Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (5): 1521-1530.doi: 10.13229/j.cnki.jdxbgxb20180356

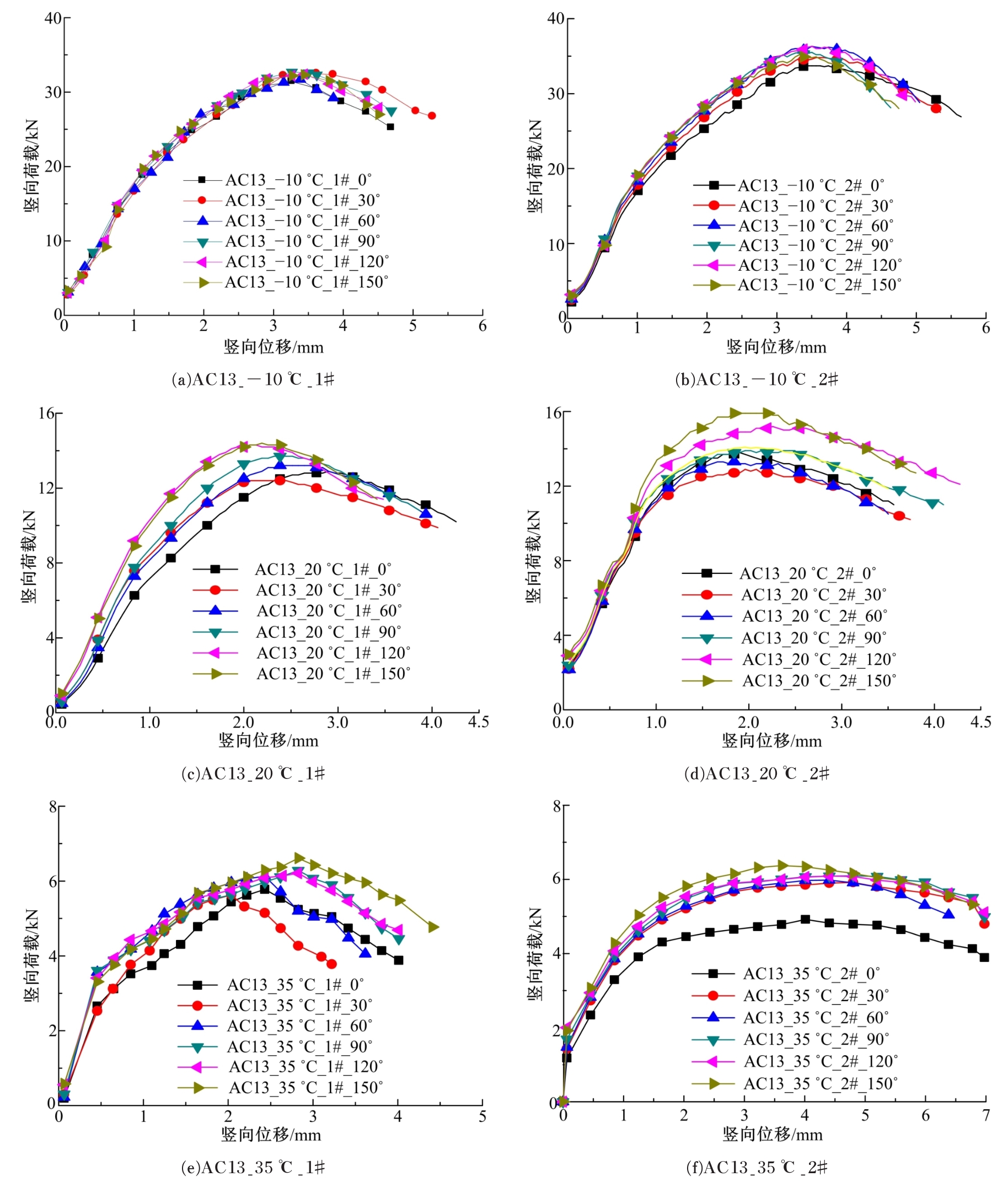

