吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1203-1211.doi: 10.13229/j.cnki.jdxbgxb20180105

• • 上一篇

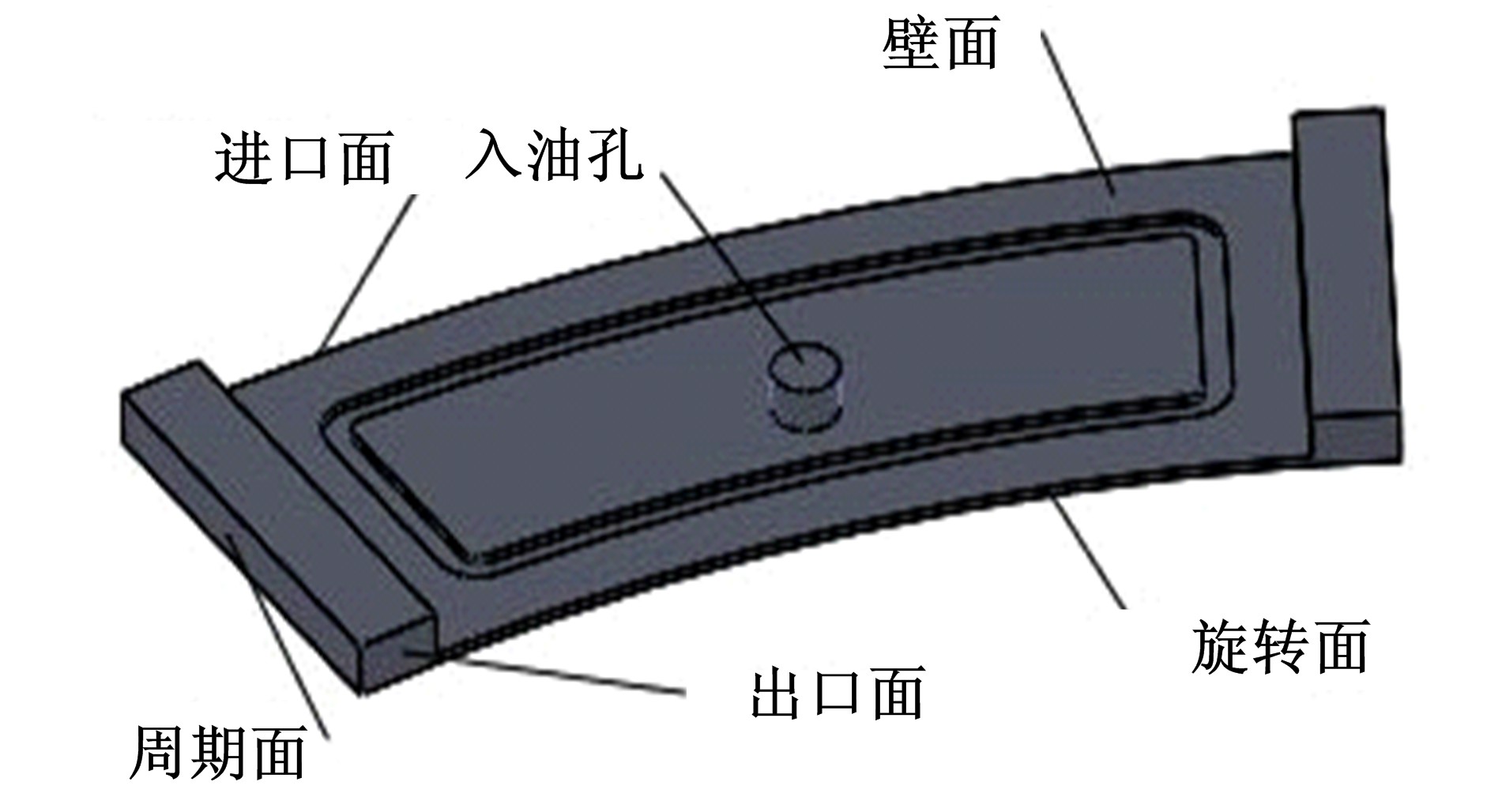

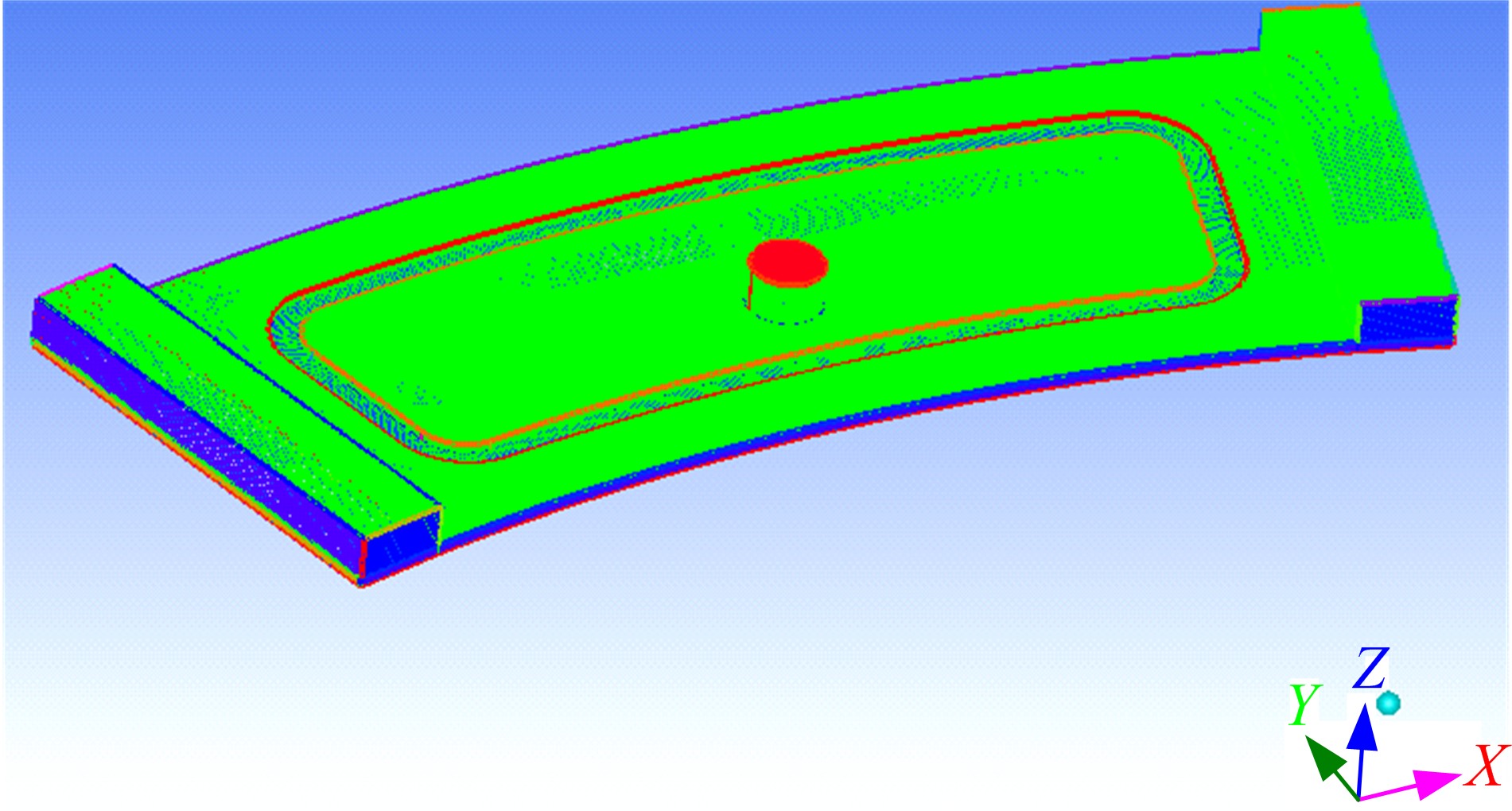

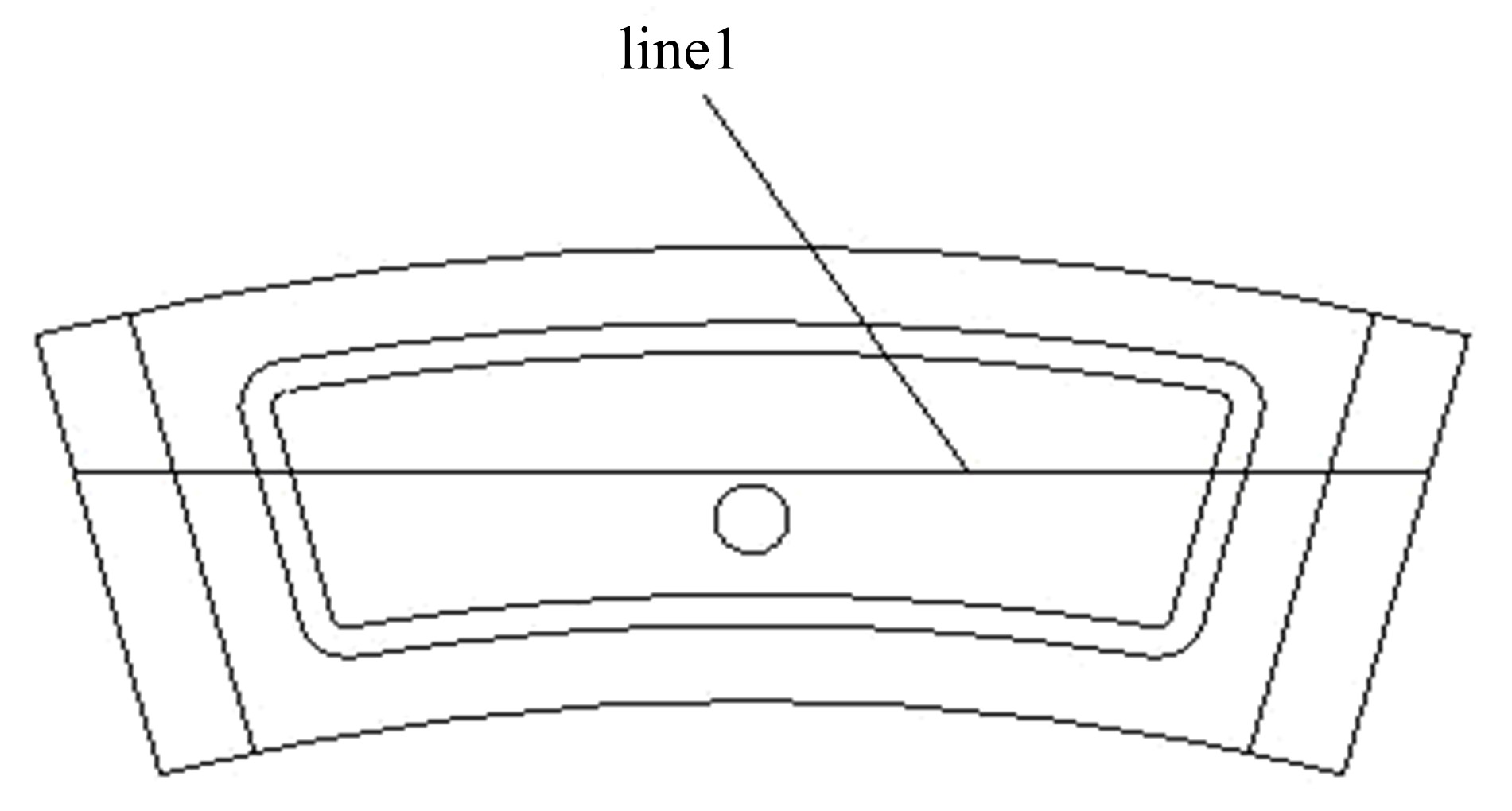

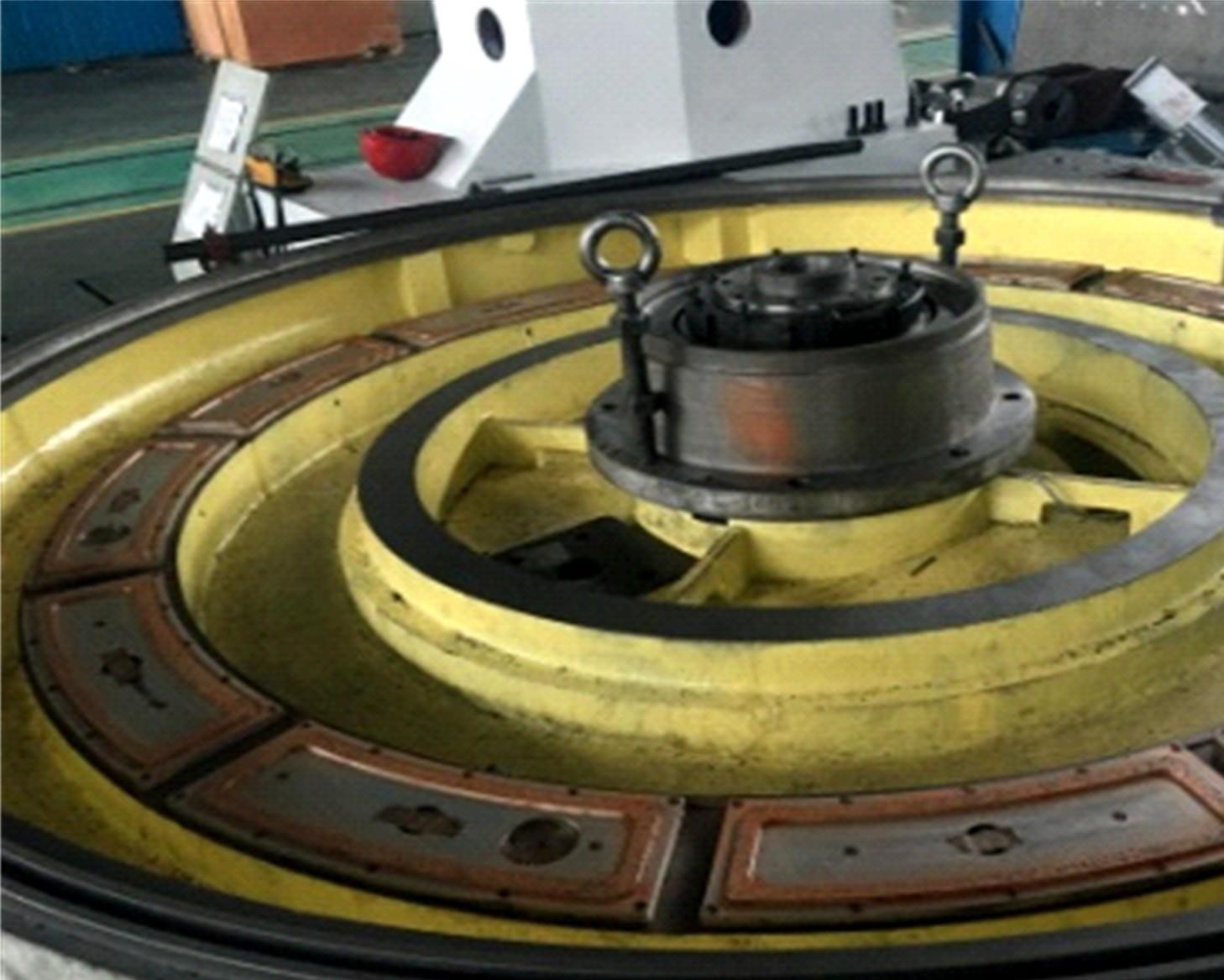

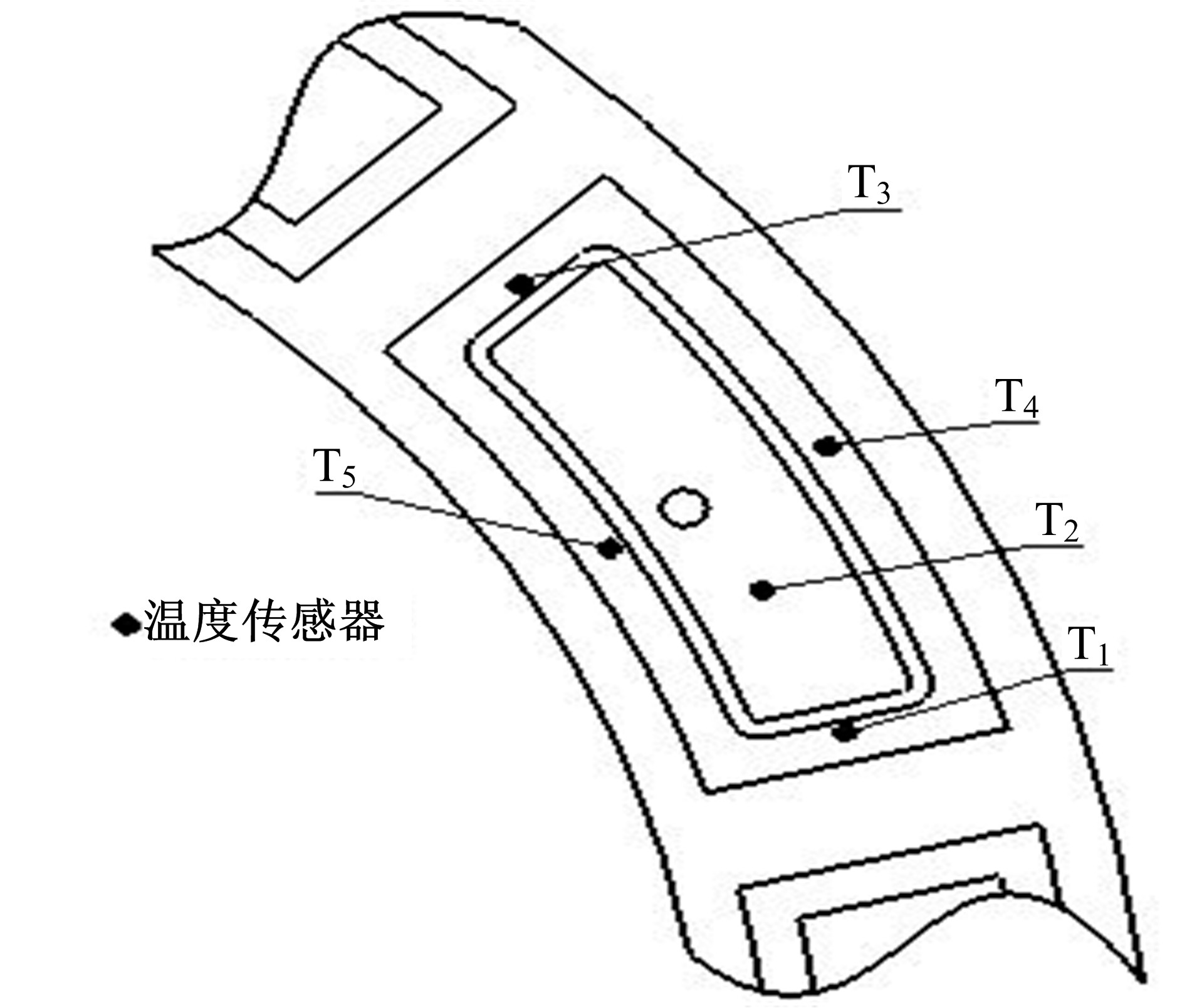

基于热油携带的静压支承油膜温度场及试验

- 1. 哈尔滨理工大学 机械动力工程学院,哈尔滨 150080

2. 南京工程学院 机械工程学院,南京 211167

Temperature field and experiment of hydrostatic bearing oil film based on hot oil carrying

Yan-qin ZHANG1,2( ),Ya-nan FENG1,Peng-rui KONG1,Xiao-dong YU1,Xiang-bin KONG1

),Ya-nan FENG1,Peng-rui KONG1,Xiao-dong YU1,Xiang-bin KONG1

- 1. College of Mechanical and Power Engineering, Harbin University of Science and Technology, Harbin 150080, China

2. College of Mechanical Engineering, Nanjing Institute of Technology, Nanjing 211167, China

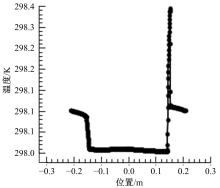

摘要:

