Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (3): 716-724.doi: 10.13229/j.cnki.jdxbgxb20200838

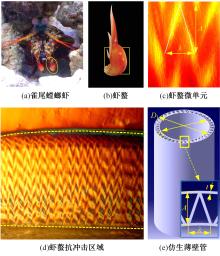

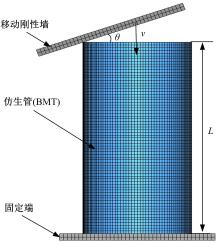

Crashworthiness investigation and optimization of bionic multi⁃cell tube based on shrimp chela

Han HUANG1( ),Qing-hao YAN1,Zhi-xin XIANG1,Xin-tao YANG1,Jin-bao CHEN1,Shu-cai XU2(

),Qing-hao YAN1,Zhi-xin XIANG1,Xin-tao YANG1,Jin-bao CHEN1,Shu-cai XU2( )

)

- 1.Academy of Astronautics,Nanjing University of Aeronautics and Astronautics,Nanjing 211106,China

2.State Key Laboratory of Automotive Safety and Energy,Tsinghua University,Beijing 100084,China

CLC Number:

- TB17

| 1 | Baroutaji A, Sajjia M, Olabi A G. On the crashworthiness performance of thin-walled energy absorbers: recent advances and future developments[J]. Thin-Walled Structures, 2017, 118: 137-163. |

| 2 | 周俊先, 秦睿贤, 陈秉智. 双面梯度多角薄壁结构的吸能特性[J]. 吉林大学学报:工学版, 2019, 49(5):1584-1592. |

| Zhou Jun-xian, Qin Rui-xian, Chen Bing-zhi. Energy absorption properties of multi-corner thin-walled columns with double surface gradients[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5):1584-1592. | |

| 3 | Tran T N. Crushing analysis under multiple impact loading cases for multi-cell triangular tubes[J]. Thin-Walled Structures, 2017, 113:262-272. |

| 4 | Chen T T, Zhang Y, Lin J M, et al. Theoretical analysis and crashworthiness optimization of hybrid multi-cell structures[J]. Thin-Walled Structures, 2019, 142:116-131. |

| 5 | Li Z X, Ma W, Xu P, et al. Crashworthiness of multi-cell circumferentially corrugated square tubes with cosine and triangular configurations[J]. International Journal of Mechanical Sciences, 2020, 165: No.105205. |

| 6 | Song J F, Xu S C, Wang H X, et al. Bionic design and multi-objective optimization for variable wall thickness tube inspired bamboo structures[J]. Thin-Walled Structures, 2018, 125: 76-88. |

| 7 | 白芳华, 张林伟, 白中浩, 等. 基于甲虫鞘翅的客车八边形仿生多胞薄壁管耐撞性研究[J]. 振动与冲击, 2019, 38(21):24-30. |

| Bai Fang-hua, Zhang Lin-wei, Bai Zhong-hao, et al. Crashworthiness of coach's octagonal bionic multi-cell thin-walled tubes based on beetle elytra[J]. Journal of Vibration and Shock, 2019, 38(21):24-30. | |

| 8 | Zhang L W, Bai Z H, Bai F H. Crashworthiness design for bio-inspired multi-cell tubes with quadrilateral, hexagonal and octagonal sections[J]. Thin-Walled Structures, 2018, 122:42-51. |

| 9 | 邹猛, 于用军, 张荣荣, 等. 仿牛角结构薄壁管吸能特性仿真分析[J]. 吉林大学学报:工学版,2015,45(6):1863-1868. |

| Zou Meng, Yu Yong-jun, Zhang Rong-rong, et al. Simulation analysis of energy-absorption properties of thin-walled tube based on horn structure[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(6): 1863-1868. | |

| 10 | Xu Tao, Liu Nian, Yu Zheng-lei, et al. Crashworthiness design for bionic bumper structures inspired by cattail and bamboo[J/OL]. [2020-10-25]. |

| 11 | Liu S T, Tong Z Q, Tang Z L, et al. Bionic design modification of non-convex multi-corner thin-walled columns for improving energy absorption through adding bulkheads[J]. Thin-Walled Structures, 2015, 88: 70-81. |

| 12 | Weaver J C, Milliron G W, Miserez A, et al. The stomatopod dactyl club: a formidable damage-tolerant biological hammer[J]. Science, 2012, 336(6086): 1275-1280. |

