Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (9): 2542-2553.doi: 10.13229/j.cnki.jdxbgxb.20211260

Previous Articles Next Articles

Stress⁃strain characteristics of geogrid reinforced rubber sand mixtures

Fang-cheng LIU1( ),Jiang WANG1,Meng-tao WU2,Guo-bin BU1(

),Jiang WANG1,Meng-tao WU2,Guo-bin BU1( ),Jie HE1

),Jie HE1

- 1.College of Civil Engineering,Hunan University of Technology,Zhuzhou 412007,China

2.School of Civil Engineering,Tianjin University,Tianjin 300072,China

CLC Number:

- TU411.3

| 1 | Patil U, Valdes J R, Evans T M. Swell mitigation with granulated tire rubber[J]. Journal of Materials in Civil Engineering, 2011, 23(5): 721-727. |

| 2 | Soltani-jigheh H, Asadzadeh M, Marefat V. Effects of tire chips on shrinkage and cracking characteristics of cohesive soils[J]. Turkish Journal of Engineering and Environmental Sciences, 2013, 37(37): 259-271. |

| 3 | Xiao M, Bowen J, Graham M, et al. Comparison of seismic responses of geosynthetically reinforced walls with tire-derived aggregates and granular backfills[J]. Journal of Materials in Civil Engineering, 2012, 24(11): 1368-1377. |

| 4 | Christ M, Park J B, Hong S S. Laboratory Observation of the response of a buried pipeline to freezing rubber-sand backfill[J]. Journal of Materials in Civil Engineering, 2010, 22(9): 943-950. |

| 5 | Mehrjardi G T, Tafreshi S N M, Dawson A R. Numerical analysis on Buried pipes protected by combination of geocell reinforcement and rubber-soil mixture[J]. International Journal of Civil Engineering, Transaction B: Geotechnical Engineering, 2015, 13(2): 90-104. |

| 6 | Feng Z Y, Sutter K G. Dynamic properties of granulated rubber-sand mixtures[J]. Geotechnical Testing Journal, 2000, 23(3): 338-344. |

| 7 | Senetakis K, Anastasiadis A, Pitilakis K. Dynamic properties of dry sand/rubber (SRM) and gravel/rubber (GRM) mixtures in a wide range of shearing strain amplitudes[J]. Soil Dynamics and Earthquake Engineering, 2012, 33(1): 38-53. |

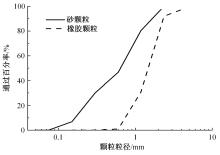

| 8 | 刘方成, 陈璐, 王海东. 橡胶砂动剪模量和阻尼比循环单剪试验研究[J]. 岩土力学, 2016, 37(7): 1903-1913. |

| Liu Fang-cheng, Chen Lu, Wang Hai-dong. Evaluation of dynamic shear modulus and damping ratio of rubber-sand mixture based on cyclic simple shear tests[J]. Rock and Soil Mechanics, 2016, 37(7): 1903-1913. | |

| 9 | 姚玉文, 刘方成, 补国斌, 等. 橡胶砂弹性动力学参数的弯曲-伸缩元试验研究[J]. 岩土力学, 2020, 41(7): 2369-2379. |

| Yao Yu-wen, Liu Fang-cheng, Bu Guo-bin, et al. Laboratory study on elastic dynamic mechanics of rubber-sand mixture by bender-extender element method[J]. Rock and Soil Mechanics, 2020, 41(7): 2369-2379. | |

| 10 | Das S, Bhowmik D. Small-strain dynamic behavior of sand and sand-crumb rubber mixture for different sizes of crumb rubber particle[J]. Journal of Materials in Civil Engineering, 2020, 32(11): No. 04020334. |

| 11 | Rios S, Kowalska M, da Fonseca A V. Cyclic and dynamic behavior of sand-rubber and clay-rubber mixtures[J]. Geotechnical and Geological Engineering, 2021, 39(5): 3449-3467. |

| 12 | Lee J, Salgado R, Bernal A, et al. Shredded tires and rubber-sand as lightweight backfill[J]. Journal of Geotechnical and Geoenvironmental Engineering, 1999, 125(2): 132-141. |

| 13 | Tsang H H, Lo S H, Xu X, et al. Seismic isolation for low-to-medium-rise buildings using granulated rubber-soil mixtures: numerical study[J]. Earthquake Engineering and Structural Dynamics, 2012, 41(14): 2009-2024. |

| 14 | 刘方成, 任东滨, 刘娜, 等. 土工格室加筋橡胶砂垫层隔震效果数值分析[J]. 土木工程学报, 2015, 47(): 1-7. |

| Liu Fang-cheng, Ren Dong-bin, Liu Na, et al. Numerical simulation on the isolation effect of geocell reinforced rubber-sand mixture cushion as earthquake base isolator[J]. China Civil Engineering Journal, 2015, 47(Sup.2): 1-7. | |

| 15 | Tsang H H, Tran D P, Hung W Y, et al. Performance of geotechnical seismic isolation system using rubber-soil mixtures in centrifuge testing[J]. Earthquake Engineering & Structural Dynamics, 2021, 50(5): 1271-1289. |

| 16 | Pitilakis D, Anastasiadis A, Vratsikidis A, et al. Large-scale field testing of geotechnical seismic isolation of structures using gravel-rubber mixtures[J]. Earthquake Engineering & Structural Dynamics, 2021, 50(10): 2712-2731. |

| 17 | Zornberg J G, Cabral A R, Viratjandr C. Behaviour of tire shred sand mixtures[J]. Canadian Geotechnical Journal, 2004, 41(2): 227-241. |

| 18 | 辛凌, 刘汉龙, 沈扬, 等. 废弃轮胎橡胶颗粒轻质混合土强度特性试验研究[J]. 岩土工程学报, 2010, 32(3): 428-433. |

| Xin Ling, Liu Han-long, Shen Yang, et al. Consolidated undrained triaxial compression tests on lightweight soil mixed with rubber chips of scrap tires[J]. Chinese Journal of Geotechnical Engineering, 2010, 32(3): 428-433. | |

| 19 | Cabalar A F. Direct shear tests on waste tires-sand mixtures[J]. Geotechnical and Geological Engineering, 2011, 29(4): 411-418. |

| 20 | Vinod J S, Sheikh M N, Mastello D, et al. The direct shear strength of sand tyre shred mixtures[C]∥Proceedings of the International Conference on Geotechnical Engineering, Sri Lanka, 2015: 193-196. |

| 21 | 汪明元, 施戈亮, 丁金华, 等. 土工格栅与压实膨胀土的界面模型及其参数[J]. 吉林大学学报:工学版, 2010, 40(3): 688-693. |

| Wang Ming-yuan, Shi Ge-liang, Ding Jin-hua, et al. Interface model and its parameters between geogrids and compacted expansive soil[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(3): 688-693. | |

| 22 | 王蔓, 李泽成, 白瑞祥. 复合材料格栅加筋板的分层扩展特性[J]. 吉林大学学报:工学版, 2007, 37(1): 229-233. |

| Wang Man, Li Ze-cheng, Bai Rui-xiang, Delamination growth characteristics for composite grid stiffened plates[J]. Journal of Jilin University(Engineering and Technology Edition), 2007, 37(1): 229-233. | |

| 23 | 杨广庆. 土工格栅加筋土结构理论及工程应用[M]. 北京:科学出版社, 2010. |

| 24 | Han J. Principles and Practice of Ground Improvement[M]. New York: John Wiley & Sons, 2015. |

