吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (10): 2884-2896.doi: 10.13229/j.cnki.jdxbgxb.20221551

• 交通运输工程·土木工程 • 上一篇

聚丙烯纤维混凝土断裂韧度试验与数值分析

- 哈尔滨工业大学(深圳) 广东省土木工程智能韧性结构重点实验室,广东 深圳 518055

Experiment and numerical analysis on fracture toughness of polypropylene fiber reinforced concrete

Ying XU( ),Yue FAN,Qing-yuan WANG,Zhen-yu ZHANG

),Yue FAN,Qing-yuan WANG,Zhen-yu ZHANG

- Guangdong Provincial Key Laboratory of Intelligent and Resilient Structures for Civil Engineering,Harbin Institute of Technology,Shenzhen 518055,China

摘要:

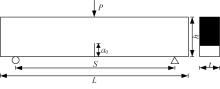

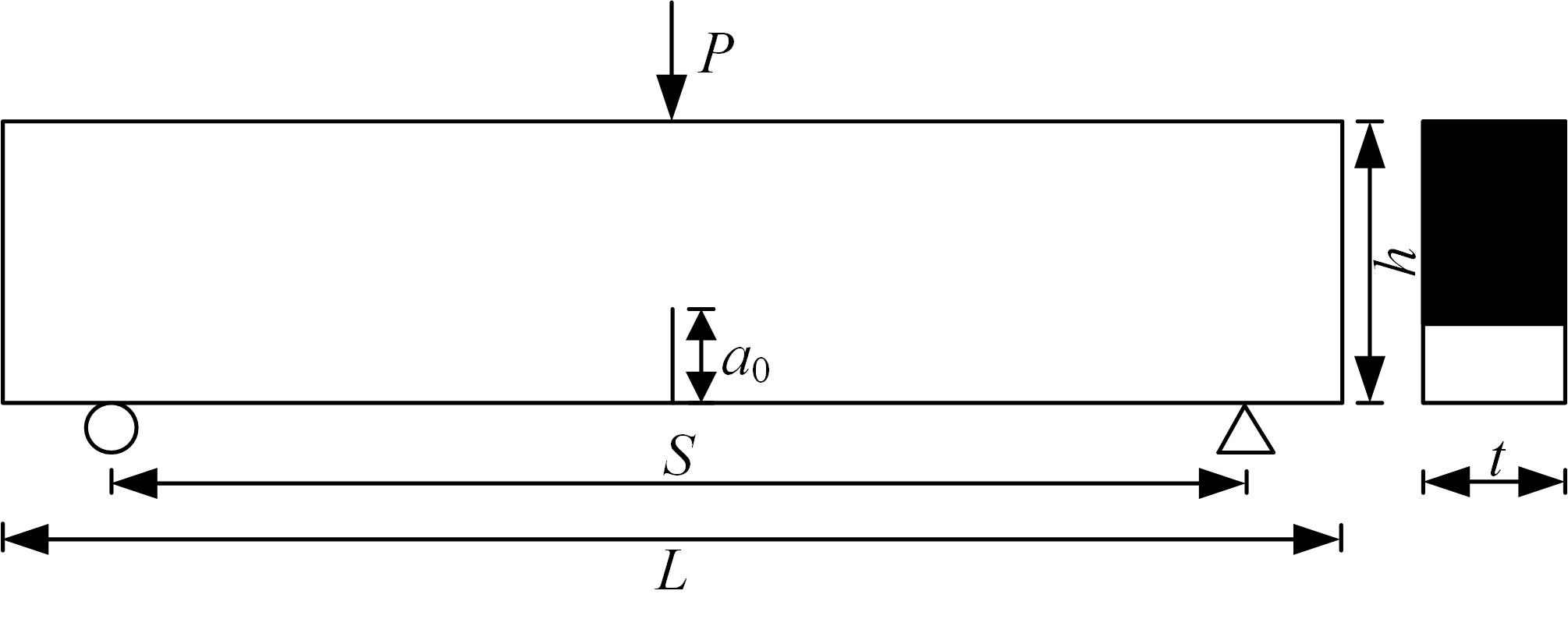

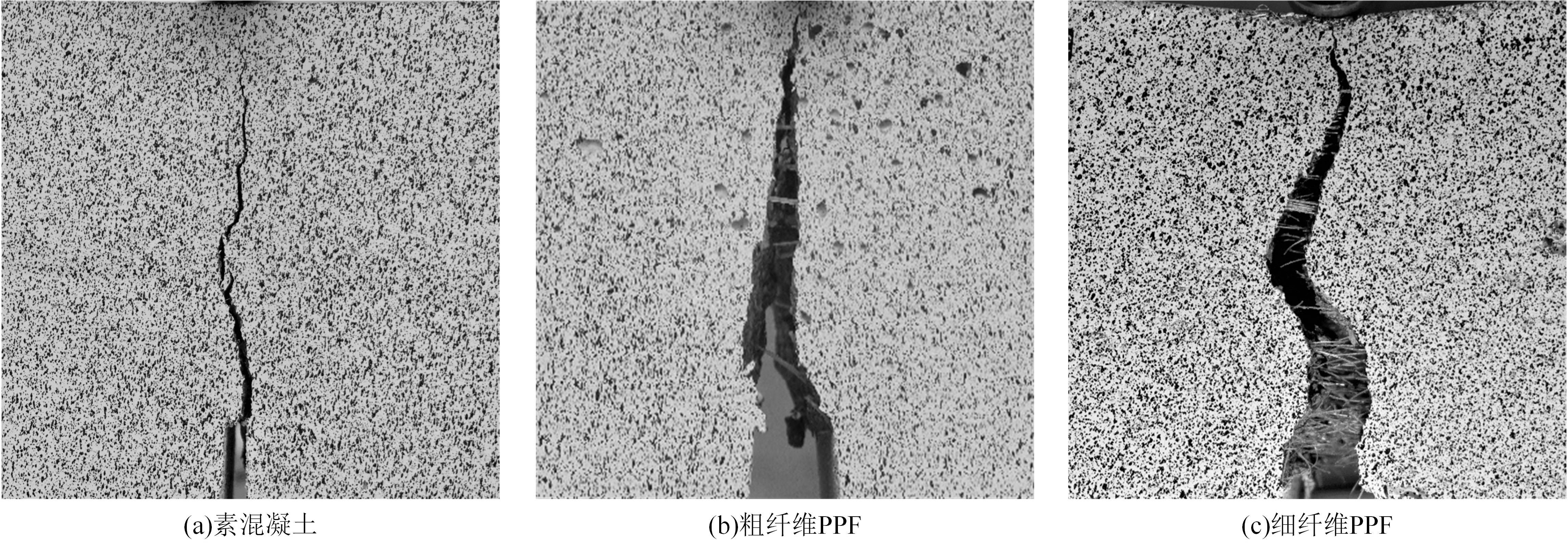

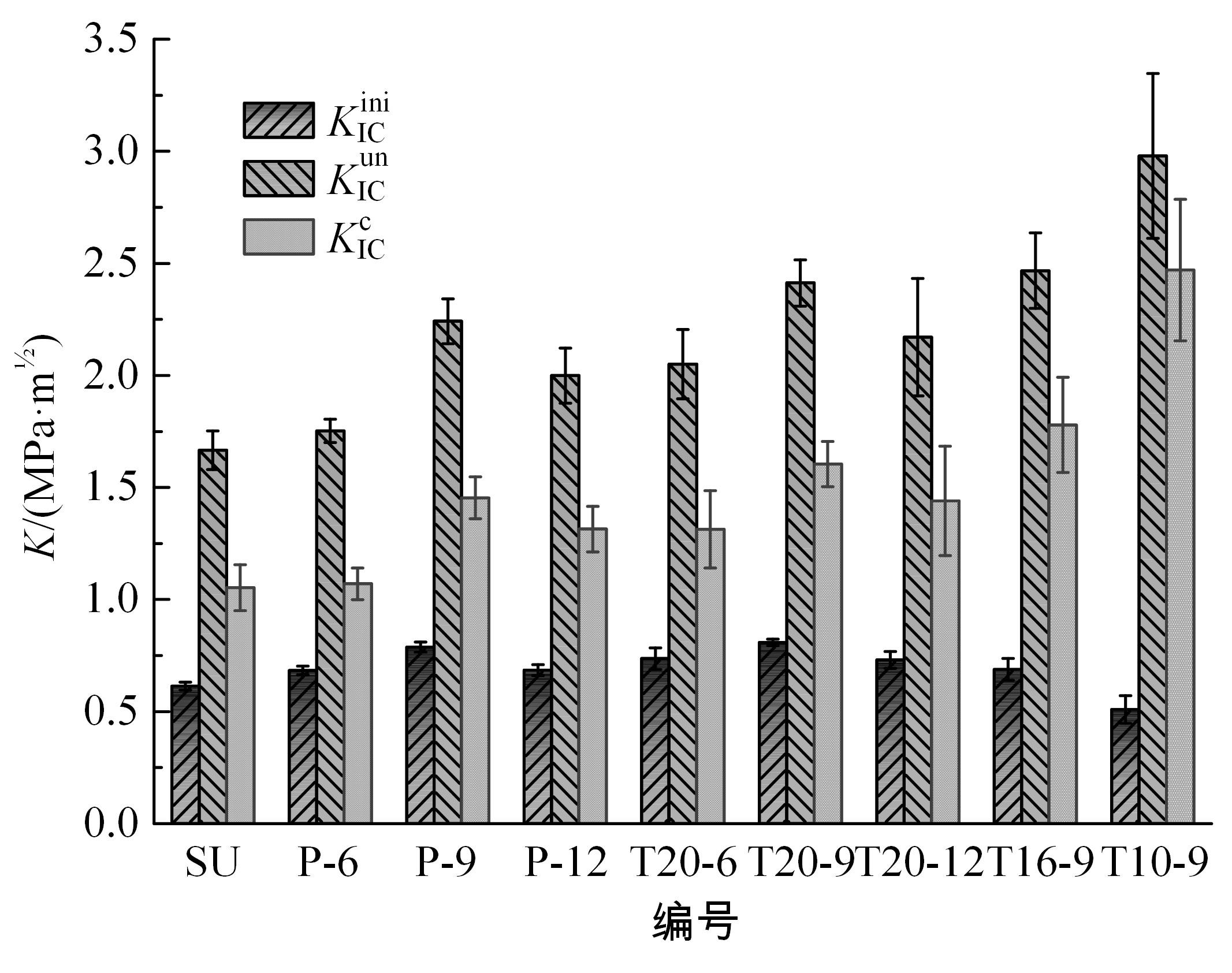

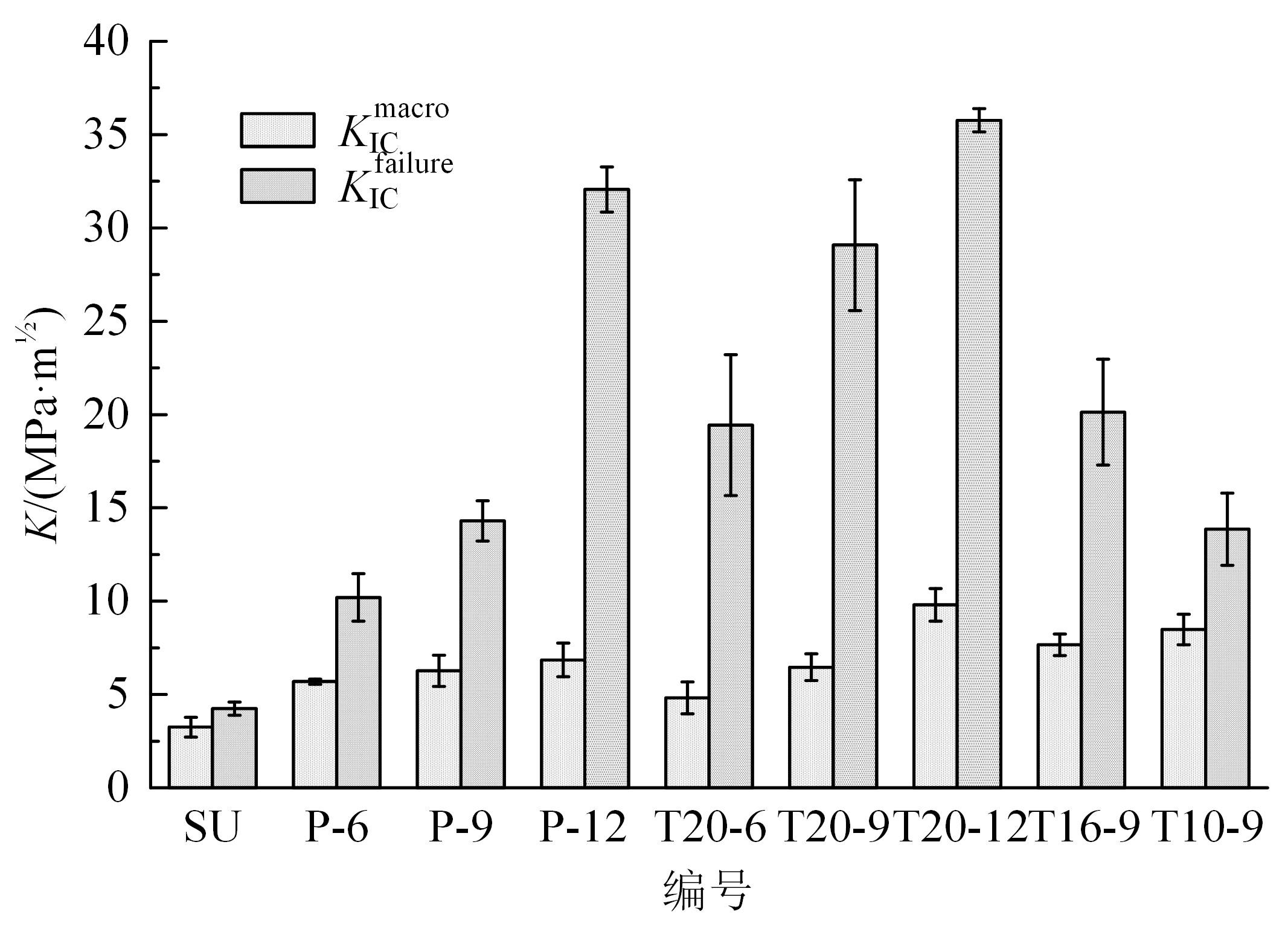

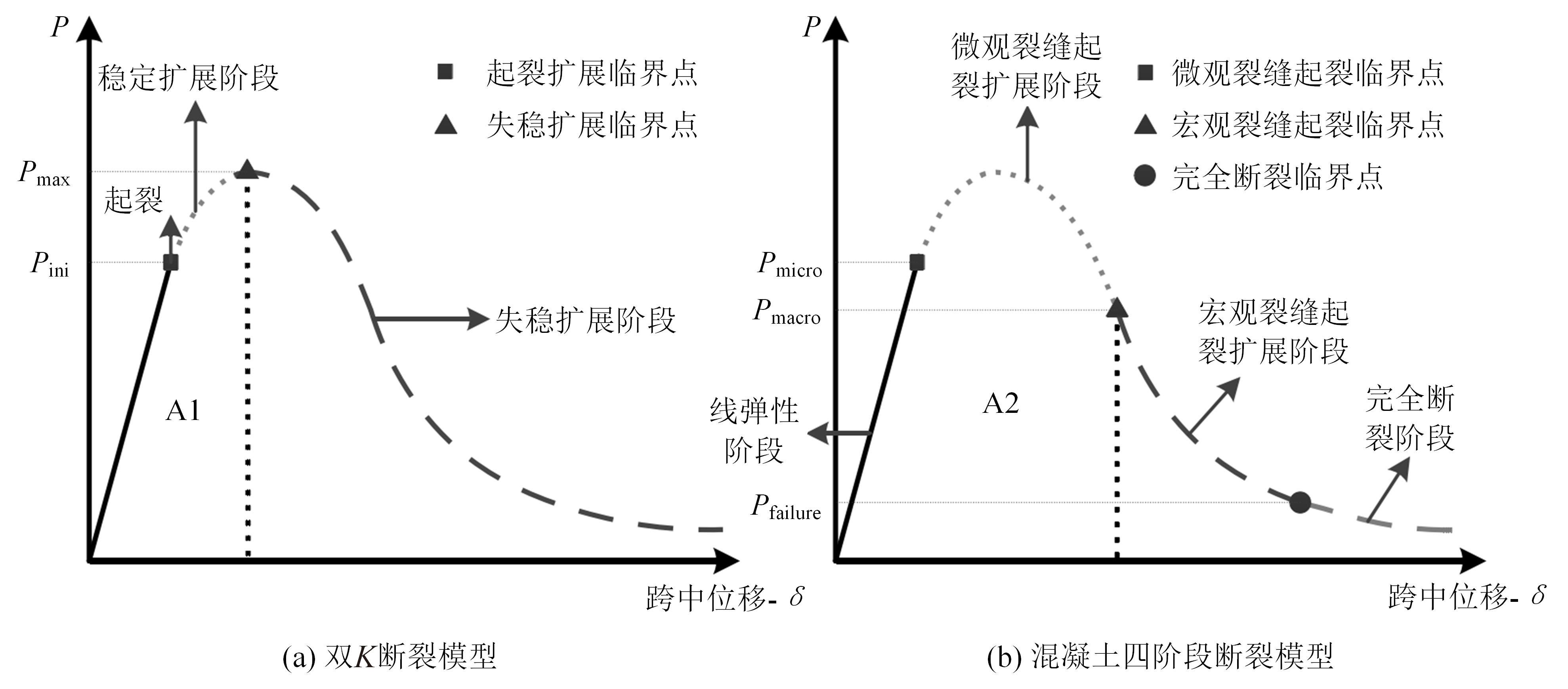

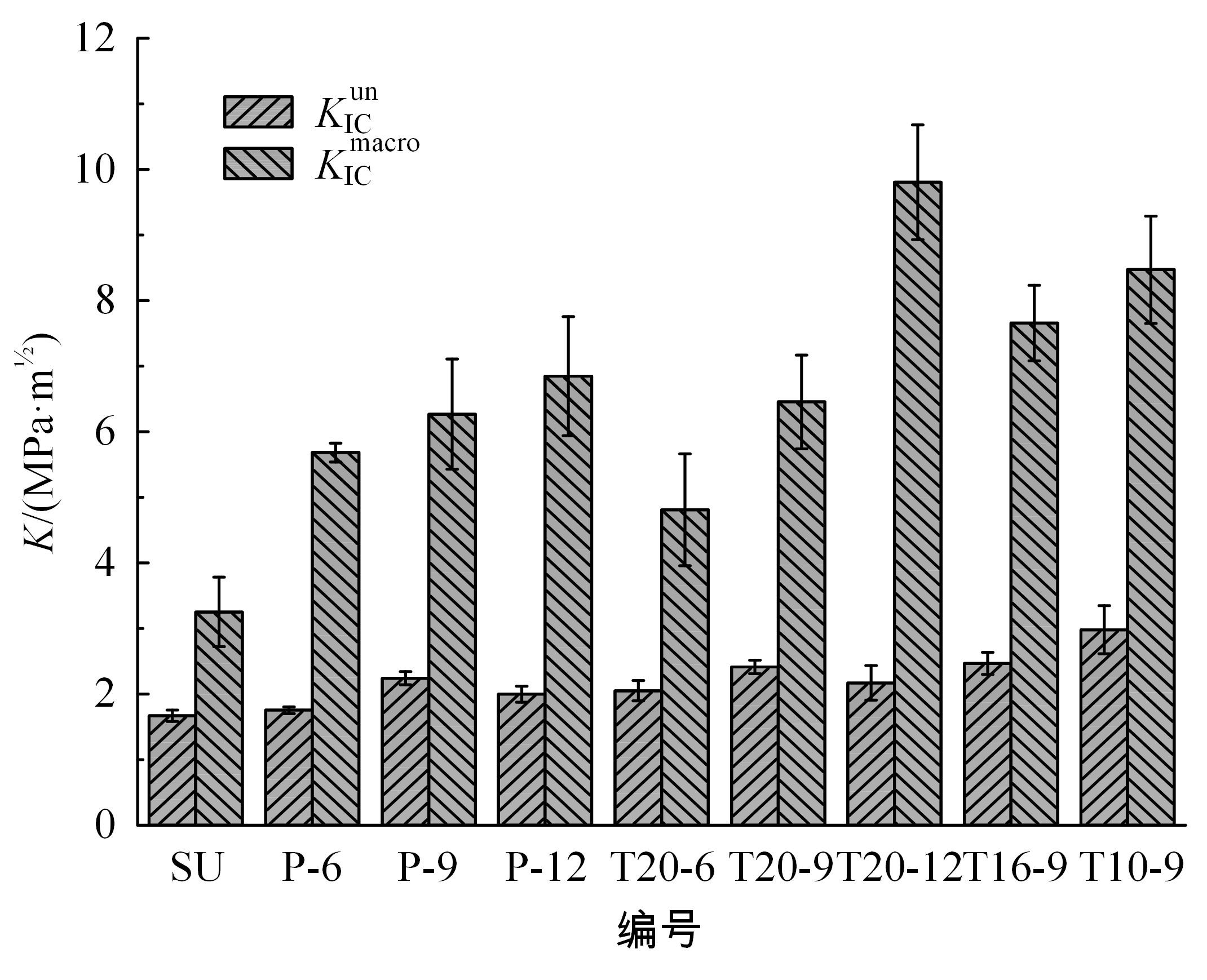

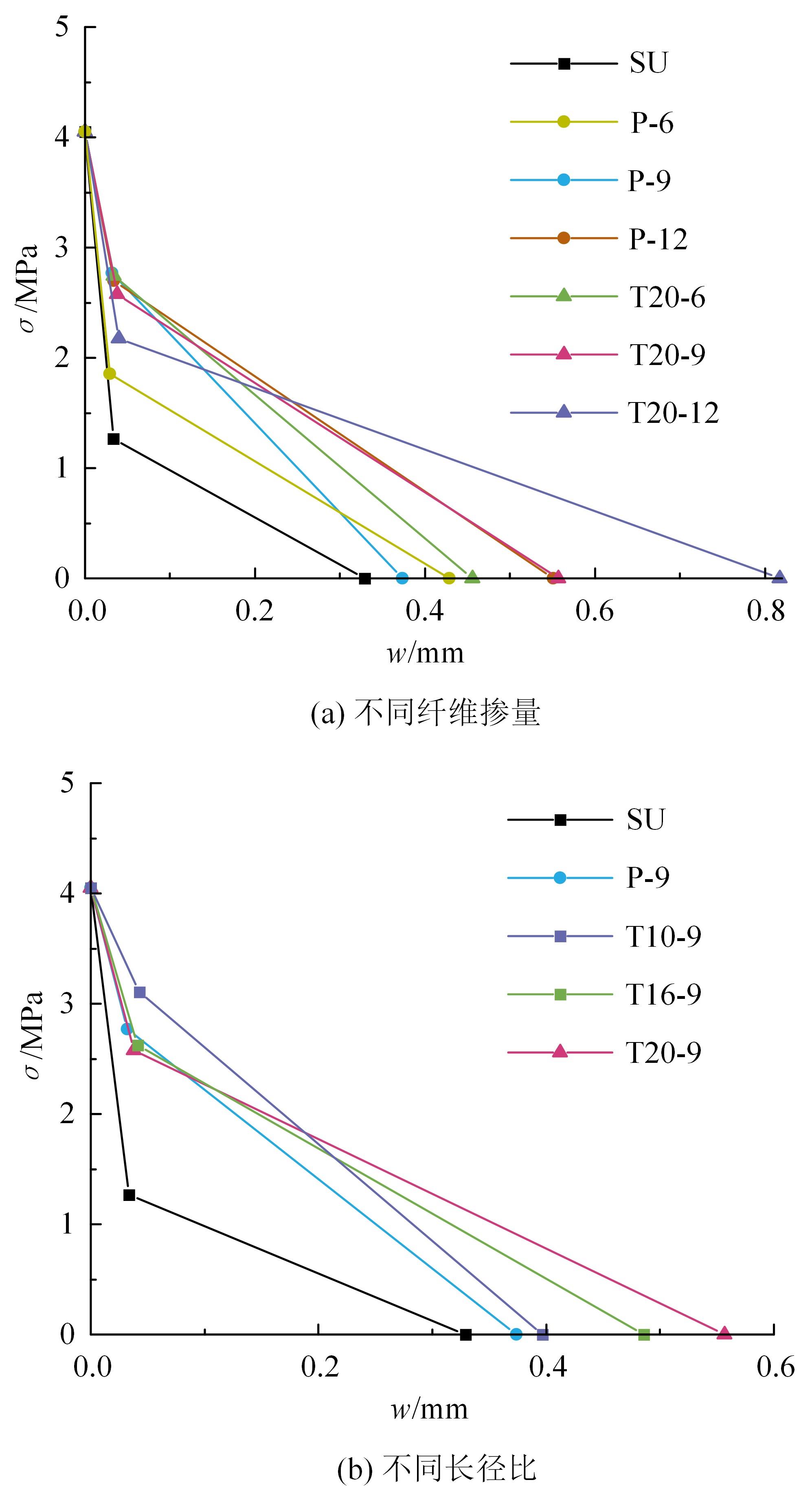

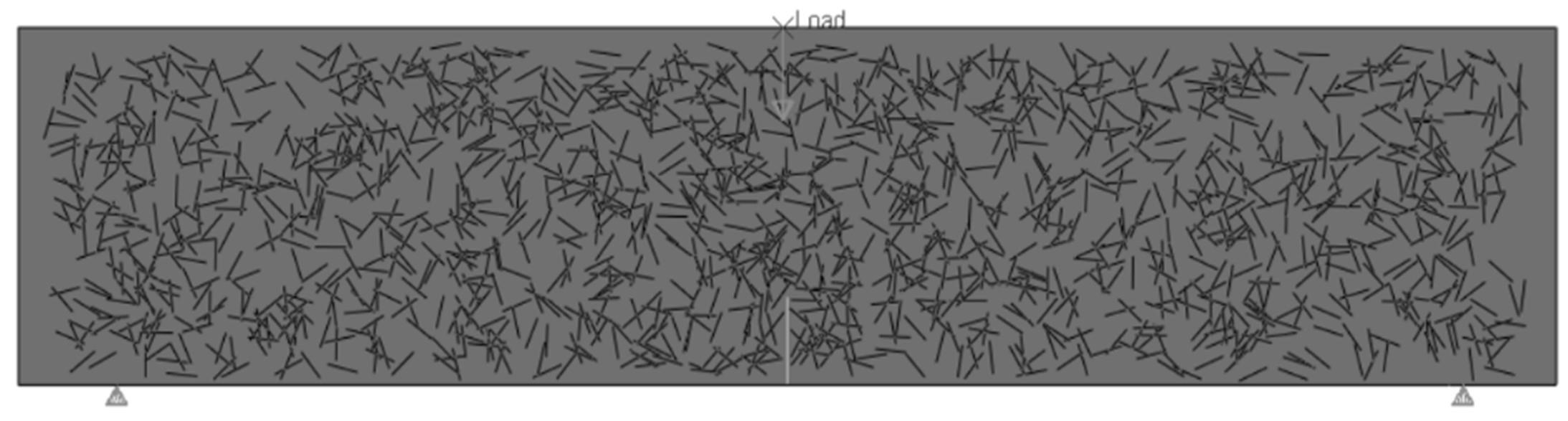

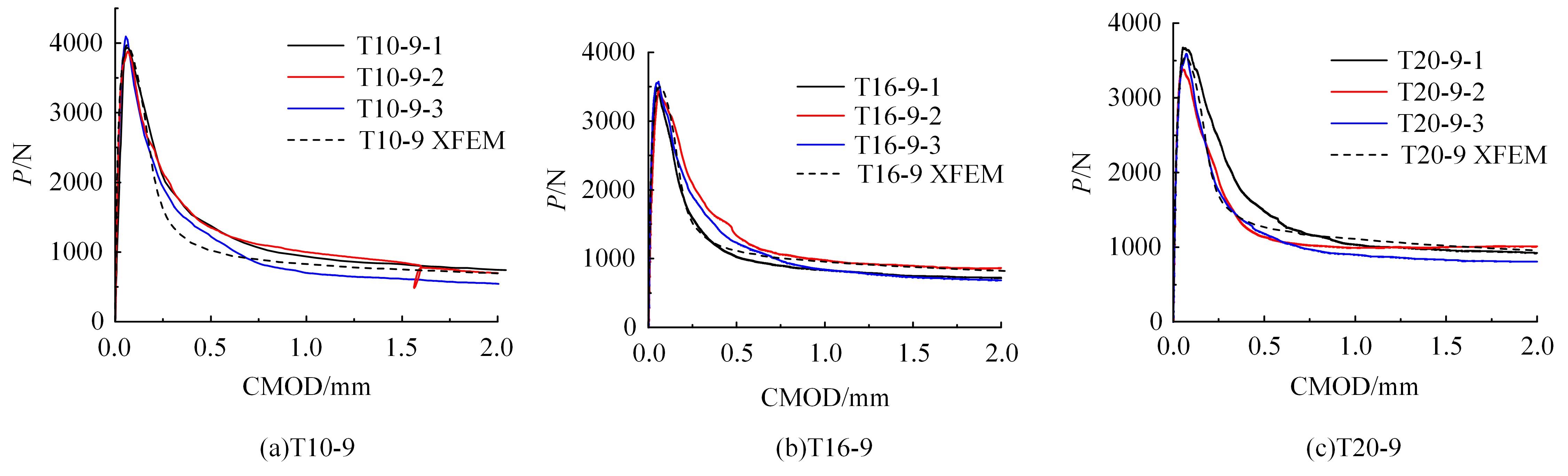

