Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1663-1668.doi: 10.13229/j.cnki.jdxbgxb20190580

Effect of EP/EN Balance on droplet transfer and weld formation of Al alloy by VP⁃CMT

Yin-bao TIAN1,2( ),Jun-qi SHEN1(

),Jun-qi SHEN1( ),Sheng-sun HU1,Jian GOU1

),Sheng-sun HU1,Jian GOU1

- 1.School of Materials Science and Engineering, Tianjin University, Tianjin 300354, China

2.Department of Mechanical Engineering, University of Michigan, Ann Arbor 48109, USA

CLC Number:

- TG455

| 1 | Zapico E P, Lutey A H A, Ascari A, et al. An improved model for cold metal transfer welding of aluminium alloys[J]. Journal of Thermal Analysis and Calorimetry, 2017, 131: 3003-3009. |

| 2 | 庞杰. 铝合金CMT+P焊接熔滴过渡行为研究[D]. 天津: 天津大学材料科学与工程学院, 2016. |

| Pang Jie. Study on metal transfer behavior of CMT+P welding for aluminum alloys[D]. Tianjin: School of Materials Science and Engineering, Tianjin University, 2016. | |

| 3 | 汪殿龙, 张志洋, 王波, 等. 铝锂合金交流CMT焊接高频脉冲复合电弧焊接技术研究进展[J]. 河北科技大学学报, 2013, 34(2): 91-96. |

| Wang Dian-long, Zhang Zhi-yang, Wang Bo, et al. Alternating current CMT and high frequency pulse composite arc on Al-Li alloys welding technique[J]. Journal of Hebei University of Science and Technology, 2013, 34(2): 91-96. | |

| 4 | Zhang C, Li Y F, Gao M, et al. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source[J]. Materials Science & Engineering A, 2018, 711: 415-423. |

| 5 | Li G J, Zhang P L, Wu X, et al. Gap bridging of 6061 aluminum alloy joints welded by variable-polarity cold metal transfer[J]. Journal of Materials Processing Technology, 2018, 255: 927-935. |

