Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (8): 1777-1785.doi: 10.13229/j.cnki.jdxbgxb20210201

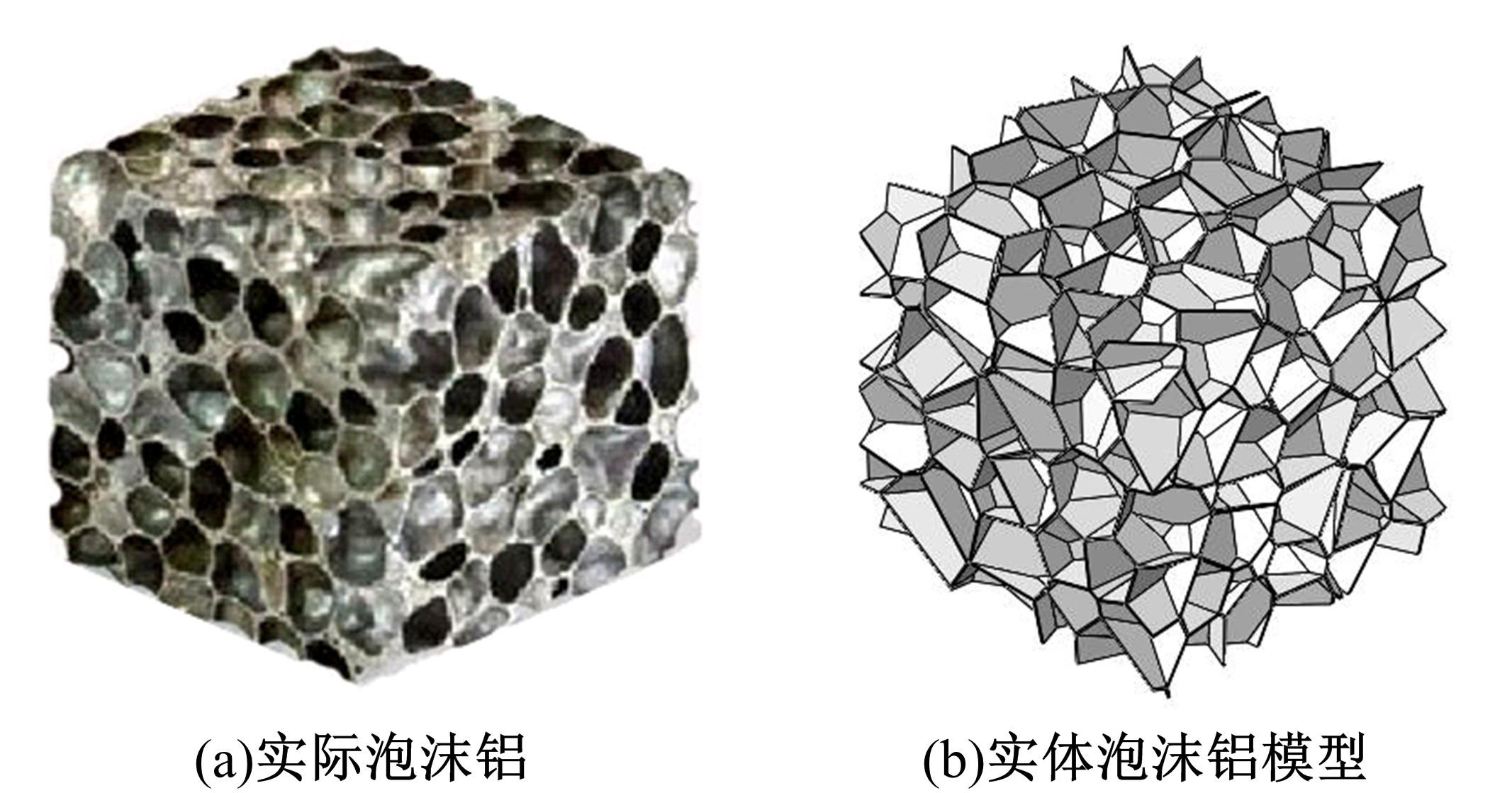

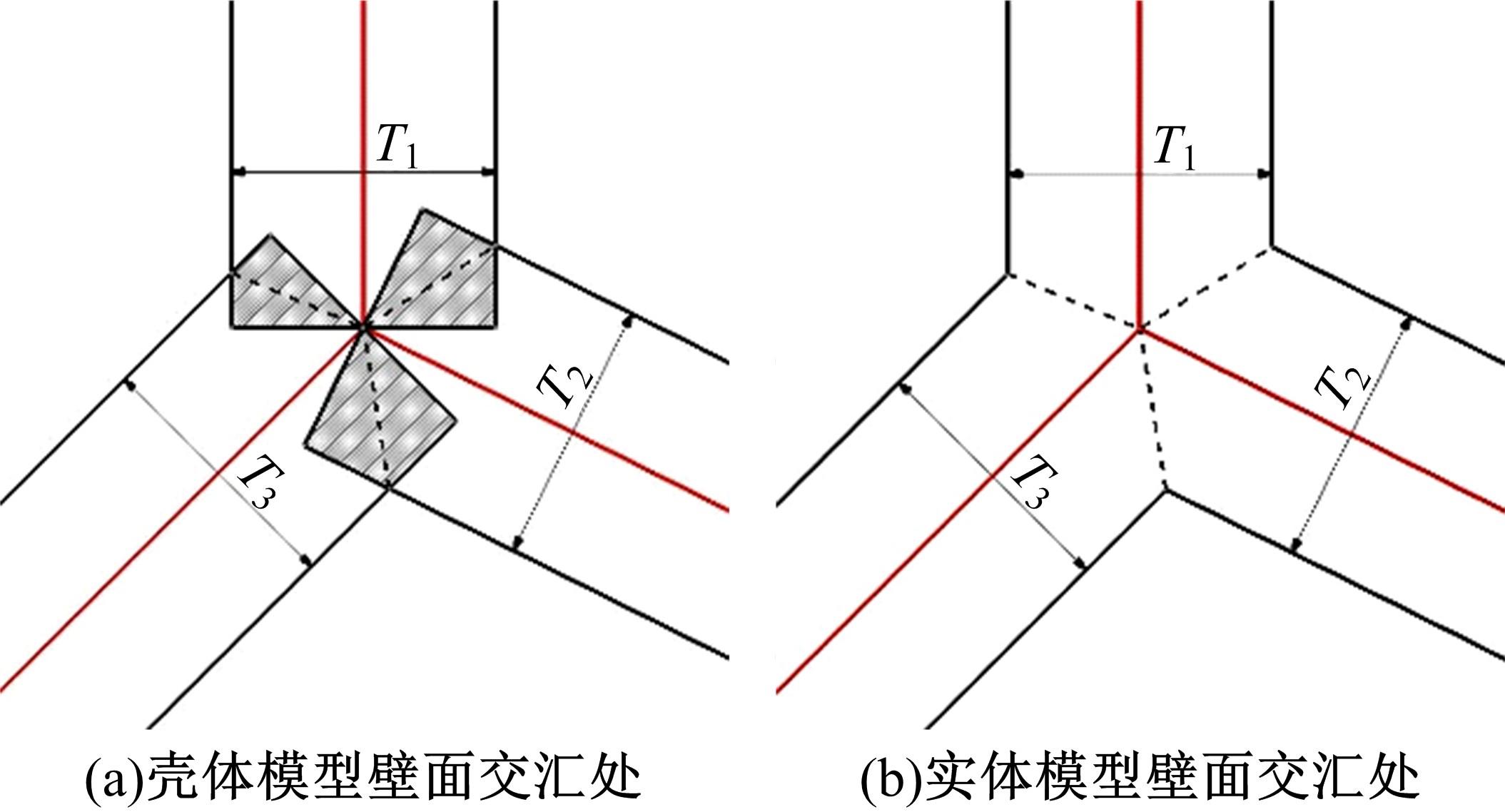