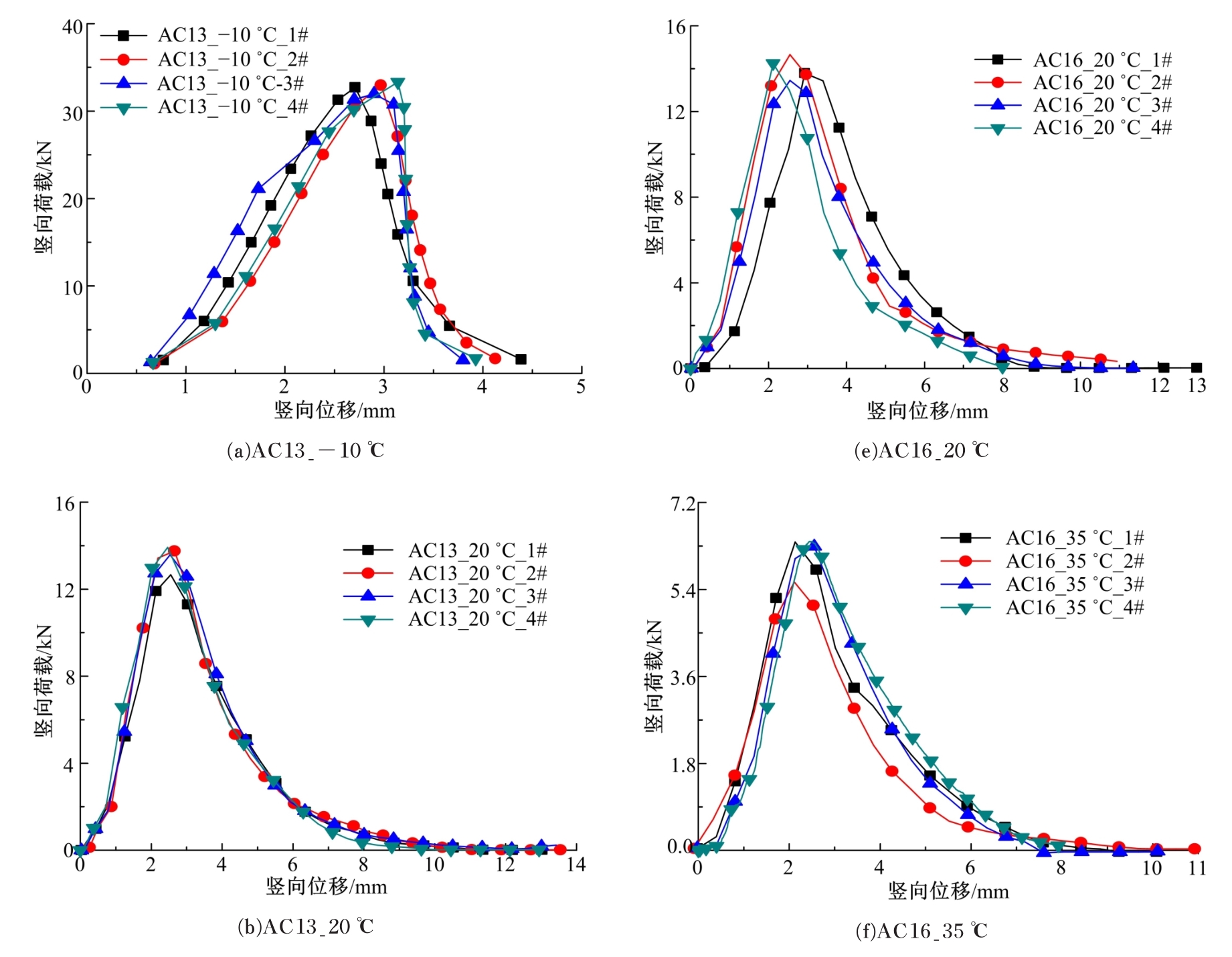

Numerical simulation of influence factors of splitting strength of asphalt mixtures