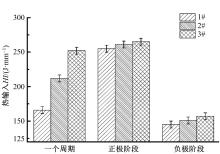

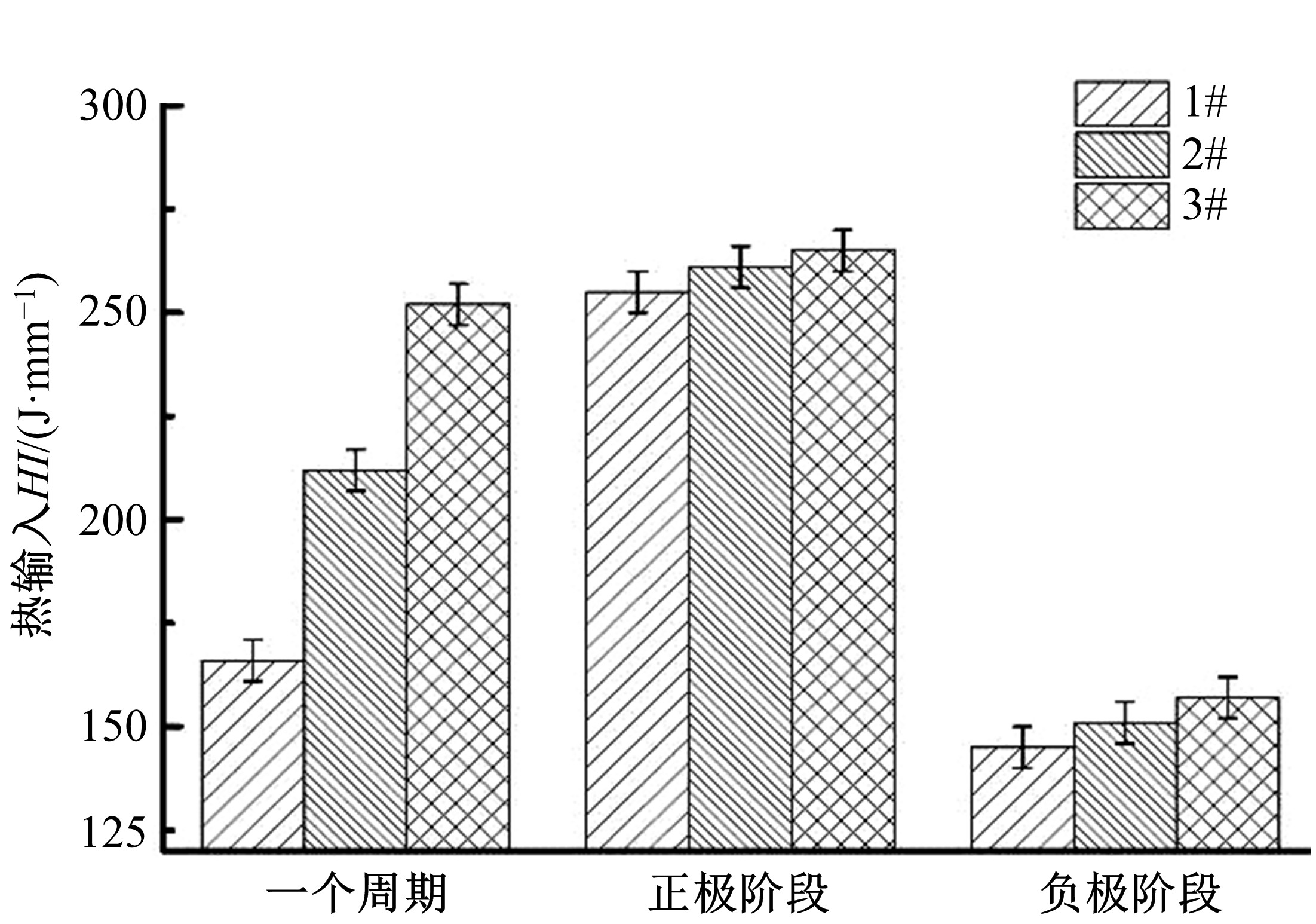

| 6 | Wang P, Hu S S, Shen J Q, et al. Effects of electrode positive/negative ratio on microstructure and mechanical properties of Mg/Al dissimilar variable polarity cold metal transfer welded joints[J]. Materials Science & Engineering A, 2016, 652: 127-135. |

| 7 | Nie Y P, Zhang P L, Wu X, et al. Rapid prototyping of 4043 Al-alloy parts by cold metal transfer[J]. Science and Technology of Welding and Joining, 2018, 23(6): 527-535. |

| 8 | Tian Y B, Shen J Q, Hu S S, et al. Effects of ultrasonic vibration in the CMT process on welded joints of Al alloy [J]. Journal of Materials Processing Technology, 2018, 259: 282-291. |

| 9 | Feng J C, Zhang H T, He P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding[J]. Materials and Design, 2009, 30(5): 1850-1852. |

| 10 | 汪殿龙, 张志洋, 梁志敏, 等. 交流CMT动态电弧特征及熔滴过渡行为分析[J]. 焊接学报, 2014, 35(3): 6-10. |

| Wang Dian-long, Zhang Zhi-yiang, Liang Zhi-min, et al. Analysis of dynamic arc characteristics and melt transfer behavior of AC CMT[J]. Transactions of the China Welding Institution, 2014, 35(3): 6-10. | |

| 11 | 王鹏. 基于CMT焊接能量输入过程控制的镁/铝异种金属焊接研究[D]. 天津: 天津大学材料科学与工程学院, 2017. |

| Wang Peng. Study on CMT welding process of Mg/Al dissimilar metals based on the control of energy input process[D]. Tianjin: School of Materials Science and Engineering, Tianjin University, 2017. | |

| 12 | 张瑞英,穆森,王军. 铝合金薄板交流CMT焊接过程能量分配研究[J]. 电焊机, 2013, 43(6): 22-26. |

| Zhang Rui-ying, Mu Sen, Wang Jun. Research on energy distribution of AD CMT advanced welding with aluminum alloy sheet[J]. Electric Welding Machine, 2013, 43(6): 22-26. | |

| 13 | Niu S, Chen S, Dong H G, et al. Microstructure and properties of lap joint between aluminum alloy and galvanized steel by CMT[J]. Journal of Materials Engineering and Performance, 2016, 25(5): 1839-1847. |

| 14 | 谷晓燕, 刘东锋, 刘婧, 等. 焊接能量对Cu/Al超声波焊接接头组织与性能的影响[J]. 吉林大学学报: 工学版, 2019, 49(5): 1600-1607. |

