:

- TG519.3

| 1 | 黄卫清, 宁青双, 安大伟, 等. 压电超声辅助研磨抛光技术研究进展[J]. 压电与声光, 2020, 42(2): 240-244, 247. |

| Huang Wei-qing, Ning Qing-shuang, An Da-wei, et al. Advances in piezoelectric ultrasonic assisted grinding and polishing technology[J]. Piezoelectrics & Acoustooptics, 2020, 42(2): 240-244, 247. | |

| 2 | 万林林, 戴鹏, 刘志坚, 等. 蓝宝石超精密研磨加工研究进展[J]. 兵器材料科学与工程, 2018, 41(1):115-123. |

| Wan Lin-lin, Dai Peng, Liu Zhi-jian,et al. Research progress in ultra-precision lapping process of sapphire [J]. Ordnance Material Science and Engineering, 2018, 41(1):115-123. | |

| 3 | 徐慧敏, 王建彬, 李庆安, 等. 碳化硅晶片的化学机械抛光技术研究进展[J]. 现代制造工程, 2022(6):153-161, 116. |

| Xu Hui-min, Wang Jian-bin, Li Qing-an,et al. Research progress of chemical mechanical polishing technology of silicon carbide wafer[J]. Modern Manufacturing Engineering, 2022(6):153-161, 116. | |

| 4 | 刘宁, 朱永伟, 李学, 等. 硬脆材料平面研抛的材料去除机理研究进展[J]. 材料导报, 2022, 36(7):86-97. |

| Liu Ning, Zhu Yong-wei, Li Xue,et al. Research progress of material removal mechanism in plane lapping and polishing of hard-brittle materials[J]. Materials Review, 2022, 36(7):86-97. | |

| 5 | 李长河, 侯亚丽, 蔡光起,等. 游离磨粒精密光整加工方法综述[J]. 精密制造与自动化, 2009(1): 4-9. |

| Li Chang-he, Hou Ya-li, Cai Guang-qi, et al. Overview of precision finishing with unbonded abrasive[J]. Precise Manufacturing & Automation, 2009(1):4-9. | |

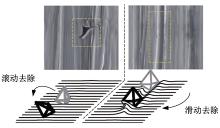

| 6 | Kang J, Hadfield M. Examination of the material removal mechanisms during the lapping process of advanced ceramic rolling elements[J]. Wear, 2005, 258(1-4): 2-12. |

| 7 | Marinescu I D, Rowe W B, Dimitrov B, et al. Tribology of Abrasive Machining Processes[M]. Norwich: William Andrew, 2004. |

| 8 | Kim H M, Park G H, Seo Y G, et al. Comparison between sapphire lapping processes using 2-body and 3-body modes as a function of diamond abrasive size[J]. Wear, 2015, 332: 794-799. |

| 9 | Evans C J, Paul E, Dornfeld D, et al. Material removal mechanisms in lapping and polishing[J]. CIRP Annals, 2003, 52(2): 611-633. |

| 10 | Zhao F, Lin B, He Y, et al. Cross-point effect of high-speed cross scratch on hard brittle materials[J]. Ceramics International, 2021, 47(7): 9317-9324. |

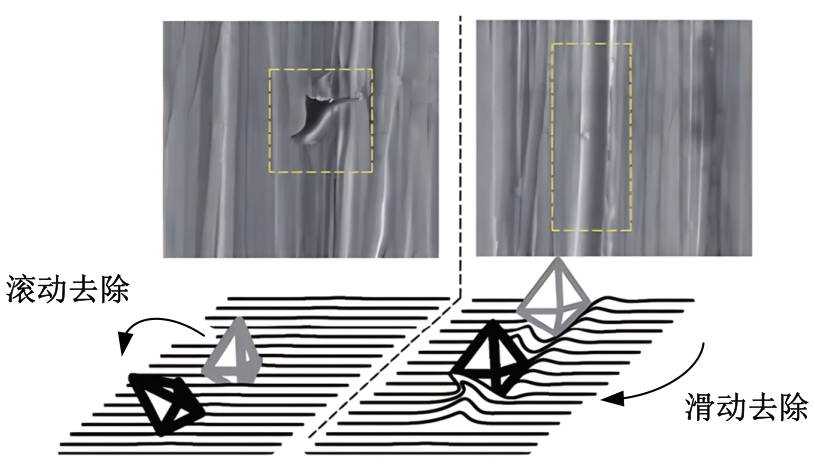

| 11 | 李琛, 张飞虎, 张宣,等. 硬脆单晶材料塑性域去除机理研究进展[J]. 机械工程学报, 2019, 55(3):181-190. |

| Li Chen, Zhang Fei-hu, Zhang Xuan,et al. Research progress of ductile removal mechanism for hard-brittle single crystal materials[J]. Journal of Mechanical Engineering, 2019, 55(3):181-190. | |

| 12 | Ya G, Qin H W, Yang S C, et al. Analysis of the rotary ultrasonic machining mechanism[J]. Journal of Materials Processing Technology, 2002, 129(1-3): 182-185. |

| 13 | 郝晓丽, 苑泽伟, 温泉,等. 超声振动辅助研磨单晶碳化硅晶片工艺研究[J]. 金刚石与磨料磨具工程, 2022, 42(3):268-274. |