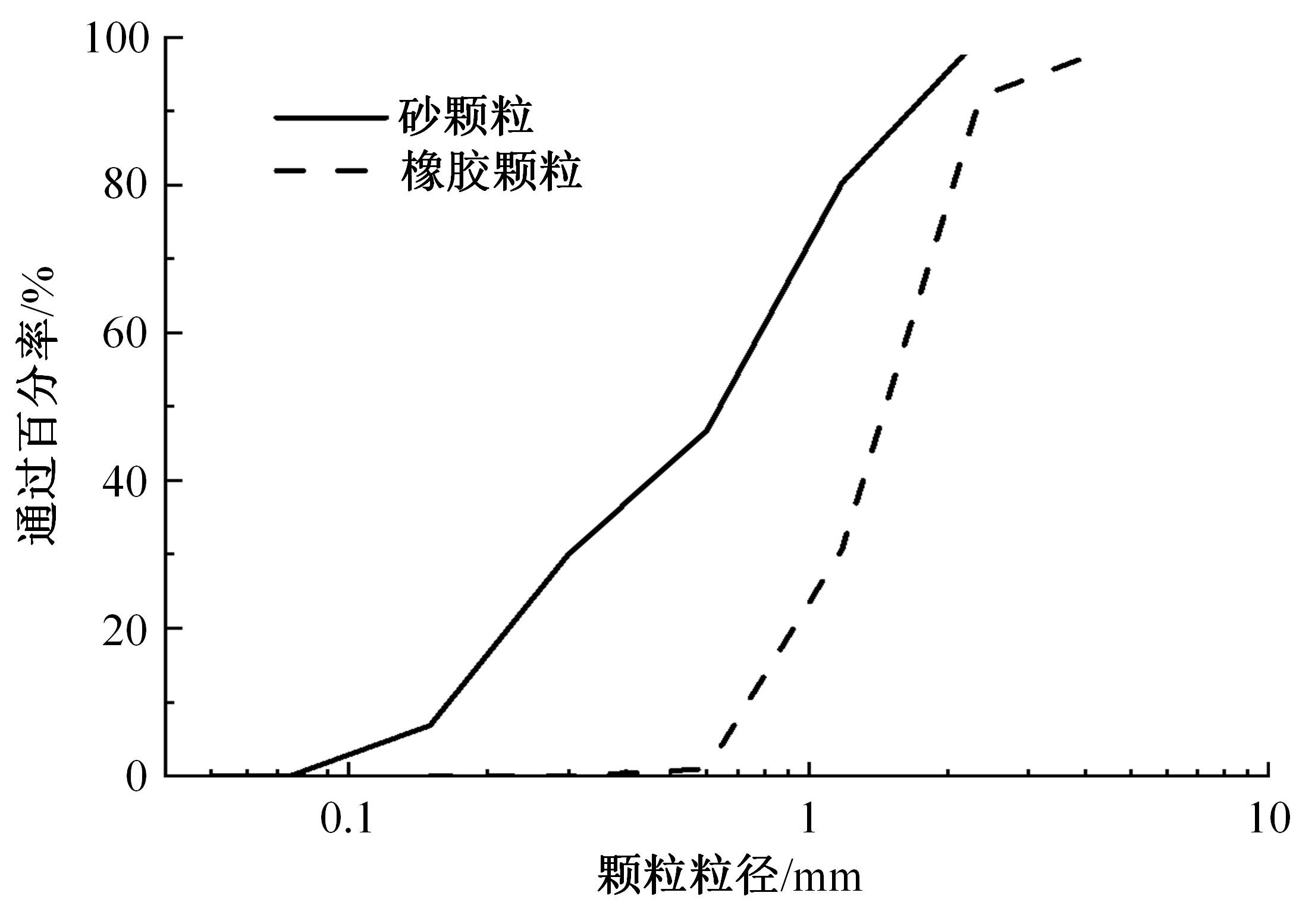

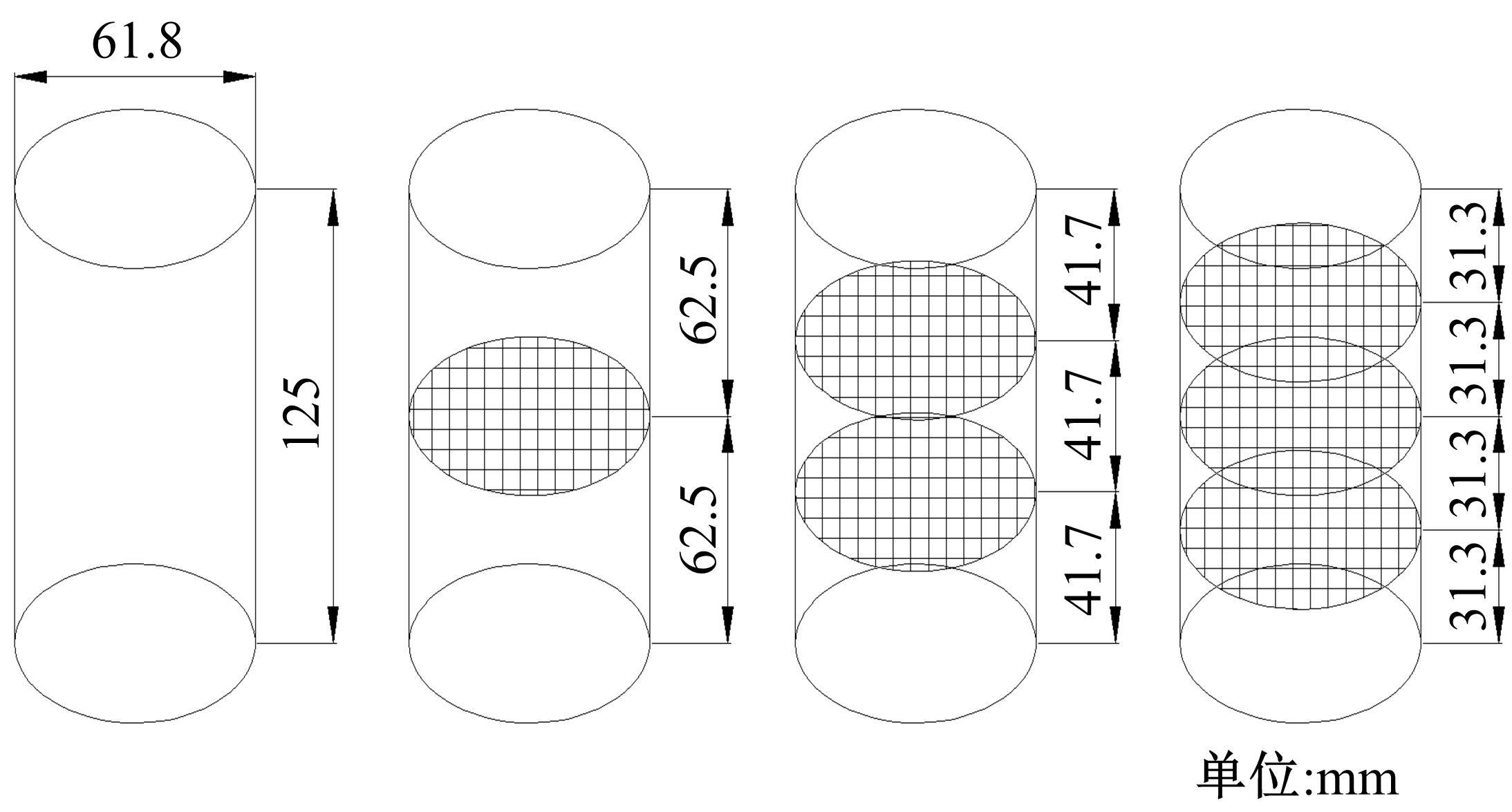

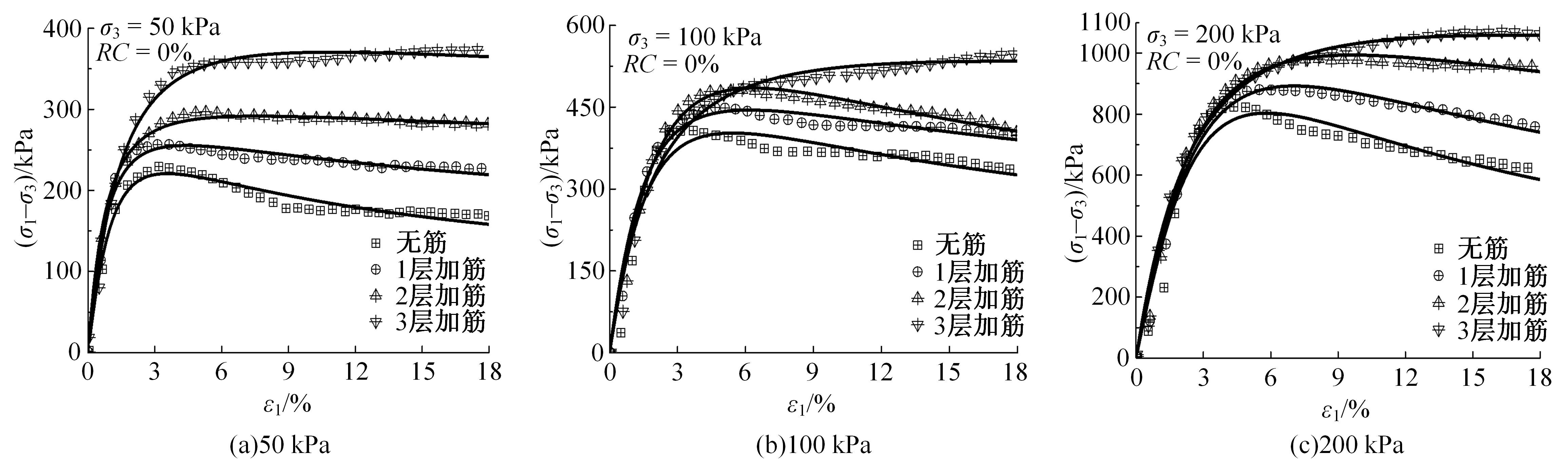

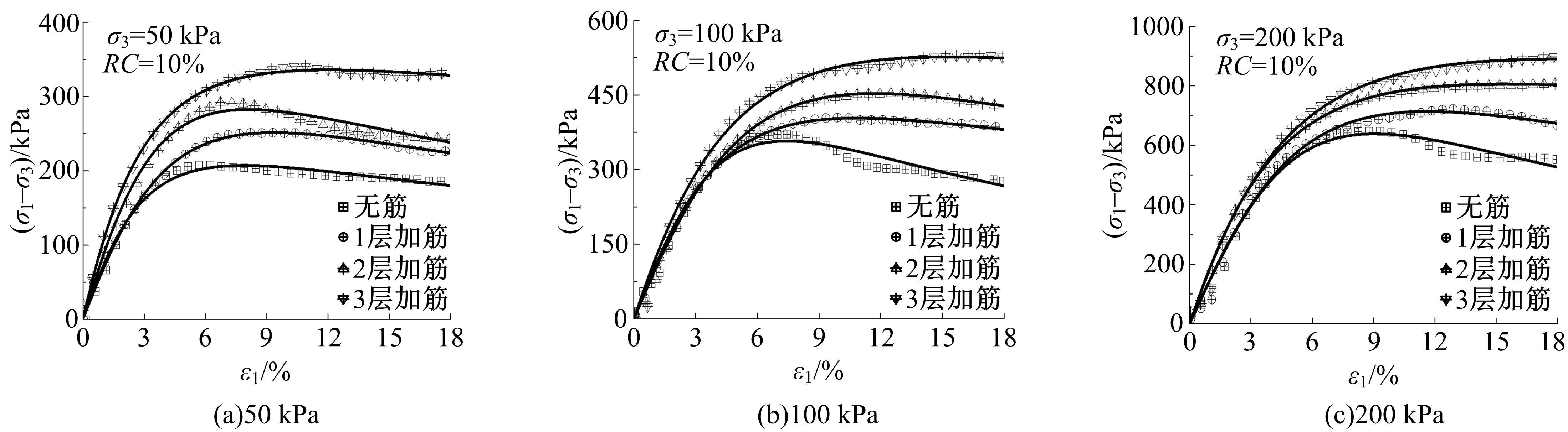

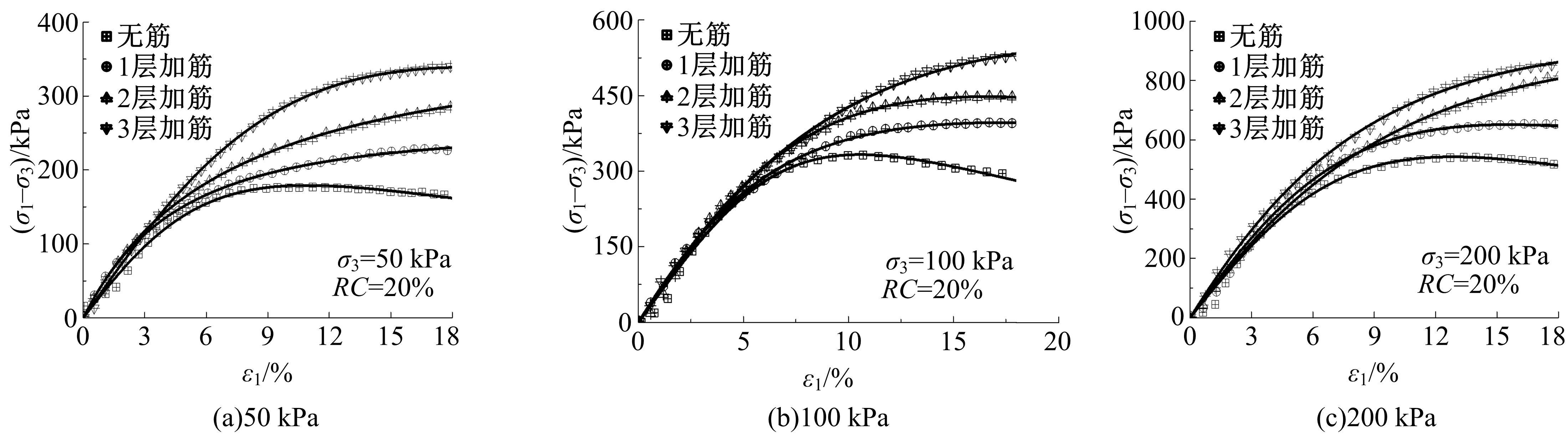

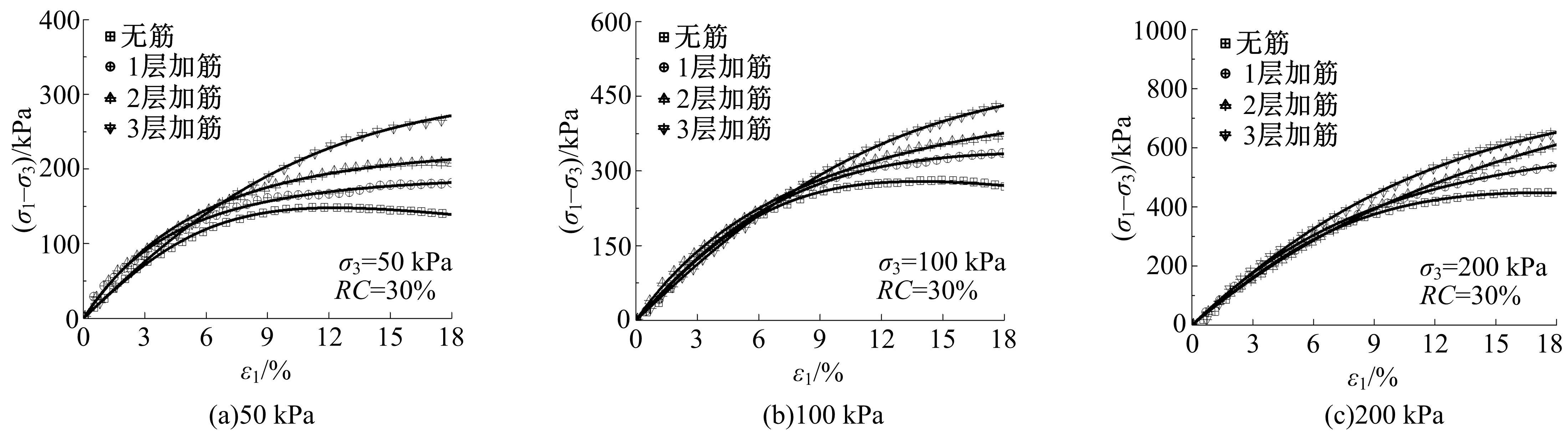

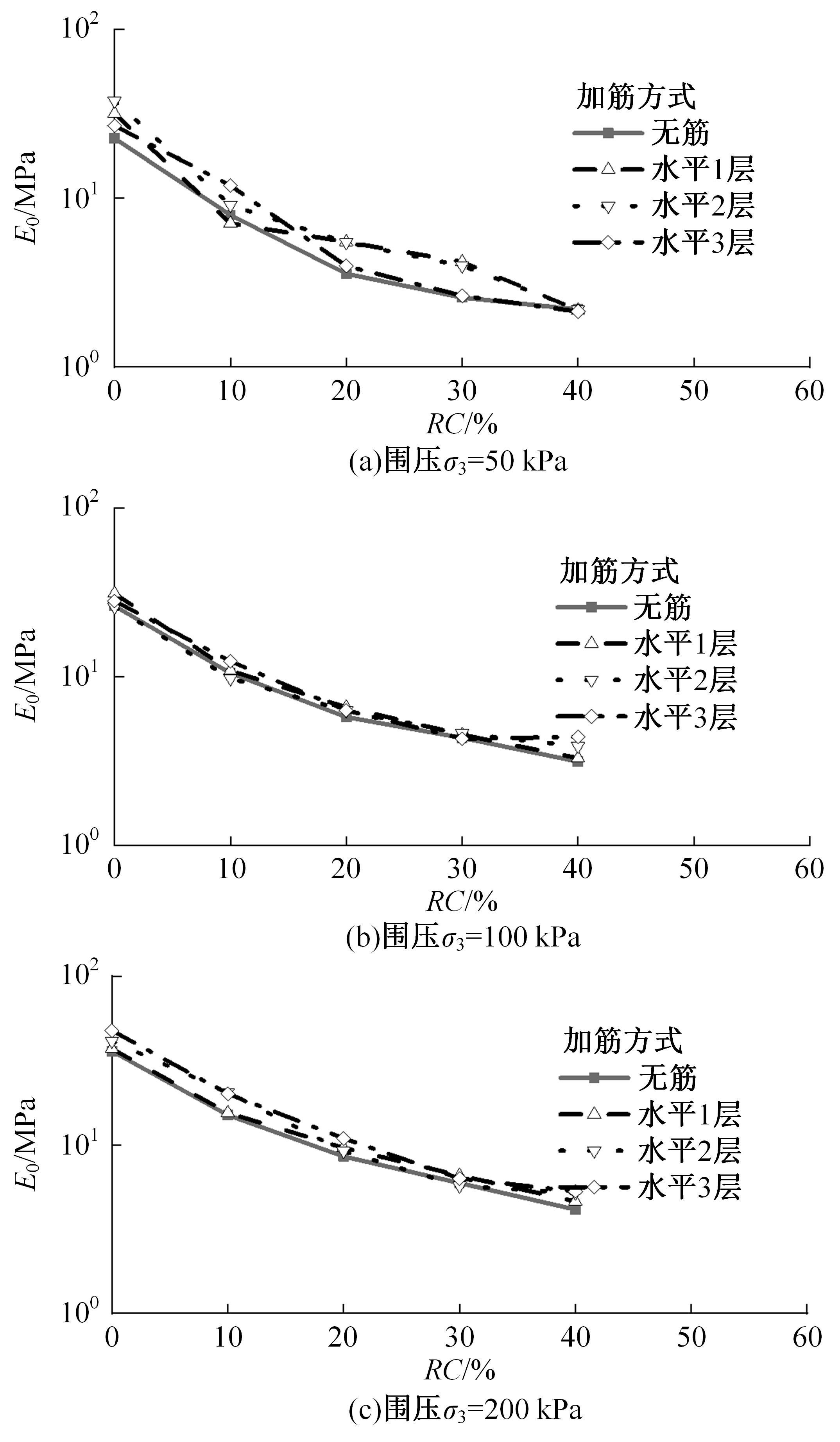

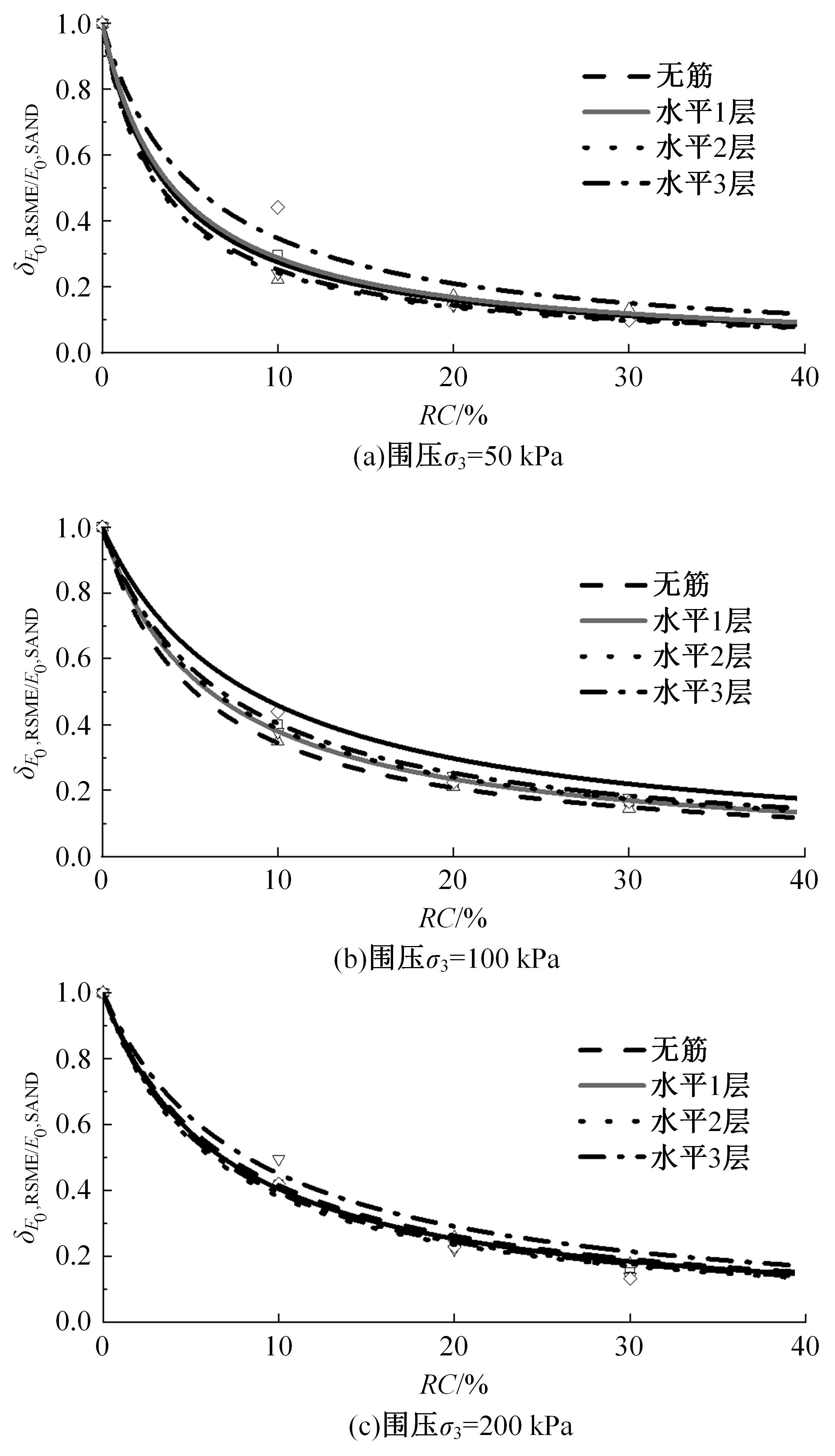

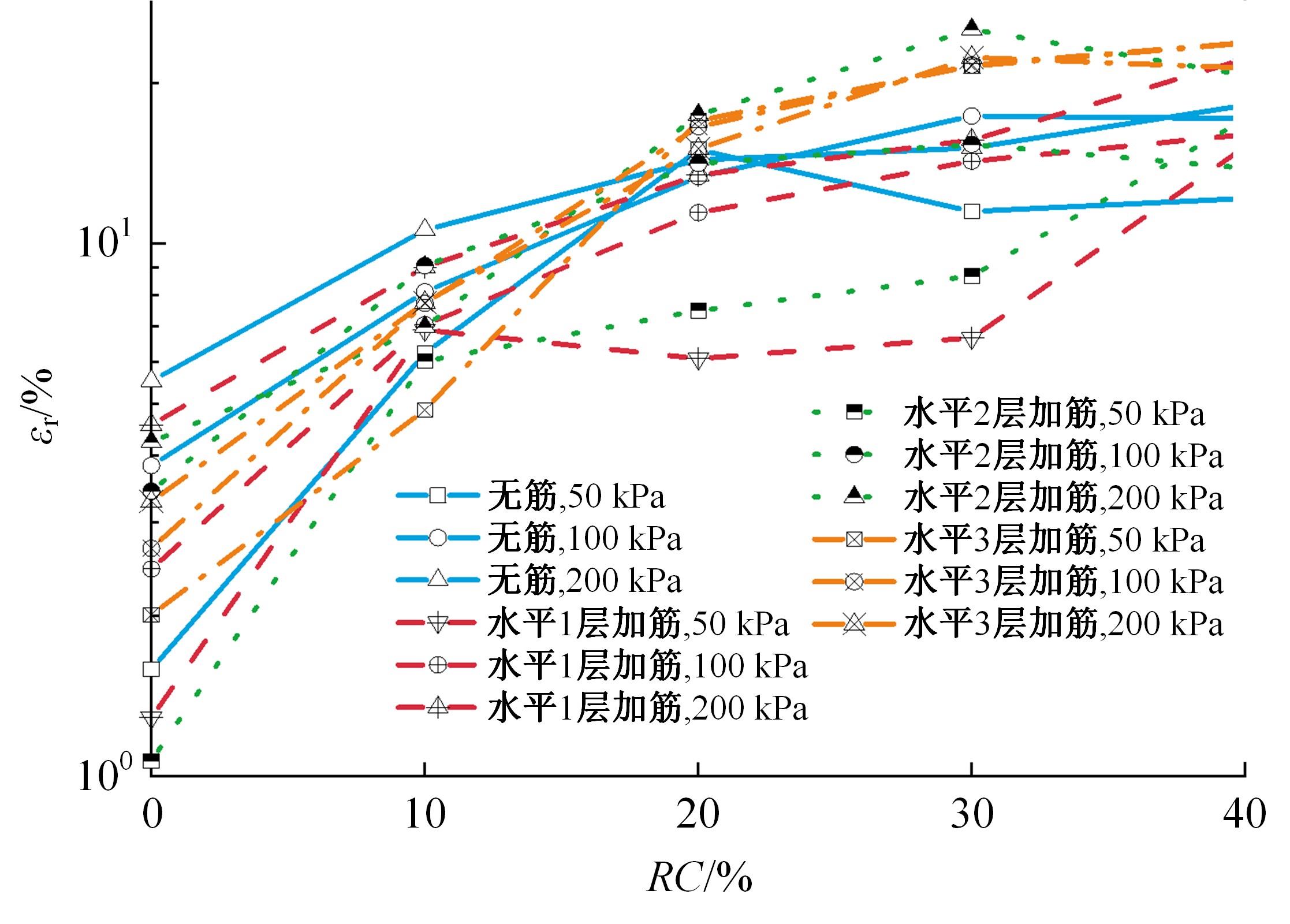

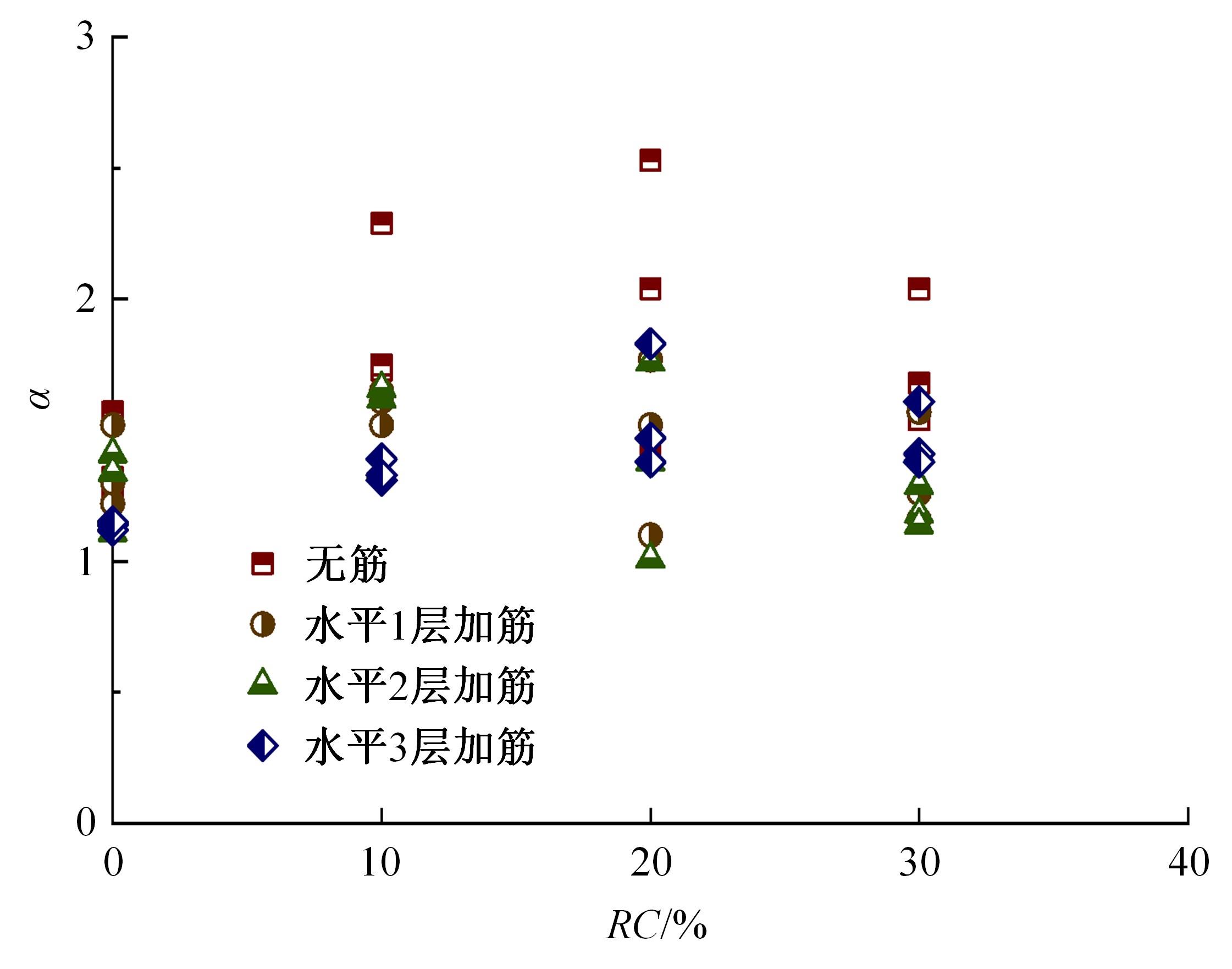

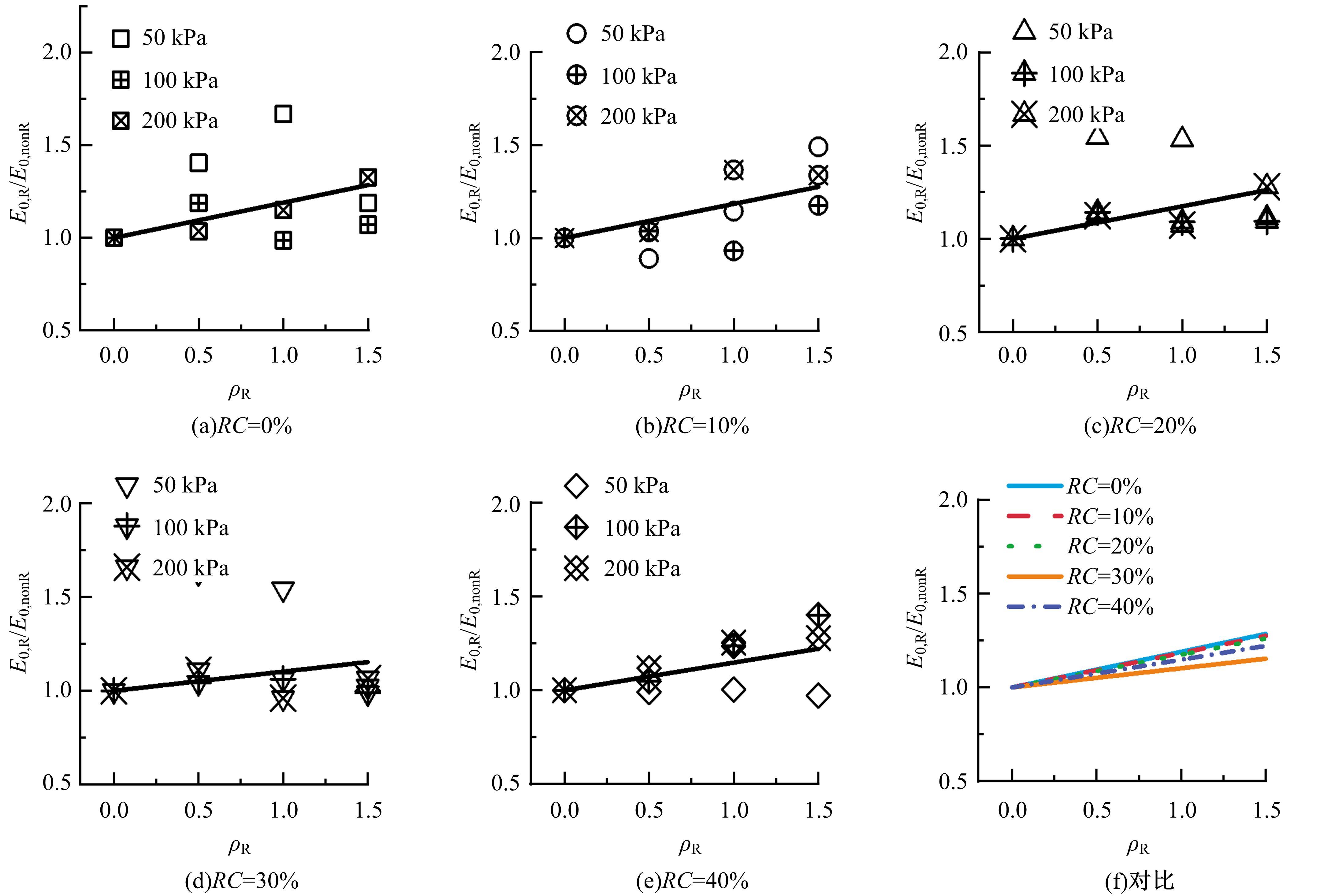

