Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (11): 2756-2764.doi: 10.13229/j.cnki.jdxbgxb20210385

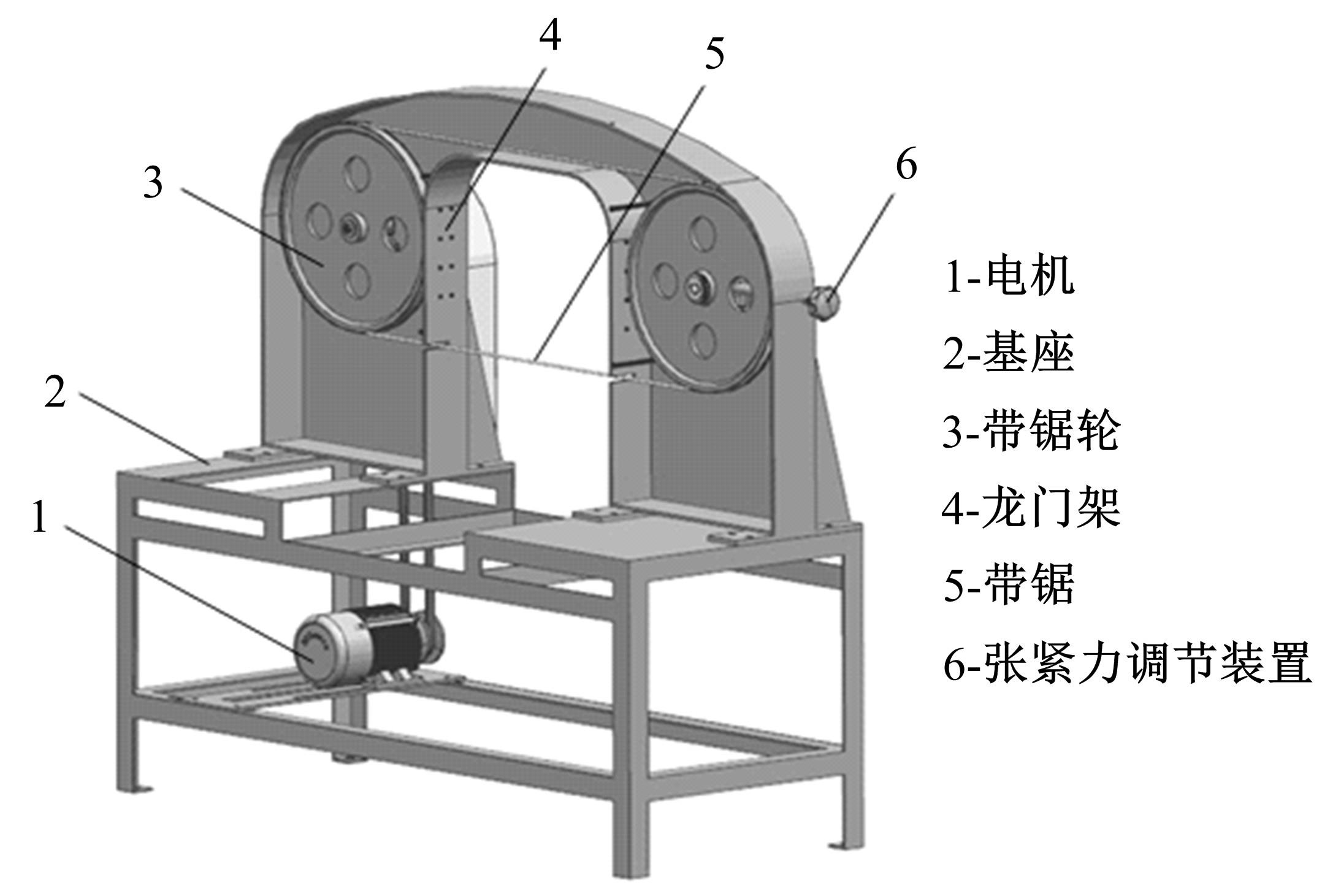

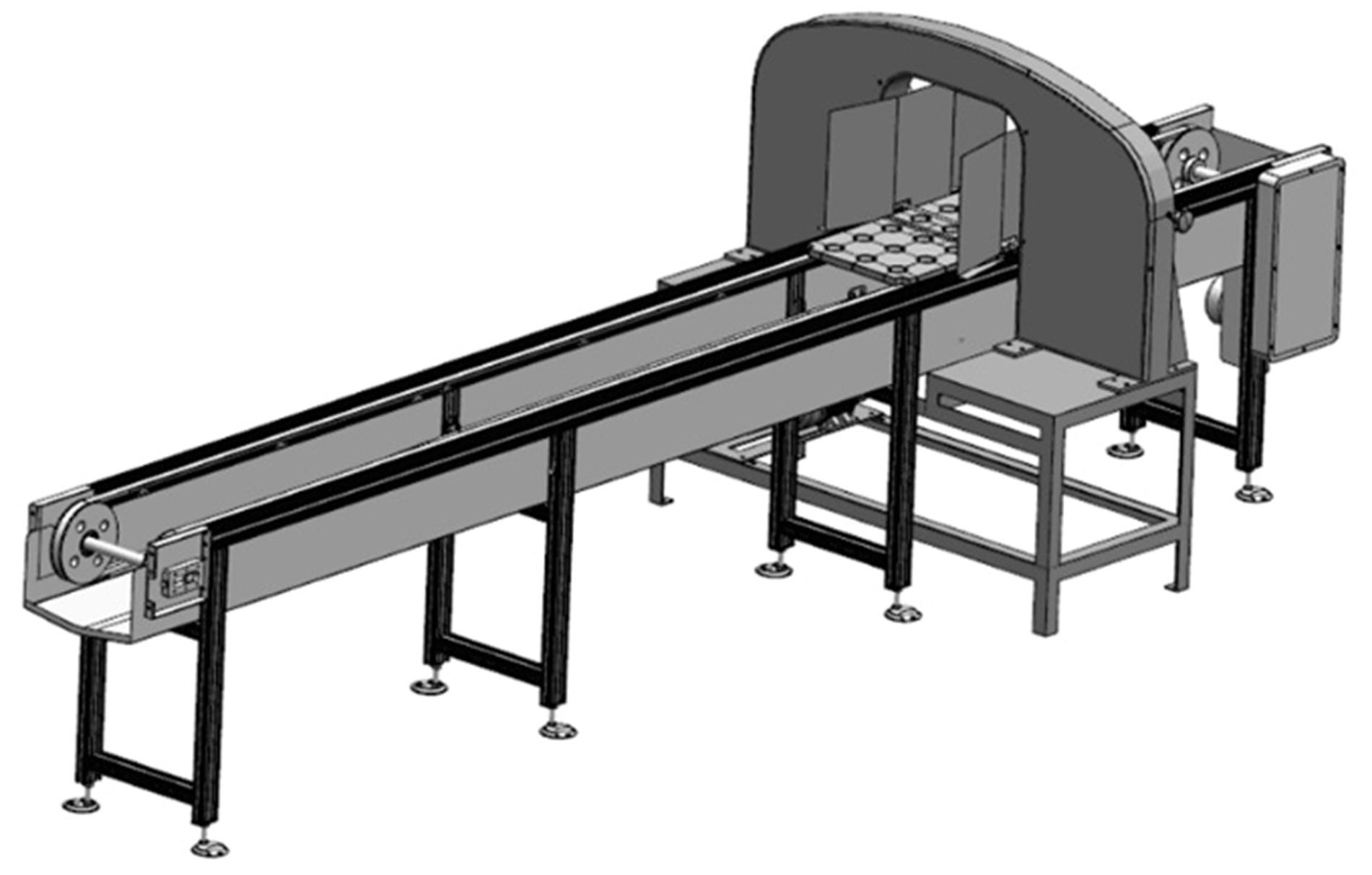

Design and experiment of harvesting device for industrialized production line of Shanghaiqing

Bai-gong ZENG1( ),Kui-liang LI1,Jin YE1,Li-li REN2(

),Kui-liang LI1,Jin YE1,Li-li REN2( ),Jaloliddin Rashidov3,Ming ZHANG1

),Jaloliddin Rashidov3,Ming ZHANG1

- 1.College of Engineering and Technology,Southwest University,Chongqing 400715,China

2.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

3.Faculty of Hydrotechnical Constructions,Tashkent Institute of Irrigation and Agricultural Mechanization Engineers,Tashkent 845250,Uzbekistan

CLC Number:

- S225.92

| 1 | 糜南宏, 赵映, 秦广明, 等. 蔬菜全程机械化研究现状与对策[J]. 中国农机化学报, 2014, 35(3): 66-69. |

| Mi Nan-hong, Zhao Ying, Qin Guang-ming, et al. Vegetables full-mechanization research present situation and the countermeasures[J]. Journal of Chinese Agricultural Mechanization, 2014, 35(3): 66-69. | |

| 2 | 李佩珊, 马善婷. 中国蔬菜种植面积目前已突破3亿亩[J]. 中国食品, 2019(15): 153. |

| Li Pei-shan, Ma Shan-ting. China's vegetable planting area having broken through 20 million hectare[J]. China Food, 2019(15): 153. | |

| 3 | 杨其长. 植物工厂现状与发展战略[J]. 农业工程技术, 2016, 36(10): 9-12. |

| Yang Qi-chang. Present situation and development strategy of plant factory[J]. Agricultural Engineering Technology, 2016, 36(10): 9-12. | |

| 4 | 金月, 肖宏儒, 肖苏伟, 等. 叶类蔬菜收获技术与装备研究现状及发展趋势[J]. 中国农业科技导报, 2018, 20(9): 78-84. |

| Jin Yue, Xiao Hong-ru, Xiao Su-wei, et al. Research statue and development trendency on leaf vegetable harvesting technology and equipment[J]. Journal of Agricultural Science and Technology, 2018, 20(9): 78-84. | |

| 5 | 王俊, 杜冬冬, 胡金冰, 等. 蔬菜机械化收获技术及其发展[J]. 农业机械学报, 2014, 45(2): 81-87. |

| Wang Jun, Du Dong-dong, Hu Jin-bing, et al.Vegetable mechanized harvesting technology and it's development[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(2): 81-87. | |

| 6 | 高国华, 王天宝. 温室雾培蔬菜收获机收获机构的研究设计[J]. 农机化研究, 2015, 37(10): 91-97. |

| Gao Guo-hua, Wang Tian-bao. Design of aeroponics greenhouse vegetable harvester harvesting machanism[J]. Journal of Agricultural Mechanization Research, 2015, 37(10): 91-97. | |

| 7 | 申屠留芳, 张炎, 孙星钊, 等. 叶类蔬菜收获机的设计[J]. 中国农机化学报, 2016, 37(11): 20-23. |

| Liu-fang Shen-tu, Zhang Yan, Sun Xing-zhao, et al. Design of leaf vegetable harvester[J]. Journal of Chinese Agricultural Mechanization, 2016, 37(11): 20-23. | |

| 8 | 秦广明, 赵映, 肖宏儒, 等. 高速双动小型手扶式叶菜收获机设计与运动分析[J]. 中国农机化学报, 2015, 36(5): 9-12. |

| Qin Guang-ming, Zhao Ying, Xiao Hong-ru, et al. Design and movement analysis of double-acting cutting device of small walking leafy vegetables harvester[J]. Journal of Chinese Agricultural Mechanization, 2015, 36(5): 9-12. | |

| 9 | 莫浩. 水培生菜自动采收装置的设计与研究[D]. 咸阳: 西北农林科技大学机械与电子工程学院, 2018. |

| Mo Hao. Design and research of the automatic harvesting machine of hydroponic lettuce[D]. Xianyang: Mechanical and Electronic Engineering, Northwest A&F University, 2018. | |

| 10 | 徐赛超. 植物工厂生菜自动化采收系统的设计及试验[D]. 镇江: 江苏大学农业工程学院, 2017. |

| Xu Sai-chao. Design and experiment of automatic harvesting system for lettuce in plant factory[D]. Zhenjiang: School of Agricultural Engineering, Jiangsu University, 2017. | |

| 11 | Brown D, Glancey J L. Theoretical and experimental analysis of a continuous-blade cutting system for leafy vegetables[J]. Transactions of the ASABE, 2007, 50(3): 803-813. |

| 12 | Nangvn Y. Development of prototype harvester for head lettuce[J]. Engineering in Agriculture, Environment and Food, 2015, 8(1): 18-25. |

| 13 | Shibata Y. Development of a crisp head lettuce harvester[J]. Bulletin of the Chugoku National Agricultural Experiment Station, 1990, 7: 17-36. |

| 14 | 韦勇, 秦广明, 金月, 等. 叶菜收获机械的研究现状及发展趋势[J]. 农业开发与装备, 2016(8): 98-100. |

| Wei Yong, Qin Guang-ming, Jin Yue, et al. Research status and development trend of leafy vegetable harvesting machinery[J]. Agricultural Development & Equipments, 2016(8): 98-100. | |