| Hao Xiao-li, Yuan Ze-wei, Wen Quan,et al. Process research on ultrasonic vibration assisted lapping of single crystal silicon carbide[J]. Diamond & Abrasives Engineering, 2022, 42(3):268-274. | |

| 14 | Zhong M, Yuan J, Yao W, et al. Double-curved disc ultrasonic-assisted lapping of precision-machined crowned rollers[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97:175-188. |

| 15 | 朱子俊, 刘顺, 韩冰,等. 超声振动复合研磨K9光学玻璃工艺研究[J]. 表面技术, 2020, 49(4):74-80. |

| Zhu Zi-jun, Liu Shun, Han Bing,et al. Study on hybrid technology of ultrasonic vibration assisted abrasive lapping K9 optical glass[J]. Surface Technology, 2020, 49(4):74-80. | |

| 16 | Sambharia J, Mali H S. Recent developments in abrasive flow finishing process: a review of current research and future prospects[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2019, 233(2): 388-399. |

| 17 | 杨范轩, 孙玉利, 马杰, 等. 航空用不锈钢磨粒流光整加工表面完整性研究[J]. 南京航空航天大学学报, 2023, 55(3): 452-460. |

| Yang Fan-xuan, Sun Yu-li, Ma Jie,et al. Study on surface integrity of aviation stainless steel in abrasive flow machining[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2023, 55(3):452-460. | |

| 18 | 王家明. 微细磨粒喷射加工的机理及其实验研究[D]. 南京:南京航空航天大学机电学院, 2011. |

| Wang Jia-ming. Mechanism of micro-abrasive Jet machining and its experimental study[D]. Nanjing: College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, 2011. | |

| 19 | 谢国宏. 光学元件表面抛光创成及其形貌研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2022. |

| Xie Guo-hong. Research on surface polishing creation and surface morphology of optical element[D]. Changchun School of Mechanical and Aerospace Engineering, Jilin University, 2022. | |

| 20 | 王林. 抛光垫微观接触对化学机械抛光材料去除的影响及其跨尺度建模方法[D]. 大连:大连理工大学机械工程学院,2021. |

| Wang Lin. Effect of the micro-scale contact status on the material removal process during the chemical mechanical polishing (CMP) and crossscale modeling of the CMP process[D]. Dalian:School of Mechanical Engineering,Dalian University of Technology,2021. | |

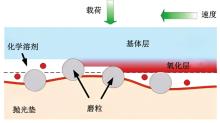

| 21 | Lee H, Lee D, Jeong H. Mechanical aspects of the chemical mechanical polishing process: a review[J]. International Journal of Precision Engineering and Manufacturing, 2016, 17: 525-536. |

| 22 | Steigerwald J M, Murarka S P, Gutmann R J, et al. Chemical processes in the chemical mechanical polishing of copper[J]. Materials Chemistry and Physics, 1995, 41(3): 217-228. |

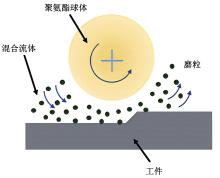

| 23 | Li M, Lyu B, Yuan J, et al. Shear-thickening polishing method[J]. International Journal of Machine Tools and Manufacture, 2015, 94: 88-99. |

| 24 | 李敏, 袁巨龙, 吴喆, 等.复杂曲面零件超精密加工方法的研究进展[J]. 机械工程学报, 2015, 51(5):178-191. |

| Li Min, Yuan Ju-long, Wu Zhe,et al. Progress in ultra-precision machining methods of complex curved parts[J]. Journal of Mechanical Engineering, 2015, 51(5): 178-191. | |

| 25 | 袁巨龙, 张飞虎, 戴一帆, 等. 超精密加工领域科学技术发展研究[J]. 机械工程学报, 2010, 46(15):161-177. |

| Yuan Ju-long, Zhang Fei-hu, Dai Yi-fan,et al. Development research of science and technologies in ultra-precision machining field[J]. Journal of Mechanical Engineering, 2010, 46(15):161-177. | |

| 26 | 李佳慧, 侯溪, 张云,等. 弹性发射光学制造技术研究进展[J].中国光学, 2021, 14(5): 1089-1103. |

| Li Jia-hui, Hou Xi, Zhang Yun,et al. Research progress of elastic emission machining in optical manufacturing[J]. Chinese Journal of Optics, 2021, 14(5):1089-1103. | |

| 27 | 肖作义. 磁粒研磨加工机理的研究[J]. 机械制造, 2004(12): 39-41. |

| Xiao Zuo-yi. Study on machining mechanism of magnetic abrasive finishing[J]. Machinery, 2004(12): 39-41. | |