Yong PENG1( ),Hua GAO1,Lei WAN1,Gui-ying LIU2

),Hua GAO1,Lei WAN1,Gui-ying LIU2

- 1. Institute of Transportation Engineering, Zhejiang University, Hangzhou 310058, China

2. China Railway Eryuan Engineering Group (Chongqing) Survey, Design and Research Co. Ltd. , Chongqing 400023, China

CLC Number:

- U414

| 1 | RotherburgL, BogoboweczA, HaasR, et al. Micromechanical modeling of asphalt concrete in connection with pavement rutting problems[C]∥7th International Conference on Asphalt Pavements, Nottingham, United Kingdom, 1992. |

| 2 | ButtlarW G, YouZ. Discrete element modeling of asphalt concrete: microfabric approach[J]. Transportation Research Record Journal of the Transportation Research Board, 2001, 1757(1): 111-118. |

| 3 | AbbasA, MasadE A, PapagiannakisT, et al. Modelling asphalt mastic stiffness using discrete element analysis and micromechanics-based models[J]. International Journal of Pavement Engineering, 2005, 6(2): 137-146. |

| 4 | CollopA C, McdowellG R, LeeY W. Modelling dilation in an idealised asphalt mixture using discrete element modelling[J]. Granular Matter, 2006, 8(3): 175-184. |

| 5 | KimH, WagonerM P, ButtlarW G. Simulation of fracture behavior in asphalt concrete using a heterogeneous cohesive zone discrete element model[J]. Journal of Materials in Civil Engineering, 2008, 20(8): 552-563. |

| 6 | YouZ, AdhikariS, DaiQ. Three-dimensional discrete element models for asphalt mixtures[J]. Journal of Engineering Mechanics, 2008, 134(12): 1053-1063. |

| 7 | YouZ, LiuY, DaiQ. Three-dimensional microstructural-based discrete element viscoelastic modeling of creep compliance tests for asphalt mixtures[J]. Journal of Materials in Civil Engineering, 2011, 23(1): 79-87. |

| 8 | LiuY, YouZ. Visualization and simulation of asphalt concrete with randomly generated three-dimensional models[J]. Journal of Computing in Civil Engineering, 2009, 23(6): 340-347. |

| 9 | YuH, ShenS. Impact of aggregate packing on dynamic modulus of hot mix asphalt mixtures using three-dimensional discrete element method[J]. Construction & Building Materials, 2012, 26(1): 302-309. |

| 10 | PengY, HarveyJ T, SunL J. Three-dimensional discrete-element modeling of aggregate homogeneity influence on indirect tensile strength of asphalt mixtures[J/OL]. [2017-08-04]. |

| 11 | 杨宇亮. 沥青混合料细观结构的分析系统[D]. 上海: 同济大学交通运输工程学院, 2003. |

| YangYu-liang. Sub-microstructure analysis system of asphalt concrete[D]. Shanghai: School of Transportation Engineering, Tongji University, 2003. | |

| 12 | 张金喜, 张建华, 王德志. 关于低品质粗集料抗冻性能研究[J]. 混凝土, 2005(8): 11-15. |

| ZhangJin-xi, ZhangJian-hua, WangDe-zhi. Frost resistance of the low quality coarse-aggregate[J]. Concrete, 2005(8): 11-15. | |

| 13 | 刘贵应, 戴俊巍, 刘勇, 等. 集料均匀性对沥青混合料低温劈裂强度影响数值研究[J]. 低温建筑技术, 2018, 40(11): 12-16. |

| LiuGui-ying, DaiJun-wei, LiuYong, et al. Numerical simulation of aggregate uniformity influence on low temperature splitting strength of asphalt mixtures[J]. Low Temperature Architecture Technology, 2018, 40(11): 12-16. | |

