Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (12): 3534-3544.doi: 10.13229/j.cnki.jdxbgxb.20230082

Previous Articles Next Articles

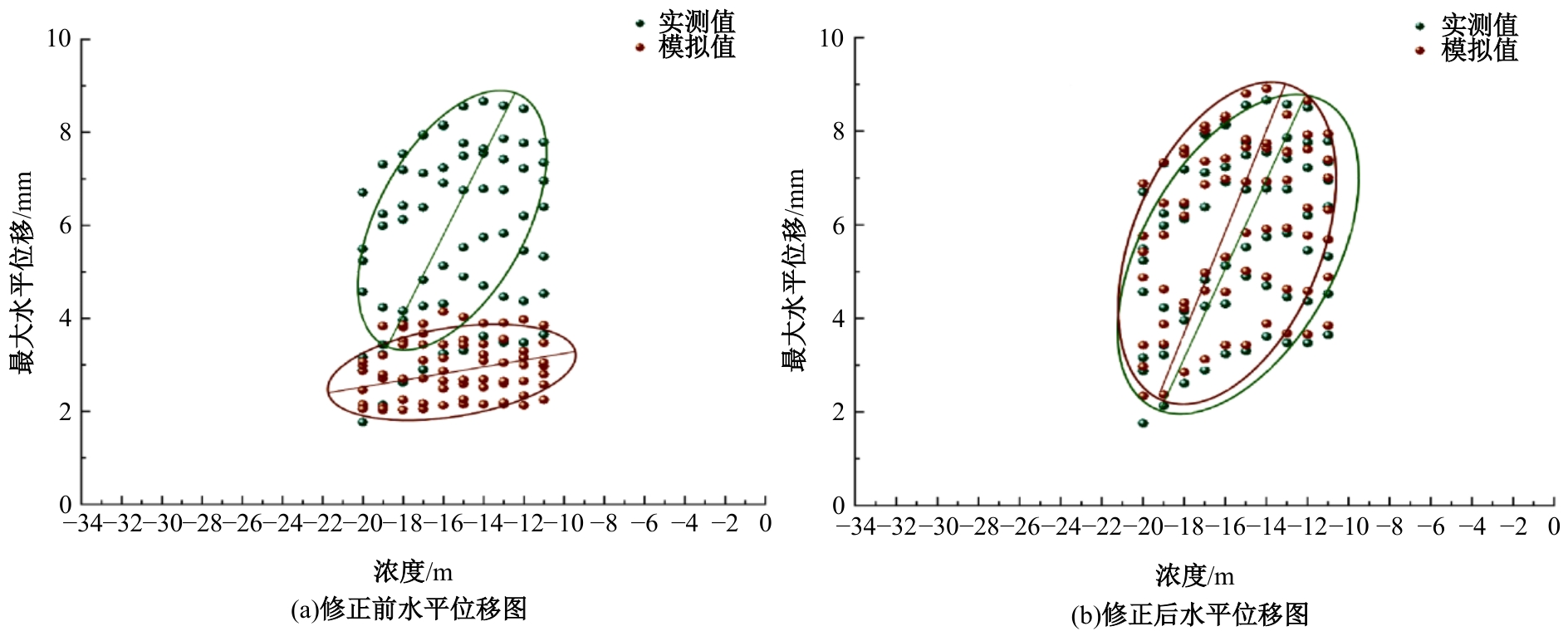

Parameter correction of probabilistic finite element benchmark model based on deep foundation pit construction

Ya-feng GONG1( ),Bai-xin LIU1,Jian-xing YANG1,Feng HE1(

),Bai-xin LIU1,Jian-xing YANG1,Feng HE1( ),Liang SUN2,Li-hua TIAN1

),Liang SUN2,Li-hua TIAN1

- 1.Transportation College of Jilin University,Changchun 130022,China

2.China Railway Tunnel Group Road & Bridge Engineering Co. ,Ltd. ,Tianjin 300308,China

CLC Number:

- TV551.4

| 1 | 杨朋超,薛松涛,谢丽宇. 结构动力模型的改进直接修正方法及工程应用[J]. 建筑结构学报, 2021, 42(3): 34-40. |

| Yang Peng-chao, Xue Song-tao, Xie Li-yu. An improved direct method for dynamic model updating and its practical engineering applications[J]. Journal of Building Structures, 2021, 42(3): 34-40. | |

| 2 | 张皓,李东升,李宏男. 有限元模型修正研究进展:从线性到非线性[J]. 力学进展, 2019, 49(1): 542-575. |

| Zhang Hao, Li Dong-sheng, Li Hong-nan. Recent progress on finite element model updating: from linearity to nonlinearity[J]. Advances in Mechanics, 2019, 49(1): 542-575. | |

| 3 | 徐志强,王彬,王海龙,等. 基于监测数据的桁架拱桥有限元模型修正[J]. 河北建筑工程学院学报, 2019, 37(4): 67-73. |

| Xu Zhi-qiang, Wang Bin, Wang Hai-long. Modification of finite element model of truss arch bridge based on monitoring data[J]. Journal of Hebei Institute of Architecture and Civil Engineering, 2019, 37(4): 67-73. | |

| 4 | 文竞舟,张永兴,王成,等. 钢拱架应力反分析隧道初期支护力学性能的研究[J]. 土木工程学报, 2012, 45(2): 170-175. |

| Wen Jing-zhou, Zhang Yong-xing, Wang Cheng, et al. Back analysis for the mechanical properties of initial tunnel support based on steel arch stresses[J]. China Civil Engineering Journal, 2012, 45(2): 170-175. | |

| 5 | 杨林德,王聿,陆峰. 初始地应力及E值的反演计算的边界单元法[C]∥中国土木工程学会隧道与地下工程学会隧道力学学组会议论文集,中国兰州, 1985:1- 15. |