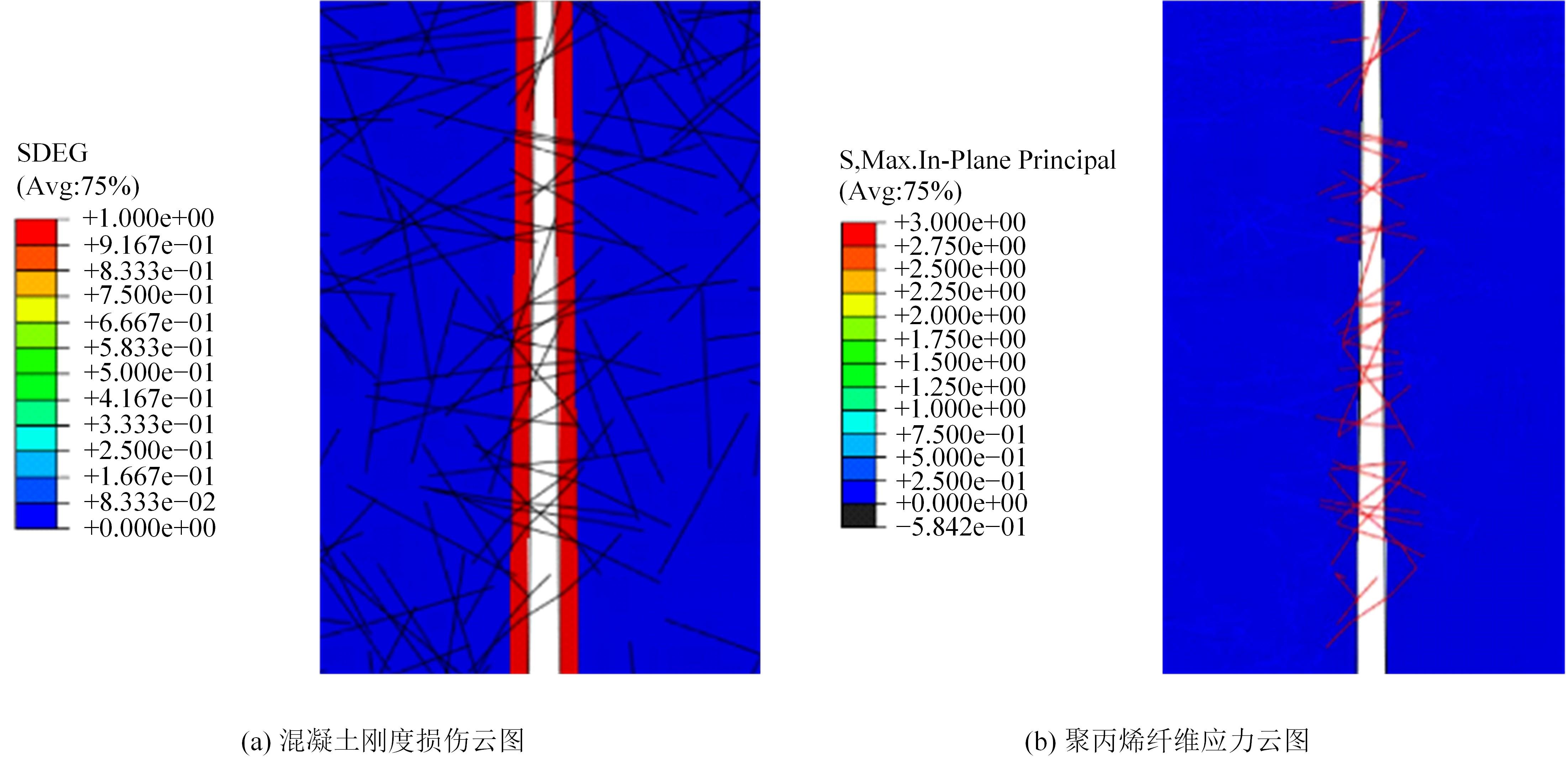

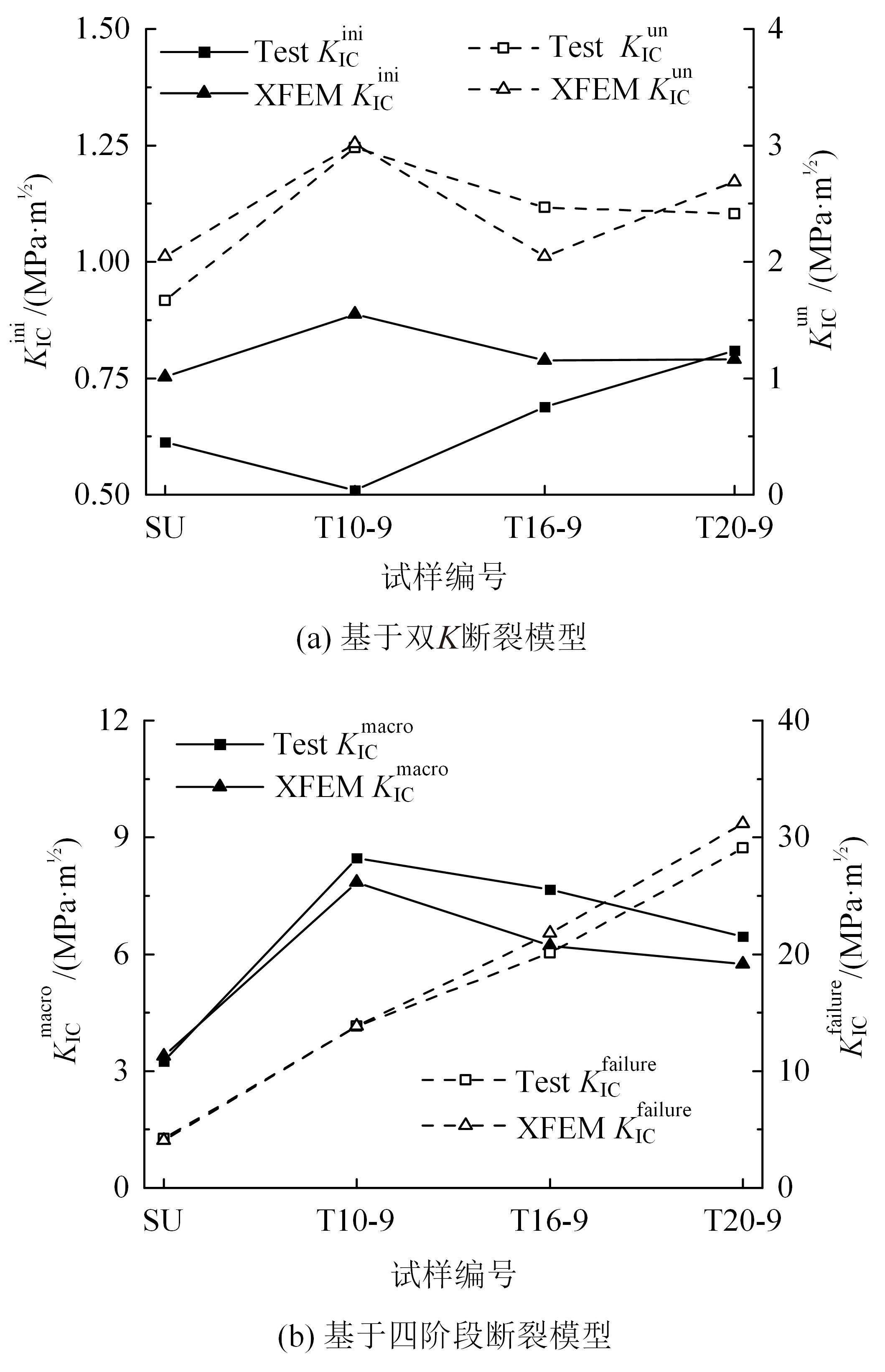

本文采用9组不同配合比的聚丙烯纤维增强混凝土(Polypropylene fiber reinforced concrete,PPFRC)进行预制裂缝梁三点弯曲试验,以聚丙烯纤维掺量和长径比为控制变量,基于双K断裂模型和四阶段断裂模型分别探讨了聚丙烯纤维对混凝土不同断裂韧度的影响,得到了PPFRC的粘聚力-裂缝张开位移双线性软化曲线,引入影响系数解决了经验计算公式的修正问题,利用ABAQUS的扩展有限元法模拟断裂过程,通过参数分析验证模型分析梁断裂行为的可行性。本文结果表明:四阶段断裂模型更适用于作为PPFRC结构失效的判定准则,模型中的宏观裂缝起裂韧度与纤维掺量成正比,与长径比成反比,结构失效韧度与掺量和长径比均呈正相关。掺入12 kg/m3、20 mm长聚丙烯纤维的混凝土宏观裂缝起裂韧度和结构失效韧度分别为9.80、55.32 MPa·m1/2。双线性软化本构经验公式中引入的聚丙烯粗纤维βp=0.849;聚丙烯细纤维βp在0.409~0.552,取值随长径比增大而上升。

