Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (6): 1281-1291.doi: 10.13229/j.cnki.jdxbgxb20210008

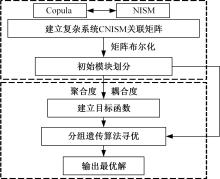

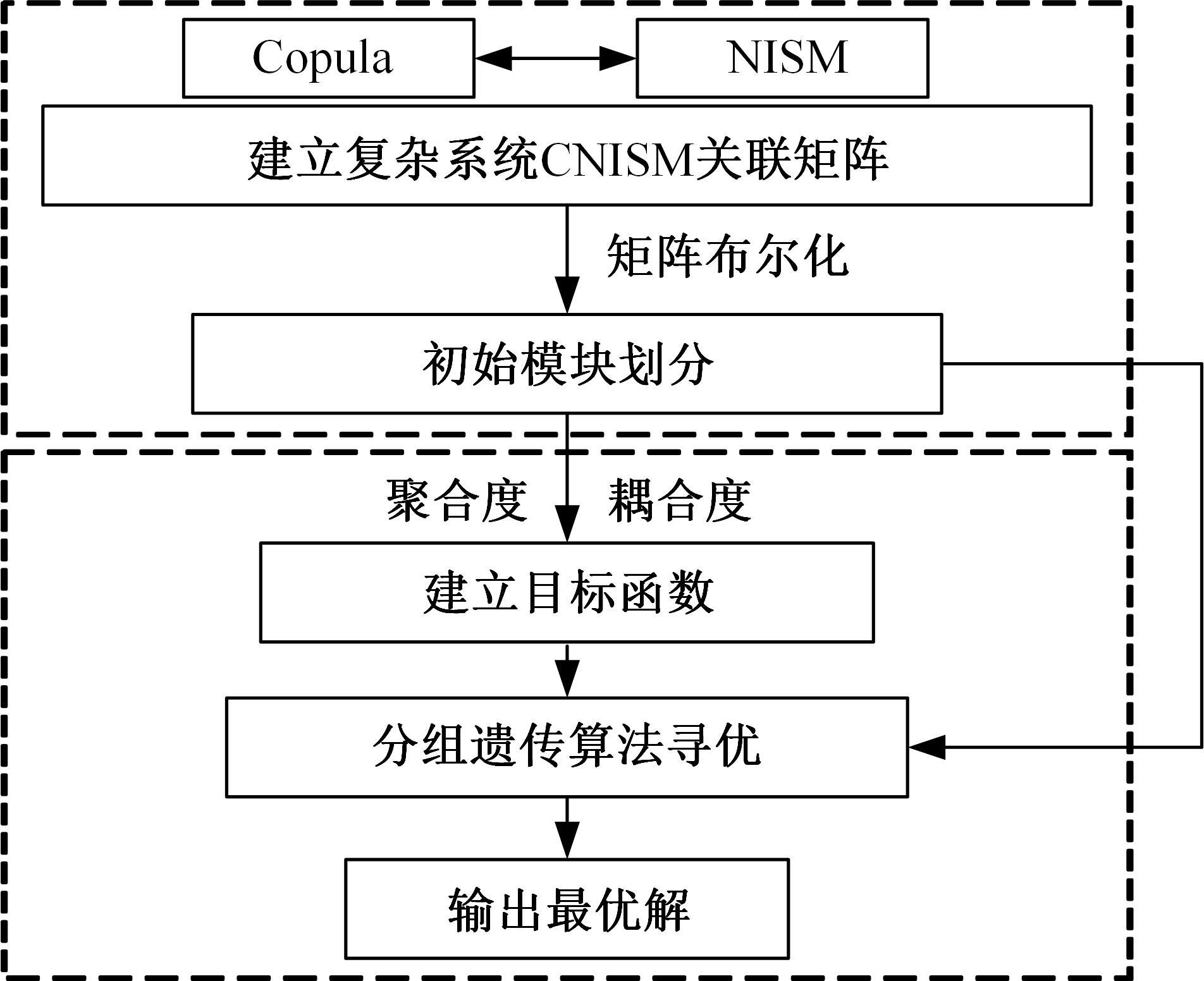

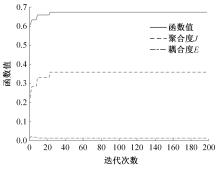

Complex system module classification based on Copula numerical interpretative structural modeling

Yu-bin ZHENG1,2( ),Jie SONG1,2,Jin-tong LIU1,2(

),Jie SONG1,2,Jin-tong LIU1,2( ),Li-ming MU1,2,Zhe-hui CHEN1,2,Jun ZHENG1,2

),Li-ming MU1,2,Zhe-hui CHEN1,2,Jun ZHENG1,2

- 1.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

CLC Number:

- TG659

| 1 | Murthy D N P, Nguyen D G. Study of a multi-component system with failure interaction[J]. European Journal of Operational Research, 1985, 21(3): 330-338. |

| 2 | Murthy D N P, Nguyen D G. Study of two-component system with failure interaction[J]. Naval Research Logistics Quarterly, 1985, 32(2): 239-247. |

| 3 | Satow T, Osaki S. Optimal replacement policies for a two-unit system with failure interactions[J]. Computers & Mathematics with Applications, 2003, 46(7): 1129-1138. |

| 4 | Leung K N F, Lai K K. A preventive maintenance and replacement policy of a series system with failure interaction[J]. Optimization, 2012, 61(2): 223-237. |

| 5 | Zhang N, Fouladirad M, Barros A. Optimal imperfect maintenance cost analysis of a two-component system with failure interactions[J]. Reliability Engineering & System Safety, 2018, 177: 24-34. |

| 6 | 高文科, 张志胜, 周一帆, 等. 存在故障相关及不完备检测的主辅并联系统可靠性建模与维修策略[J]. 自动化学报, 2015, 41(12): 2100-2114. |

| Gao Wen-ke, Zhang Zhi-sheng, Zhou Yi-fan, et al. Reliability modeling and maintenance policy for main and supplementary parallel system with failure interaction and imperfect detection[J]. Acta Automatica Sinica, 2015, 41(12): 2100-2114. | |

| 7 | 梁光夏. 基于改进模糊故障Petri网的复杂机电系统故障状态评价与诊断技术研究[D]. 南京: 南京理工大学机械工程学院, 2014. |

| Liang Guang-xia. Research on fault state evaluation and diagnosis technology of complex electromechanical system based on improved fuzzy fault Petri net[D]. Nanjing: School of Mechanical Engineering, Nanjing University of Science and Technology, 2014. | |

| 8 | 张英芝, 吴茂坤, 申桂香, 等. 基于DEMATEL/ISM的组合机床故障相关性分析[J]. 工业工程, 2014, 17(3): 92-96, 127. |

| Zhang Ying-zhi, Wu Mao-kun, Shen Gui-xiang, et al. An analysis of failure correlation of assemble machine tool based on DEMATEL / ISM[J]. Industrial Engineering Journal, 2014, 17(3): 92-96, 127. | |

| 9 | 孙曙光, 申桂香, 张英芝, 等. 基于ISM与FMECA的加工中心故障分析[J]. 湖南大学学报: 自然科学版, 2015, 42(8): 47-52. |

| Sun Shu-guang, Shen Gui-xiang, Zhang Ying-zhi, et al. Failure analysis of machining center based on ISM and FMECA[J]. Journal of Hunan University (Natural Sciences), 2015, 42(8): 47-52. | |

| 10 | 潘立峰. 数控机床的多性能与多故障关联矩阵模型研究[D]. 武汉: 华中科技大学机械科学与工程学院, 2017. |

| Pan Li-feng. Research on association matrix between multi-performance and multi-faults of cnc machine tool[D]. Wuhan: School of Mechanical Science and Engineering, Huazhong University of Science and Technology, 2017. | |

| 11 | Sushil. Interpreting the interpretive structural model[J]. Global Journal of Flexible Systems Management, 2012, 13(2): 87-106. |

| 12 | 王富强, 苏义坤. 基于ISM的工业化建筑标准体系模块构建[J]. 山西建筑, 2018, 44(11): 35-37. |

| Wang Fu-qiang, Su Yi-kun. Construction of industrial building standard system module based on interpretive structure modeling and its optimization[J]. Shanxi Architecture, 2018, 44(11): 35-37. | |

| 13 | Patton A J. A review of copula models for economic time series[J]. Journal of Multivariate Analysis, 2012, 110: 4-18. |

| 14 | 孟书. 故障率相关下数控车床预防维修策略研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2017. |

| Meng Shu. Research on preventive maintenance strategy of CNC lathe based on fault rate correlations[D]. Changchun: College of Mechanical and Aerospace Engineering, Jilin University, 2017. | |

| 15 | 彭伟. 基于故障诊断与可靠性分析的机械系统预防维修研究[D]. 成都: 电子科技大学机电工程学院, 2016. |

| Peng Wei. Mechanical system preventive maintenance research based on fault diagnosis and reliability analysis[D]. Chengdu: School of Mechatronics Engineering, University of Electronic Science and Technology, 2016. | |