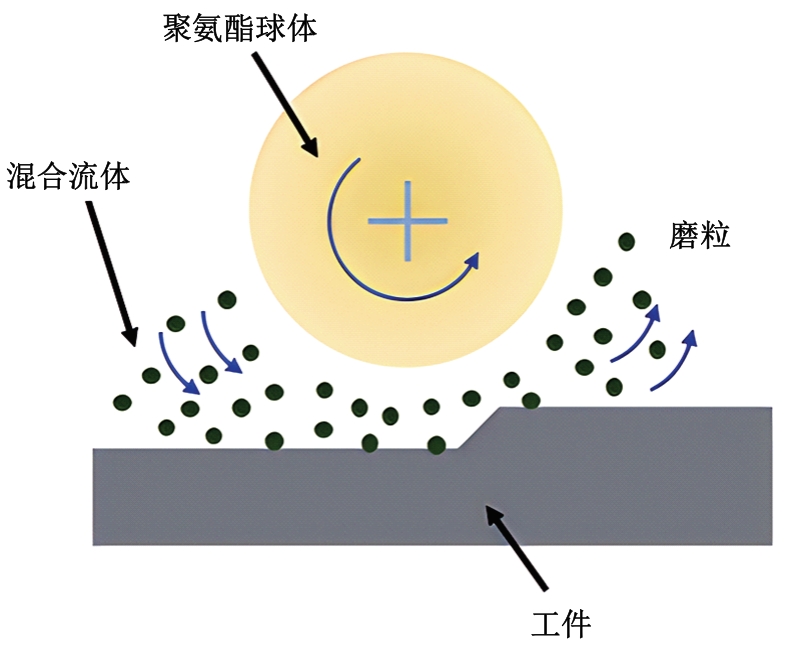

| 28 | Golini D, Kordonski W I, Dumas P, et al. Magnetorheological finishing(MRF) in commercial precision optics manufacturing[C]∥Optical Manufacturing and Testing III,Denver,USA, 1999: 80-91. |

| 29 | 王嘉琪, 肖强. 磁流变抛光技术的研究进展[J].表面技术, 2019, 48(10):317-328. |

| Wang Jia-qi, Xiao Qiang. Research progress of magnetorheological polishing technology[J]. Surface Technology, 2019, 48(10):317-328. | |

| 30 | 袁巨龙, 吴喆, 吕冰海,等. 非球面超精密抛光技术研究现状[J]. 机械工程学报, 2012, 48(23):167-177. |

| Yuan Ju-long, Wu Zhe, Bing-hai Lyu,et al. Review on ultra-precision polishing technology of aspheric surface[J]. Journal of Mechanical Engineering, 2012, 48(23):167-177. | |

| 31 | Gorana V K, Jain V K, Lal G K. Experimental investigation into cutting forces and active grain density during abrasive flow machining[J]. International Journal of Machine Tools and Manufacture, 2004, 44(2-3): 201-211. |

| 32 | Jain R K, Jain V K. Simulation of surface generated in abrasive flow machining process[J]. Robotics and Computer-Integrated Manufacturing, 1999, 15(5): 403-412. |

| 33 | Jain V K, Adsul S G. Experimental investigations into abrasive flow machining(AFM)[J]. International Journal of Machine Tools and Manufacture, 2000, 40(7): 1003-1021. |

| 34 | Jain R K, Jain V K. Specific energy and temperature determination in abrasive flow machining process[J]. International Journal of Machine Tools and Manufacture, 2001, 41(12): 1689-1704. |

| 35 | Yan B H, Tzeng H J, Huang F Y, et al. Finishing effects of spiral polishing method on micro lapping surface[J]. International Journal of Machine Tools and Manufacture, 2007, 47(6): 920-926. |

| 36 | Cong W L, Zhang P F, Pei Z J. Experimental investigations on material removal rate and surface roughness in lapping of substrate wafers: a literature review[J]. Key Engineering Materials, 2009, 404: 23-31. |

| 37 | Neauport J, Destribats J, Maunier C, et al. Loose abrasive slurries for optical glass lapping[J]. Applied Optics, 2010, 49(30): 5736-5745. |

| 38 | Asghar K, Qasim M, Das D. Effect of polishing parameters on chemical mechanical planarization of C-plane(0001) gallium nitride surface using SiO2 and Al2O3 abrasives[J]. ECS Journal of Solid State Science and Technology, 2014, 3(8): 277-284. |

| 39 | Deshpande L S, Raman S, Sunanta O, et al. Observations in the flat lapping of stainless steel and bronze[J]. Wear, 2008, 265(1-2): 105-116. |

| 40 | Kim J D, Choi M S. Stochastic approach to experimental analysis of cylindrical lapping process[J]. International Journal of Machine Tools and Manufacture, 1995, 35(1): 51-59. |

| 41 | Heisel U, Avroutine J. Process analysis for the evaluation of the surface formation and removal rate in lapping[J]. CIRP Annals, 2001, 50(1): 229-232. |

| 42 | 李国梁. 磨粒流加工工艺参数对表面质量影响的研究[D]. 大连: 大连理工大学机械工程学院, 2022. |

| Li Guo-liang. Study on the effect of process parameters on surface quality in abrasive flow machining[D]. Dalian: School of Mechanical Engineering, Dalian University of Technology, 2022. | |

| 43 | 邱腾雄, 丘永亮. k9光学玻璃磁性研磨抛光的工艺研究[J]. 机床与液压, 2016, 44(1): 112-115. |

| Qiu Teng-xiong, Qiu Yong-liang. Research of process in k9 optical glass polishing of magnetic abrasive finishing[J]. Machine Tool and Hydraulics, 2016, 44(1):112-115. | |

