Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (6): 1612-1623.doi: 10.13229/j.cnki.jdxbgxb.20220930

Experiment on cyclic shear of geosynthetic reinforced construction waste soil

Li-hua LI1,2( ),Zi-jian LI1,2,Heng-lin XIAO1,2(

),Zi-jian LI1,2,Heng-lin XIAO1,2( ),Wen-zhe CAO1,2,Xin-long ZHOU1,2,Shao-ping HUANG1,2

),Wen-zhe CAO1,2,Xin-long ZHOU1,2,Shao-ping HUANG1,2

- 1.School of Civil Engineering,Architecture and Environment,Hubei University of Technology,Wuhan 430068,China

2.Key Laboratory of Health Intelligent Perception and Ecological Restoration of River and Lake,Ministry of Education,Hubei University of Technology,Wuhan 430068,China

CLC Number:

- TU41

| 1 | 张小娟. 国内城市建筑垃圾资源化研究分析[D].西安:西安建筑科技大学管理学院, 2013. |

| Zhang Xiao-juan. Studies and analysis on the resourcization of city construction waste in China[D]. Xi'an: School of Management, Xi'an University of Architectural Science and Technology, 2013. | |

| 2 | 李丽华, 文贝, 胡智, 等. 建筑垃圾填料与土工合成材料加筋剪切性能研究[J]. 武汉大学学报:工学版, 2019, 52(4): 311-316. |

| Li Li-hua, Wen Bei, Hu Zhi, et al. Study on reinforced shear behavior ofconstruction waste filler and geosynthetics[J]. Engineering Journal of Wuhan University, 2019, 52(4): 311-316. | |

| 3 | Zhou Xin-long, Hu Shao-hua, Zhang Guang, et al. Experimental investigation and mathematical strength model study on the mechanical properties of cemented paste backfill[J]. Construction and Building Materials, 2019, 226: 524-533. |

| 4 | 唐娴, 王社良. 城市建筑垃圾路面基层应用研究[J]. 科技导报, 2009, 27(7): 88-90. |

| Tang Xian, Wang She-liang. Urban building waste materials used in base layers of road sueface[J]. Science & Technology Review, 2009, 27(7): 88-90. | |

| 5 | Santos E C G, Vilar O M. Use of recycled construction and demolition wastes (RCDW) as backfill of reinforced soil structures[J/OL]. [2022-07-15]. |

| 6 | Arulrajah A, Rahman M A, Piratheepan J, et al. Evaluation of interface shear strength properties of geogrid-reinforced construction and demolition materials using a modified large-scale direct shear testing apparatus[J]. Journal of Materials in Civil Engineering, 2013, 26(5): 974-982. |

| 7 | Arulrajah A, Rahman M A, Piratheepan J, et al. Interface shear strength testing of geogrid-reinforced construction and demolition materials[J]. Advances in Civil Engineering Materials, 2013, 2(1): 189-200. |

| 8 | Ying Meng-jie, Liu Fei-yu, Wang Jun, et al. Coupling effects of particle shape and cyclic shear history on shear properties of coarse-grained soil–geogrid interface[J]. Transportation Geotechnics, 2020, 27:No. 100504. |

| 9 | 李丽华, 秦浪灵, 肖衡林, 等. 加筋建筑垃圾土大型动三轴试验及加筋机制探讨[J]. 岩石力学与工程学报, 2020, 39(8): 1682-1695. |

| Li Li-hua, Qin Lang-ling, Xiao Heng-lin, et al. Large dynamic triaxial test study on reinforcement mechanisms of reinforced construction waste[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(8): 1682-1695. | |

| 10 | 李丽华, 臧天宝, 刘永莉, 等. 纤维底渣混合土循环剪切性能研究[J]. 岩石力学与工程学报, 2021, 40(1): 196-205. |

| Li Li-hua, Zang Tian-bao, Liu Yong-li, et al. Cyclic shear performance of fiber bottom ash mixed soils[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(1): 196-205. | |