| 16 | 张英芝, 郑锐, 申桂香, 等. 基于Copula理论的数控装备故障相关性[J]. 吉林大学学报: 工学版, 2011, 41(6): 636-640. |

| Zhang Ying-zhi, Zheng Rui, Shen Gui-xiang, et al. Failure dependency of CNC equipment based on copula theory[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(6): 636-640. | |

| 17 | James T, Brown E, Ragsdale C T. Grouping genetic algorithm for the blockmodel problem[J]. IEEE Transactions on Evolutionary Computation, 2010, 14(1): 103-111. |

| 18 | 曹永春, 邵亚斌, 田双亮, 等. 一种基于分组遗传算法的聚类新方法[J]. 西华大学学报: 自然科学版, 2013, 32(1): 39-43. |

| Cao Yong-chun, Shao Ya-bin, Tian Shuang-liang, et al. A new clustering method based on grouping genetic algorithm[J]. Journal of Xihua University (Natural Science), 2013, 32(1): 39-43. | |

| 19 | 张英芝, 刘津彤, 申桂香, 等. 基于故障相关性分析的数控机床系统可靠性建模[J]. 吉林大学学报:工学版, 2017, 47(1): 169-173. |

| Zhang Ying-zhi, Liu Jin-tong, Shen Gui-xiang, et al. Reliability modeling of CNC machine tools system based on failure correlation analysis[J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(1): 169-173. |

| [1] | Xin-tian LIU,Mu-zhou MA,Jia-long HE. Reliability prediction method of machining precision of machine tool parts based on fuzzy coupling [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 377-383. |

| [2] | Ying-zhi ZHANG,Sheng-dong HOU,Zhi-qiong WANG,Ren-hao DONG,Sheng YANG. Fault analysis of machining center based on gray theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 433-438. |

| [3] | Hai-ji YANG,Jia-long HE,Guo-fa LI,Li-ding WANG,Si-yuan WANG. Application of improved failure mode and effect analysis method in risk analysis of spindle system of machining center [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 345-352. |

| [4] | Gui-xiang SHEN,Lan LUAN,Ying-zhi ZHANG,Li-ming MU,Shu-bin LIANG. Fault propagation impact assessment of machining center components [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 63-69. |

| [5] | Fang XU,Jun-ming ZHANG,Yun-feng HU,Ting QU,Yi QU,Qi-fang LIU. Lateral and longitudinal coupling real⁃time predictive controller for intelligent vehicle path tracking [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2287-2294. |

| [6] | Feng XUE,Chuan-lei HE,Qian HUANG,Jian LUO. Coordination degree of multimodal rail transit network [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2040-2050. |

| [7] | Wei LI,Jian CHEN,Shan-yong TAO. Method of enhancing stochastic resonance signal of self⁃adaptive coupled periodic potential system [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1091-1096. |

| [8] | Zhen-jie QIAN,Cheng-qian JIN,Wen-sheng YUAN,You-liang NI,Guang-yue ZHANG. Frictional impact dynamics model of threshing process between flexible teeth and grains [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1121-1130. |

| [9] | Guang-tai ZHANG,Jin-peng ZHANG,Ming-yang WANG,Dong-liang LU,Mei ZHANG. Seismic isolation performance of waste scrap tire pads under aging-loading coupling [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 96-106. |

| [10] | Jun FU,Yi-chen ZHANG,Chao CHENG,Zhi CHEN,Xin-long TANG,Lu-quan REN. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 730-738. |

| [11] | Peng-hui WANG,Hong-xia QIAO,Qiong FENG,Hui CAO,Shao-yong WEN. Durability model of magnesium oxychloride-coated reinforced concrete under the two coupling factors [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 191-201. |

| [12] | Jun-long LIU,Dong-ye SUN,Xiao-jun LIU,Yong YOU. Speed ratio control of electro⁃mechanical continuously variable transmission based on coupling characteristic [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1951-1958. |

| [13] | Guang YAN,Jian-zhong LU,Kai-yu ZHANG,Fan-yong MENG,Lian-qing ZHU. Temperature decoupling large range fiber Bragg grating strain sensor [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1682-1688. |

| [14] | Hong-yan WANG,Yun-fei FANG,Sheng-qi ZHU,Bing-nan PEI. DOA estimation method considering mutual coupling effect in presence of non⁃uniform noise [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1706-1714. |

| [15] | ZHAO Wei-qiang, GAO Ke, WANG Wen-bin. Prevention of instability control of commercial vehicle based on electric-hydraulic coupling steering system [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1305-1312. |

|

||