Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (11): 3175-3183.doi: 10.13229/j.cnki.jdxbgxb.20230621

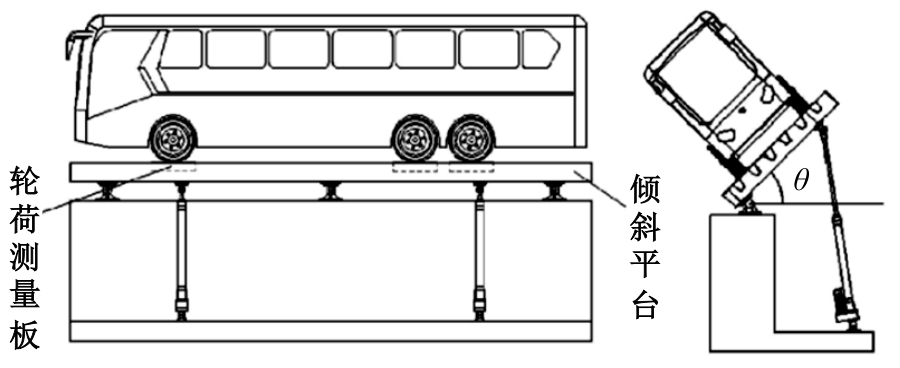

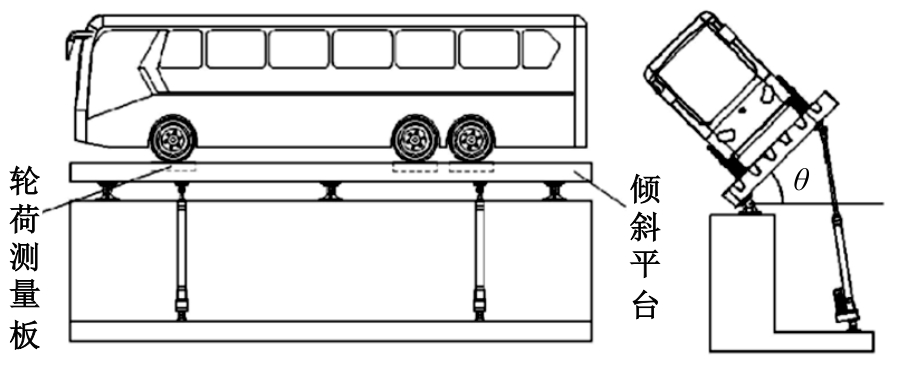

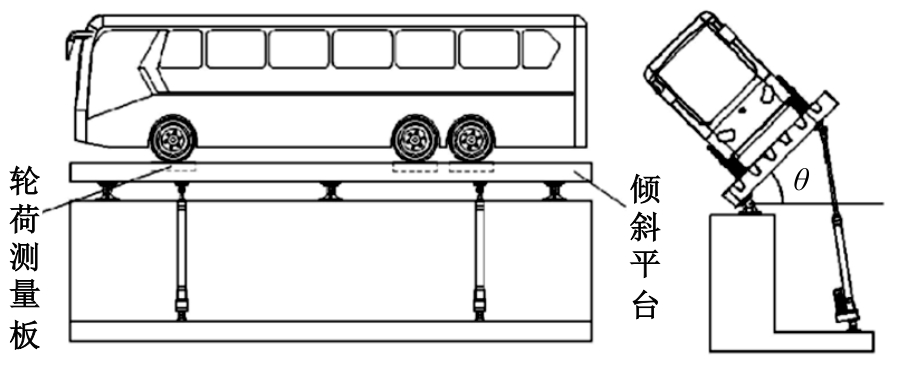

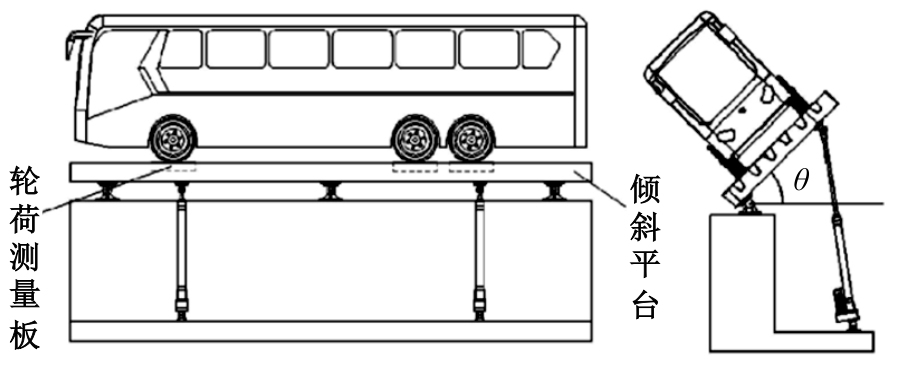

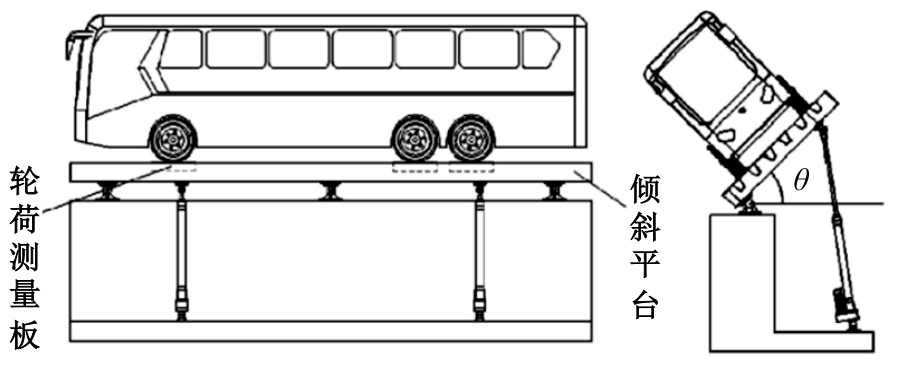

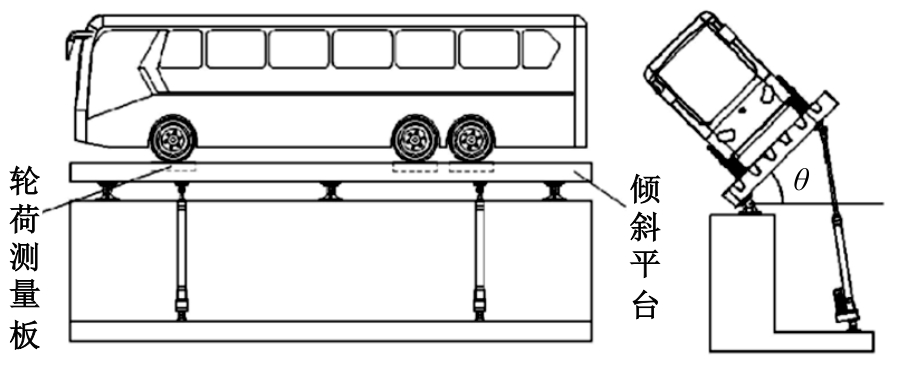

Improved tilting method for vehicle mass center measurement

Ren-jun LI1( ),Yi-bing ZHAO2,Li-dong GU1(

),Yi-bing ZHAO2,Li-dong GU1( ),Hong-qiang TAN1,Lin-sen SONG1,Yan TIAN3

),Hong-qiang TAN1,Lin-sen SONG1,Yan TIAN3

- 1.School of Mechanical and Electrical Engineering,Changchun University of Science and Technology,Changchun 130022,China

2.The No. 63850th Troop of PLA,Baicheng 137000,China

3.Research and Development Center,BMW-Brilliance Automotive Ltd. ,Shenyang 110000,China

CLC Number:

- TH39

| 1 | 郑德喜. 三轴重型车辆行驶操纵稳定性研究[D]. 秦皇岛: 燕山大学机械工程学院, 2021. |

| Zheng De-xi. Research on driving and handling stability of three-axle heavy vehicle[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University, 2021 | |

| 2 | 李涛, 卢海波, 林泛业, 等. 质心高度对车辆动力学性能的影响[J]. 汽车实用技术, 2019(3): 110-112. |

| Li Tao, Lu Hai-bo, Lin Fan-ye, et al. Effect of center of mass height on vehicle dynamic performance[J]. Automotive Practical Technology, 2019(3): 110-112. | |

| 3 | Brancati R, Russo R, Savino S. Method and equipment for inertia parameter identification[J]. Mechanical Systems and Signal Processing, 2010, 24(1): 29-40. |

| 4 | 李俊鹏, 顾宇庆, 陈华杰. 稳定摆法在汽车质心高度测量中的应用及不确定评定[J]. 中国检验检测, 2020, 28(2): 42-45. |

| Li Jun-peng, Gu Yu-qing, Chen Hua-jie. Application of stable pendulum method in the height measurement of automobile center of mass and uncertainty evaluation[J]. China Inspection and Testing, 2020, 28(2): 42-45. | |

| 5 | 杨丽君. 基于侧倾法的车辆质心测量台技术研究[D]. 哈尔滨: 哈尔滨理工大学机械动力工程学院, 2015. |

| Yang Li-jun. Technology research of vehicle center of mass measurement table based on roll method[D]. Harbin: School of Mechanical Power Engineering, Harbin University of Science and Technology, 2015. | |

| 6 | 贾晓东, 向飞. 侧倾台测量汽车质心高度的核查方法[J]. 装备制造技术, 2022(4): 95-98. |

| Jia Xiao-dong, Xiang Fei. Verification method for measuring the height of center of mass of automobile by tilting table[J]. Equipment Manufacturing Technology, 2022(4): 95-98. | |

| 7 | 唐平建, 孙泽林, 张畔, 等. 基于三点支承的特种车辆质心测量误差分析[J]. 兵器装备工程学报, 2021, 42(7): 234-238. |

| Tang Ping-jian, Sun Ze-lin, Zhang Pan, et al. Error analysis of centroid measurement of special vehicle based on three-point support[J]. Journal of Ordnance Equipment Engineering, 2021, 42(7): 234-238. | |

| 8 | 钟江, 赵章风, 乔欣, 等. 基于三点支承的质心测量系统及误差分析[J]. 中国机械工程, 2010, 21(12): 1469-1472. |

| Zhong Jiang, Zhao Zhang-feng, Qiao Xin, et al. Center of mass measurement system and error analysis based on three-point support[J]. China Mechanical Engineering, 2010, 21(12): 1469-1472. | |

| 9 | 邱银燕, 熊云, 李剑斌. 基于质量反应法的车辆质心位置测量平台研究[J]. 农业装备与车辆工程, 2018, 56(9): 88-90. |

| Qiu Yin-yan, Xiong Yun, Li Jian-bin. Research on vehicle centroid position measurement platform based on mass response method[J]. Agricultural Equipment and Vehicle Engineering, 2018, 56(9): 88-90. | |

| 10 | Elaal S M A. Empirical equations to predict the tractor center of gravity[J]. Ama Agricultural Mechanization in Asia Africa & Latin America, 2009, 40(3): 64-68. |

| 11 | Fabbri A, Molari G. Static measurement of the centre of gravity height on narrow-track agricultural tractors[J]. Biosystems Engineering, 2004, 87(3): 299-304. |

| 12 | 王德民, 张龙易, 许镇全, 等. 陆行车质心测量机设计与分析[J]. 长春理工大学学报: 自然科学版, 2021, 44(3): 76-82. |

| Wang De-min, Zhang Long-yi, Xu Zhen-quan, et al. Design and analysis of center of mass measuring machine for land vehicle[J]. Journal of Changchun University of Science and Technology (Natural Science Edition), 2021, 44(3): 76-82. | |

| 13 | Zhang Q, Jin X, Zhou K, et al. Novel design method of cog measurement system via supporting reaction method[J]. Journal of Beijing Institute of Technology, 2020, 29(2): 251-259. |

| 14 | Gobbi M, Mastinu G, Previati G. A method for measuring the inertia properties of rigid bodies[J]. Mechanical Systems&Signal Processing, 2011, 25(1): 305-318. |