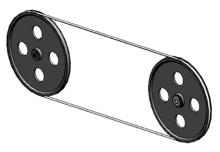

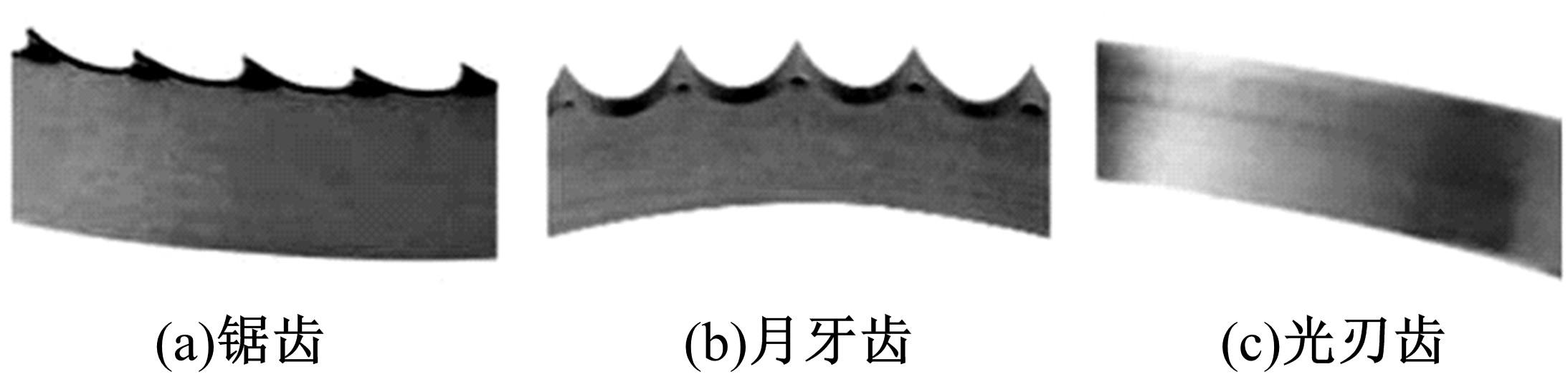

| 15 | 花军. 现代木工机床结构[M]. 哈尔滨: 东北林业大学出版社, 2006. |

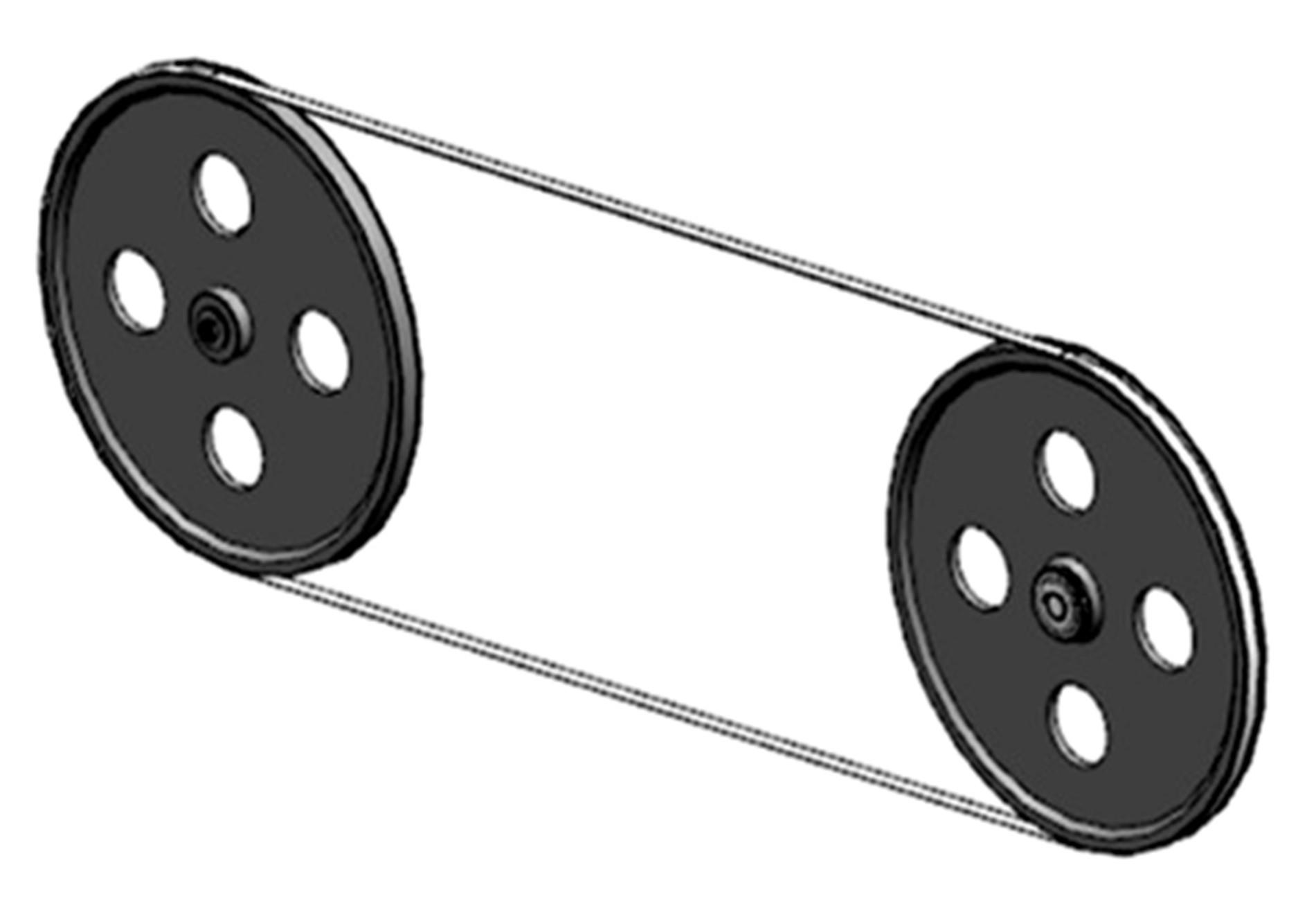

| 16 | 中华人民共和国机械行业标准. . 木工带锯机 锯轮 [S]. |

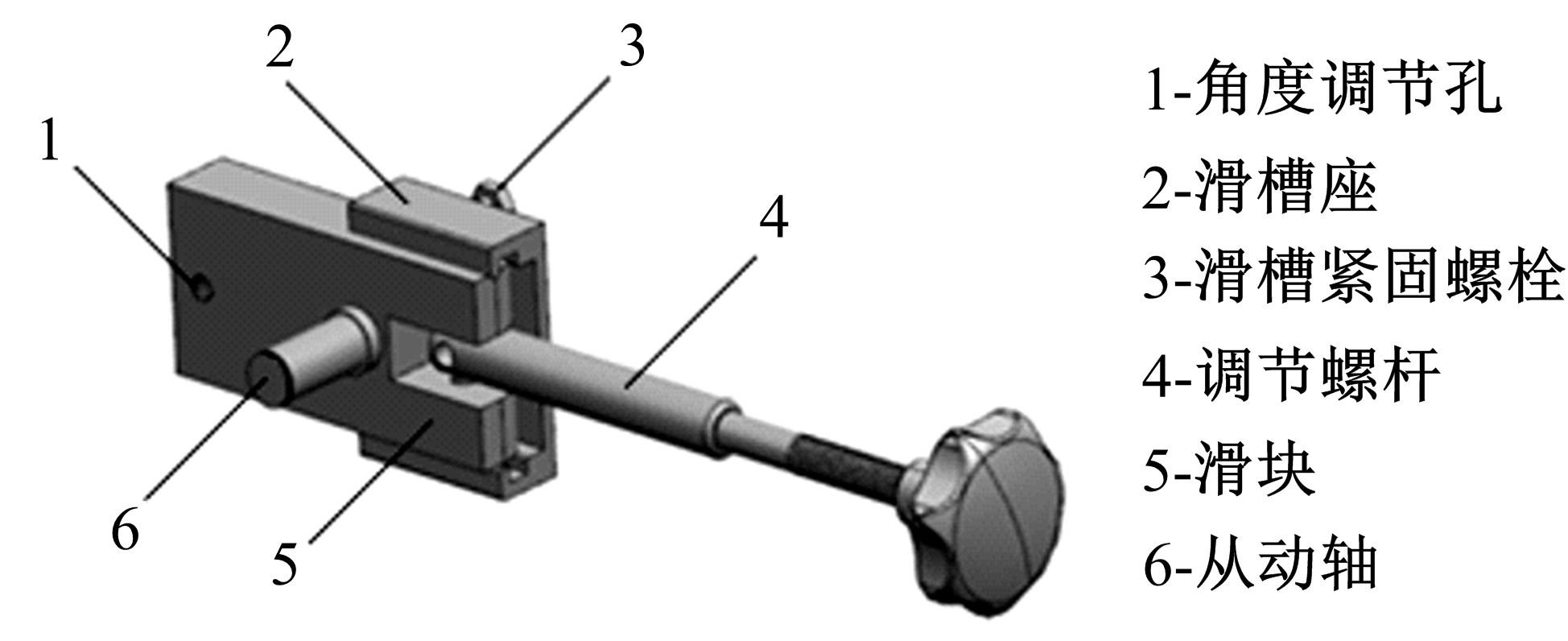

| 17 | 江平, 丁泽林, 丁侠胜, 等. 带锯床张紧装置结构设计[J]. 轻工机械, 2017, 35(1): 82-85. |

| Ping Jang, Ding Ze-lin, Ding Xia-sheng, et al. Structural design of tensioning device in band sawing machine[J]. Light Industry Machinery, 2017, 35(1): 82-85. | |

| 18 | 孙桓. 机械原理[M]. 西安: 西北工业大学出版社, 2016. |

| 19 | 丛茜, 徐金, 马博帅, 等. 基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J]. 吉林大学学报: 工学版, 2021, 51(2): 754-760. |

| Cong Qian, Xu Jin, Ma Bo-shuai, et al. Design and test of tractor hydraulic suspension system testing device based on virtual simulation[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 754-760. | |