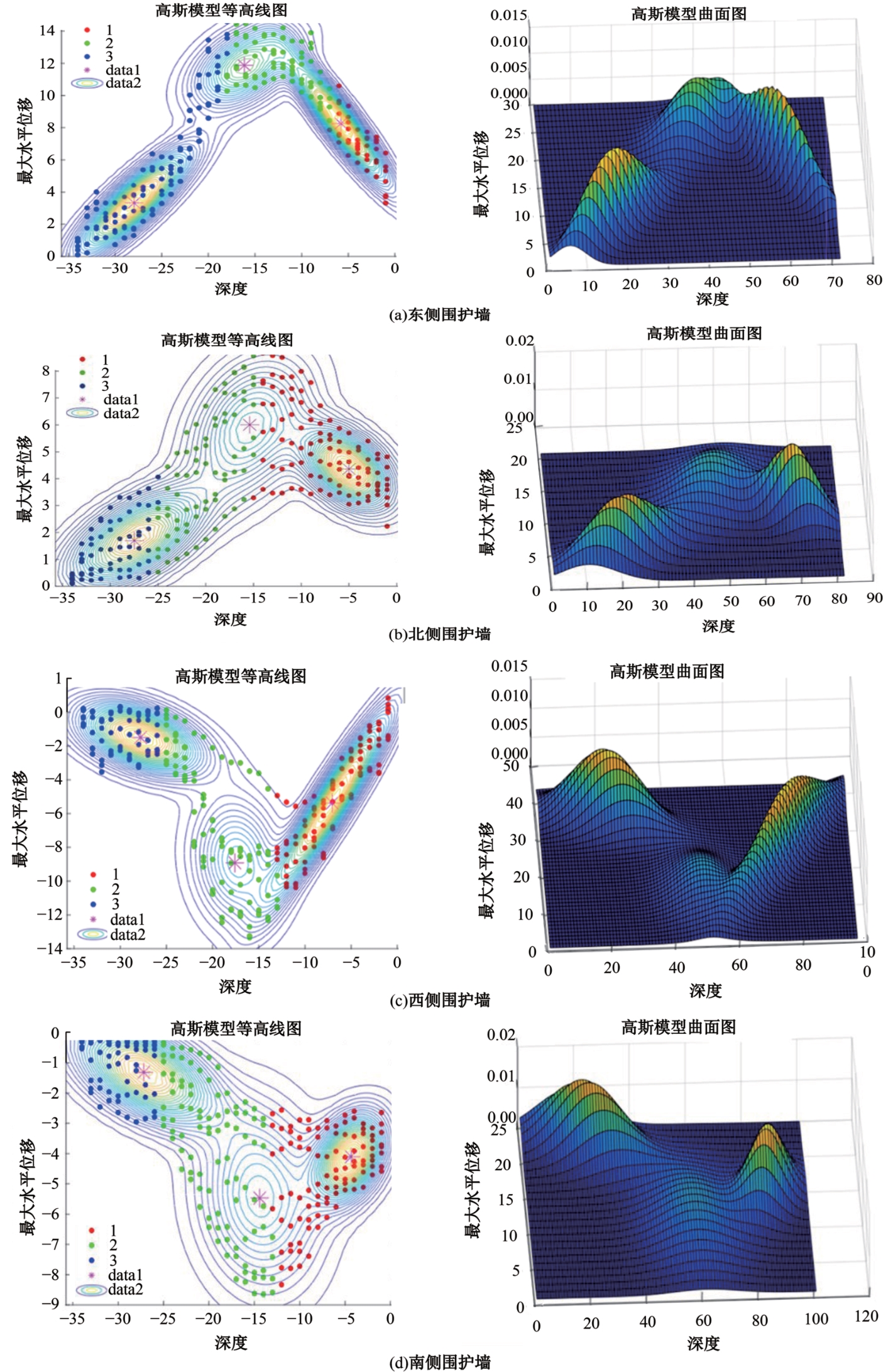

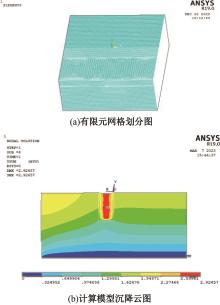

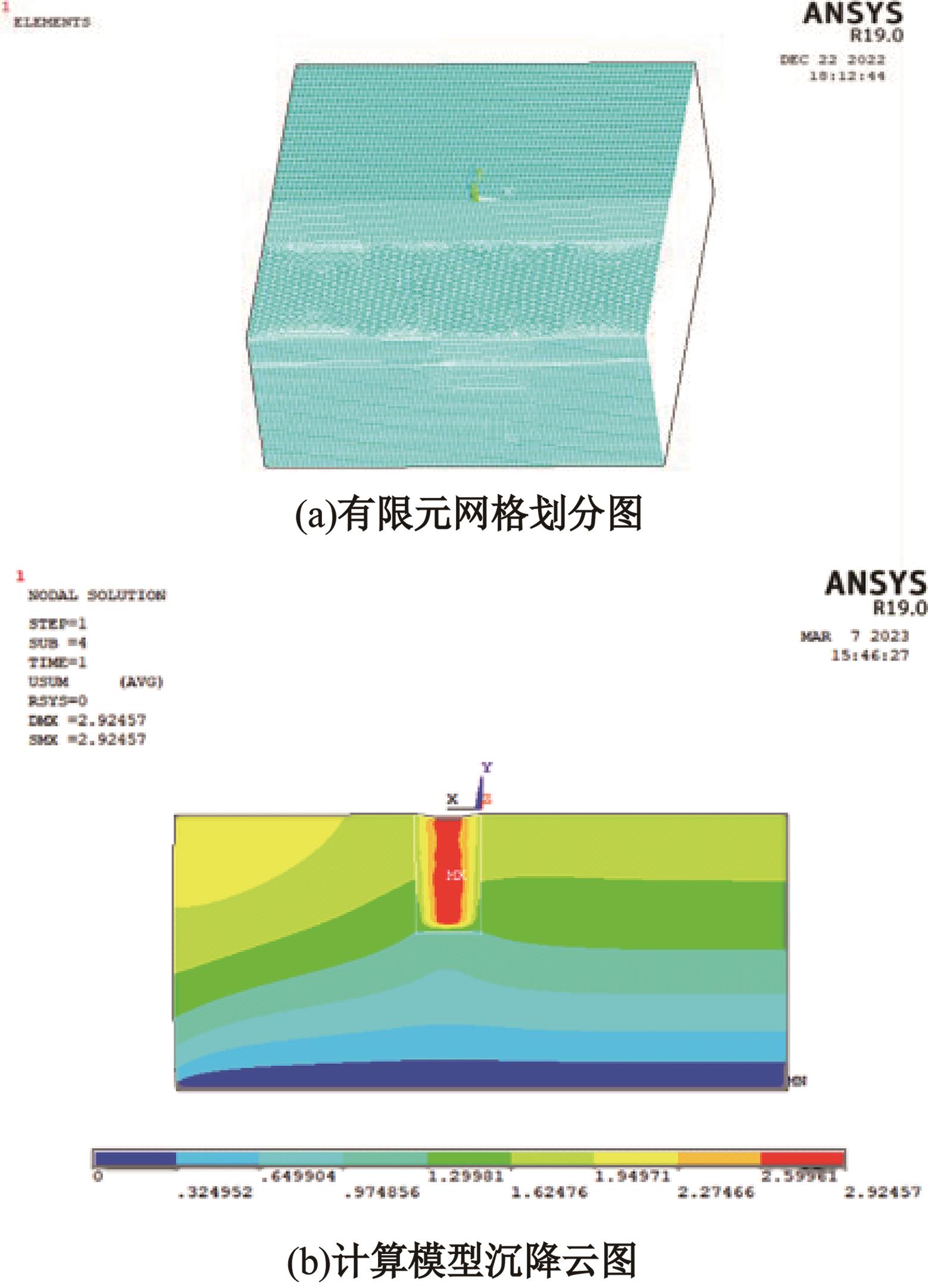

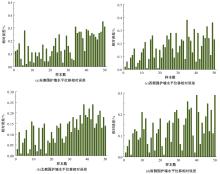

| 6 | 张前进,李德巧,宫亚峰,等. 基于响应面法的基坑有限元模型修正[J]. 现代隧道技术, 2022, 59(S2): 69-76. |

| Zhang Qian-jin, Li De-qiao, Gong Ya-feng, et al. Modification of finite element model of foundation pit based on response surface method[J]. Modern Tunnelling Technology, 2022, 59(S2): 69-76. | |

| 7 | 曲强,李昊波. 软土深基坑土体本构模型适用性及参数敏感性分析[J]. 铁道勘察, 2022, 48(3): 94-99, 106. |

| Qu Qiang, Li Hao-bo. Analysis of the applicability of constitutive model and parameter sensitivity for deep foundation pit with soft soil[J]. Railway Investigation and Surveying, 2022, 48(3): 94-99, 106. | |

| 8 | 马印平,刘永健,刘江. 基于响应面法的钢管混凝土组合桁梁桥多尺度有限元模型修正[J]. 中国公路学报, 2019, 32(11): 51-61. |

| Ma Yin-ping, Liu Yong-jian, Liu Jiang. Multi-scale finite element model updating of CFST composite truss bridge based on response surface method[J]. China Journal Highway and Transport, 2019, 32(11): 51-61. | |

| 9 | 冀伟,邵天彦. 波形腹板钢箱-混凝土箱梁桥的有限元模型修正[J]. 西南交通大学学报, 2021, 56(1): 1-11. |

| Ji Wei, Shao Tian-yan. Finite element model updating of box girder bridges with corrugated steel webs[J]. Journal of Southwest Jiaotong University, 2021, 56(1): 1-11. | |

| 10 | 廖汉超,单汨源. 基于模糊聚类最大树算法的高层建筑基坑工程风险识别方法[J]. 吉林大学学报: 工学版, 2022, 52(12): 2892-2897. |

| Liao Han-chao, Shan Mi-yuan. Risk identification method of foundation pit engineering of high⁃rise buildings based on fuzzy clustering maximum tree algorithm[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(12): 2892-2897. | |