| 11 | Pinho-Lopes M, Lopes M. Soil-geosynthetic interaction in inclined-plane shear and geosynthetic short-term tensile response-influence of installation damage[J]. Construction and Building Materials, 2021, 274(2):No. 122018. |

| 12 | Yang K H, Chiang J, Lai C W, et al. Performance of geosynthetic-reinforced soil foundations across a normal fault[J]. Geotextiles and Geomembranes, 2020, 48(3): 357-373. |

| 13 | De A, Zimmie T F. Estimation of dynamic interfacial properties of geosynthetics[J]. Geosynthetics International, 1998, 5(1/2): 17-39. |

| 14 | Abdel-Rahman A H, Ibbrahim A M. Soil-geogrid behavior subjected to cyclic loading[J]. Geo-frontiers: Advances in Geotechnical Engineering, 2011: 3087-3096. |

| 15 | 刘方成, 王将, 吴孟桃, 等. 土工格栅加筋橡胶砂应力-应变特性试验[J]. 吉林大学学报:工学版, 2023,53(9): 2542-2553. |

| Liu Fang-cheng, Wang Jiang, Wu Meng-cheng, et al. Stress⁃strain characteristics of geogrid reinforced rubber sand mixtures[J]. Journal of Jilin University (Engineering and Technology Edition), 2023,53(9): 2542-2553. | |

| 16 | 汪明元, 施戈亮, 丁金华, 等. 土工格栅与压实膨胀土的界面模型及其参数[J]. 吉林大学学报:工学版, 2010,40(3):688-693. |

| Wang Ming-yuan, Shi Ge-liang, Ding Jin-hua, et al. Interface model and its parameters between geogrids and compacted expansive soil[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(3): 688-693. | |