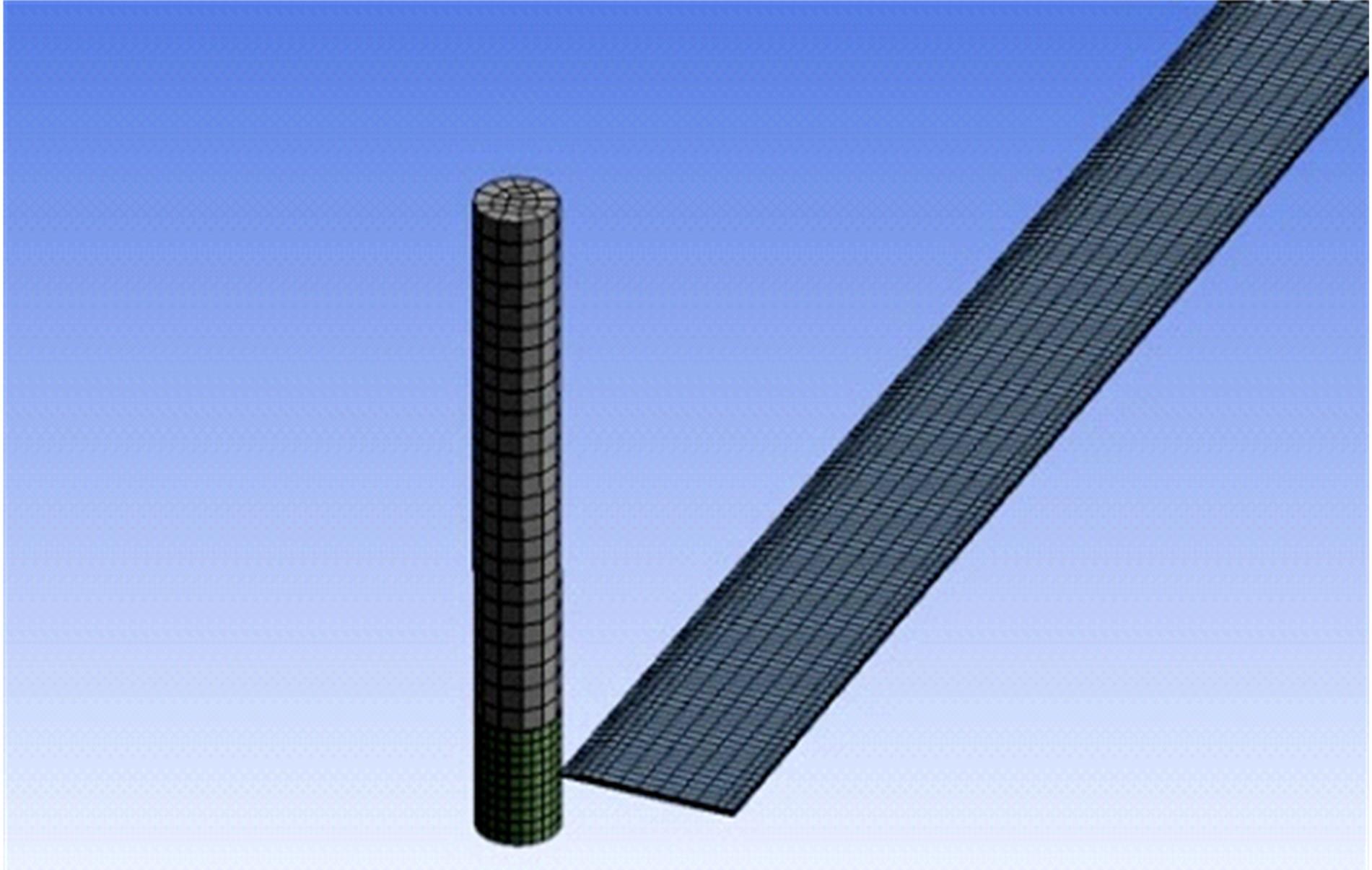

| 20 | 张克平, 黄建龙, 杨敏, 等. 冬小麦籽粒受挤压特性的有限元分析及试验验证[J]. 农业工程学报, 2010(6): 352-356. |

| Zhang Ke-ping, Huang Jian-long, Yang Min, et al. Finite element analysis and experimental verification of wheat grain under compression loads[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010(6): 352-356. | |

| 21 | 薛钊, 付君, 陈志, 等. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报: 工学版, 2020, 50(2): 739-748. |

| Xue Zhao, Fu Jun, Chen Zhi, et al. Optimization experiment on parameters of chopping device of forage maize harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. | |

| 22 | 马义东, 徐灿, 崔永杰, 等. 水培生菜整株低损收获装置设计与试验[J]. 农业机械学报, 2019, 50(1): 162-169. |

| Ma Yi-dong, Xu Can, Cui Yong-jie, et al. Design and test of harvester for whole hydroponic lettuce with low damage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(1): 162-169. |

| [1] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

| [2] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [3] | Xing-yu WAN,Qing-xi LIAO,Ya-jun JIANG,Yi-yin SHAN,Yu ZHOU,Yi-tao LIAO. Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. |

| [4] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU. Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2486-2500. |

| [5] | Wen-hui ZHANG,Jing YI,Wei LIU,Qiu-ying YU,Lian-zhen WANG. Injury mechanism of occupants in bus during rear-end crash based on MADYMO [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 118-126. |

