Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1653-1662.doi: 10.13229/j.cnki.jdxbgxb20190514

Effect of Ti addition on microstructure and mechanical properties of ductile iron

Jin-guo WANG1,2( ),Zhi-qiang WANG1,2,Shuai REN1,2,Rui-fang YAN1,2,Kai HUANG1,2,Jin GUO1,2

),Zhi-qiang WANG1,2,Shuai REN1,2,Rui-fang YAN1,2,Kai HUANG1,2,Jin GUO1,2

- 1.Key Laboratory of Automotive Materials Ministry of Education, Jilin University, Changchun 130022, China

2.College of Materials Science and Engineering, Jilin University, Changchun 130022, China

CLC Number:

- TG143.5

| 1 | 李艳霞, 王文韶, 刘俊友, 等. 钛含量对中铬铸铁组织和性能的影响[J]. 材料导报, 2015, 29(1): 406-408, 416. |

| Li Yan-xia, Wang Wen-shao, Liu Jun-you, et al. Influences of Ti content on microstructure and property of medium-chromium cast iron[J]. Materials Reports, 2015, 29(1): 406-408, 416. | |

| 2 | 钟兵. 高Ti对灰铸铁组织及性能的影响[J]. 铸造技术, 2017, 38(8): 1949-1952. |

| Zhong Bing. Influence of high Ti on microstructure and properties of gray cast iron[J]. Foundry Technology, 2017, 38(8): 1949-1952. | |

| 3 | 赵玉谦, 方世杰, 赵宇光, 等. (Ti,Fe)-Al-C体系钢铁基复合材料的热力学计算与分析[J]. 吉林大学学报: 工学版, 2005, 35(4): 343-347. |

| Zhao Yu-qian, Fang Shi-jie, Zhao Yu-guang, et al. Thermodynamic calculation and analysis of steel matrix composite of(Ti, Fe)-Al-C system[J]. Journal of Jilin University(Engineering and Technology Edition), 2005, 35(4): 343-347. | |

| 4 | 赵宇光, 姜启川, 任露泉, 等. Fe-C-Ti-Mn合金系中TiC原位生成反应的热力学分析[J]. 吉林大学学报: 工学版, 2004, 34(1): 1-6. |

| Zhao Yu-guang, Jiang Qi-chuan, Ren Lu-quan, et al. Thermodynamic analysis on in-situ TiC synthesis in Fe-C-Ti-Mn system[J]. Journal of Jilin University(Engineering and Technology Edition), 2004, 34(1): 1-6. | |