| 11 | 许世展,李杨,冯冠杰,等. 基于响应面法的桥梁节段参数模型修正[J]. 铁道科学与工程学报, 2022, 19(6): 1658-1665. |

| Xu Shi-zhan, Li Yang, Feng Guan-jie, et al. Model updating of bridge segment parameter based on response surface method[J]. Journal of Railway Science and Engineering, 2022, 19(6): 1658-1665. | |

| 12 | 张绍逸. 时变环境下桥梁集群结构损伤诊断方法[D]. 哈尔滨: 哈尔滨工业大学交通科学与工程学院, 2019. |

| Zhang Shao-yi. Damage diagnosis of bridges monitored within one cluster under time-varying environment[D]. Harbin: School of Transposition Science and Engineering, Harbin Institute of Technology, 2019. | |

| 13 | 申文永,张克利,姚爱敏. 某地铁车站深基坑监测数据分析[C]∥第十一届深基础工程发展论坛论文集,中国太原, 2022: 37-42. |

| 14 | 古海东,罗春红. 疏排桩-土钉墙组合支护基坑土拱效应模型试验[J]. 吉林大学学报: 工学版, 2018, 48(6): 1712-1724. |

| Gu Hai-dong, Luo Chun-hong. Experiment of soil arching effect of pit supporting structure with scattered row piles and soil nail wall[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(6): 1712-1724. | |

| 15 | 黄明辉,李梦云,代煜. 基于Savitzky-Golay算法的某深基坑监测数据降噪处理[J]. 汕头大学学报: 自然科学版, 2022, 37(2): 50-60. |

| Huang Ming-hui, Li Meng-yun, Dai Yu. Based on the Savitzky-Golay noise reduction algorithm of a deep foundation pit monitoring data processing[J]. Journal of Shantou University (Natural Science), 2022, 37(2): 50-60. | |

| 16 | 钟龙凯. 深基坑监测技术与数据分析[D]. 南昌: 南昌大学建筑工程学院, 2021. |

| Zhong Long-kai. Monitoring technology and data analysis of deep foundation pit[D]. Nanchang: School of infrastructure Engineering, Nanchang University, 2012. | |