| [6] | Ming LI,Qing-feng XUE,Ke-xin ZHANG,Ran LYU,Chang-hua WEI. Performance analysis of electric vehicle heat pump air conditioning system [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1943-1952. |

| [7] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [8] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [9] | Xue-shen CHEN,Zhu-jian HUANG,Xu MA,Long QI,Gui-jin FANG. Design and test of control system for rice mechanical weeding and seedling-avoiding control [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 386-396. |

| [10] | Jun FU,Yi-chen ZHANG,Chao CHENG,Zhi CHEN,Xin-long TANG,Lu-quan REN. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 730-738. |

| [11] | Zhao XUE,Jun FU,Zhi CHEN,Feng-de WANG,Shao-ping HAN,Lu-quan REN. Optimization experiment on parameters of chopping device of forage maize harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. |

| [12] | Chao CHENG,Jun FU,Fu-ping HAO,Zhi CHEN,De-yi ZHOU,Lu-quan REN. Effect of motion parameters of cleaning screen on corn cob blocking law [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 351-360. |

| [13] | Chao CHENG,Jun FU,Xin⁃long TANG,Zhi CHEN,Lu⁃quan REN. Effects of vibration mode on interface adhesion law of rice threshed mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1228-1235. |

| [14] | WANG Yang, WANG Xiao-mei, CHEN Ze-ren, YU Jian-qun. Modeling method of maize kernels based on discrete element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1537-1547. |

| [15] | WANG Yang, LYU Feng-yan, XU Tian-yue, YU Jian-qun. Shape and size analysis of soybean kernel and modeling [J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

|

||