| 44 | 邱腾雄, 阎秋生, 高伟强, 等. 曲面磁性研磨加工的表面粗糙度特性研究[J]. 金刚石与磨料磨具工程, 2008(3):26-30. |

| Qiu Teng-xiong, Yan Qiu-sheng, Gao Wei-qiang,et al. Research on surface roughness characteristics of curved surface in magnetic abrasive finishing[J]. Diamond and Abrasives Engineering, 2008(3):26-30. | |

| 45 | 徐江. 小工具头磁流变抛光工艺及抛光轨迹研究[D]. 哈尔滨:哈尔滨工业大学机电工程学院, 2015. |

| Xu Jiang. Research on process and polishing trace of magnetorheological polishing with a small tool[D]. Harbin: School of Mechatronics Engineering, Harbin Institute of Technology, 2015. | |

| 46 | 何潮, 牛新环, 刘江皓,等. 半导体材料CMP过程中磨料的研究进展[J]. 微纳电子技术,2024, 61(1):27-40. |

| He Chao, Niu Xin-huan, Liu Jiang-hao,et al. Research progress of abrasives in semiconductor material CMP process[J]. Micronanoelectronic Technology, 2024, 61(1):27-40. | |

| 47 | Werrell J M, Mandal S, Thomas E L H, et al. Effect of slurry composition on the chemical mechanical polishing of thin diamond films[J]. Science and Technology of Advanced Materials, 2017, 18(1): 654-663. |

| 48 | Tam H Y, Cheng H B, Wang Y W. Removal rate and surface roughness in the lapping and polishing of RB-SiC optical components[J]. Journal of Materials Processing Technology, 2007, 192: 276-280. |

| 49 | Su J X, Xu R, Wang Y P, et al. Study on lapping paste of 6H-SiC single-crystal substrate in tribochemical mechanical lapping[J]. Journal of the Institution of Engineers(India): Series E, 2020, 101: 141-148. |

| 50 | 张克华, 闵力, 丁金福,等. 磨料流微去除力学分析与可控因素影响[J].中国机械工程, 2014, 25(18):2432-2438. |

| Zhang Ke-hua, Min Li, Ding Jin-fu,et al. Micro-cutting of driving force and controllable influencing factors in abrasive flow machining[J]. China Mechanical Engineering, 2014, 25(18): 2432-2438. | |

| 51 | 李俊烨, 胡敬磊, 杨兆军, 等. 离散相磨粒粒径对磨粒流研抛共轨管质量的影响[J]. 吉林大学学报:工学版, 2018, 48(2):492-499. |

| Li Jun-ye, Hu Jing-lei, Yang Zhao-jun, et al. Effect of the size of discrete phase abrasive particles on the abrasive flow polishing quality[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(2):492-499. | |

| 52 | Basim G B, Adler J J, Mahajan U, et al. Effect of particle size of chemical mechanical polishing slurries for enhanced polishing with minimal defects[J]. Journal of the Electrochemical Society, 2000, 147(9): No. 3523. |

| 53 | Li Z C, Pei Z J. Funkenbusch P D. Machining processes for sapphire wafers: a literature review[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2011, 225: 975-989. |

| 54 | Namba Y, Tsuwa H. Ultrafine finishing of sapphire single crystal[J]. ANN CIRP, 1977, 26: 325-329. |

| 55 | Su J X, Liu X L, Zhang Z Q, et al. Influence of lapping parameters on 6H-SiC crystal substrate (0001) C surface based on diamond particle[J]. Advanced Materials Research, 2012, 565: 237-242. |

| 56 | Wang Y, Xu Z, Yin S. Removal characteristics and performance of brick-shape permanent magnet-assisted magnetorheological lapping[J]. The International Journal of Advanced Manufacturing Technology, 2019, 105: 4461-4480. |

| 57 | Farahnakian M, Shahrajabian H. Experimental study on surface roughness and flatness in lapping of AISI 52100 steel[J]. International Journal of Advanced Design and Manufacturing Technology, 2016, 9(2):61-68. |

| 58 | 张争艳, 戴立达, 乔国朝. 磁流变抛光表面形貌仿真与试验研究[J]. 河北工业大学学报, 2023, 52(2):1-8. |

| Zhang Zheng-yan, Dai Li-da, Qiao Guo-chao. Simulation and experimental study on surface topography of magnetorheological polishing[J]. Journal of Hebei University of Technology, 2023, 52(2):1-8. | |

| 59 | 褚清清, 蔡瑾瑜, 李倍, 等. 无心超精研磨GCr15轴承钢圆柱滚子的圆度优化正交试验研究[J]. 科技与创新, 2023(7):16-20. |

| Chu Qing-qing, Cai Jin-yu, Li Bei,et al. Orthogonal experimental study of roundness optimization of centerless super-finish ground GCr15 bearing steel cylindrical rollers[J]. Science and Technology & Innovation, 2023(7):16-20. | |

