Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (4): 865-873.doi: 10.13229/j.cnki.jdxbgxb.20221060

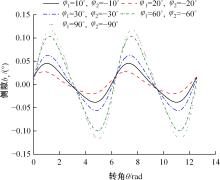

Numerical simulation and experiment of non-circular gear transmission error and backlash

Chang-bin DONG( ),Long-kun LI,Yong-ping LIU,Wang-peng PEI

),Long-kun LI,Yong-ping LIU,Wang-peng PEI

- School of Mechanical and Electrical Engineering,Lanzhou University of Technology,Lanzhou 730050,China

CLC Number:

- TH132.4

| 1 | 董长斌, 刘永平, 魏永峭. 不同载荷条件下椭圆柱齿轮动态接触特性分析[J]. 华中科技大学学报: 自然科学版, 2019, 47(8): 103-107. |

| Dong Chang-bin, Liu Yong-ping, Wei Yong-qiao. Dynamic contact characteristics analysis of elliptic cylinder gear under different load conditions[J]. J Huazhong Univ of Sci & Tech(Natural Science Edition) 2019, 47(8): 103-107. | |

| 2 | 董长斌. 椭圆齿轮传动系统的啮合特性研究[D]. 兰州: 兰州理工大学机电工程学院, 2021. |

| Dong Chang-bin. Study on meshing characteristics of elliptic gear transmission system[D]. Lanzhou: School of Mechanical & Electronical Engineering,Lanzhou University of Technology, 2021. | |

| 3 | Kim S C, Moon S G. Macro geometry optimization of a helical gear pair for mass, efficiency, and transmission error[J]. Mechanism and Machine Theory, 2020, 144: No. 103634. |

| 4 | 刘国政, 史文库, 陈志勇. 考虑安装误差的准双曲面齿轮传动误差有限元分析[J]. 吉林大学学报: 工学版, 2018, 48(4): 984-989. |

| Liu Guo-zheng, Shi Wen-ku, Chen Zhi-yong. Finite element analysis of transmission error for hypoid gears considering installation error[J]. Journal of Jilin Univeraity (Engineering and Technology Edition), 2018, 48(4): 984-989. | |

| 5 | Rezaei M, Poursina M, Jazi S H. Multi crack detection in helical gear teeth using transmission error ratio[J]. Journal of Mechanical Science and Technology, 2019, 33(3): 1115-1121. |

| 6 | Hotait M A, Kahraman A. Experiments on the relationship between the dynamic transmission error and the dynamic stress factor of spur gear pairs[J]. Mechanism and Machine Theory, 2013, 70: 116-128. |

| 7 | Liu D W, Ba Y B, Ren T Z. Flow fluctuation abatement of high-order elliptic gear pump by external noncircular gear drive[J]. Mechanism and Machine Theory, 2019, 134: 338-348. |

| 8 | 刘大伟, 任廷志, 巴延博, 等. 基于弹性转角分离的非圆齿轮扭振模型及其动态特性[J]. 振动与冲击, 2016, 35(23): 228-233. |

| Liu Da-wei, Ren Ting-zhi, Ba Yan-bo, et al. Torsional vibration model and its dynamic characteristics for a noncircular gear based on separation of elastic rotating angle[J]. Journal of Vibration and Shock, 2016, 35(23): 228-233. | |

| 9 | Liu D W, Wang G H, Ren T Z. Transmission principle and geometrical model of eccentric face gear[J]. Mechanism and Machine Theory, 2017, 109: 51-64. |

| 10 | David B D, Domenico M. Unloaded transmission error and instantaneous gear ratio for non-circular gears with misalignments[J]. Mechanism and Machine Theory, 2022, 170: No.104728. |

| 11 | Dong C, Liu Y, Wei Y, et al. Analysis on meshing characteristics and transmission error of elliptic gears[J]. Mathematical Problems in Engineering, 2020(1): 1-10. |