| Gu Xiao-yan, Liu Dong-feng, Liu Jing, et al. Effect of welding energy on microstructure and mechanical properties of Cu/Al joints welded by ultrasonic welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1600-1607. | |

| 15 | 宫文彪, 朱芮, 郄新哲, 等. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报: 工学版, 2020, 50(2): 512-519. |

| Gong Wen-biao, Zhu Rui, Xin-zhe Qie, et al. Microstructure and properties of 6082 aluminum alloy ultra-thick plate prepared by friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. |

| [1] | Jin-guo WANG,Zhi-qiang WANG,Shuai REN,Rui-fang YAN,Kai HUANG,Jin GUO. Effect of Ti addition on microstructure and mechanical properties of ductile iron [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1653-1662. |

| [2] | Wen-biao GONG,Rui ZHU,Xin-zhe QIE,Heng CUI,Ming-yue GONG. Microstructure and properties of 6082 aluminum alloyultra⁃thick plate preparated by friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. |

| [3] | Jin-guo WANG,Shuai REN,Rui-fang YAN,Kai HUANG,Zhi-qiang WANG. Effect of TiC particles on microstructure and mechanical properties of as cast ductile iron [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2010-2018. |

| [4] | Yu⁃peng LI,Da⁃qian SUN,Wen⁃biao GONG. Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 836-841. |

| [5] | ZHAO Yu-guang, YANG Xue-hui, XU Xiao-feng, ZHANG Yang-yang, NING Yu-heng. Effects of Al-10Sr modifiers with different states, modification temperature and holding time on microstructure of ZL114A alloy [J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [6] | TANG Hua-guo, MA Xian-feng, ZHAO Wei, LIU Jian-wei, ZHAO Zhen-ye. Synthesis microstructure and thermal properties of high performance bulk Al [J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [7] | LIU Xiao-bo, ZHOU De-kun, ZHAO Yu-guang. Microstructure and mechanical property of Mg2Si/Al composites fabricated by semi-solid extrusion under different isothermal heat treatments [J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [8] | LI Chun-ling, FAN Ding, WANG Bin, YU Shu-rong. 5A06 aluminum alloy and galvanized steel butt welding-brazing by laser with preset filler powder [J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [9] | ZHANG Jia-tao, ZHAO Yu-guang, TAN Juan. Effect of starting microstructure on refining potency of electro-pulsing on reverse austenite grain [J]. 吉林大学学报(工学版), 2016, 46(1): 193-198. |

| [10] | GUAN Qing-feng, LI Yan, HOU Xiu-li, YANG Sheng-zhi, WANG Xiao-tong. Modification of solid solution Mg-Gd-Y-Nd alloy irradiated by high current pulsed electron beam [J]. 吉林大学学报(工学版), 2015, 45(4): 1200-1205. |

| [11] | MA Yun-hai, SHANG Wen-bo, FAN Xue-ying, GAO Zhi-hui, TONG Jin, YAN Zhi-feng, CHANG Zhi-yong. Preparation and degradation of porous β-tricalcium phosphate bioceramic for bone imitaion [J]. 吉林大学学报(工学版), 2015, 45(4): 1367-1374. |

| [12] | GAO Song, LIANG Ji-cai, CHEN Guang-yi, WEI Zhi-yong, TENG Fei. Rapid adjusting of fundamental units in process of flexible 3D stretch-bending [J]. 吉林大学学报(工学版), 2014, 44(6): 1723-1728. |

| [13] | HUANG Jian-kang, HE Cui-cui, SHI Yu, FAN Ding. Thermodynamic analysis of Al-Fe intermetallic compounds formed by dissimilar joining of aluminum and galvanized steel [J]. 吉林大学学报(工学版), 2014, 44(4): 1037-1041. |

| [14] | LI Xin,WANG Gang,LU Guan-han,GU Zheng-wei,XU Hong. Weldability of 22MnB5 after hot stamping by TIG welding processes [J]. 吉林大学学报(工学版), 2014, 44(3): 708-711. |

| [15] | GUAN Qing-feng,JI Le,CAI Jie,YANG Sheng-zhi,LIU Shi-chao,ZHANG Zai-qiang,HOU Xiu-li. Surface microstructure and properties of 3Cr13 martensitic stainless steel after high current pulsed electron beam bombardment [J]. 吉林大学学报(工学版), 2014, 44(3): 712-717. |

|

||