| 17 | Feng T, Wang C, Zhang J, et al. An improved artificial bee colony-random forest (IABC-RF) model for predicting the tunnel deformation due to an adjacent foundation pit excavation[J]. Underground Space,2022, 7(4): 514-527. |

| 18 | 张浩,张陈蓉,时振昊,等. 基于IGS小应变模型的基坑开挖对隧道影响数值模拟[J]. 岩土工程学报, 2021, 43(S2): 72-75. |

| Zhang Hao, Zhang Chen-rong, Shi Zhen-hao, et al. Numerical simulation of excavation effects on tunneling with IGS small strain model[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(S2): 72-75. | |

| 19 | 马险峰,刘畅,徐良义. 修正双屈服面模型在软土基坑开挖中的应用[J]. 岩石力学与工程学报, 2019, 38(): 3883-3893. |

| Ma Xian-feng, Liu Chang, Xu Liang-yi. Application of modified double-yield surface model in foundation excavation of soft soil[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(Sup.2): 3883-3893. | |

| 20 | 何维,孙宏磊,陶袁钦,等. 开挖引起的隧道位移动态多目标优化反演预测[J]. 上海交通大学学报, 2022, 56(12): 1688-1699. |

| He Wei, Sun Hong-lei, Tao Yuan-qin, et al. Dynamic multi-objective optimization inverse prediction of excavation-induced tunnel displacement[J]. Journal of Shanghai Jiao Tong University, 2022, 56(12): 1688-1699. |

| [1] | Hua-min LIU,Shu-han YANG,Yi LI,Ce LIANG,Qi-gang Han. Thrust rod ball hinge bionic surface improvement and finite element analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2733-2740. |

| [2] | Ce LIANG,Min LI,Yi LI,Ji-cai LIANG,Qi-gang HAN. Numerical simulation on friction characteristics of rubber bushing with bionic flexible surfaces [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2181-2186. |

| [3] | Jian-xiao ZHENG,Wen-bo WANG,Jin-song LIU,Li-ming ZHOU,Yu LI. Moisture-electro-mechanical coupling smoothed finite element method based on asymptotic homogenization [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1876-1886. |

| [4] | Hua-fei HE,Zhao-ping LI,Rui-an FU,Shao-lin MA,Ming-li HUANG. Experiment on seismic performance of prefabricated sidewall joints considering strata restraint effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1601-1611. |

| [5] | Li-hua LI,Zi-jian LI,Heng-lin XIAO,Wen-zhe CAO,Xin-long ZHOU,Shao-ping HUANG. Experiment on cyclic shear of geosynthetic reinforced construction waste soil [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1612-1623. |

| [6] | Zhen-yong DI,Yong ZHANG. Calculation method for bearing capacity of seismic joints of beam column rigid connections in multi story and high rise buildings [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1058-1064. |

| [7] | Yi-fan LIU,Zhi-wei MIAO,Chen SHEN,Xiang-dong GENG. Evaluation of mechanical properties of non-uniform corroded rebars based on Monte Carlo method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1007-1015. |

| [8] | Bin FENG,Tao ZHANG,Tao LIANG,Ying ZHANG,Xing-long TANG,Guan-ping WANG. Design and experiment of silage baling and wrapping machine with electric driving [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 564-573. |

| [9] | Zhi-jun YANG,Chi ZHANG,Guan-xin HUANG. Mechanical model of rigid⁃flexible coupling positioning stage based on floating coordinate method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 385-393. |

| [10] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [11] | Xiao HAN,Xian-zhang LING,Shuang TIAN,Sheng-yi CONG. Analysis and control of mud spillover in high⁃speed railway ballast⁃track subgrade caused by grouting [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 506-515. |

| [12] | Li-hua LI,Hao-ran KANG,Xin ZHANG,Heng-lin XIAO,Yi-ming LIU,Xin-long ZHOU. Dynamic characteristics of reinforced soil-rock mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 2897-2907. |

| [13] | Ying XU,Yue FAN,Qing-yuan WANG,Zhen-yu ZHANG. Experiment and numerical analysis on fracture toughness of polypropylene fiber reinforced concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 2884-2896. |

| [14] | Fang-cheng LIU,Jiang WANG,Meng-tao WU,Guo-bin BU,Jie HE. Stress⁃strain characteristics of geogrid reinforced rubber sand mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2542-2553. |

| [15] | Shu-pei ZHANG,Ming-yue XIA,Wei ZHANG,Zhao CHEN,Yi-xiang CHEN. Impact dynamic modeling and simulation for ball joint with clearance considering nonlinear stiffness [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2227-2235. |

|