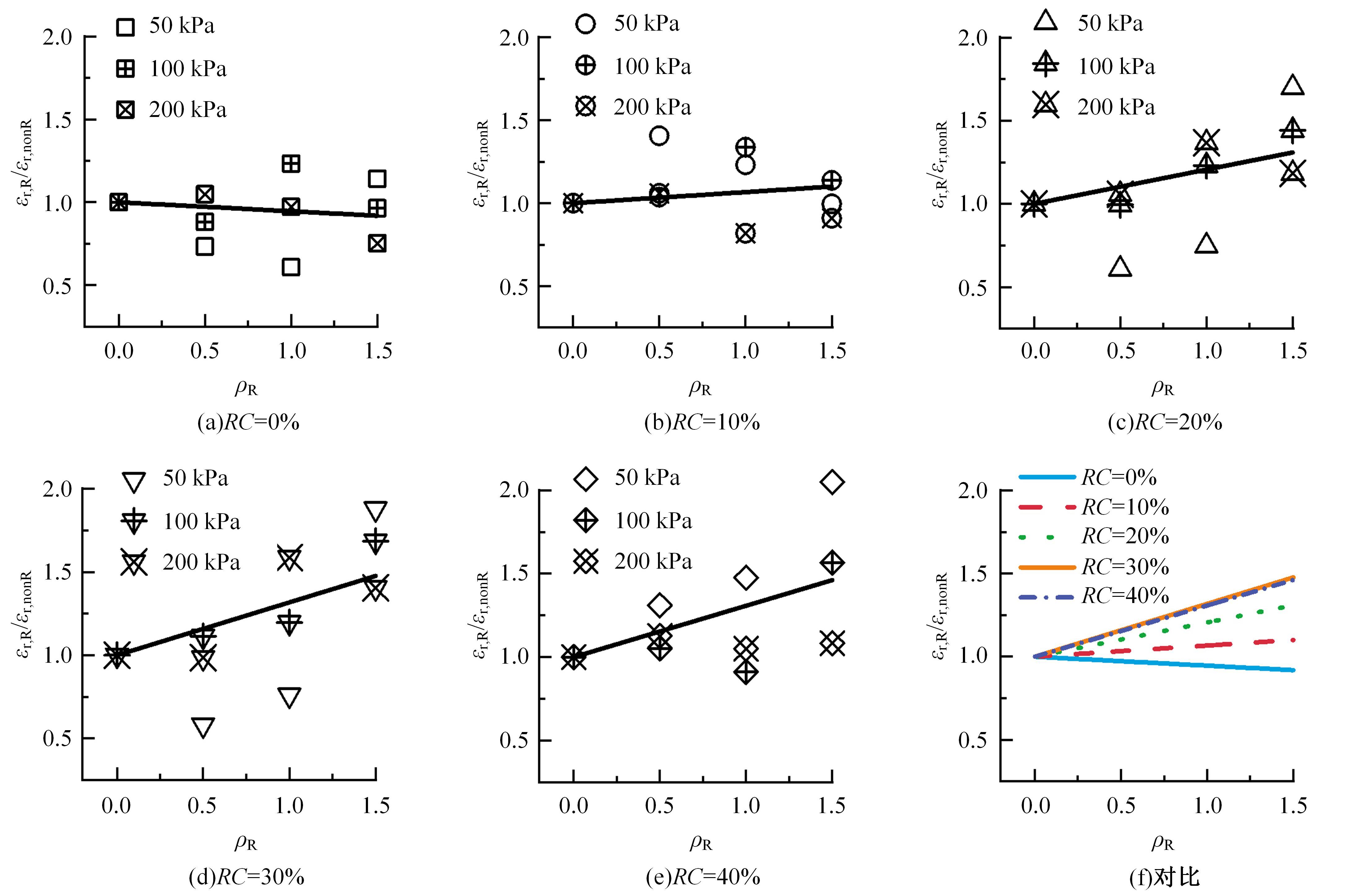

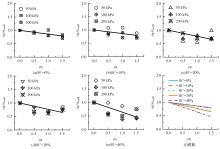

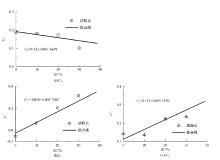

| 25 | 刘方成, 吴孟桃, 杨峻. 土工格栅加筋橡胶砂强度特性试验研究[J]. 岩土力学, 2019,40(2): 580-591. |

| Liu Fang-cheng, Wu Meng-tao, Yang Jun. Experimental study on strength characteristics of geogrid reinforced rubber sand mixtures[J]. Rock and Soil Mechanics, 2019, 40(2): 580-591. | |

| 26 | 刘启菲, 庄海洋, 陈佳,等.废旧轮胎橡胶颗粒-砂混合料抗剪强度与破坏模式试验研究[J].岩土工程学报, 2021, 43(10): 1887-1895. |