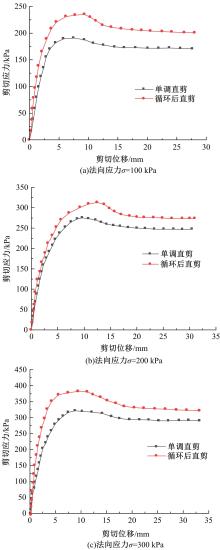

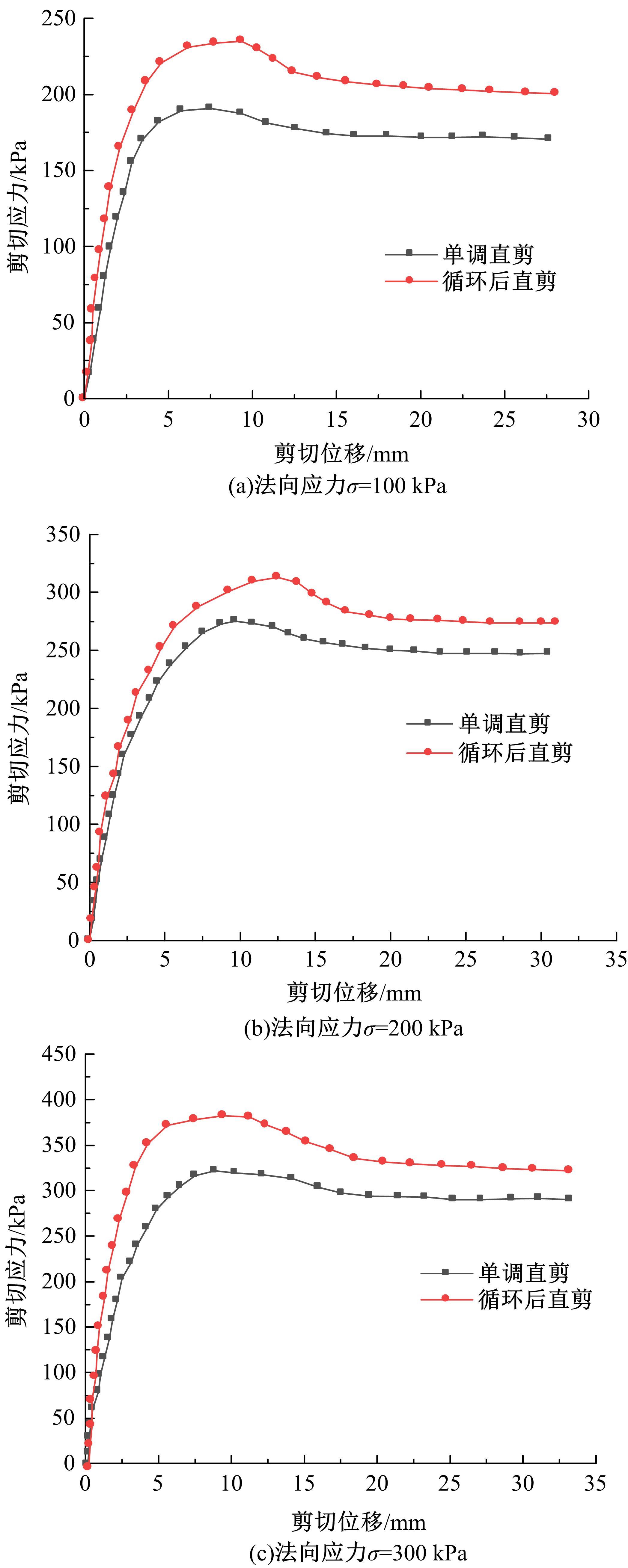

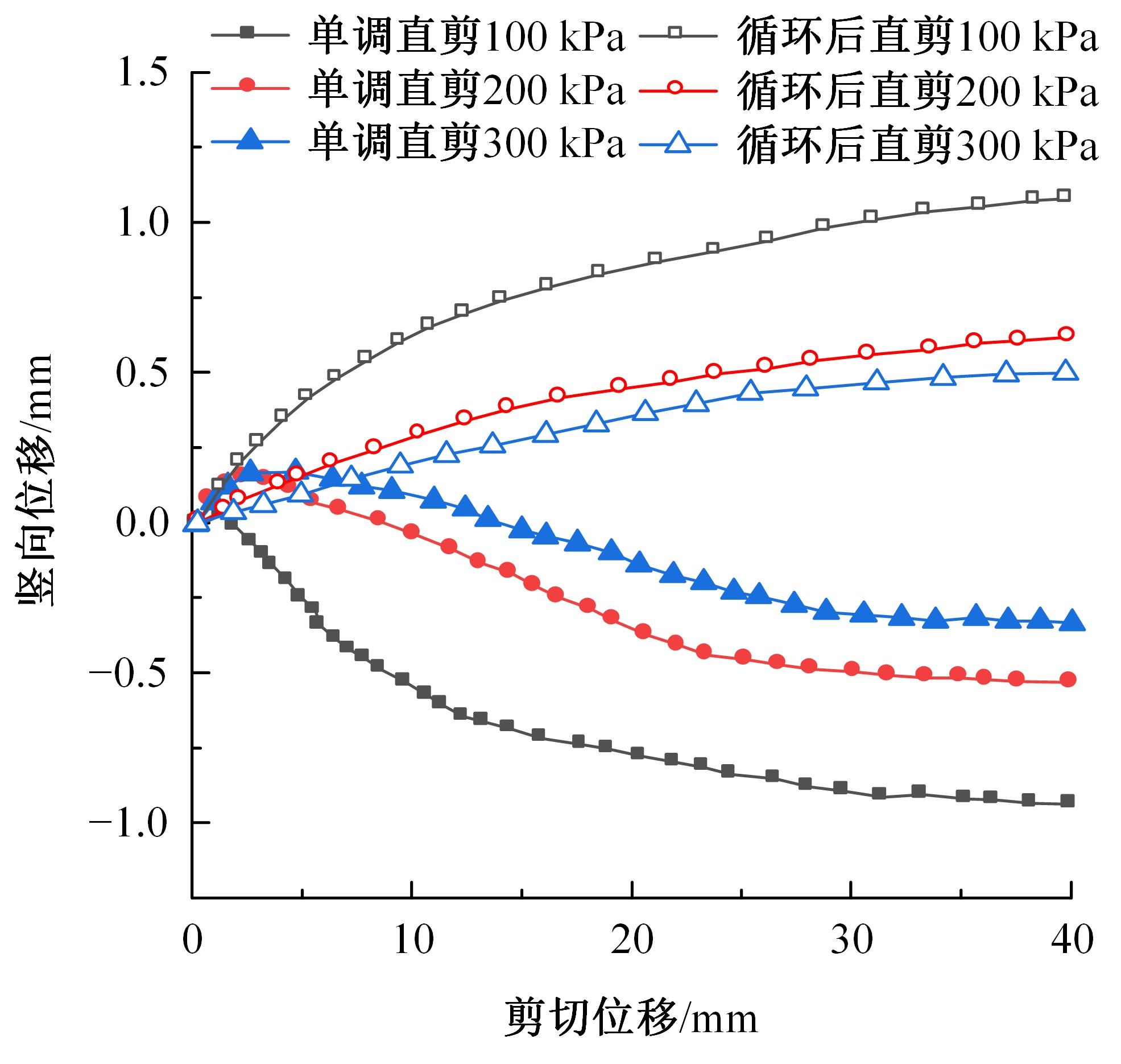

| 17 | 刘飞禹, 王攀, 王军, 等. 不同剪切速率下格栅-土界面循环剪切及其后直剪特性[J]. 岩石力学与工程学报, 2016, 35(2): 387-395. |

| Liu Fei-yu, Wang Pan, Wang Jun,et al. Cyclic and post-cyclic shear behavior of sand-geogrid interface under different shear rates[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(2): 387-395. | |

| 18 | 刘飞禹, 施静, 王军, 等. 三明治形加筋土筋-土界面动力剪切特性[J]. 岩土力学, 2018, 39(6): 1991-1998. |

| Liu Fei-yu, Shi Jing, Wang Jun, et al. Dynamic shear behavior of interface for clay reinforced with geogrid encapsulated in thin layers of sand[J]. Rock and Soil Mechanics, 2018, 39(6): 1991-1998. | |

| 19 | 赖丰文, 李丽萍, 陈福全,等. 双向土工格栅与砂土界面循环剪切特性研究[J]. 中国科技论文, 2017, 12(13): 1559-1564. |

| Lai Feng-wen, Li Li-ping, Chen Fu-quan, et al. The cyclic shear behavior of interface between sand-biaxial geogrid[J]. China Science Paper, 2017, 12(13): 1559-1564. | |

| 20 | 左政,杨广庆,王贺,等.土工格室规格对加筋土剪切性能的影响[J].岩土工程学报, 2022, 44(6):1053-1060. |

| Zuo Zheng, Yang Guang-qing, Wang He, et al. Effect of geocell size on the shear behavior of reinforced soil[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(6): 1053-1060. | |