中图分类号:

- TU528

| 1 | Güneyisi E, Gesoglu M, Özturan T,et al. Fracture behavior and mechanical properties of concrete with artificial lightweight aggregate and steel fiber[J]. Construction & Building Materials,2015,84:156-168. |

| 2 | 韩菊红,李明轩,杨孝青,等. 混杂钢纤维二级配混凝土断裂性能试验研究[J]. 土木工程学报,2020,53(9):31-40. |

| Han Ju-hong, Li Ming-xuan, Yang Xiao-qing, et al. Experimental study on fracture behavior of mixed steel fiber secondary concrete[J]. Journal of Civil Engineering, 2020,53(9):31-40. | |

| 3 | 代继飞. 基于双K准则的多尺寸聚丙烯纤维混凝土断裂韧性研究[D]. 重庆:重庆大学土木工程学院,2017. |

| Dai Ji-fei. Fracture toughness of multi-size polypropylene fiber reinforced concrete based on double K criterion[D]. Chongqing:School of Civil Engineering, Chongqing University, 2017. | |

| 4 | 梁宁慧,缪庆旭,刘新荣,等. 聚丙烯纤维增强混凝土断裂韧度及软化本构曲线确定[J]. 吉林大学学报:工学版,2019,49(4):1144-1152. |

| Liang Ning-hui, Miao Qing-xu, Liu Xin-rong,et al. Determination of fracture toughness and softening constitutive curve of polypropylene fiber reinforced concrete[J]. Journal of Jilin University(Engineering and Technology Edition), 2019,49(4):1144-1152. | |

| 5 | 左文锌. 基于双K模型的纤维混凝土I型断裂特性研究[D]. 哈尔滨:哈尔滨工业大学交通科学与工程学院,2011. |

| Zuo Wen-xin. Study on type I fracture characteristics of fiber reinforced concrete based on double K model[D]. Harbin: School of Transportation Science and Engineering,Harbin Institute of Technology,2011. | |

| 6 | 符永康. 混凝土四阶段断裂模型及其在刚性道面断裂分析中的应用[D]. 哈尔滨:哈尔滨工业大学交通科学与工程学院,2019:52-71. |

| Fu Yong-kang. Four-stage fracture model of concrete and its application in fracture analysis of rigid pavement[D]. Harbin:School of Transportation Science and Engineering,Harbin Institute of Technology,2019:52-71. | |

| 7 | Marzec I, Bobiński J. Quantitative assessment of the influence of tensile softening of concrete in beams under bending by numerical simulations with XFEM and cohesive cracks[J]. Materials,2022,15(2): No.626. |