| Liu Qi-fei, Zhuang Hai-yang, Chen Jia, et al. The shear strength and failure mode of rubber particle-sand mixtures in the test[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(10): 1887-1895. | |

| 27 | 杨广庆, 李广信, 张保俭. 土工格栅界面摩擦特性试验研究[J]. 岩土工程学报, 2006, 28(8): 948-952. |

| Yang Guang-qing, Li Guang-xin, Zhang Bao-jian. Experimental studies on interface friction characteristics of geogrids[J]. Chinese Journal of Geotechnical Engineering, 2006, 28(8): 948-952. | |

| 28 | Abdi M R, Arjomand M A. Pullout tests conducted on clay reinforced with geogrid encapsulated in thin layers of sand[J]. Geotextiles and Geomembranes, 2011, 29(6): 588-595. |

| 29 | 周小凤, 张孟喜, 邱成春, 等. 不同形式土工格栅加筋砂的强度特性[J]. 上海交通大学学报, 2013, 47(9): 1377-1381. |

| Zhou Xiao-feng, Zhang Meng-xi, Qiu Cheng-chun, et al. Strength of sand reinforced with different forms of geogrid[J]. Journal of Shanghai Jiao Tong University, 2013, 47(9): 1377-1381. | |

| 30 | 胡幼常, 申俊敏, 赵建斌, 等. 土工格栅加筋掺砂黄土工程性质试验研究[J]. 岩土力学, 2013(): 74-80. |

| Hu You-chang, Shen Jun-min, Zhao Jian-bin, et al. Experimental study of engineering properties of geogrid-reinforced loess mixed with sand[J]. Rock and Soil Mechanics, 2013(Sup.2): 74-80. | |

| 31 | 王协群, 郭敏, 胡波. 土工格栅加筋膨胀土的三轴试验研究[J]. 岩土力学, 2011, 32(6): 1649-1653. |

| Wang Xie-qun, Guo Min, Hu Bo. Triaxial testing study of expansive soil reinforced with geogrid[J]. Rock and Soil Mechanics, 2011, 32(6): 1649-1653. | |

| 32 | Ahmed I. Laboratory Study on Properties of Rubber-soils[M]. Indiana, USA: Purdue University, 1993. |

| 33 | Verdugo R, Ishihara K. The steady state of sandy soils[J]. Soils and Foundations, 1996, 36(2): 81-91. |

| 34 | Zheng Y F, Kevin G S. Dynamic properties of granulated rubber/sand mixtures[J]. Geotechnical Testing Journal, 2000, 23(3): 338-344. |