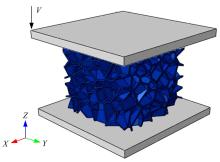

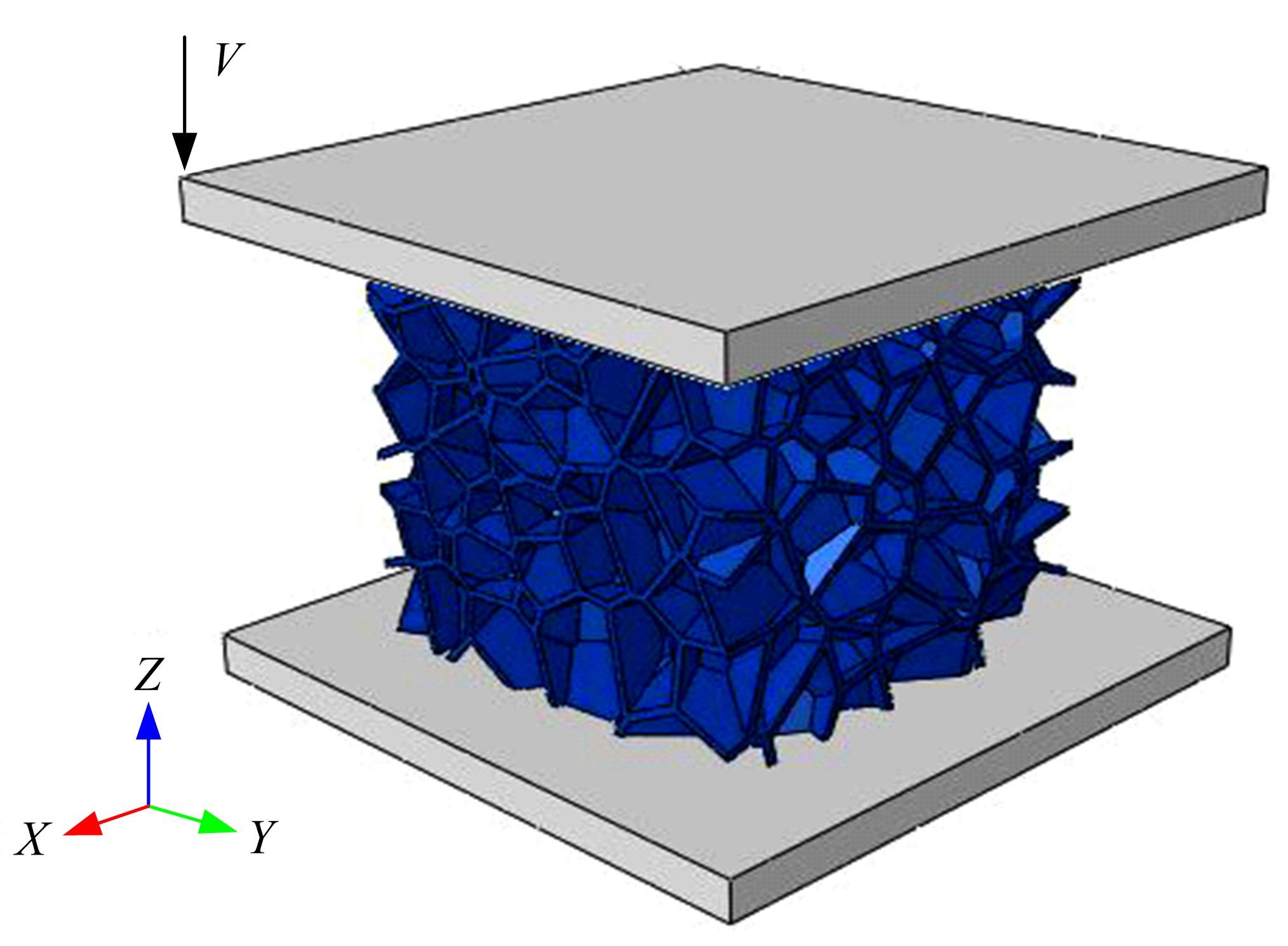

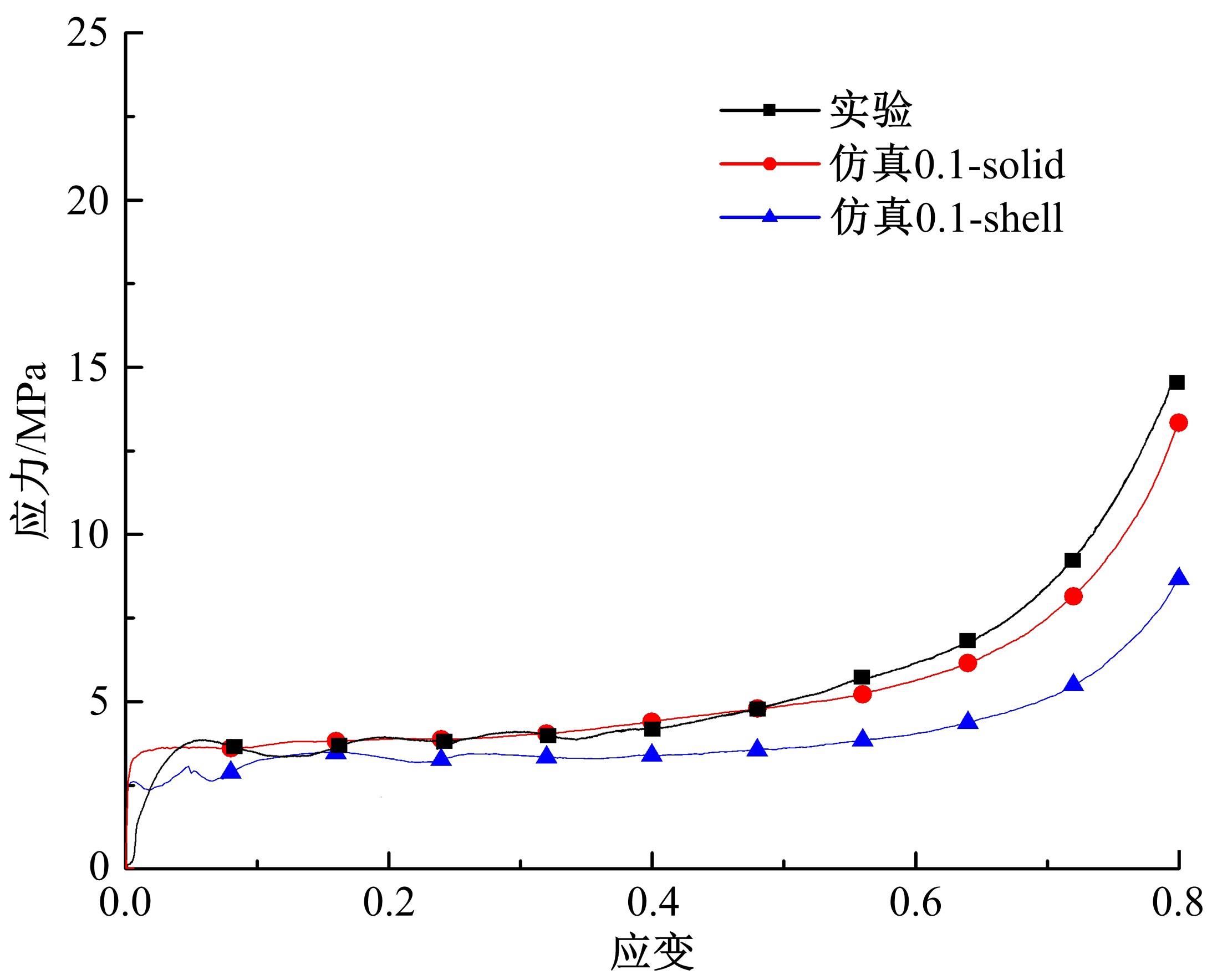

Modeling and compression simulation of 3D solid aluminum foam with random cell wall thickness