| 60 | Sasani K, Abbasi S P, Kolian B S, et al. Relationship between concentration, time and surface roughness of GaAs wafer in lapping process: an experimental investigation[C]∥Symposium on Photonics and Optoelectronics (SOPO), Wuhan,China, 2011: 1-4. |

| 61 | Park C, Kim H, Lee S, et al. The influence of abrasive size on high-pressure chemical mechanical polishing of sapphire wafer[J]. International Journal of Precision Engineering and Manufacturing—Green Technology, 2015, 2: 157-162. |

| 62 | Cong W L, Zhang P F, Pei Z J. Experimental investigations on material removal rate and surface roughness in lapping of substrate wafers: a literature review[J]. Key Engineering Materials, 2009, 404: 23-31. |

| 63 | Deaconescu T, Deaconescu A. Developing an analytical model and computing tool for optimizing lapping operations of flat objects made of alloyed steels[J]. Materials, 2020, 13(6): No.1343. |

| 64 | 李俊烨, 乔泽民, 杨兆军, 等. 介观尺度下磨料浓度对磨粒流加工质量的影响[J]. 吉林大学学报:工学版, 2017, 47(3): 837-843. |

| Li Jun-ye, Qiao Ze-min, Yang Zhao-jun, et al. Influence of abrasive concentration on processing quality of abrasive flow in mesoscopic scale[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(3):837-843. | |

| 65 | 汤勇, 周德明, 杨钢, 等. 磨料流光整加工性研究[J].华南理工大学学报: 自然科学版, 2001, 29(9):17-19. |

| Tang Yong, Zhou De-ming, Yang Gang, et al. Machinability of abrasive flowing machining[J]. Journal of South China University of Technology(Natural Science Edition), 2001, 29(9):17-19. | |

| 66 | Tseng W T, Wang Y L. Re-examination of pressure and speed dependences of removal rate during chemical-mechanical polishing processes[J]. Journal of the Electrochemical Society, 1997, 144(2): 15-17. |

| 67 | Gullu A, Calimli H. The investigation of the effects of machining parameters on surface roughness in lapping[J]. Gazi University Journal of Science, 2005, 18(2): 229-237. |

| 68 | 邓家云. 单晶SiC电芬顿化学机械抛光机理研究[D]. 广州: 广东工业大学机电工程学院, 2022. |

| Deng Jia-yun. Mechanism of electro-fenton chemical mechanical polishing for single crystal SiC[D]. Guangzhou: School of Electromechanical Engineering, Guangdong University of Technology, 2022. | |

| 69 | 卓志佳. 单晶GaN电芬顿化学机械抛光加工机理研究[D]. 广州: 广东工业大学机电工程学院, 2022. |

| Zhuo Zhi-jia. Mechanism reserch of electro-fenton chemical mechanical polishing for single crystal GaN [D]. Guangzhou: School of Electromechanical Engineering, Guangdong University of Technology, 2022. | |

| 70 | 郑锦华, 魏新煦, 吴双, 等. 载荷及研磨颗粒粒径对金属表面微孔织构的影响[J]. 机械工程学报, 2017, 53(7): 200-206. |

| Zheng Jin-hua, Wei Xin-xu, Wu Shuang, et al. Influence of load and size of abrasive particle on micro-pore texture on metal surface[J]. Journal of Mechanical Engineering, 2017, 53(7): 200-206. | |

| 71 | 郑宸曦, 陈书凝, 张鑫龙. 磨料流光整加工理论与技术研究进展[J]. 表面技术, 2024(17): 17-40, 111. |

| Zheng Chen-xi, Chen Shu-ning, Zhang Xin-long, et al. Research progress of theory and technology in abrasive flow machining[J]. Surface Technology, 2024(17):17-40, 111. | |

| 72 | Chang K Y, Song Y H, Lin T R. Analysis of lapping and polishing of a gauge block[J]. The International Journal of Advanced Manufacturing Technology, 2002, 20: 414-419. |

| 73 | Li Y, Lai M, Fang F. Effects of polishing speed and a water environment on the mechanism of nanometric mechanical polishing of single-crystal lutetium oxide[J]. Materials Today Communications, 2022, 30:No. 103194. |

| 74 | Ye K, Wang J, Gao H, et al. Optimization of lapping process parameters of CP-Ti based on PSO with mutation and BPNN[J]. The International Journal of Advanced Manufacturing Technology, 2021, 117(9-10): 2859-2866. |

| 75 | Kala P, Pandey P M. Experimental investigations into ultrasonic-assisted double-disk magnetic abrasive finishing of two paramagnetic materials[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2017, 231(6):1021-1038. |

| 76 | 舒坤, 孙岩, 陈燕. 超声振动辅助磁粒研磨技术的研究进展[J]. 振动与冲击, 2023, 42(6): 39-54, 78. |

| Shu Kun, Sun Yan, Chen Yan. Review of research progress on ultrasonic assisted magnetic abrasive finishing technology[J]. Journal of Vibration and Shock, 2023, 42(6): 39-54, 78. | |

| 77 | Jha S, Jain V K. Modeling and simulation of surface roughness in magnetorheological abrasive flow finishing(MRAFF) process[J]. Wear, 2006, 261(7-8): 856-866. |