| 12 | Margielewicz J, Gąska D, Litak G. Modelling of the gear backlash[J]. Nonlinear Dynamics, 2019, 97(1):355-368. |

| 13 | Wang G, Chen L, Li Y. Research on the dynamic transmission error of a spur gear pair with eccentricities by finite element method[J]. Mechanism and Machine Theory, 2017, 109:1-13. |

| 14 | 邹帅东, 王光建. 双齿轮偏心的传动误差计算与研究[J]. 电子科技大学学报, 2017, 46(6): 955-960. |

| Zou Shuai-dong, Wang Guang-jian. Research on transmission error of dual-eccentric gears[J]. Journal of University of Electronic Science and Technology of China, 2017, 46(6): 955-960. | |

| 15 | 邹帅东, 王光建, 蒋宇将, 等. 交变负载下变齿厚齿轮副侧隙控制试验研究[J]. 机械工程学报, 2020, 56(15): 152-160. |

| Zou Shuai-dong, Wang Guang-jian, Jiang Yu-jiang, et al. Experimental investigation on backlash control of variable tooth thickness gear pair under varying load excitation[J]. Journal of Mechanical Engineering, 2020, 56(15): 152-160. | |

| 16 | Han J, Li D, Tian X, et al. Meshing principle and transmission analysis of a beveloid non-circular gear[J]. Advances in Mechanical Engineering, 2020, 12(11):1-11. |

| [1] | Fei WU,Hao-ye NONG,Chen-hao MA. Tool wear prediction method based on particle swarm optimizationlong and short time memory model [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 989-997. |

| [2] | Lin SONG,Li-ping WANG,Jun WU,Li-wen GUAN,Zhi-gui LIU. Reliability analysis based on cyber⁃physical system and digital twin [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 439-449. |

| [3] | Guo-long LI,Xiao-hui TAO,Kai XU,Zhe-yu LI. Rapid measurement and identification of position dependent geometric errors of CNC machine tool turntable [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 458-467. |

| [4] | Yun-wei ZHAO,De-xu GENG,Xiao-min LIU,Qi LIU. Implementation and stability on turning with constant radius of pneumatic flexible hexapod robot [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 472-482. |

| [5] | Chun-zheng DUAN,Fang-yuan ZHANG,Wen-neng KOU,Bin WEI. Martensitic transformation of surface white layer in high speed hard cutting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1575-1583. |

| [6] | LIU Guo-zheng, SHI Wen-ku, Chen Zhi-yong. Finite element analysis of transmission error for hypoid gears considering installation error [J]. 吉林大学学报(工学版), 2018, 48(4): 984-989. |

| [7] | ZONG Chang-fu, REN Ming-hui, WAN Ying, CHEN Tao, BAI Ying-bo. Optimization of macro-geometric parameters of helical gears of transmissions to reduce vibration [J]. 吉林大学学报(工学版), 2016, 46(6): 1772-1779. |

| [8] | REN Shu-nan, YANG Xiang-dong, WANG Guo-lei, LIU Zhi, CHEN Ken. Base position planning of mobile manipulator for large parts painting [J]. 吉林大学学报(工学版), 2016, 46(6): 1995-2002. |

| [9] | GUO Li-bin, ZHANG Bin, CUI Hai, ZHANG Zhi-hang. Structural parameters of 3D roughness for micro wire electrical discharge machining surface [J]. 吉林大学学报(工学版), 2015, 45(3): 851-856. |

| [10] | ZHANG Lei, ZHAO Yun-wei, YANG Zhuo, ZHAO Ji. Shear yield property of electrorheological polishing fluid [J]. , 2012, 42(05): 1145-1150. |

| [11] | ZHANG Lei,HE Xin-sheng,ZHANG Ying,YANG He-ran. Development of new type ER fluid-assisted polishing tool and its polishing experiment [J]. 吉林大学学报(工学版), 2010, 40(04): 1009-1014. |

|

||