| 15 | Mastinu G, Gobbi M, Miano C M. The influence of the body inertia tensor on the active safety and ride comfort of road vehicles[J]. Journal of Passenger Car: Mechanical Systems Journal, 2002, 111(6): 1980-1990. |

| 16 | 秦剑文, 李波辉. 两种测量质心高度方法的研究[J]. 装备制造技术, 2020(12): 95-96. |

| Qin Jian-wen, Li Bo-hui. Research on two methods for measuring the height of the center of mass[J]. Equipment Manufacturing Technology, 2020(12): 95-96. | |

| 17 | 丁伟, 高浩, 张坤, 等. 多轴车辆轮荷计算方法研究[J]. 汽车技术, 2014, 469(10): 18-21. |

| Ding Wei, Gao Hao, Zhang Kun, et al. Research on calculation method of wheel load for multi-axle vehicle[J]. Automotive Technology, 2014, 469(10): 18-21. |

| [1] | Bing ZHU,Tian-xin FAN,Wen-bo ZHAO,Wei-nan LI,Pei-xing ZHANG. Continuous test scenario complexity evaluation method for automated driving vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 456-467. |

| [2] | Tian-yang GAO,Da-wei HU,Rui-sen JIANG,Xue WU,Hui-tian LIU. Optimization study of zonal-based flexible feeder bus routes based on modular vehicle system [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 537-545. |

| [3] | Jian-hui LIU,Qiong WANG. Optimization method for emergency material delivery vehicle scheduling in multiple distribution centers based on multi-objective ant colony algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 631-638. |

| [4] | Sheng JIN,Bo-lin LI,Wei XUE. Collaborative optimization for signals and trajectories of connected automated vehicles on dedicated bus lanes [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 566-576. |

| [5] | Hua-zhen FANG,Li LIU,Qing GU,Xiao-feng XIAO,Yu MENG. Driving intention recognition based on trajectory prediction and extreme gradient boosting [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 623-630. |

| [6] | Jun-long QU,Wen-ku SHI,Sheng-yi XUAN,Zhi-yong CHEN. Parameter design method of multiple dynamic vibration absorbers for suppressing multi-frequency resonance of automotive powertrain [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 444-455. |

| [7] | Xin CHEN,Xiang-yuan ZHANG,Zi-tao WU,Gui-shen YU,Li-fei YANG. Effect of process sequence on tensile shear properties of PFSSW joints for automotive aluminum sheets [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 468-475. |

| [8] | Li-min ZHENG,Shuang CHEN,Gang LI. Multiple object detection of violated vehicles in traffic surveillance video based on YOLOv5 network algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 693-699. |

| [9] | Hui-zhi XU,Shi-sen JIANG,Xiu-qing WANG,Shuang CHEN. Vehicle target detection and ranging in vehicle image based on deep learning [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 185-197. |

| [10] | Hong-yu HU,Zheng-guang ZHANG,You QU,Mu-yu CAI,Fei GAO,Zhen-hai GAO. Driver behavior recognition method based on dual-branch and deformable convolutional neural networks [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 93-104. |

| [11] | Chang-shuai WANG,Cheng-cheng XU,Wei-lin REN,Chang PENG,Hao TONG. Impacts of driving ability recovery state on characteristics of traffic oscillation in automated driving takeover process [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 150-161. |

| [12] | Jun-nian WANG,Yu-jing CAO,Zhi-ren LUO,Kai-xuan LI,Wen-bo ZHAO,Ying-yi MENG. Online detection algorithm of road water depth based on binocular vision [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 175-184. |

| [13] | Cao TAN,Hao-xin REN,Wen-qing GE,Ya-dong SONG,Jia-yu LU. Improved active disturbance rejection control for hydraulic vibration stages based on the direct-drive valve [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 84-92. |

| [14] | Shou-tao LI,Lu YANG,Ru-yi QU,Peng-peng SUN,Ding-li YU. Slip rate control method based on model predictive control [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2687-2696. |

| [15] | Jin-xing WU,Yu-xiang MA,Jia-bang XIAO,Yao XU,Song-ge LI. Numerical simulation of erosion characteristics of H-type finned elliptical tubes [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2495-2501. |

|

||