| 21 | Morsy A M, Zornberg J G. Soil-reinforcement interaction: stress regime evolution in geosynthetic-reinforced soils[J]. Geotextiles and Geomembranes, 2020, 49(1): 323-342. |

| 22 | 徐超, 石志龙. 循环荷载特征对筋土界面剪切特性的影响试验[J]. 中国公路学报, 2011, 24(3): 1-7. |

| Xu Chao, Shi Zhi-long. Experiment of influence of cyclic load characteristics on shear properties of geogrid-soil interface[J]. China Journal of Highway and Transport, 2011, 24(3): 1-7. | |

| 23 | Sweta K, Hussaini S. Behavior evaluation of geogrid-reinforced ballast-subballast interface under shear condition[J]. Geotextiles and Geomembranes, 2019, 47(1): 23-31. |

| 24 | Ying Meng-jie, Wang Jun. Analysis of cyclic shear characteristics of reinforced soil interfaces under cyclic loading and unloading[J]. Geotextiles and Geomembranes, 2021, 50(1): 99-115. |

| 25 | 林志伟. 基于综合利用建筑垃圾再生骨料混凝土的研究[D]. 昆明:昆明理工大学材料科学与工程学院, 2007. |

| Lin Zhi-wei. Research on recycled aggregate concrete of construction waste based on comprehensive utilization[D]. Kunming: School of Materials Science and Engineering, Kunming University of Science and Technology, 2007. | |

