Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (12): 3450-3459.doi: 10.13229/j.cnki.jdxbgxb.20231257

Previous Articles Next Articles

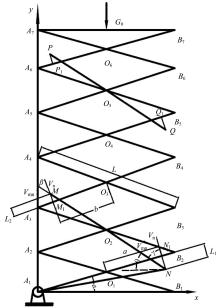

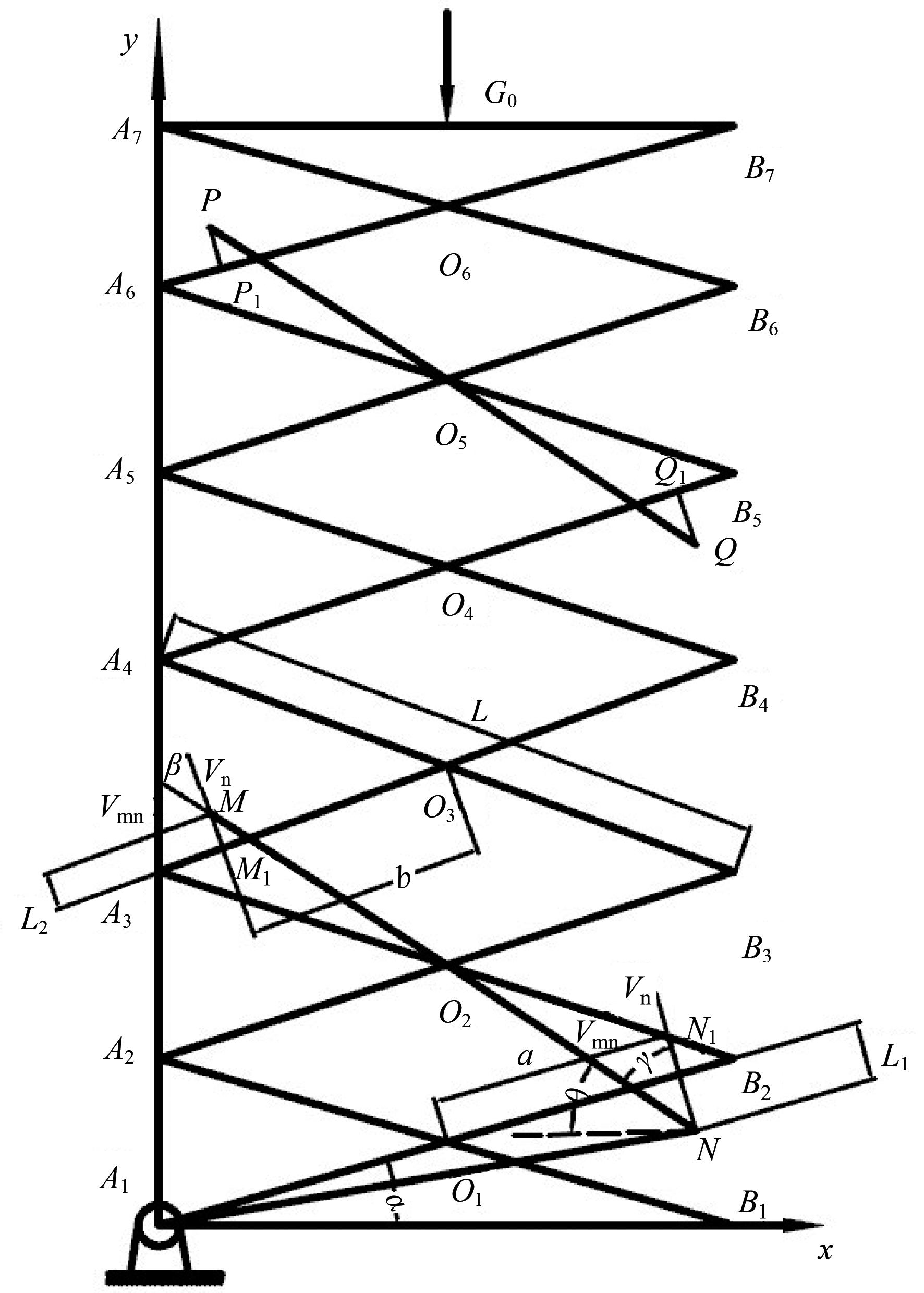

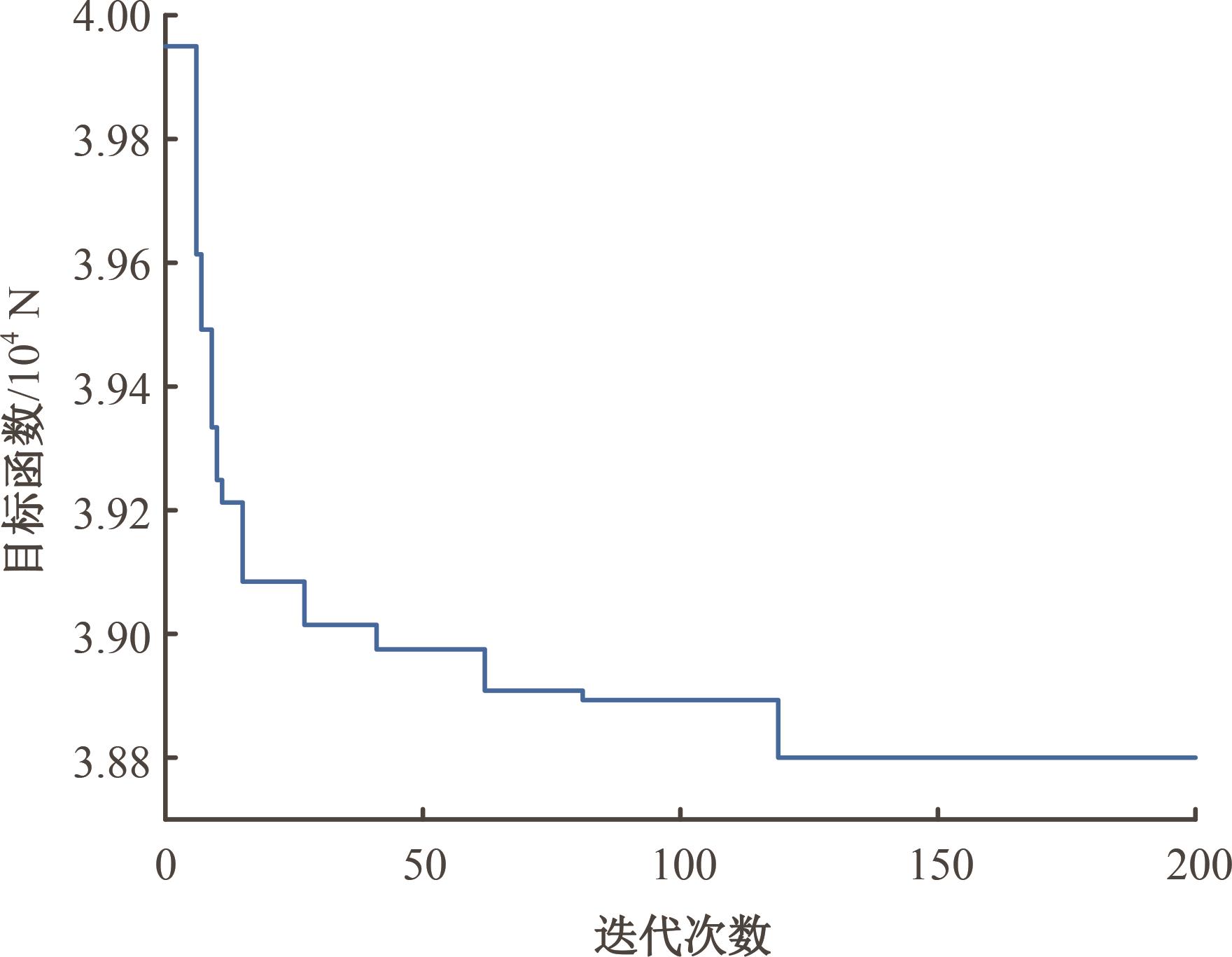

Stability analysis and scale synthesis of new multifunctional aerial work platform

Wei-jun WU1,2( ),Jiang-bo WU1,Jia-le ZHANG1,Qiang ZHOU1,Qiao-hong YANG2,Xun-peng QIN2(

),Jiang-bo WU1,Jia-le ZHANG1,Qiang ZHOU1,Qiao-hong YANG2,Xun-peng QIN2( )

)

- 1.State Power Investment Group Jiangxi Electric Power Co. ,Ltd. ,New Energy Power Generation Branch,Nanchang 330038,China