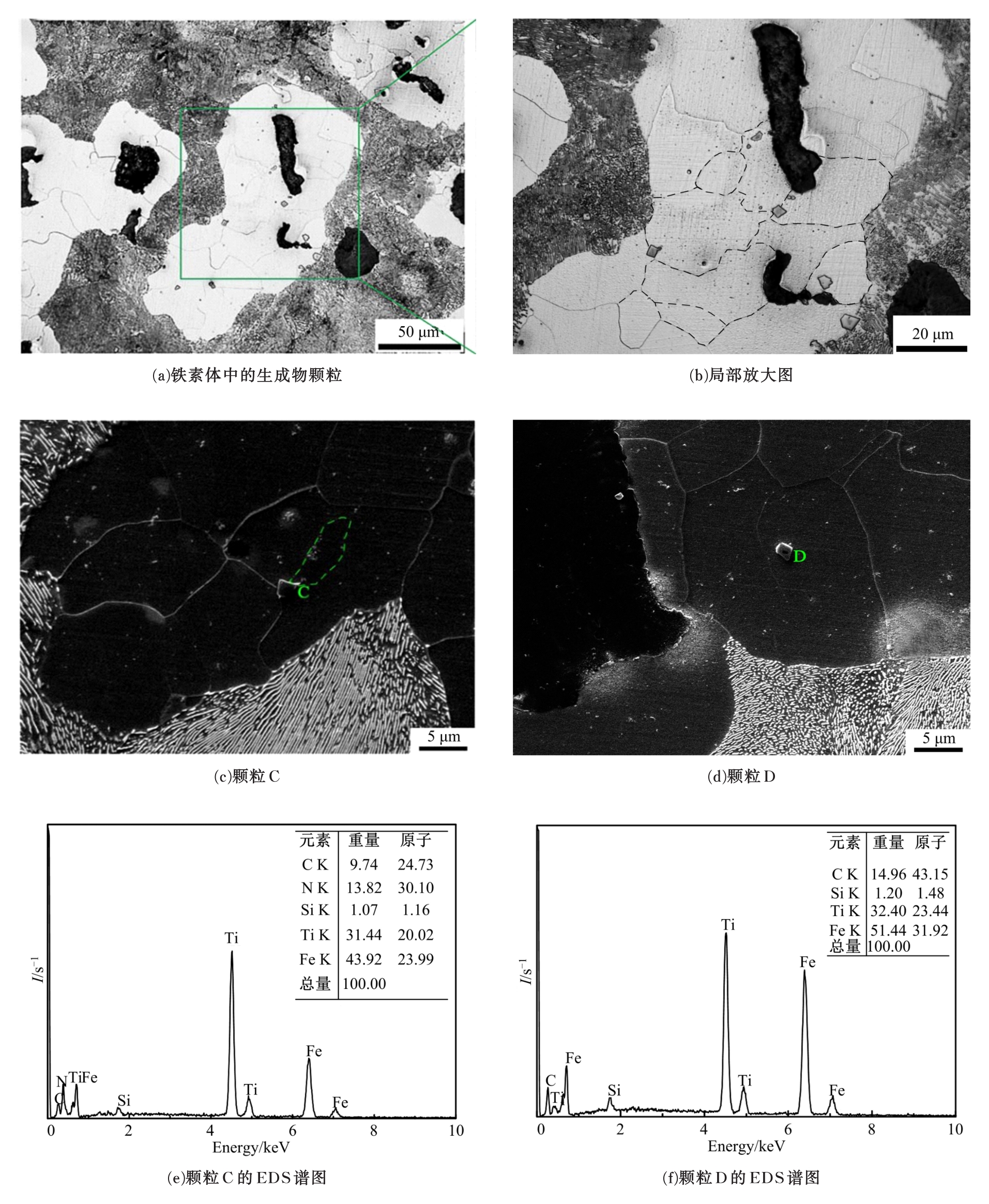

| 5 | 郭文涛, 陈淑英, 李青春, 等. 球墨铸铁中含Ti夹杂物的研究[J]. 铸造, 2012, 61(1): 92-96. |

| Guo Wen-tao, Chen Shu-ying, Li Qing-chun, et al. Study on Ti-inclusions in ductile iron[J]. China Foundry, 2012, 61(1): 92-96. | |

| 6 | 吕维洁, 杨志峰, 张荻, 等. 原位合成钛基复合材料增强体TiC的微结构特征[J]. 中国有色金属学报, 2002, 12(3): 511-516. |

| Lv Wei-jie, Yang Zhi-feng, Zhang Di, et al. Microstructural characterization of TiC in in situ synthesized titanium matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 511-516. | |

| 7 | Lv W J, Zhang D, Zhang X N, et al. Growth mechanism of reinforcements in in-situ synthesized(TiB+TiC)/Ti composites[J]. Transactions of Nonferrous Metals Society of China, 2001, 11(1): 67-71. |

| 8 | Li Y, Li Y Q, Fruehan R J. Foamation of titanium carbonitride from hot metal[J]. ISIJ International, 2001, 41(12): 1417-1422. |

| 9 | 申志清, 田学雷, 郑洪亮, 等. 球墨铸铁石墨球核心组成及形核机制的研究[J]. 铸造, 2012, 61(4): 357-361. |

| Shen Zhi-qing, Tian Xue-lei, Zheng Hong-liang, et al. Phase composition and nucleation mechanism of spheroidal graphite nucleus in ductile iron[J]. China Foundry, 2012, 61(4): 357-361. | |

| 10 | Fraś E, Górny M. Inoculation effects of cast iron[J]. Arichives of Foundry Engineering, 2012, 12(4): 39-46. |

| 11 | Xu Z M, Liang G F, Guan Q F, et al. TiC as heterogeneous nuclei of the(Fe, Mn)3C and austenite intergrowth eutectic in austenite steel matrix wear resistant composite[J]. Materials Research Bulletin, 2003, 39(3): 457-463. |