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

CLC Number:

- TG146.21

| 1 | 张士卫. 泡沫金属的研究与应用进展[J]. 粉末冶金技术, 2016, 34(3): 222-227. |

| Zhang Shi-wei. Foam metal research and application progress[J]. Powder Metallurgy Technology, 2016, 34(3): 222-227. | |

| 2 | 陈明营, 纪箴, 贾成厂, 等. 泡沫铝及其复合材料的研究进展[J]. 粉末冶金技术, 2019, 37(1): 68-73. |

| Chen Ming-ying, Ji Zhen, Jia Cheng-chang, et al. Research progress of aluminum foam and its composites[J]. Powder Metallurgy Technology, 2019, 37(1): 68-73. | |

| 3 | 张君媛, 张秋实, 刘卫国, 等.泡沫铝填充矩形截面薄壁梁压溃力理论表达式[J]. 吉林大学学报: 工学版, 2016, 46(3): 745-750. |

| Zhang Jun-yuan, Zhang Qiu-shi, Liu Wei-guo, et al. Crushing model of rectangular section thin-walled beam filled with aluminum foam[J]. Journal of Jilin University(Engineering and Technology Edition),2016, 46(3): 745-750. | |

| 4 | 刘家安, 于思荣, 朱先勇. Zn-22Al泡沫夹芯复合板的三点弯曲性能[J]. 吉林大学学报: 工学版, 2012, 42(2): 344-348. |

| Liu Jia-an, Yu Si-rong, Zhu Xian-yong. Three-point bending properties of Zn-22A1 foam sandwich panel[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(2): 344-348. | |

| 5 | Zhang X, Tang L, Liu Z, et al. Yield properties of closed-cell aluminum foam under triaxial loadings by a 3D voronoi model[J]. Mechanics of Materials, 2017, 104: 73-84. |

| 6 | Li Z, Zhang J, Fan J, et al. On crushing response of the three-dimensional closed-cell foam based on voronoi model[J]. Mechanics of Materials, 2014, 68: 85-94. |

| 7 | Shi X, Liu S, Nie H, et al. Study of cell irregularity effects on the compression of closed-cell foams[J]. International Journal of Mechanical Sciences, 2018, 135: 215-225. |

| 8 | Randrianalisoa J, Baillis D, Martin C L, et al. Microstructure effects on thermal conductivity of open-cell foams generated from the laguerre-voronoi tessellation method[J]. International Journal of Thermal Sciences, 2015, 98: 277-286. |

| 9 | Vengatachalam B, Poh L H, Liu Z S, et al. Three dimensional modelling of closed-cell aluminium foams with predictive macroscopic behaviour[J]. Mechanics of Materials, 2019, 136: 103067. |

| 10 | 杨宝, 汤立群, 刘逸平, 等. 冲击条件下泡沫铝的细观变形特征分析[J]. 爆炸与冲击, 2012, 32(4): 399-403. |

| Yang Bao, Tang Li-qun, Liu Yi-ping, et al. Meso deformation characteristics analysis of aluminum foam under impact[J]. Explosion and Shock Waves, 2012, 32(4): 399-403. | |

| 11 | 王巍, 安子军, 彭春彦, 等. 闭孔泡沫材料3-D几何建模及力学性能分析[J]. 塑性工程学报, 2017, 24(4): 194-200. |

| Wang Wei, An Zi-jun, Peng Chun-yan, et al. 3-D geometry modeling and mechanical properties analysis of closed-cell foams[J]. Journal of Plasticity Engineering, 2017, 24(4): 194-200. | |

| 12 | 程振, 方秦, 张锦华, 等. 闭孔泡沫金属三维细观模型建模方法[J]. 工程力学, 2017, 34(8): 212-221. |

| Cheng Zhen, Fang Qin, Zhang Jin-hua, et al. Mesoscopic methodology for the three-dimensional modelling of closed-cell metallic foam[J]. Engineering Mechanics, 2017, 34(8): 212-221. | |