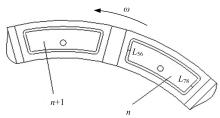

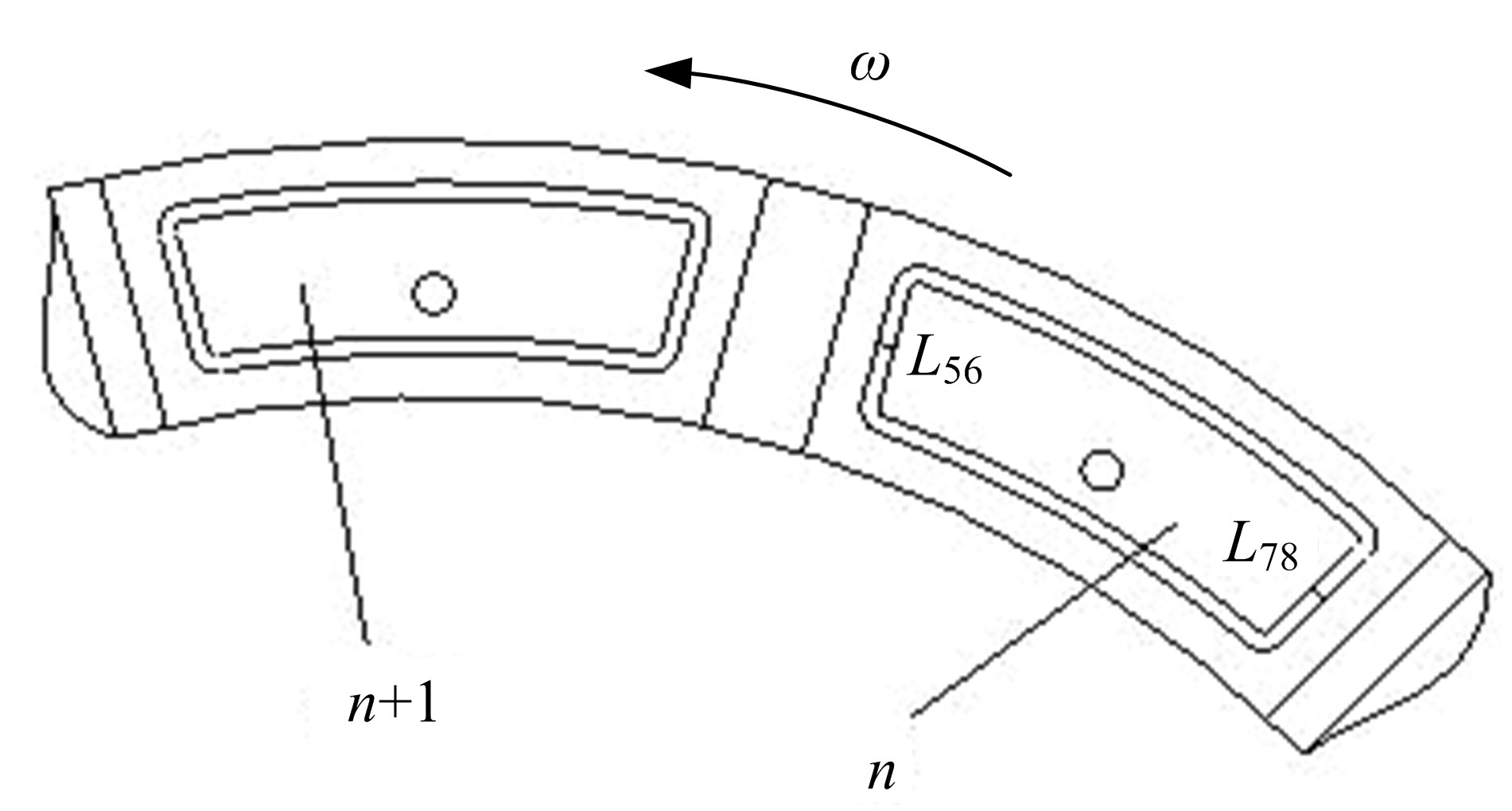

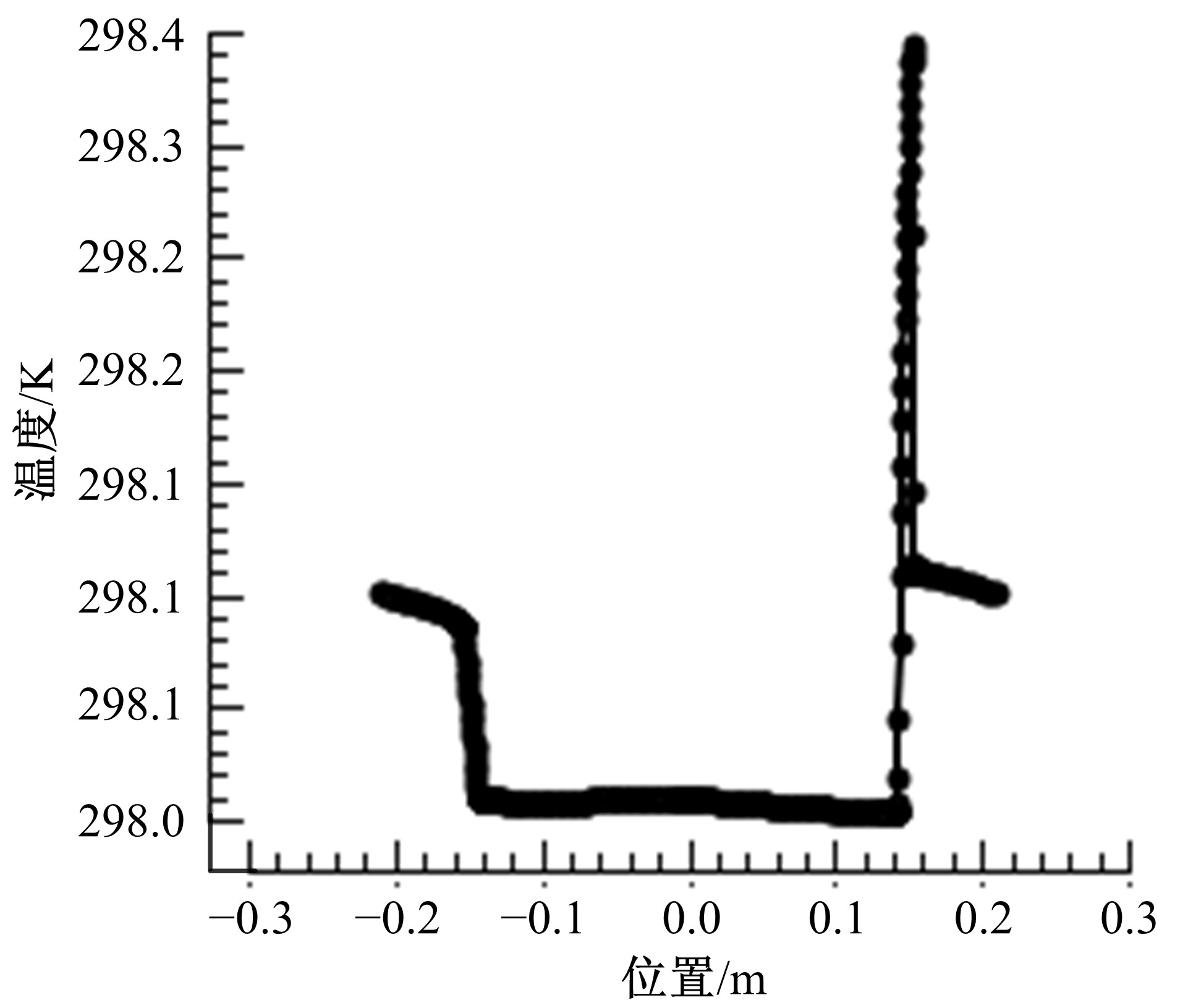

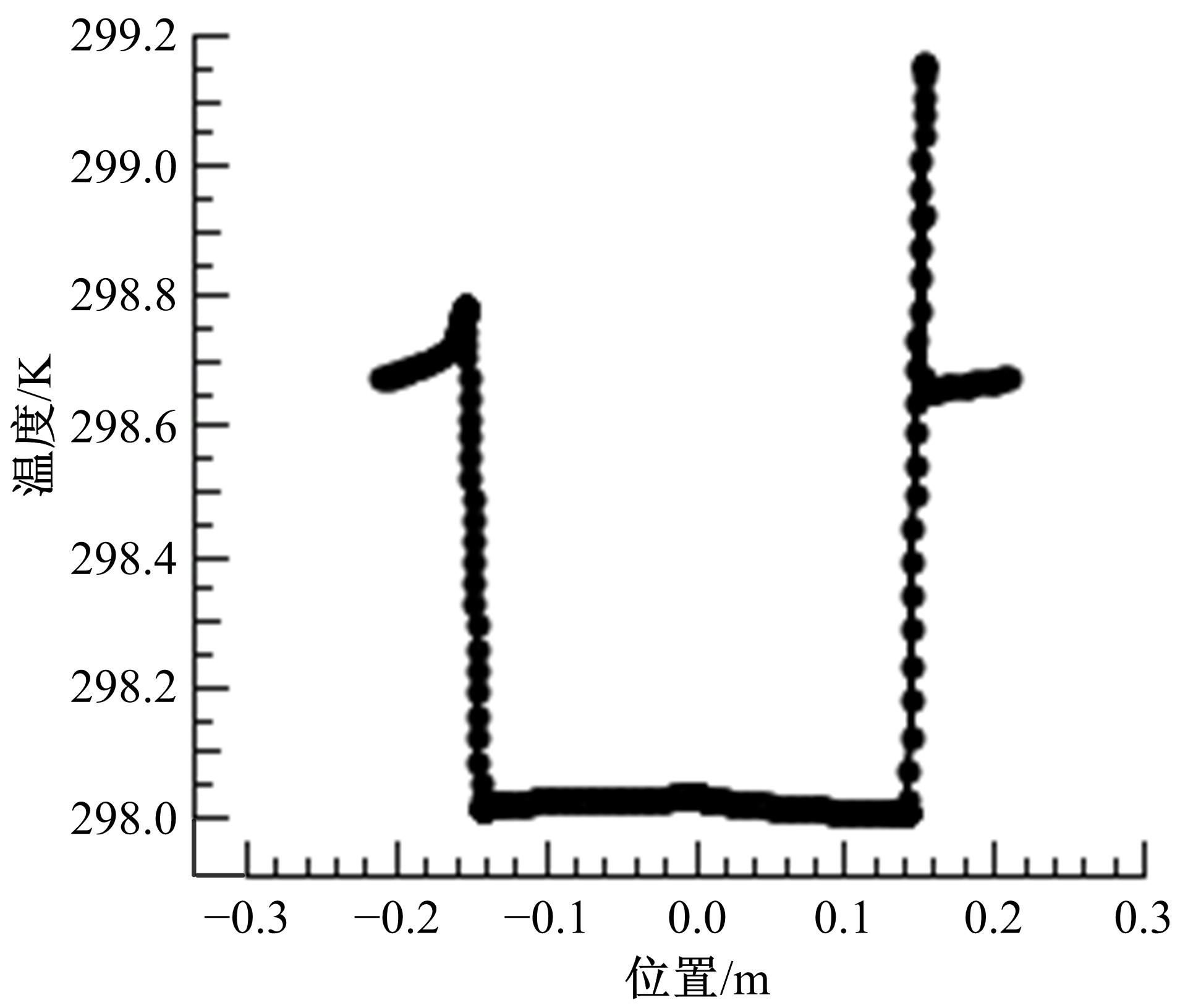

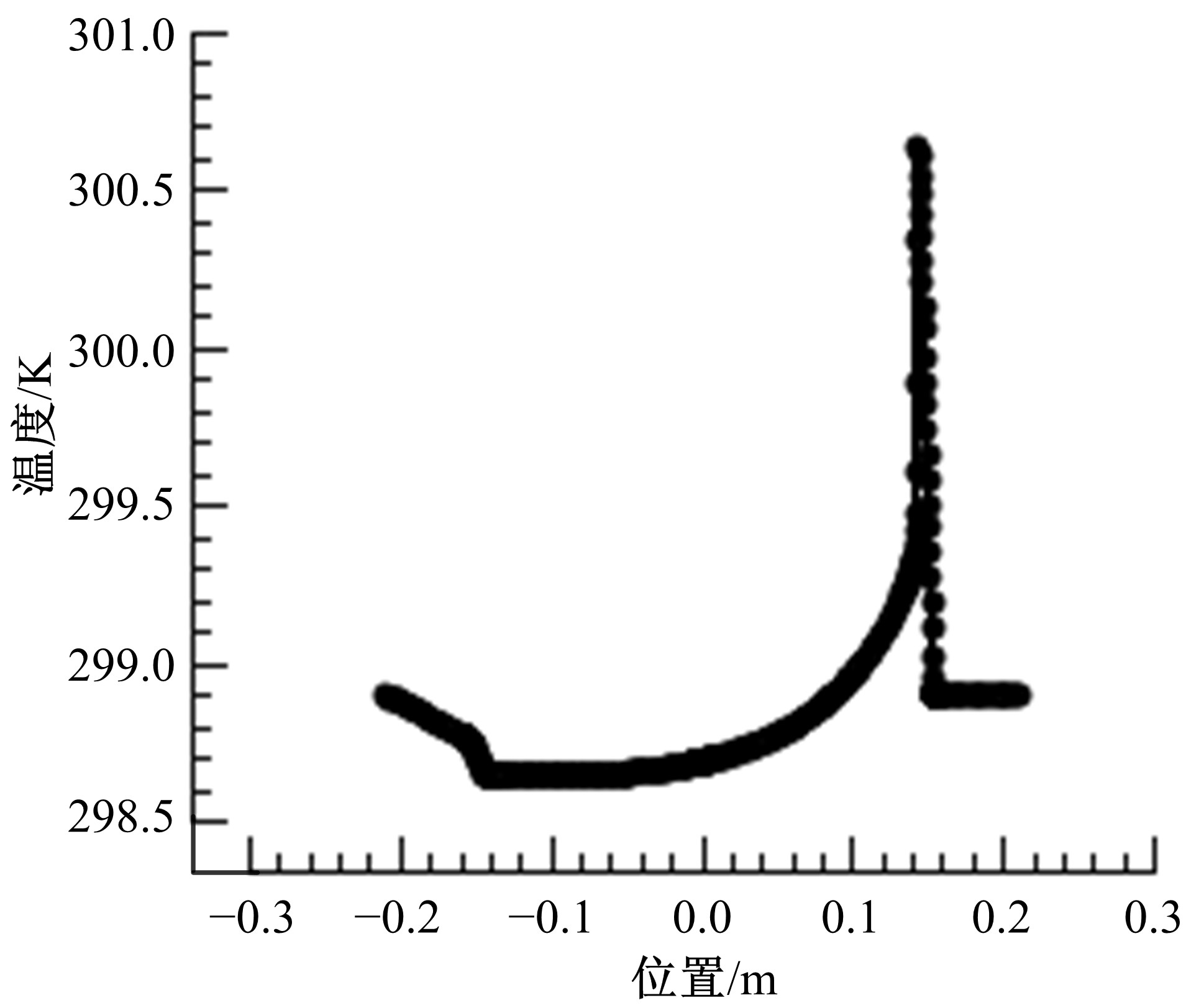

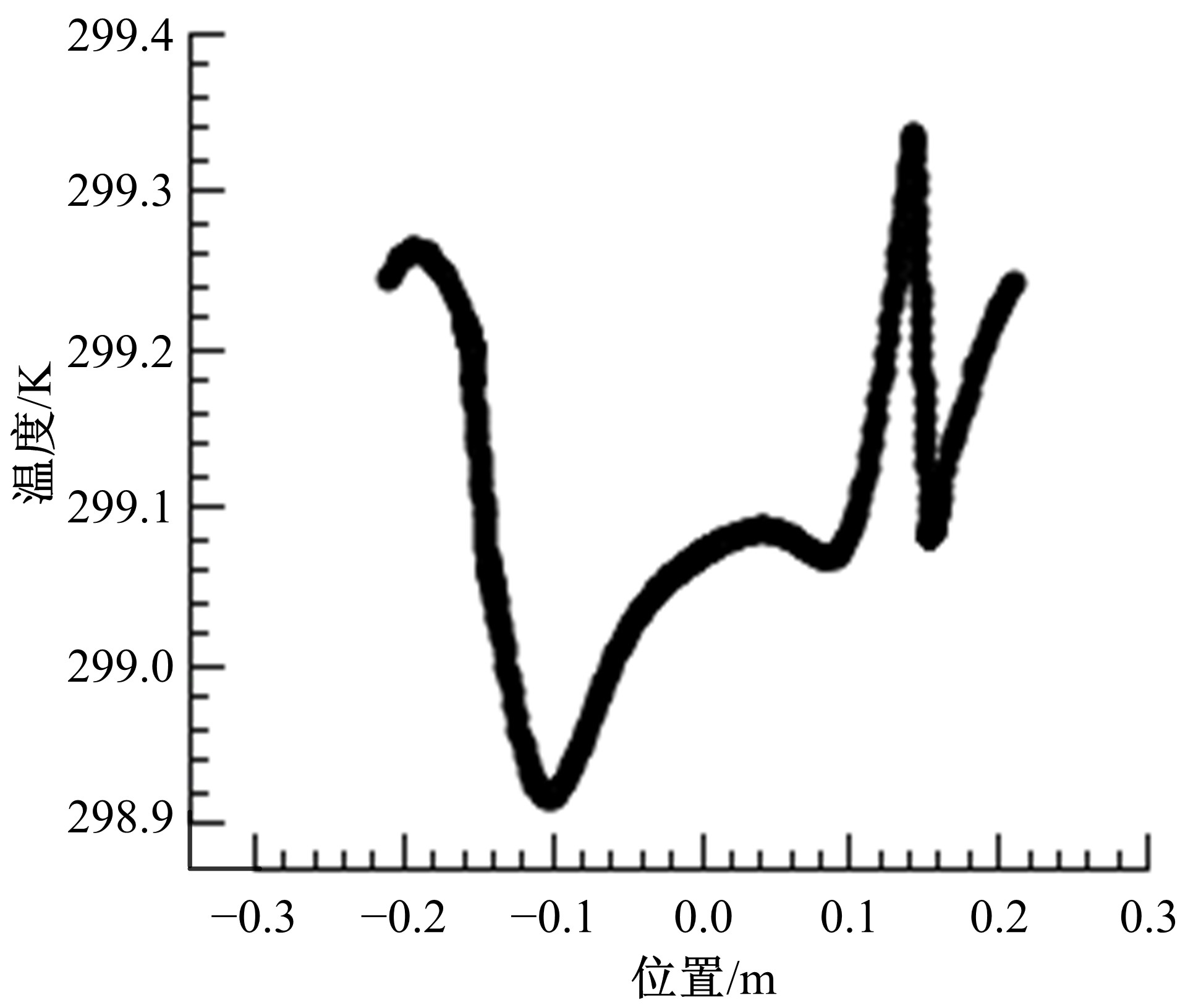

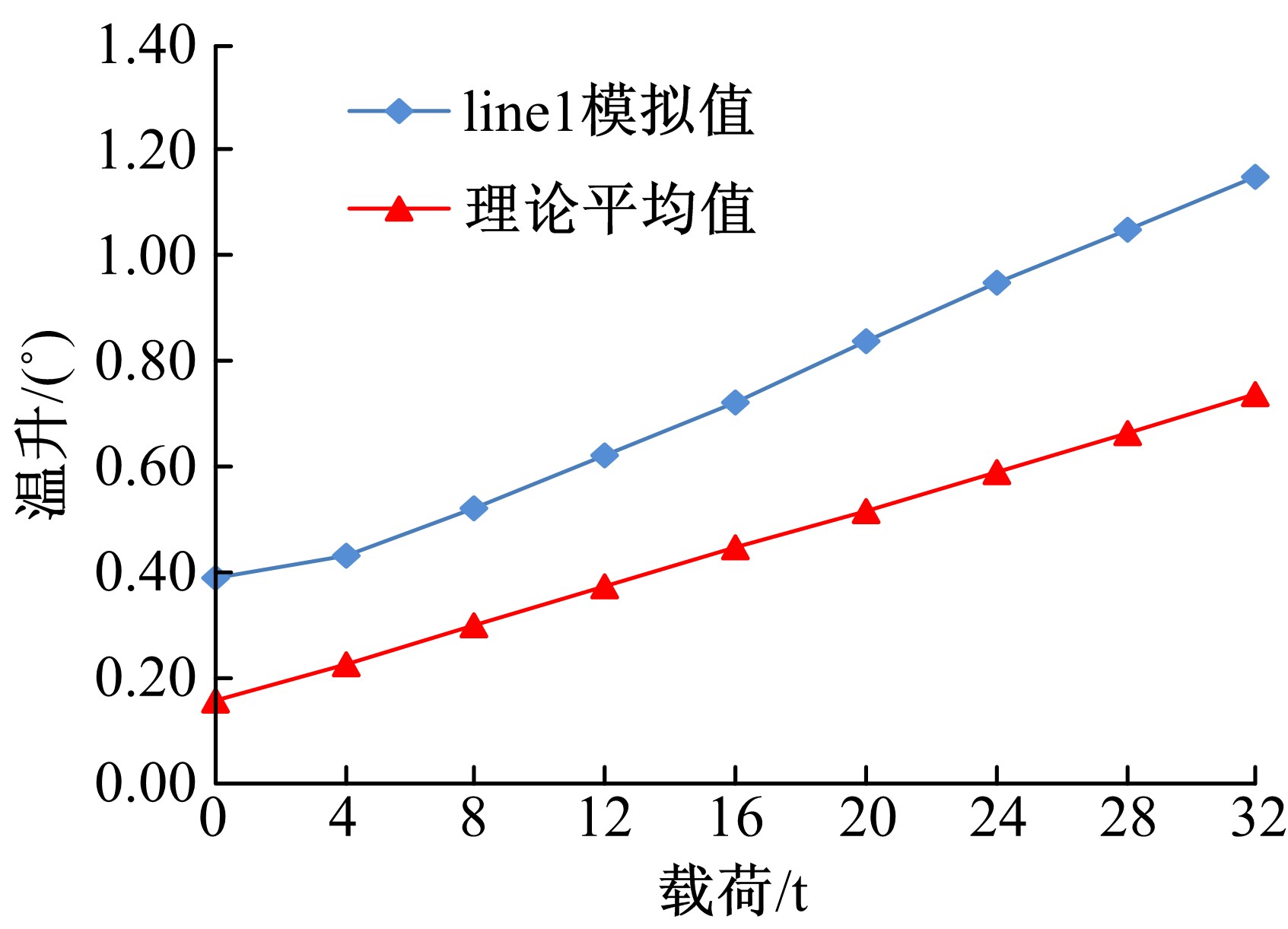

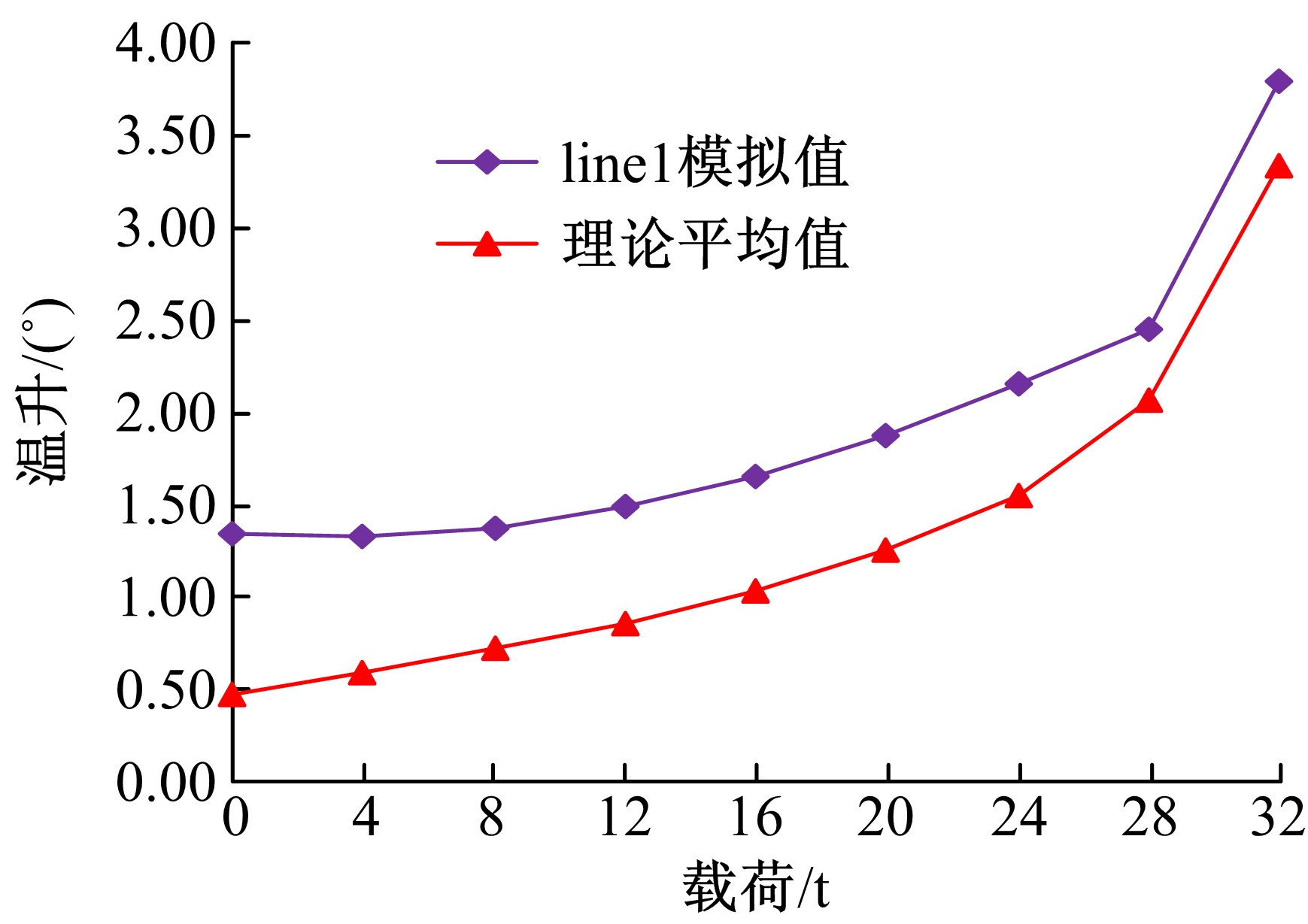