| 78 | 肖强, 王嘉琪, 靳龙平. 磁流变抛光表面粗糙度建模与仿真[J]. 工具技术, 2022, 56(4): 52-59. |

| Xiao Qiang, Wang Jia-qi, Jin Long-ping. Modeling and simulation of surface roughness in magnetorheological finishing[J]. Tool Engineering, 2022, 56(4):52-59. | |

| 79 | Yao C, Wang C, Niu X, et al.The stability of a novel weakly alkaline slurry of copper interconnection CMP for GLSI[J]. Journal of Semiconductors, 2018, 39(2): 82-89. |

| 80 | Yin T, Wang Z D, Kurokawa S, et al. Characteristic of SiC slurry in ultra precision lapping of sapphire substrates[J]. International Journal of Precision Engineering and Manufacturing, 2021, 22(6): 1021-1029. |

| 81 | Khanna A J, Gupta S, Kumar P, et al. Study of agglomeration behavior of chemical mechanical polishing slurry under controlled shear environments[J]. ECS Journal of Solid State Science and Technology, 2018, 7(5): 238-242. |

| 82 | 阎秋生, 徐沛杰, 路家斌, 等. 硅溶胶抛光液稳定性及对SiC化学机械抛光的影响[J]. 半导体技术, 2018, 43(9): 664-668. |

| Yan Qiu-sheng, Xu Pei-jie, Lu Jia-bin,et al. Stability of colloidal silica polishing solution and its effect on SiC chemical mechanical polishing[J]. Semiconductor Technology, 2018, 43(9): 664-668. | |

| 83 | 程佳宝, 石芸慧, 牛新环,等. CMP抛光液中SiO2磨料分散稳定性的研究进展[J]. 微纳电子技术, 2024, 61(2): 31-41. |

| Cheng Jia-bao, Shi Yun-hui, Niu Xin-huan,et al. Research progress on dispersion stability of SiO2 abrasive in CMP slurr[J]. Micronanoelectronic Technology, 2024, 61(2): 31-41. | |

| 84 | Luo Q, Ramarajan S, Babu S V. Modification of the preston equation for the chemical-mechanical polishing of copper[J]. Thin Solid Films, 1998, 335(1-2): 160-167. |

| 85 | Luo Q, Campbell D R, Babu S V. Chemical-mechanical polishing of copper in alkaline media[J]. Thin Solid Films, 1997, 311(1-2): 177-182. |

| 86 | Wei H, Peng C, Gao H, et al. On establishment and validation of a new predictive model for material removal in abrasive flow machining[J]. International Journal of Machine Tools and Manufacture, 2019, 138: 66-79. |

| 87 | 薛进学, 贾松阳, 杨柏松. 贯穿式超精研圆锥滚子的研磨特性分析[J].制造业自动化, 2016,38(1):33-37. |

| Xue Jin-xue, Jia Song-yang, Yang Bai-song. The polish properties analysis of through-feed superfinishing tapered roller[J]. Manufacturing Automation, 2016, 38(1):33-37. | |

| 88 | Cheng K, Shao Y, Jadva M, et al. Development of the improved preston equation for abrasive flow machining of aerofoil structures and components[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2019, 233(9): 1397-1404. |

| 89 | Zhao B, Shi F G. Chemical mechanical polishing: threshold pressure and mechanism[J]. Electrochemical and Solid-State Letters, 1998, 2(3):No. 145. |

| 90 | Runnels S R. Feature-scale fluid-based erosion modeling for chemical-mechanical polishing[J]. Journal of the Electrochemical Society, 1994, 141(7): 1900-1904. |

| 91 | Luo J, Dornfeld D A. Effects of abrasive size distribution in chemical mechanical planarization: modeling and verification[J]. IEEE Transactions on Semiconductor Manufacturing, 2003, 16(3): 469-476. |

| 92 | Sundararajan S, Thakurta D G, Schwendeman D W, et al. Two-dimensional wafer-scale chemical mechanical planarization models based on lubrication theory and mass transport[J]. Journal of the Electrochemical Society, 1999, 146(2): 761-766. |

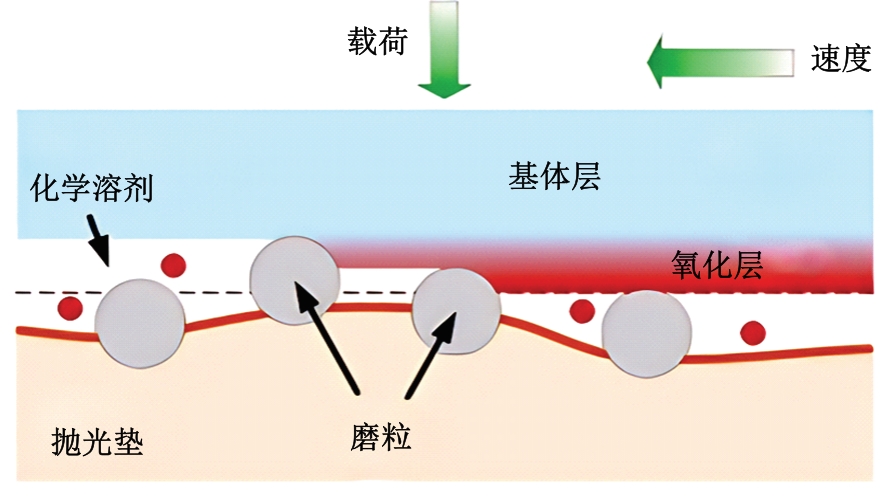

| 93 | 李敏, 吕冰海, 袁巨龙,等. 剪切增稠抛光的材料去除数学模型[J]. 机械工程学报, 2016, 52(7):142-151. |

| Li Min, Bing-hai Lyu, Yuan Ju-long,et al. Material removal mathematics model of shear thickening polishing[J]. Journal of Mechanical Engineering, 2016, 52(7):142-151. | |