2.Hubei Key Laboratory of Advanced Technology for Automotive Components,Wuhan University of Technology,Wuhan 430070,China

CLC Number:

- TH137.331

| 1 | 范茂, 李世芸. 基于ADAMS的压紧机构运动学仿真研究[J].软件, 2020,41(2):145-148. |

| Fan Mao, Li Shi-yun. Kinematic simulation of compression mechanism based on ADAMS[J]. Software,20, 41(2): 145-148. | |

| 2 | Zhong G, Yi H, Dou W. Design of dual-drive vertical lift servo system and synchronous control performance analysis[J]. IEEE/ASME Transactions on Mechatronics, 2020, 25(6): 2927-2937. |

| 3 | Doçi I, Lajqi S, Makolli S, et al. Scissor lift dynamic analysis and motion regulation for the case of lifting with maximum load[J]. Trans & Motauto World, 2021, 6(2): 38-42. |

| 4 | 吴硕博, 董文龙, 孟哲, 等. 剪叉式作业平台稳定性仿真分析与计算[J]. 起重运输机械, 2021(19):73-76. |

| Wu Shuo-bo, Dong Wen-long, Meng Zhe, et al. Stability simulation analysis and calculation of shear fork operating platform[J]. Hoisting and Transporting Machinery, 2021(19):73-76. | |

| 5 | 王斌. 剪叉式高空作业平台上车液压系统的稳定性分析[J]. 矿业装备, 2023(1): 160-162. |

| Wang Bin. Stability analysis of on-board hydraulic system of shear fork aerial work platform[J]. Mining Equipment, 2023(1): 160-162. | |

| 6 | 高旭宏, 徐向阳, 王书翰, 等. 自行式高空作业平台的动态稳定性分析[J].中南大学学报: 自然科学版,2017, 48(10): 2836-2842. |

| Gao Xu-hong, Xu Xiang-yang, Wang Shu-han, et al. Analysis of dynamic stability of self-propelled aerial work platform [J]. Journal of Central South University (Science and Technology),2017,48(10):2836-2842. | |

| 7 | 喻向阳, 黄斌, 银峰, 等. 基于有限元分析的剪叉式高空作业平台叉臂轻量化设计[J]. 建设机械技术与管理, 2023, 36(1): 57-60. |

| Yu Xiang-yang, Huang Bin, Yin Feng, et al. Lightweight design of fork arm of shear fork aerial working platform based on finite element analysis[J]. Construction Machinery Technology and Management, 2023, 36(1): 57-60. | |

| 8 | Danh T H, Ngoc N D, Nga N T T, et al. Application of MOORA and MEREC methods to select the best schema of scissors mechanisms[J]. Journal of Military Science and Technology, 2022(FEE): 177-184. |