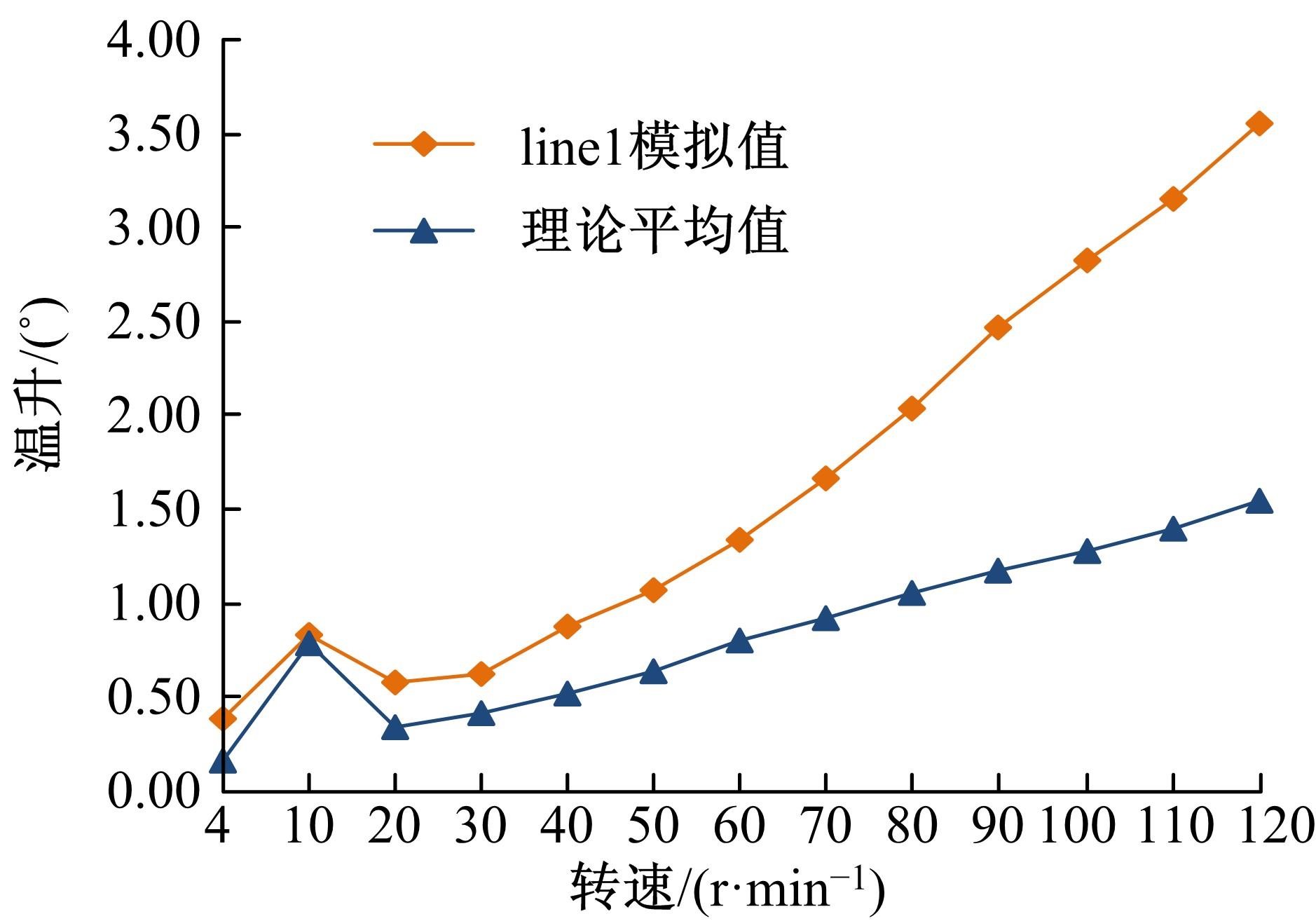

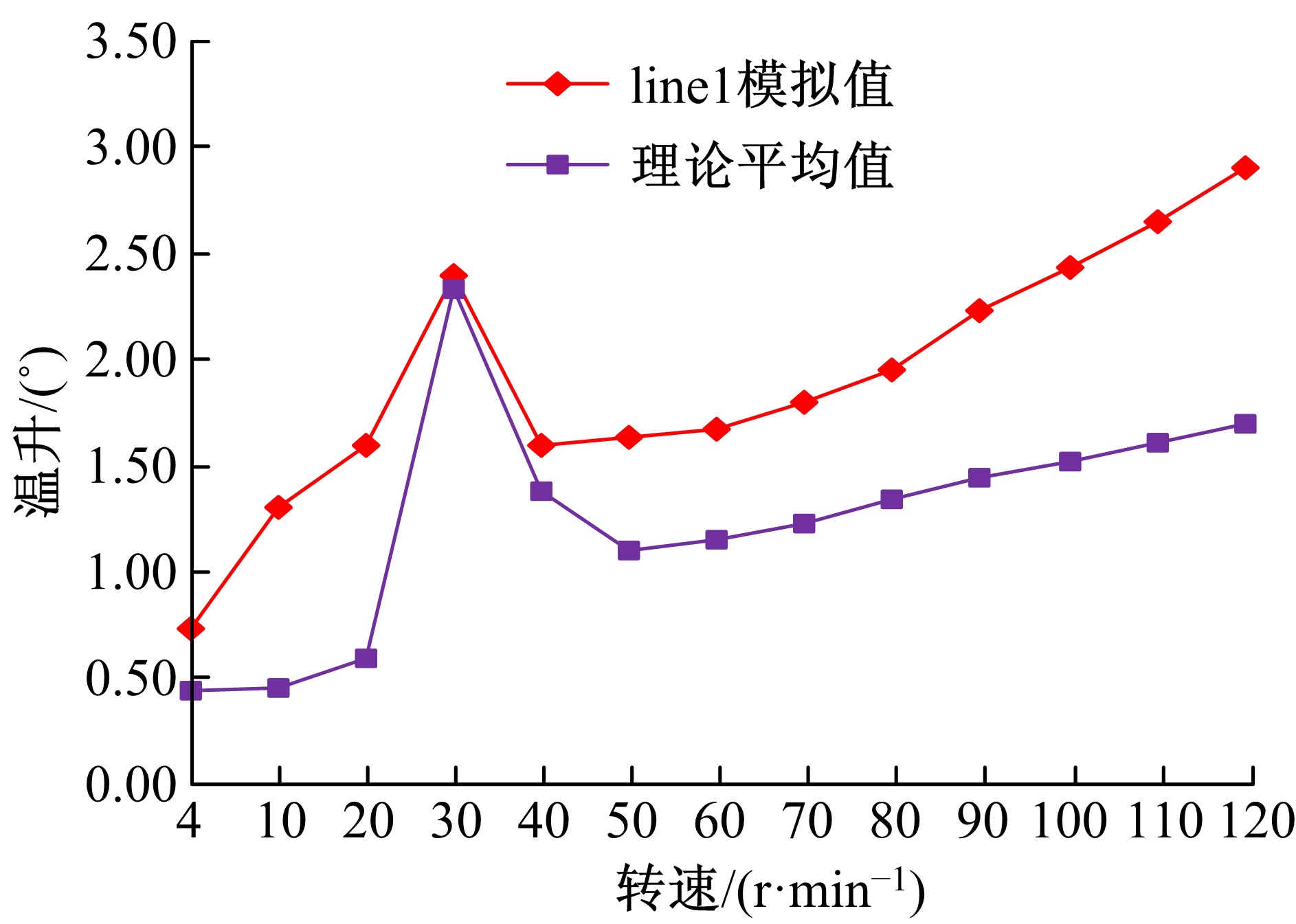

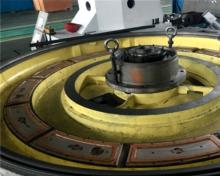

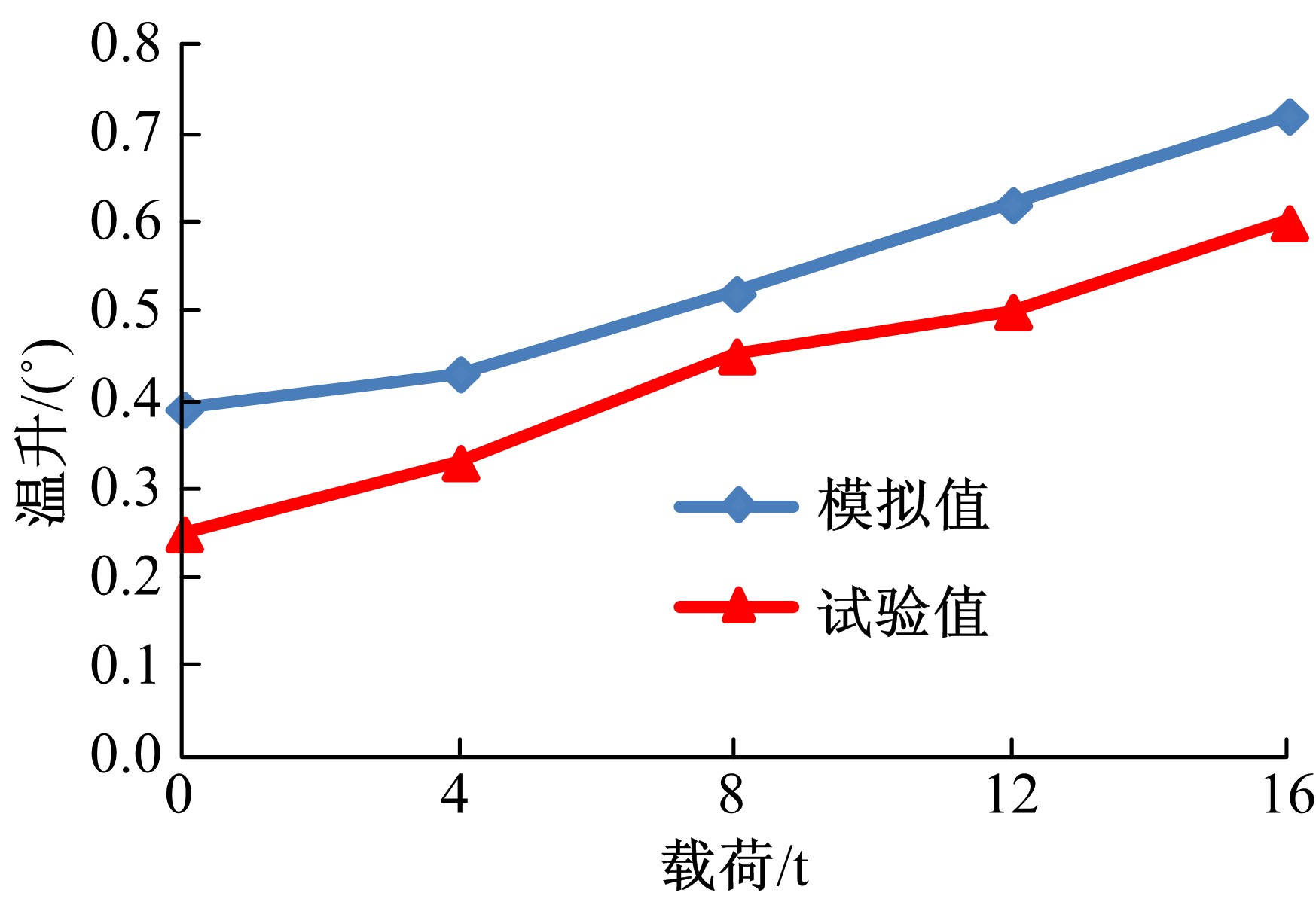

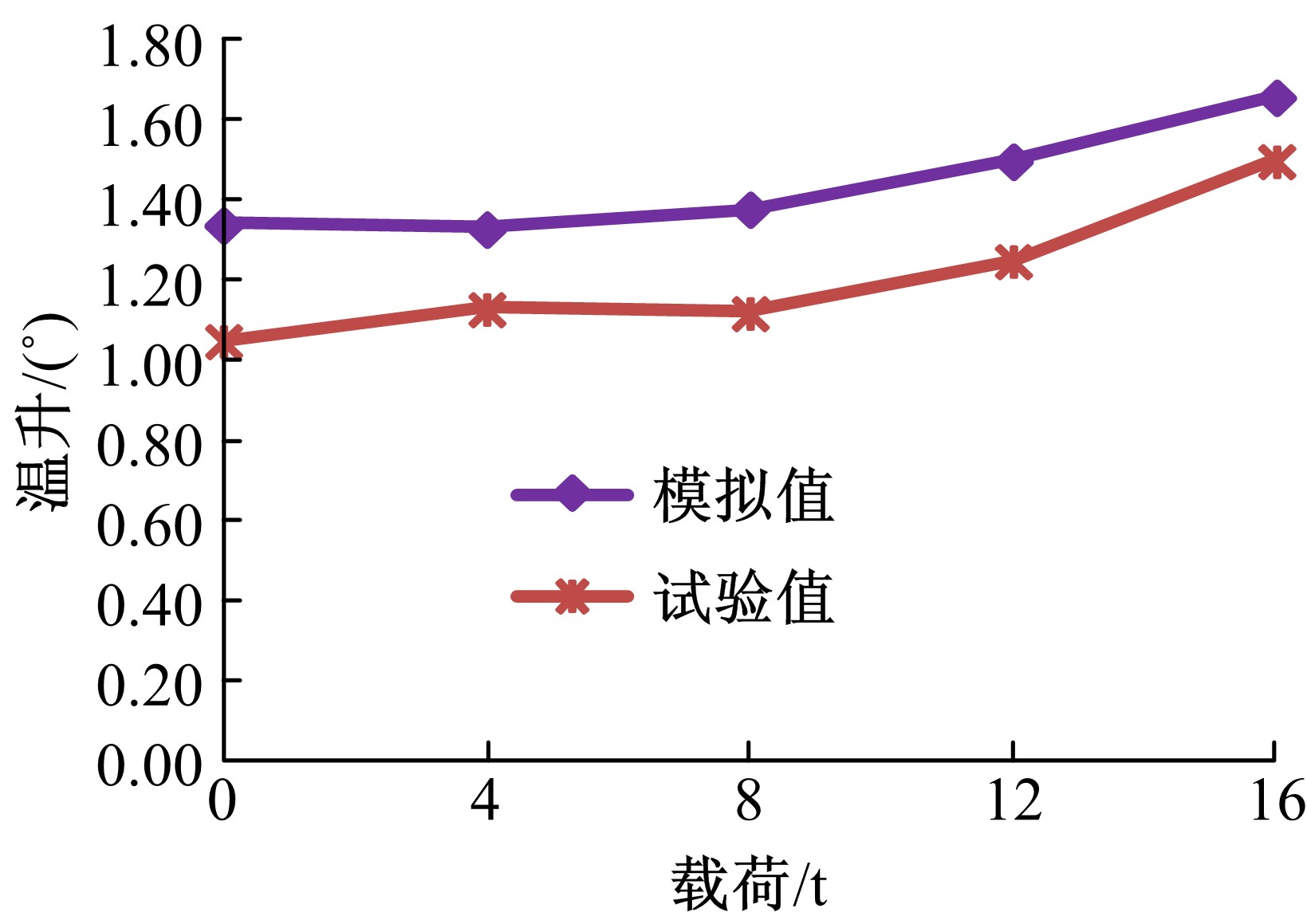

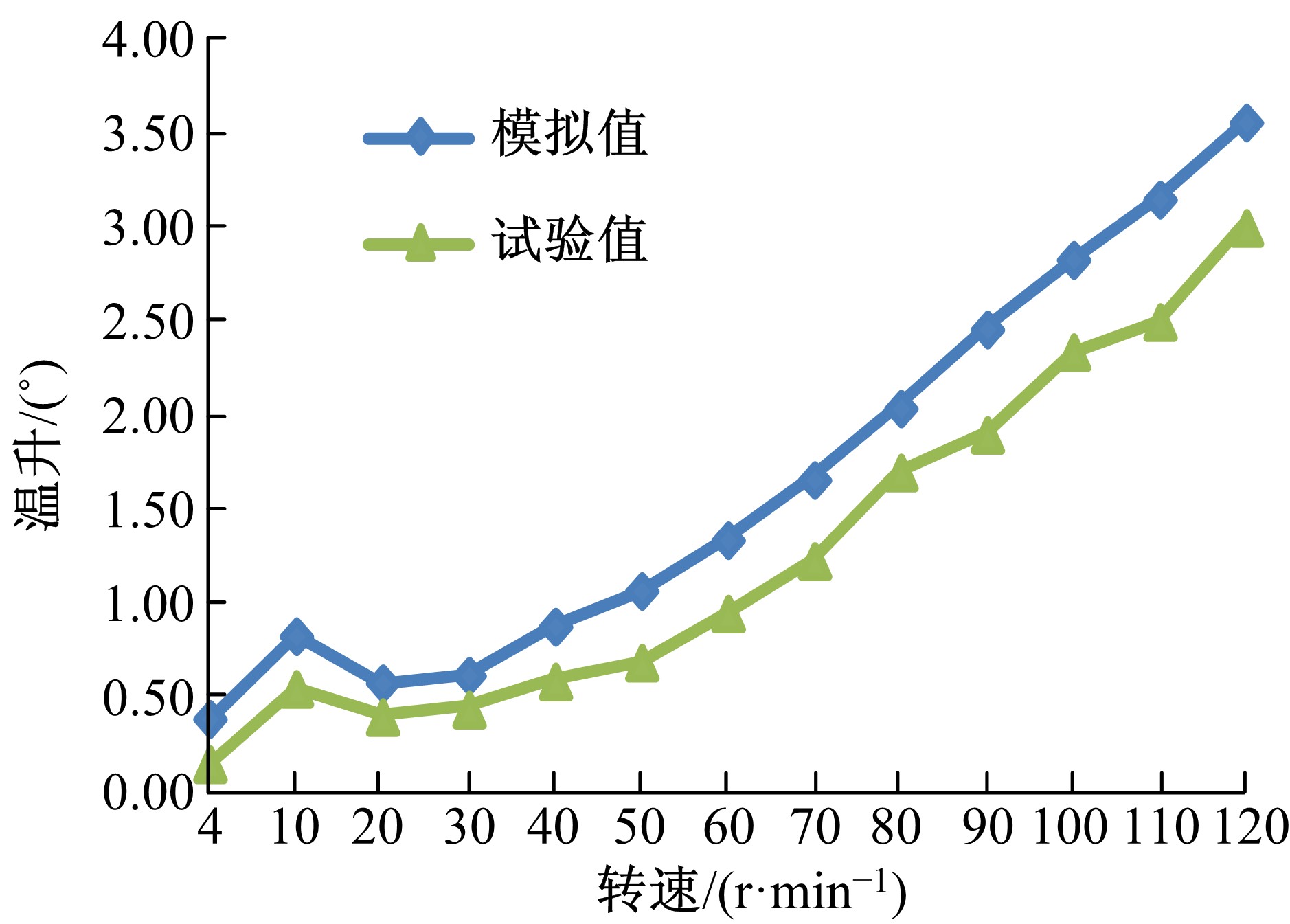

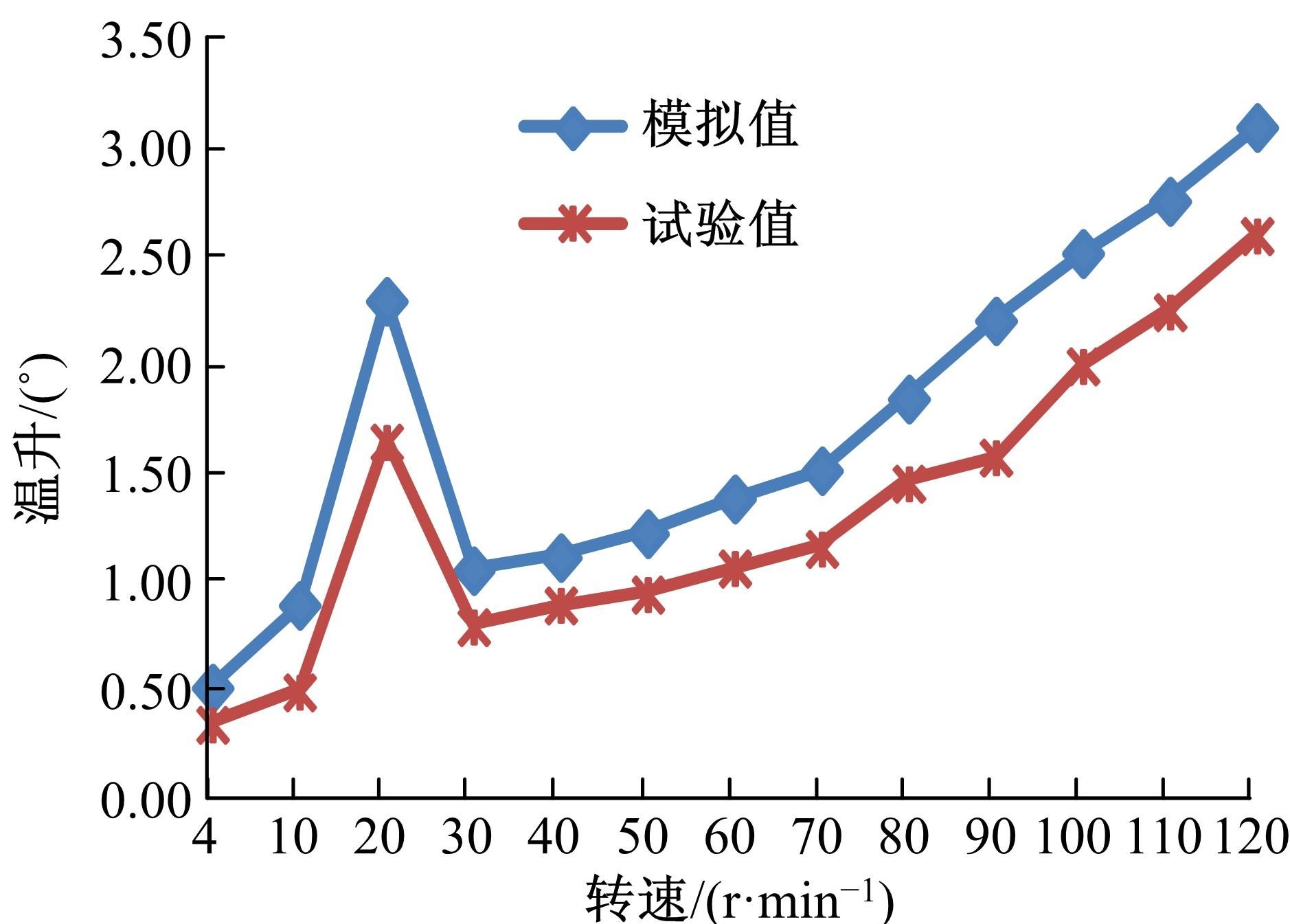