| 13 | Yaraghi N A, Guarín‐Zapata N, Grunenfelder L K, et al. A sinusoidally architected helicoidal biocomposite[J]. Advanced Materials, 2016, 28(32): 6835-6844. |

| 14 | Patek S N, Korff W L, Caldwell R L. Biomechanics: deadly strike mechanism of a mantis shrimp[J]. Nature, 2004, 428(6985):819-820. |

| 15 | Huang H, Xu S C. Crashworthiness analysis and bionic design of multi-cell tubes under axial and oblique impact loads[J]. Thin-Walled Structures, 2019, 144(C): No.106333. |

| 16 | Yin H F, Xiao Y Y, Wen G L, et al. Multiobjective optimization for foam-filled multi-cell thin-walled structures under lateral impact[J]. Thin-Walled Structures, 2015, 94:1-12. |

| 17 | Barakat S, Bani-Hani K, Taha M Q. Multi-objective reliability-based optimization of prestressed concrete beams[J]. Structural Safety, 2004, 26(3): 311-342. |

| [1] | Bin-xiang JIANG,Tong-tong JIANG,Yong-lei WANG. Optimization of consensus algorithm for drug detection block chain based on cultural genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 684-692. |

| [2] | Li-jie ZHANG,Xi-ta A,Xiao TIAN,Wen LI. Multi⁃objective optimization design of accelerated degradation test based on Gamma process [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 361-367. |

| [3] | Zheng-lei YU,Li-xin CHEN,Ze-zhou XU,Ren-long XIN,Long MA,Jing-fu JIN,Zhi-hui ZHANG,Shan JIANG. Analysis of mechanical characteristics and recovery characteristics of bionic protective structures based on additive manufacturing [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1540-1547. |

| [4] | Zheng-lei YU,Ren-long XIN,Li-xin CHEN,Yi-ning ZHU,Zhi-hui ZHANG,Qing CAO,Jing-fu JIN,Jie-liang ZHAO. Load bearing characteristics of honeycomb protection structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1140-1145. |

| [5] | Bing-hai ZHOU,Zhao-xu HE. Static semi⁃kitting strategy⁃based multi⁃objective just⁃in⁃time material distribution scheduling [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 910-916. |

| [6] | Bao-feng SUN,Xin-xin REN,Zai-si ZHENG,Guo-yi Li. Multi⁃objective flow shop optimal scheduling considering worker's load [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 900-909. |

| [7] | Ji-cheng HUANG,Cheng SHEN,Ai-min JI,Xian-wang LI,Bin ZHANG,Kun-peng TIAN,Hao-lu LIU. Optimization of cutting⁃conveying key working parameters of hemp harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 772-780. |

| [8] | Bing-hai ZHOU,Qiong WU. Balancing and bi⁃objective optimization of robotic assemble lines [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 720-727. |

| [9] | Fang-wu MA,Li HAN,Liang WU,Jin-hang LI,Long-fan YANG. Damping optimization of heavy⁃loaded anti⁃vibration platform based on genetic algorithm and particle swarm algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1608-1616. |

| [10] | Xue-shen CHEN,Tao CHEN,Tao WU,Xu MA,Ling-chao ZENG,Lin-tao CHEN. Design and experiment on harvester for winter planting potato of straw coverage [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 749-757. |

| [11] | Yin-ping LI,Tian-xu JIN,Li LIU. Design and dynamic characteristic simulation of pantograph⁃catenary continuous energy system for pure electric LHD [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 454-463. |

| [12] | Fang-wu MA,Hong-yu LIANG,Ying ZHAO,Meng YANG,Yong-feng PU. Multi⁃objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 29-35. |

| [13] | Zhong-yi CAI,Fan-xiang MENG,Qing-min CHEN,Xuan ZHAO. Preform optimization for near-net-shape forming process of complex knuckle forging [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 84-90. |

| [14] | Chun-bao LIU,Shan-shi CHEN,Chuang SHENG,Zhi-hui QIAN,Lu-quan REN,Lei REN. Bionic hydraulic driving mechanism of spider and its bio⁃inspiration [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 375-381. |

| [15] | Fu-chun JIA,Xian-jie MENG,Yu-long LEI. Optimal design of two degrees of freedom dynamic vibration absorber based on multi-objective genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1969-1976. |

|

||