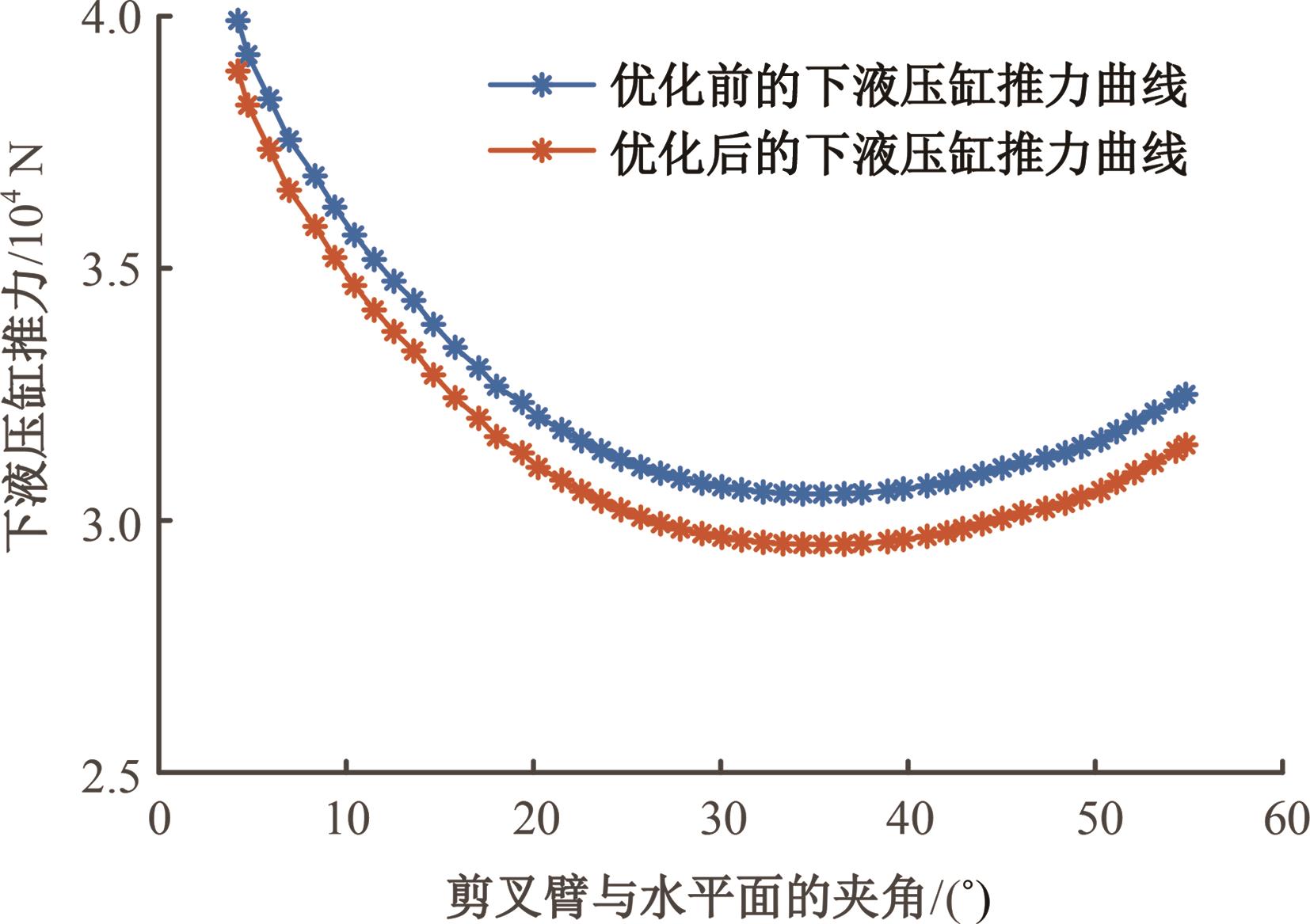

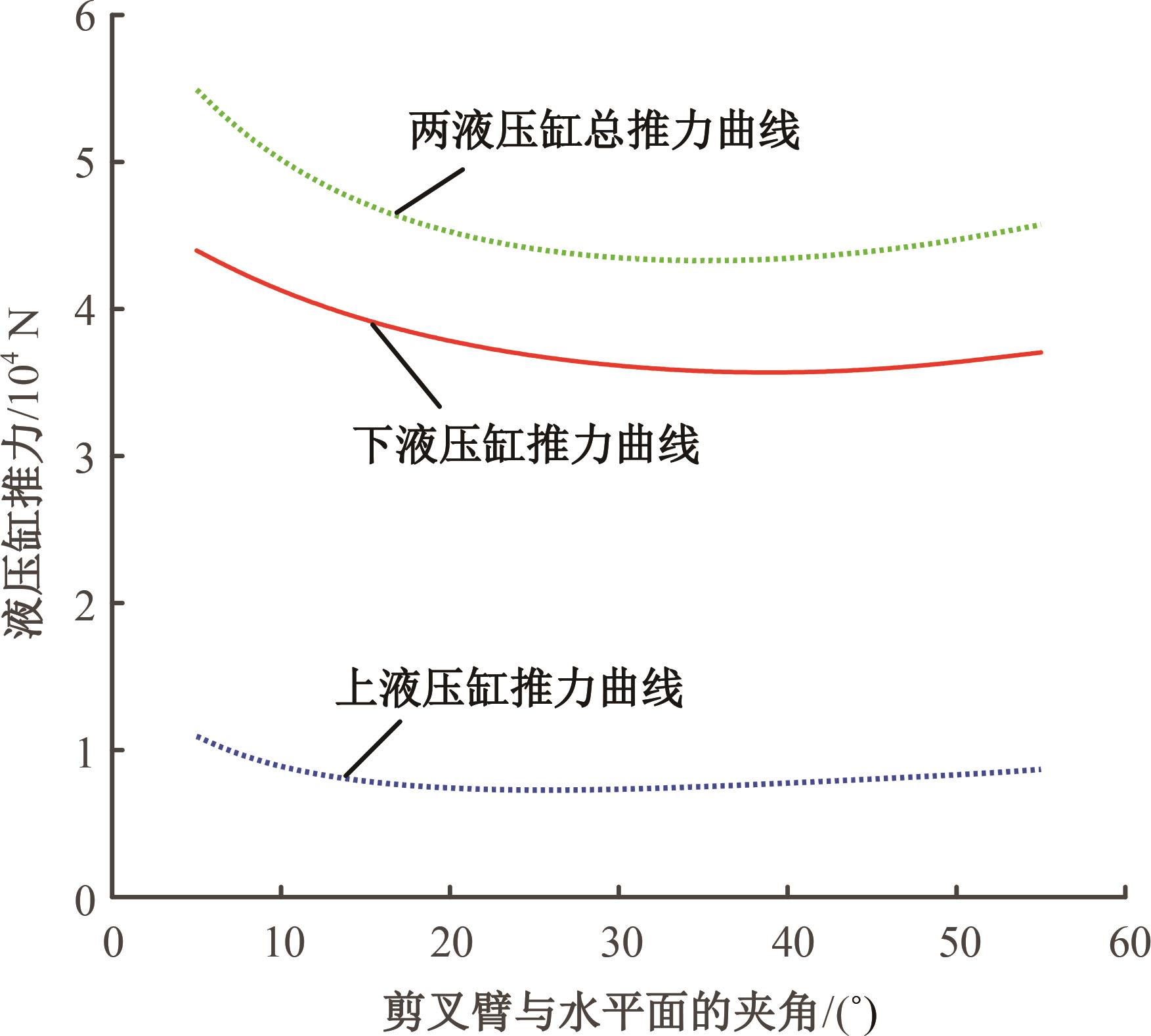

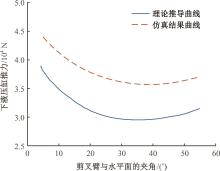

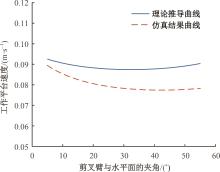

| 9 | 吉喆, 董文龙, 刘涛, 等.剪叉式高空作业车液压缸安装参数优化[J].起重运输机械, 2021(22): 43-46. |

| Ji Zhe, Dong Wen-long, Liu Tao, et al. Optimization of hydraulic cylinder installation parameters of shear fork aerial truck[J]. Hoisting and Transporting Machinery, 2021(22): 43-46. | |