| 14 | PengY, WanL, SunL J. Three-dimensional discrete element modelling of influence factors of indirect tensile strength of asphalt mixtures[J]. International Journal of Pavement Engineering, 2019, 20(6): 724-733. |

| [1] | Tian⁃lai YU,Hai⁃sheng LI,Wei HUANG,Si⁃jia WANG. Shear strengthening of reinforced concrete beam with prestressed steel wire ropes [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1134-1143. |

| [2] | Xiao⁃zhen LI,Jun⁃zhe LIU,Yan⁃hua DAI,Zhi⁃min HE,Ming⁃fang BA,Yu⁃shun LI. Effect of carbonation on nitrite ion distribution in cement paste [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1162-1168. |

| [3] | Xiao⁃ming HUANG,Qing⁃qing CAO,Xiu⁃yu LIU,Jia⁃ying CHEN,Xing⁃lin ZHOU. Simulation of vehicle braking performance on rainy daysbased on pavement surface fractal friction theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 757-765. |

| [4] | Jing WANG,Xiang LYU,Xiao⁃long QU,Chun⁃ling ZHONG,Yun⁃long ZHANG. Analysis of relationship between subgrade soil shear strength and chemical and minerals component [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 766-772. |

| [5] | LI Yi,LIU Li-ping,SUN Li-jun. Prediction model on rutting equivalent temperature for asphalt pavement at different depth [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1703-1711. |

| [6] | BI Qiu-shi,WANG Guo-qiang,HUANG Ting-ting,MAO Rui,LU Yan-peng. Tooth strength analysis of mineral sizer by coupling discrete element method and finite element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1770-1776. |

| [7] | WANG Yang, WANG Xiao-mei, CHEN Ze-ren, YU Jian-qun. Modeling method of maize kernels based on discrete element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1537-1547. |

| [8] | ZANG Guo-shuai, SUN Li-jun. Method based on inertial point for setting depth to rigid layer [J]. 吉林大学学报(工学版), 2018, 48(4): 1037-1044. |

| [9] | NIAN Teng-fei, LI Ping, LIN Mei. Micro-morphology and gray entropy analysis of asphalt characteristics functional groups and rheological parameters under freeze-thaw cycles [J]. 吉林大学学报(工学版), 2018, 48(4): 1045-1054. |

| [10] | GONG Ya-feng, SHEN Yang-fan, TAN Guo-jin, HAN Chun-peng, HE Yu-long. Unconfined compressive strength of fiber soil with different porosity [J]. 吉林大学学报(工学版), 2018, 48(3): 712-719. |

| [11] | WANG Yang, LYU Feng-yan, XU Tian-yue, YU Jian-qun. Shape and size analysis of soybean kernel and modeling [J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [12] | CHENG Yong-chun, BI Hai-peng, MA Gui-rong, GONG Ya-feng, TIAN Zhen-hong, LYU Ze-hua, XU Zhi-shu. Pavement performance of nano materials-basalt fiber compound modified asphalt binder [J]. 吉林大学学报(工学版), 2018, 48(2): 460-465. |

| [13] | JI Wen-yu, LI Wang-wang, GUO Min-long, WANG Jue. Experimentation and calculation methods of prestressed RPC-NC composite beam deflection [J]. 吉林大学学报(工学版), 2018, 48(1): 129-136. |

| [14] | ZHANG Yang-peng, WEI Hai-bin, JIA Jiang-kun, CHEN Zhao. Numerical evaluation on application of roadbed with composite cold resistance layer inseasonal frozen area [J]. 吉林大学学报(工学版), 2018, 48(1): 121-126. |

| [15] | MA Ye, NI Ying-sheng, XU Dong, DIAO Bo. External prestressed strengthening based on analysis of spatial grid model [J]. 吉林大学学报(工学版), 2018, 48(1): 137-147. |

|

||