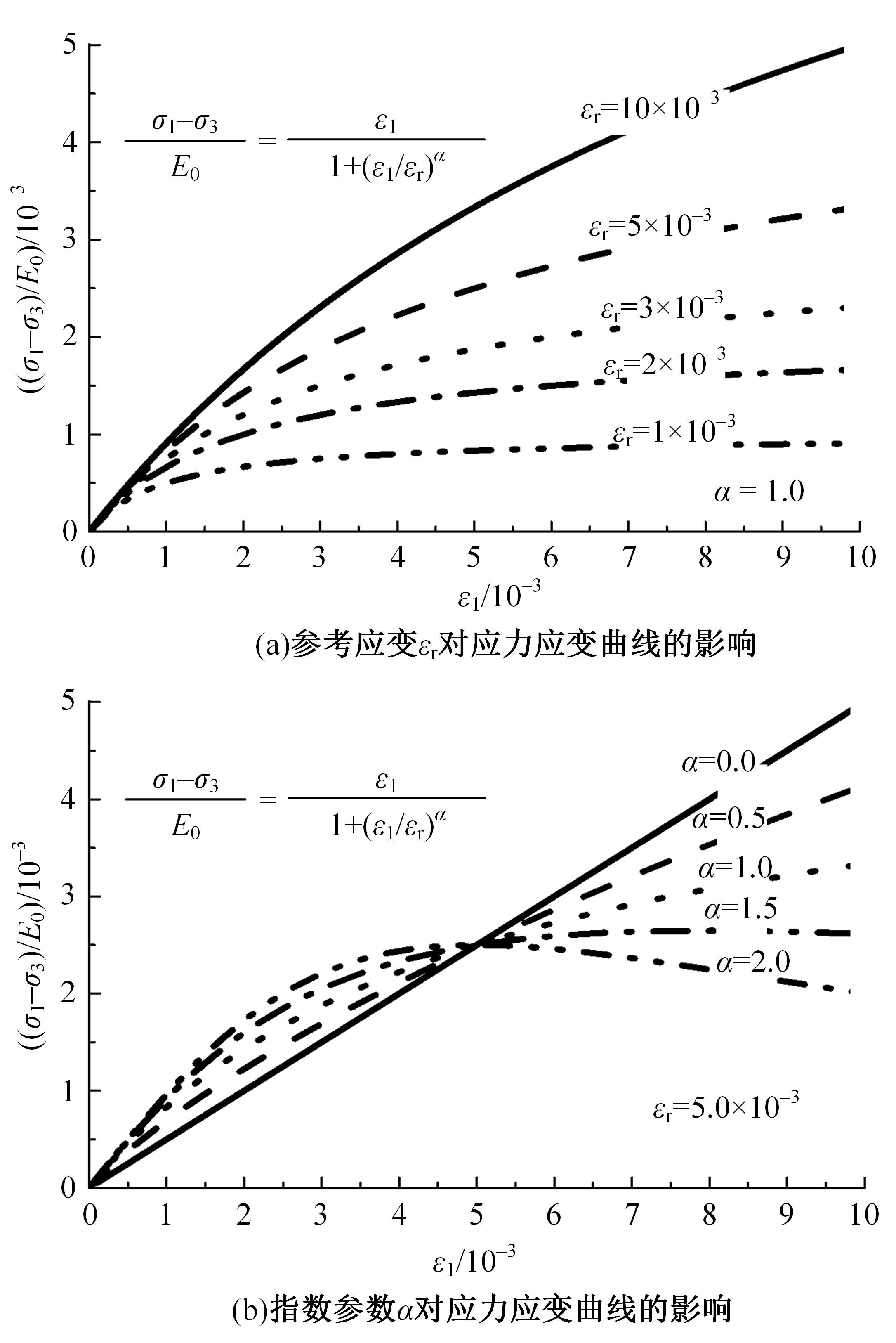

| 35 | Duncan J M, Chang C Y. Nonlinear analysis of stress and strain in soils[J]. Journal of Soil Mechanics and Foundations Division, 1970, 96(5): 1629-1653. |

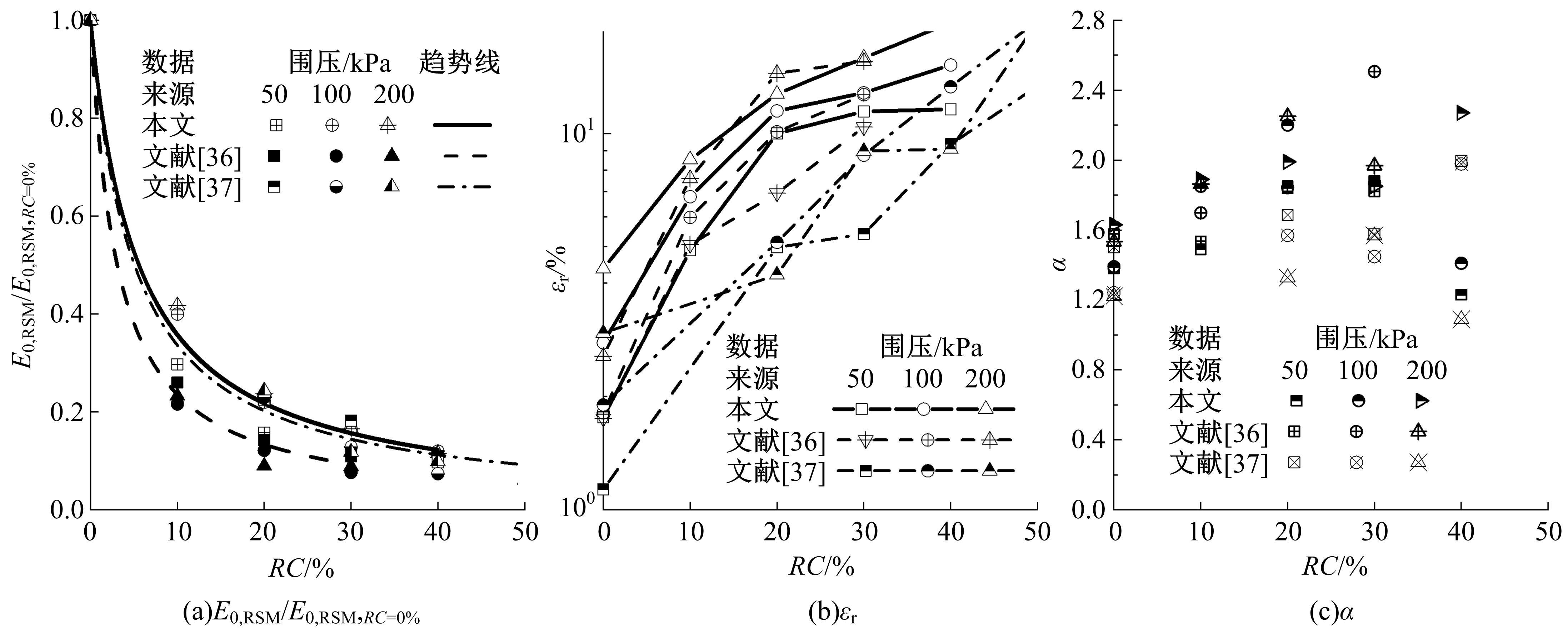

| 36 | 刘方成, 张永富, 任东滨. 橡胶砂应力-应变特性三轴-单剪联合试验研究[J]. 岩土力学, 2016, 37(10): 2769-2779. |

| Liu Fang-cheng, Zhang Yong-fu, Ren Dong-bin. Stress-strain characteristics of rubber-sand mixtures in united triaxial shear and simple shear tests[J]. Rock and Soil Mechanics, 2016, 37(1): 2769-2779. | |

| 37 | Youwai S, Bergado D T. Strength and deformation characteristics of shredded rubber tire sand mixtures[J]. Canadian Geotechnical Journal, 2003, 40(2): 254-264. |

| [1] | Ya-feng GONG,Shu-zheng WU,Hai-peng BI,Guo-jin TAN. Temperature field and frost heaving analysis of prefabricated box culvert based on field monitoring [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2321-2331. |

| [2] | Ying-xin HUI,Jia-wei CHEN. Squeezed branch pile groups optimization method based on improved genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2089-2098. |

| [3] | Ya-feng GONG,Shu-zheng WU,Hai-peng BI,Dong-ming ZHOU,Guo-jin TAN,Xiao-ming HUANG. Acoustic characterization of bond⁃slip process between basalt fiber reactive powder concrete and steel strand [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1819-1832. |

| [4] | Shun LIU,Xiao-wei TANG,Yi-xiao LUAN. Influence of Rayleigh damping coefficient on seismic response of subway structure in liquefiable soil [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 159-169. |

| [5] | Liang TANG,Pan SI,Jie CUI,Xian-zhang LING,Xiao-feng MAN. Pseudo-static analysis method of pile group earthquake response in liquefying mild inclined sloping ground [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 847-855. |

| [6] | Ping JIANG,Lin ZHOU,Tian-hao MAO,Jun-ping YUAN,Wei WANG,Na LI. Damage model and time effect of cement⁃modified waste slurry [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2874-2882. |

| [7] | Fei ZHANG,Yu-ming ZHU,Shang-chuan YANG,Shu-mao WANG. Emission mitigation analysis of geosynthetic⁃reinforced walls [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 631-637. |

| [8] | Wen-bin TAO,Jun-ling HOU,Tie-lin CHEN,Bin TANG. Mechanical analysis of full⁃length anchorage with high pretension post⁃tensioning method [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 631-640. |

| [9] | Deng-hui GAO,Yi-chuan XING,Min-xia GUO,Ai-jun ZHANG,Xian-tao WANG,Bao-hong MA. Modified hyperbola model of interface between unsaturated remolded loess and concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 156-164. |

| [10] | GU Hai-dong,LUO Chun-hong. Experiment on soil arching effect of pit supporting structure with scattered row piles and soil nail wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1712-1724. |

| [11] | YANG Ai-wu,ZHOU Jin,KONG Ling-wei. Experiment on mechanical properties of stabilized soft dredger fill [J]. 吉林大学学报(工学版), 2014, 44(3): 661-667. |

|