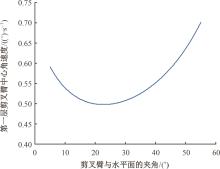

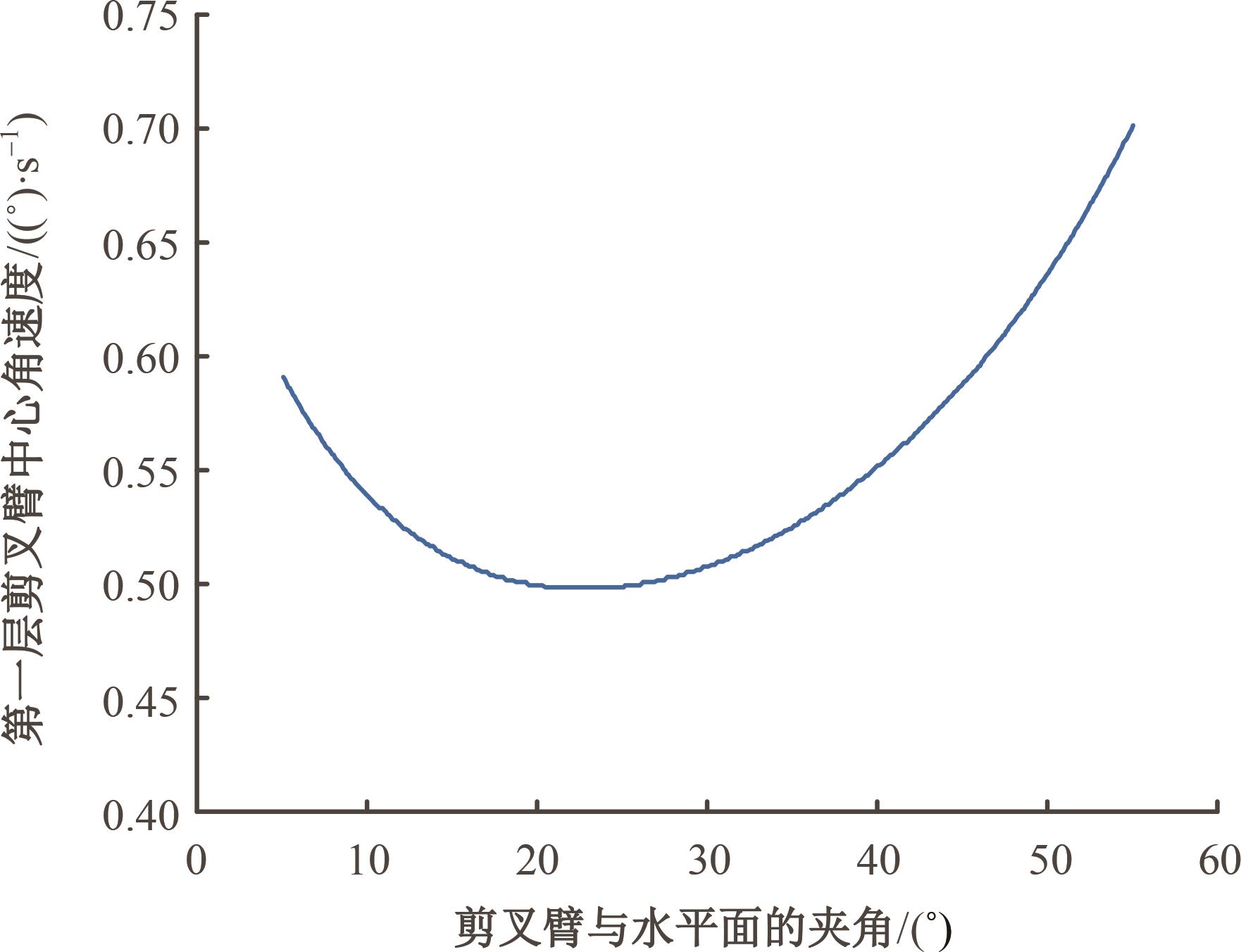

| 10 | 刘吉超, 张伟康, 郑自冲, 等. 剪叉式高空作业平台举升机构参数匹配研究[J]. 机电工程, 2022, 39(2):173-179. |

| Liu Ji-chao, Zhang Wei-kang, Zheng Zi-chong, et al. Research on parameter matching of lifting mechanism of shear fork aerial working platform [J]. Mechanical and Electrical Engineering,2022, 39(2): 173-179. | |

| 11 | He S, Ouyang M, Gong J, et al. Mechanical simulation and installation position optimisation of a lifting cylinder of a scissors aerial work platform[J]. The Journal of Engineering,2019,2019(13):74-78. |

| 12 | 秦基磊, 史蔚. 伸缩臂式自行走高空作业车液压系统的改进探讨[J]. 内燃机与配件, 2021(23):68-69. |

| Qin Ji-lei, Shi Wei. Discussion on improvement of hydraulic system of telescopic boom self-propelled aerial work vehicle[J]. Internal Combustion Engines and Accessories, 2021(23): 68-69. | |

| 13 | 王铎, 王尚斌, 李超, 等.基于虚功原理剪叉机构驱动力计算[J]. 锻压装备与制造技术, 2020, 55(2):36-38. |

| Wang Duo, Wang Shang-bin, Li Chao, et al. Calculation of driving force of shear fork mechanism based on virtual work principle[J]. Forging Equipment & Manufacturing Technology, 2020, 55(2): 36-38. | |

| 14 | 刘军. 一种高空作业车液压系统设计与仿真[J]. 液压与气动, 2021, 45(7):154-163. |

| Liu Jun. Design and simulation of a hydraulic system for aerial work vehicle [J]. Chinese Hydraulics & Pneumatics, 2021, 45(7):154-163. | |