| 13 | Li Q M. Compressive strain at the onset of densification of cellular solids[J]. Journal of Cellular Plastics, 2006, 42(5): 371-392. |

| 14 | Liu Y, Yu J, Zheng Z, et al. A numerical study on the rate sensitivity of cellular metals[J]. International Journal of Solids and Structures, 2009, 46(22): 3988-3998. |

| [1] | Yin-bao TIAN,Jun-qi SHEN,Sheng-sun HU,Jian GOU. Effect of EP/EN Balance on droplet transfer and weld formation of Al alloy by VP⁃CMT [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1663-1668. |

| [2] | Jin-guo WANG,Zhi-qiang WANG,Shuai REN,Rui-fang YAN,Kai HUANG,Jin GUO. Effect of Ti addition on microstructure and mechanical properties of ductile iron [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1653-1662. |

| [3] | Wen-biao GONG,Rui ZHU,Xin-zhe QIE,Heng CUI,Ming-yue GONG. Microstructure and properties of 6082 aluminum alloyultra⁃thick plate preparated by friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. |

| [4] | Xue-wen CHEN,Ji-ye WANG,Xi-qing YANG,Tao HUANG,Ke-xing SONG. Hot deformation behavior and dislocation density evolution regularity of Cr8 alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 91-99. |

| [5] | Jin-guo WANG,Shuai REN,Rui-fang YAN,Kai HUANG,Zhi-qiang WANG. Effect of TiC particles on microstructure and mechanical properties of as cast ductile iron [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2010-2018. |

| [6] | Yu⁃peng LI,Da⁃qian SUN,Wen⁃biao GONG. Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 836-841. |

| [7] | GUAN Qing-feng,ZHANG Fu-tao,PENG Tao,LYU Peng,LI Yao-jun,XU Liang,DING Zuo-jun. Hot deformation behavior of 9%Cr steel contained B and Co elements [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1799-1805. |

| [8] | GUAN Qing-feng, DONG Shu-heng, ZHENG Huan-huan, LI Chen, ZHANG Cong-lin, LV-Peng. Cr surface alloying of 45# steel by high-current pulsed electron beam treatment [J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [9] | ZHAO Yu-guang, YANG Xue-hui, XU Xiao-feng, ZHANG Yang-yang, NING Yu-heng. Effects of Al-10Sr modifiers with different states, modification temperature and holding time on microstructure of ZL114A alloy [J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [10] | TANG Hua-guo, MA Xian-feng, ZHAO Wei, LIU Jian-wei, ZHAO Zhen-ye. Synthesis microstructure and thermal properties of high performance bulk Al [J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [11] | GUAN Qing-feng, ZHANG Yuan-wang, SUN Xiao, ZHANG Chao-ren, LYU Peng, ZHANG Cong-lin. Surface alloying of Al-W alloy by high current pulsed electron beam treatment [J]. 吉林大学学报(工学版), 2017, 47(4): 1171-1178. |

| [12] | YANG Xiao-hong, HANG Wen-xian, QIN Shao-gang, LIU Yong-bing, LIU Li-ping. Microstructure and wear properties of Co-based composite coatings on H13 steel surface by laser cladding [J]. 吉林大学学报(工学版), 2017, 47(3): 891-899. |

| [13] | GUAN Qing-feng, HUANG Wei, LI Huai-fu, GONG Xiao-hua, ZHANG Cong-lin, LYU Peng. Diffusion alloying of Cu-C induced by high current pulsed electron beam [J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

| [14] | LIU Xiao-bo, ZHOU De-kun, ZHAO Yu-guang. Microstructure and mechanical property of Mg2Si/Al composites fabricated by semi-solid extrusion under different isothermal heat treatments [J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [15] | ZHANG Xue-guang, LIU Chun-guo, ZHENG Yuan, JIANG Zhong-hai, LI Xiang-ji. Forming limit prediction of aluminum alloy based on ductile damage and shear damage [J]. 吉林大学学报(工学版), 2016, 46(5): 1558-1566. |

|

||