| 26 | 李炯. 河砂与建筑垃圾混合料回填路基工程特性研究[D]. 济南:山东大学土建与水利学院, 2017. |

| Li Jiong. Study on the characteristics of the mixture of river sand and construction waste in filling subgrade [D]. Jinan: School of Civil Engineering, Shandong University, 2017. | |

| 27 | Chang Ji-Yun, Feng Shi-Jin. Dynamic shear behaviors of textured geomembrane/nonwoven geotextile interface under cyclic loading[J]. Geotextiles and Geomembranes, 2021, 49(2): 388-398. |

| 28 | Desai C S, Drumm E C, Zaman M M. Cyclic testing and modeling of interfaces[J]. Journal of Geotechnical Engineering, 1985, 111(6): 793-815. |

| 29 | Yegian M K, Kadakal U. Geosynthetic interface behavior under dynamic loading[J]. Geosynthetics International, 1998, 5(1/2): 1-16. |

| 30 | Nye C J, Fox P J. Dynamic shear behavior of a needle-punched geosynthetic clay liner[J]. Journal of Geotechnical & Geoenvironmental Engineering, 2007, 133(8): 973-983. |

| 31 | Vieira C S, Lopes M L, Caldeira L M. Sand-geotextile interface characterisation through monotonic and cyclic direct shear tests[J]. Geosynthetics International, 2013, 20(1): 26-38. |

| [1] | Hua-fei HE,Zhao-ping LI,Rui-an FU,Shao-lin MA,Ming-li HUANG. Experiment on seismic performance of prefabricated sidewall joints considering strata restraint effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1601-1611. |

| [2] | Fang-cheng LIU,Jiang WANG,Meng-tao WU,Guo-bin BU,Jie HE. Stress⁃strain characteristics of geogrid reinforced rubber sand mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2542-2553. |

| [3] | Ya-feng GONG,Shu-zheng WU,Hai-peng BI,Guo-jin TAN. Temperature field and frost heaving analysis of prefabricated box culvert based on field monitoring [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2321-2331. |

| [4] | Ying-xin HUI,Jia-wei CHEN. Squeezed branch pile groups optimization method based on improved genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2089-2098. |

| [5] | Ya-feng GONG,Shu-zheng WU,Hai-peng BI,Dong-ming ZHOU,Guo-jin TAN,Xiao-ming HUANG. Acoustic characterization of bond⁃slip process between basalt fiber reactive powder concrete and steel strand [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1819-1832. |

| [6] | Shun LIU,Xiao-wei TANG,Yi-xiao LUAN. Influence of Rayleigh damping coefficient on seismic response of subway structure in liquefiable soil [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 159-169. |

| [7] | Liang TANG,Pan SI,Jie CUI,Xian-zhang LING,Xiao-feng MAN. Pseudo-static analysis method of pile group earthquake response in liquefying mild inclined sloping ground [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 847-855. |

| [8] | Ping JIANG,Lin ZHOU,Tian-hao MAO,Jun-ping YUAN,Wei WANG,Na LI. Damage model and time effect of cement⁃modified waste slurry [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2874-2882. |

| [9] | Fei ZHANG,Yu-ming ZHU,Shang-chuan YANG,Shu-mao WANG. Emission mitigation analysis of geosynthetic⁃reinforced walls [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 631-637. |

| [10] | Wen-bin TAO,Jun-ling HOU,Tie-lin CHEN,Bin TANG. Mechanical analysis of full⁃length anchorage with high pretension post⁃tensioning method [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 631-640. |

| [11] | Deng-hui GAO,Yi-chuan XING,Min-xia GUO,Ai-jun ZHANG,Xian-tao WANG,Bao-hong MA. Modified hyperbola model of interface between unsaturated remolded loess and concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 156-164. |

| [12] | GU Hai-dong,LUO Chun-hong. Experiment on soil arching effect of pit supporting structure with scattered row piles and soil nail wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1712-1724. |

|

||