| 94 | 张峰. 磁流变抛光数学模型的建立[J]. 光学技术, 2000(2): 190-192. |

| Zhang Feng. Oundation of mathematics model of magnetorheological finishing[J]. Optical Technique, 2000(2): 190-192. | |

| 95 | 张学成, 戴一帆, 李圣怡,等. 基于CFD的磁射流抛光去除机理分析[J]. 国防科技大学学报, 2007(4):110-115. |

| Zhang Xue-cheng, Dai Yi-fan, Li Sheng-yi,et al. Analysis of material removal mechanism in magnetorheological jet polishing by CFD[J]. Journal of National University of Defense Technology, 2007(4):110-115. | |

| 96 | Zhou F, Yao W, Yuan J, et al. Establishment of material removal model for lapping ceramic balls with variable-radius groove plate[J]. The International Journal of Advanced Manufacturing Technology, 2020, 111: 2577-2587. |

| 97 | Farsakoglu O F, Kocabas H, Bayar M, et al. Lapping with loose abrasives in lens manufacturing[C]∥Current Developments in Lens Design and Optical Systems Engineering, San Diego,USA, 2000: 451-460. |

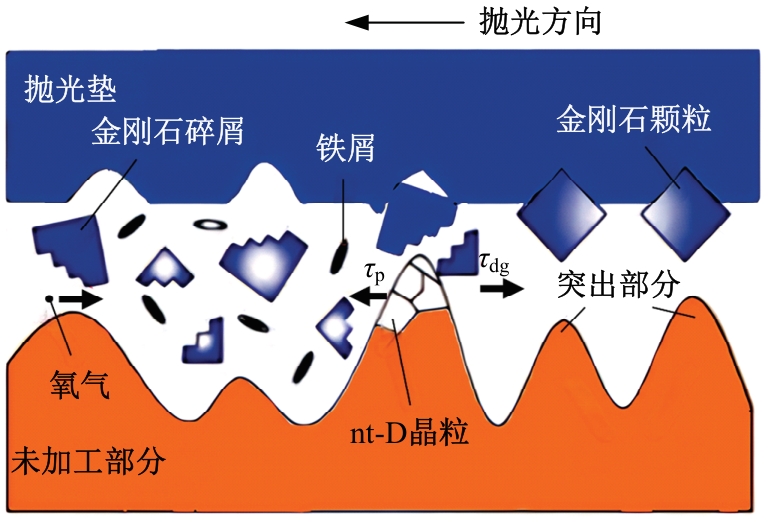

| 98 | Jin T, Ma M, Li B, et al. Mechanical polishing of ultrahard nanotwinned diamond via transition into hard sp2-sp3 amorphous carbon[J]. Carbon, 2020, 161: 1-6. |

| 99 | Luo J, Dornfeld D A. Material removal mechanism in chemical mechanical polishing: theory and modeling[J]. IEEE Transactions on Semiconductor Manufacturing, 2001, 14(2): 112-133. |

| 100 | Suratwala T, Feit M, Steele W, et al. Microscopic removal function and the relationship between slurry particle size distribution and workpiece roughness during pad polishing[J]. Journal of the American Ceramic Society, 2014, 97(1): 81-91. |

| 101 | Suratwala T I, Feit M D, Steele W A. Toward deterministic material removal and surface figure during fused silica pad polishing[J]. Journal of the American Ceramic Society, 2010, 93(5): 1326-1340. |

| 102 | Suratwala T, Steele W, Feit M, et al. Relationship between surface μ-roughness and interface slurry particle spatial distribution during glass polishing[J]. Journal of the American Ceramic Society, 2017, 100(7): 2790-2802. |

| 103 | Hu Y, Shi D, Hu Y, et al. Investigation on the material removal and surface generation of a single crystal SiC wafer by ultrasonic chemical mechanical polishing combined with ultrasonic lapping[J]. Materials, 2018, 11(10): 1-13. |

| 104 | Kordonski W, Gorodkin S. Material removal in magnetorheological finishing of optics[J]. Applied Optics, 2011, 50(14): 1984-1994. |

| 105 | 彭小强, 戴一帆, 李圣怡. 磁流变抛光的材料去除数学模型[J]. 机械工程学报, 2004(4): 67-70. |

| Peng Xiao-qiang, Dai Yi-fan, Li Sheng-yi. Material removal model of magnetorheological finishing[J]. Chinese Journal of Mechanical Engineering, 2004(4):67-70. | |