| 15 | 刘志, 纪爱敏, 张磊, 等. 剪叉式高空作业平台上车液压系统的稳定性研究[J]. 机电工程,2020, 37(6):600-606. |

| Liu Zhi, Ji Ai-min, Zhang Lei, et al. Study on the stability of on-board hydraulic system of shear fork aerial work platform[J]. Mechanical and Electrical Engineering, 2020, 37(6): 600-606. | |

| 16 | 何宇, 孙瑜. 基于ADAMS的液压叉剪式升降机的仿真研究[J]. 萍乡学院学报, 2018, 35(3): 44-47. |

| He Yu, Sun Yu. Simulation research of hydraulic fork shear elevator based on ADAMS [J]. Journal of Pingxiang University, 2018, 35(3): 44-47. | |

| 17 | 邓彧, 陆进添, 谢仁军. 一种保障高空作业平台稳定性的重心分配方法[J]. 建筑机械化, 2021, 42(12):35-37. |

| Deng Yu, Lu Jin-tian, Xie Ren-jun. A method of gravity distribution to ensure the stability of aerial work platform [J]. Construction Mechanization, 2021, 42(12): 35-37. |

| [1] | Lei SHANG,Ping YANG,Xiang-guo YANG,Jian-xin PAN,Jun YANG,Meng-ru ZHANG. Temperature control of proton exchange membrane fuel cell thermal management system based on APSO-BP-PID control strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2401-2413. |

| [2] | Lin JIANG,Guo-long LI,Shi-long WANG,Kai XU,Zhe-yu LI. Thermal expansion error modeling of feed axis based on principal component regression [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2149-2155. |

| [3] | Xue-lian GUO,Wan-shui HAN,Tao WANG,Kai ZHOU,Xiu-shi ZHANG,Shu-ying ZHANG. Assessment method of resistant overturning stability safety factors of curved bridge under customized transport vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2229-2237. |

| [4] | Xiao-hong TANG,Yong-jian GONG. Trajectory planning algorithm for grasping manipulator considering energy consumption and load factors [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1862-1868. |

| [5] | Rong LUO,Yu LIANG,Long-chang NIU,Ting-ting HUANG,Qiang MIAO. Threshold value of water stability evaluation index of asphalt mixture under multi-temperature conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1966-1977. |

| [6] | Ze-qiang ZHANG,Can WANG,Jun-qi LIU,Dan JI,Si-lu LIU. Parallel row ordering problem based on improved sparrow search algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1851-1861. |

| [7] | Yong-sheng WANG,Bao-hong LYU,Jin-ke WANG,Da-jiang YANG,Si-zhe XIONG,Bin-wei ZHANG. Stability analysis of novel ground anchor and beam string debris flow grid dam [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1719-1729. |

| [8] | Cai-xia SHU,Jia YANG,Qing-xi LIAO,Xing-yu WAN,Jia-cheng YUAN. Design and experiment of diversion type double-cylinder cyclone separation system for rapeseed combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1807-1820. |

| [9] | Yun PU,Yin XU,Hai-xu LIU,Yi-fan TAN. An improved car⁃following model for connected and automated vehicles considering impact of multiple vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1285-1292. |

| [10] | Xue-jing DU,Ning WANG,Jie ZHANG,Yu-long PEI. Control strategy of lateral stability of semi-trailer train in dangerous section of cold area [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 996-1006. |

| [11] | Wan-bin YAN,Kong-hua YANG,Kai-diao JIN,Su-jiao CHEN,Yong-hua ZHANG,Chun-bao LIU. Internal flow field in a hydrodynamic torque converter with dynamic hybrid RANS/LES model [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 926-937. |

| [12] | Da-yi QU,Ke-kun ZHANG,Yuan GU,Tao WANG,Hui SONG,Shou-chen DAI. Analysis of lane⁃changing decision⁃making behavior and molecular dynamics modeling for autonomous vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 700-710. |

| [13] | Li HUI,Lei JIN,Wan-wan SONG,Song ZHOU,Jin-lan AN. Crack growth rate of SMA490BW steel in different welding areas for bogie [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 650-656. |

| [14] | Jiao-rong WU,Qing-kai LIN,Yong-qi DENG. Identification method of potential public transportation lane demand based on bus line operation stability [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 692-699. |

| [15] | Yu-mei LIU,Jia-xiang SHENG,Jiao-jiao ZHUANG,Rong CHEN,Da-long ZHAO. Structural optimization and dynamic characteristics of high⁃speed variable gauge bogie [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 453-460. |

|