| 8 | 伍江飞. 基于黏聚裂纹模型的混凝土断裂过程扩展有限元法模拟[J]. 水利水电技术,2019,50(4):205-211. |

| Wu Jiang-fei. Simulation of concrete fracture process by extended finite element method based on cohesive crack model[J]. Water Conservancy and Hydropower Technology, 2019,50(4):205-211. | |

| 9 | Tawfik A B, Mahfouz S Y, Taher S E-D F. Nonlinear ABAQUS simulations for notched concrete beams[J]. Materials,2021,14(23): No.7349. |

| 10 | 雷志鹏. 基于扩展有限元法的混凝土梁开裂特性研究[D]. 广州:华南理工大学土木与交通学院,2017. |

| Lei Zhi-peng. Cracking characteristics of concrete beams based on extended finite element method[D]. Guangzhou: School of Civil Engineering and Transportation, South China University of Technology, 2017. | |

| 11 | 齐西力. 基于断裂力学与扩展有限元对混凝土开裂扩展的研究[D]. 贵阳:贵州大学土木工程学院,2017. |

| Qi Xi-li. Study on crack propagation of concrete based on fracture mechanics and extension finite element[D]. Guiyang: College of Civil Engineering, Guizhou University, 2017. | |

| 12 | 2:2006. |

| Fibres for concrete—part 2: polymer fibres—definitions,specifications and conformity [S]. | |

| 13 | .水泥混凝土和砂浆用合成纤维 [S]. |

| 14 | 周兴宇. 多尺度聚丙烯纤维混凝土性能研究[D]. 扬州:扬州大学建筑科学与工程学院,2020. |

| Zhou Xing-yu. Study on properties of multi-scale polypropylene fiber concrete[D]. Yangzhou: College of Architectural Science and Engineering,Yangzhou University, 2020. | |

| 15 | RILEM Committee FMT 89. Determination of fracture parameter Kc and CTOD of plain concrete using three point bend tests[J]. Materials and Structures,1990,23:457-460. |

| 16 | RILEM Committee FMC 50. Determination of the fracture energy of mortar and concrete by means of the three-point bend test[J]. Materials and Structures,1985,18:285-290. |

| 17 | RILEM Committee FMT 89. Size effect method for determining fracture energy and process zone size of concrete[J]. Materials and Structures,1990,23:461-465. |

| 18 | 徐世烺,赵艳华. 混凝土裂缝扩展的断裂过程准则与解析[J]. 工程力学,2008,25():20-33. |

| Xu Shi-lang, Zhao Yan-hua. Fracture process criterion and analysis of concrete crack propagation[J]. Engineering Mechanics, 2008,25(Sup.2):20-33. | |

| 19 | Gaedicke C, Roesler J, Jr F E. Three-dimensional cohesive crack model prediction of the flexural capacity of concrete slabs on soil[J]. Engineering Fracture Mechanics,2012,94(4):6-12. |

| 20 | Hu X J, Duan K. Influence of fracture process zone height on fracture energy of concret[J].Cement and Concrete Research,2004,34(8):1321-1330. |

| 21 | 李东洋. 湿热环境下 CFRP 加固 RC 梁疲劳主裂纹扩展规律研究[D]. 广州:华南理工大学土木与交通学院,2018. |

| Li Dong-yang. Study on fatigue main crack propagation law of RC beams reinforced by CFRP under humid and hot environment [D]. Guangzhou: School of Civil Engineering and Transportation,South China University of Technology, 2018. |

| [1] | 张广泰,周乘孝,刘诗拓. 盐渍土环境下纤维锂渣混凝土柱恢复力模型[J]. 吉林大学学报(工学版), 2024, 54(7): 1944-1957. |

| [2] | 陈凯祥,张鹤年,席培胜,王长丹,余涛,张炳锌. 碳化湿度对碳化砌块力学与耐久性能的影响[J]. 吉林大学学报(工学版), 2024, 54(2): 445-452. |

| [3] | 秦拥军,陈楠,蔺鹏杰,于江. 掺锂渣再生混凝土三点弯曲梁双K断裂特性[J]. 吉林大学学报(工学版), 2021, 51(6): 2121-2127. |

| [4] | 刘寒冰,高鑫,宫亚峰,刘诗琪,李文俊. 表面处理对玄武岩纤维活性粉末混凝土力学性能的影响及断裂特性[J]. 吉林大学学报(工学版), 2021, 51(3): 936-945. |

| [5] | 袁杰,陈歆,何虹霖,杨博,朱小骏. 微生物矿化作用下混凝土裂缝修复与性能补偿[J]. 吉林大学学报(工学版), 2020, 50(2): 641-647. |

| [6] | 何娟,程从密,杨毅男,张亚芳,钟明峰. 湿热养护时掺合料对玻纤增强水泥性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 648-653. |

| [7] | 梁宁慧,缪庆旭,刘新荣,代继飞,钟祖良. 聚丙烯纤维增强混凝土断裂韧度及软化本构曲线确定[J]. 吉林大学学报(工学版), 2019, 49(4): 1144-1152. |

| [8] | 高小建, 孙博超, 叶焕, 王子龙. 矿物掺合料对自密实混凝土流变性能的影响[J]. 吉林大学学报(工学版), 2016, 46(2): 439-444. |

| [9] | 肖锐, 邓宗才, 兰明章, 申臣良. 不掺硅粉的活性粉末混凝土配合比试验[J]. 吉林大学学报(工学版), 2013, 43(03): 671-676. |

| [10] | 孟松鹤, 高慧婷, 孙莉安, 史洪军. 硅灰-矿渣对聚丙烯纤维混凝土性能的影响[J]. 吉林大学学报(工学版), 2010, 40(增刊): 214-0217. |

| [11] | 刘寒冰,何岩,魏海斌,刘昊. 聚丙烯纤维改良粉煤灰土的动力特性[J]. 吉林大学学报(工学版), 2010, 40(03): 672-0675. |

| [12] | 刘寒冰, 何岩, 魏海斌, 葛琪. 聚丙烯纤维改良粉煤灰土[J]. 吉林大学学报(工学版), 2010, 40(02): 431-0434. |

|

||