| 106 | Lee J W, Ha S J, Cho Y K, et al. Investigation of the polishing characteristics of metal materials and development of micro MR fluid jet polishing system for the ultra precision polishing of micro mold pattern[J]. Journal of Mechanical Science and Technology, 2015, 29: 2205-2211. |

| 107 | 郭继通, 郑方志, 徐成宇,等. 基于遗传算法和神经网络的软脆工件研磨加工工艺智能决策系统[J]. 表面技术, 2020, 49(4): 23-29, 46. |

| Guo Ji-tong, Zheng Fang-zhi, Xu Cheng-yu,et al. Intelligent decision system for lapping process of soft and brittle workpiece based on genetic algorithm and neural network[J]. Surface Technology, 2020, 49(4):23-29, 46. | |

| 108 | 潘杰, 陈凡, 杨炜,等. 基于SPSO–BP神经网络的自适应抛光工艺参数匹配[J]. 表面技术, 2022, 51(8): 387-399. |

| Pan Jie, Chen Fan, Yang Wei,et al. Adaptive polishing process parameter matching based on SPSO-BP neural network[J]. Surface Technology, 2022, 51(8):387-399. | |

| 109 | Jain R K, Jain V K, Kalra P K. Modelling of abrasive flow machining process: a neural network approach[J]. Wear, 1999, 231(2): 242-248. |

| 110 | 卞达, 宋恩敏, 倪自丰,等. 基于响应面法的单晶硅CMP抛光工艺参数优化[J]. 金刚石与磨料磨具工程, 2022, 42(6): 745-752. |

| Bian Da, Song En-min, Ni Zi-feng,et al. Optimization of CMP processing parameters for Si based on response surface method[J]. Diamond & Abrasives Engineering, 2022, 42(6): 745-752. |

| [1] | Guang-bao LI,Dong GAO,Yong LU,Hao PING,Yuan-yuan ZHOU. Internal surface treatment of gas-liquid-solid technology based on improved neural network and Fluent [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1537-1547. |

| [2] | Xiao-hua ZHAO,Chang LIU,Hang QI,Ju-shang OU,Ying YAO,Miao GUO,Hai-yi YANG. Influencing factors and heterogeneity analysis of highway traffic accidents [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 987-995. |

| [3] | Zheng-wei GU,Pan ZHANG,Dong-ye LYU,Chun-li WU,Zhong YANG,Guo-jin TAN,Xiao-ming HUANG. Earthquake⁃induced residual displacement analysis of simply supported beam bridge based on numerical simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1711-1718. |

| [4] | Jing GUO,Lin GUI,Wei HOU,Jun-ye LI,Zhi-bao ZHU,Li-wei SUN. Quality analysis of abrasive flow precision machining of cross hole of valve sleeve [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3367-3378. |

| [5] | Yong-hui SHANG,Lin-rong XU,Zhao-feng CHEN. Consolidation characteristics and influencing factors of rigid pile-raft foundation of high-speed railway [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1588-1597. |

| [6] | Hai-xiao WANG,Yong-xiang LI,Xu DING,Bao-hua ZHANG. Traffic safety prediction of urban underpass tunnel vehicles based on edge intelligence [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1337-1343. |

| [7] | Liang JIANG,Yi HE. Risky driving behavior and influencing factors analysis for electric two⁃wheeler [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1107-1113. |

| [8] | LI Jun-ye, HU Jing-lei, YANG Zhao-jun, ZHANG Xin-ming, ZHOU Zeng-wei. Effect of the size of discrete phase abrasive particles on the abrasive flow polishing quality of common rail pipe [J]. 吉林大学学报(工学版), 2018, 48(2): 492-499. |

| [9] | LI Jun-ye, QIAO Ze-min, YANG Zhao-jun, ZHANG Xin-ming. Influence of abrasive concentration on processing quality of abrasive flow in mesoscopic scale [J]. 吉林大学学报(工学版), 2017, 47(3): 837-843. |

| [10] | GUO Zhe-feng, TANG Wen-cheng. Stress analysis of cup-shaped parts in secondary deep drawing [J]. 吉林大学学报(工学版), 2016, 46(2): 494-499. |

| [11] | WEI Li-ying,WU Rong-hua,WANG Zhi-long,ZHU Jian-hui. Lane-changing behavior based on mixed traffic flow [J]. 吉林大学学报(工学版), 2014, 44(5): 1321-1326. |

| [12] | XIN Da-bo, WANG Liang, DUAN Zhong-dong, OU Jin-ping, LI Hui, LI Zhong-hua. Static characteristics of bridge deck sections of long-span bridges under simultaneous actions of wind and rain [J]. 吉林大学学报(工学版), 2011, 41(增刊2): 174-179. |

| [13] | ZHOU Zhu-ping,REN Gang,WANG Wei. Hierarchical structure model for modal split [J]. 吉林大学学报(工学版), 2009, 39(增刊2): 116-0120. |

| [14] | WANG Yun-peng, KUI Hai-lin, TONG Jin, DUAN Qiu-shi, REN Lu-quan . Influencing Factors of the Contact Interfaces between Cement Concrete and its Working Parts [J]. 吉林大学学报(工学版), 2003, (1): 56-59. |

|