| 12 | 韩悦. 内生纳米/亚微米TiC增强铁基复合材料组织与力学性能[D]. 长春: 吉林大学材料科学与工程学院, 2016. |

| Han Yue. Microstructures and mechanical properties of in situ synthesized nano/sub-micron-sized TiC reinforced iron composites[D]. Changchun: School of Materials Science and Engineering, Jilin University, 2016. | |

| 13 | 陈刚, 毛永锋, 赵玉涛, 等. 一种原位碳化钛颗粒增强铁基复合材料及其制备方法[P]. 中国: CN201210054540.9, 2012-07-18. |

| 14 | 刘志科. 原位合成铁基复合材料的微结构特征、生长机制以及界面反应机理的研究[D]. 南宁: 广西大学机械工程学院, 2009. |

| Liu Zhi-ke. Study on the microstructure, grow mechanism of reinforcement and interface in in situ synthesized ferrous matrix composite[D]. Nanning: College of Mechanical Engineering, Guangxi University, 2009. |

| [1] | Wei LAN,Jiang LIU,Li XIN,Jing-xi LI,Xing-jun HU,Jing-yu WANG,Tao SANG. Influence of rearview mirror styling on water phase distribution on side windows [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1590-1599. |

| [2] | Fang-wu MA,Li HAN,Liang WU,Jin-hang LI,Long-fan YANG. Damping optimization of heavy⁃loaded anti⁃vibration platform based on genetic algorithm and particle swarm algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1608-1616. |

| [3] | Chang-qing DU,Xi-liang CAO,Biao HE,Wei-qun REN. Parameters optimization of dual clutch transmission based on hybrid particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1556-1564. |

| [4] | Ji-qing CHEN,Qing-sheng LAN,Feng-chong LAN,Zhao-lin LIU. Trajectory tracking control based on tire force prediction and fitting [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1565-1573. |

| [5] | Zhi-gang YANG,Ya-jun FAN,Chao XIA,Shi-jun CHU,Xi-zhuang SHAN. Drag reduction of a square⁃back Ahmed model based on bi⁃stable wake [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1635-1644. |

| [6] | Zhe SHEN,Yi-gang WANG,Zhi-gang YANG,Yin-zhi HE. Drift error correction of unknown sound source in wind tunnel using approximation method [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1584-1589. |

| [7] | Zhao LIU,Jiang-lin CHENG,Yu-tian ZHU,Li-hui ZHENG. Vertical vibration modeling and motion correlation analysis of rail vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1600-1607. |

| [8] | Hong-liang XIANG,Sheng-tao CHEN,Li-ping DENG,Wei ZHANG,Tu-sheng ZHAN. Microstructure and properties of microalloying 2205 duplex stainless steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1645-1652. |

| [9] | Jian WANG,Xin XU,Han GU,Duo-jun ZHANG,Sheng-ji LIU. Heating characteristics of DOC based on exhaust thermal management of diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 408-416. |

| [10] | Xiang-jun YU,Yuan-hui HUAI,Xue-fei LI,De-wu WANG,An YU. Shoveling trajectory planning method for wheel loader based on kriging and particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 437-444. |

| [11] | Wei WANG,Jian-ting ZHAO,Kuan-rong HU,Yong-cang GUO. Trajectory tracking of robotic manipulators based on fast nonsingular terminal sliding mode [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 464-471. |

| [12] | Chang-bin DONG,Yong-ping LIU,Yong-qiao WEI,Hai-qing DENG,Jie Xu. Analysis of nonlinear dynamic characteristic of elliptic gear transmission system [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 483-493. |

| [13] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Experimental of loading-bearing capacity of one-way laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 654-667. |

| [14] | Yun-wei ZHAO,De-xu GENG,Xiao-min LIU,Qi LIU. Implementation and stability on turning with constant radius of pneumatic flexible hexapod robot [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 472-482. |

| [15] | Qian-hui PU,Jing-wen LIU,Gang-yun ZHAO,Meng YAN,Xiao-bin LI. Theoretical analysis of bearing capacity of concrete eccentric compressive column reinforced by HTRCS [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 606-612. |

|

||