为了更加准确地阐明静压支承油膜发热机理,提出了一种考虑热油携带的油膜温升计算方法。定义了油膜热油携带因子并推导出表达式,从理论上对不同工况条件扇环腔油垫是否发生热油携带进行了判定。建立了热油携带影响下供油温升方程,采用有限体积法进行油膜温度场模拟,得到不同工况条件下考虑热油携带的油膜温升曲线,并与试验结果进行对比分析,吻合较好。结果表明:针对本结构静压支承,当转速小于10 r/min时,任何载荷工况下均无热油携带发生;当转速大于60 r/min时,在整个载荷范围(0~32 t)内均有热油携带现象发生。当发生热油携带时,油膜温升加剧,且转速对温升的影响比载荷对温升的影响更明显。

中图分类号:

- TH122

| 1 | 杜威 . 重型龙门数控机床静压导轨的热特性研究[D]. 北京: 北京工业大学机械工程与应用电子工程学院, 2013. |

| Du Wei . The thermal characteristic research of heavy-duty gantry cnc machine tool’ hydrostatic guideway[D]. Beijing: College of Mechanical Engineering and Applied Electronics Technology, Beijing University of Technology, 2013. | |

| 2 | 陈玲, 黄智, 衡凤琴, 等 . 大型车铣磨复合机床静压转台油膜热特性分析及其优化研究[J]. 机床与液压, 2016, 44(19): 109-114. |

| Chen Ling , Huang Zhi , Heng Feng-qin , et al . Thermal characteristics analysis and optimization study of hydrostatic rotary table oil film for large lathe milling and grinder compound machine tool[J]. Machine Tool & Hydraulics, 2016, 44(19): 109-114. | |

| 3 | Nelias D , Antaluca E , Boucly V . Rolling of an elastic ellipsoid upon an elastic-plastic flat[J]. Journal of Tribology, 2007, 129(4): 791-800. |

| 4 | Kim S , Cho J W . Thermal characteristic analysis of a high-precision centerless grinding machine for machining ferrules[J]. International Journal of Precision Engineering and Manufacturing, 2007, 8(1): 32-39. |

| 5 | Johansen P , Roemer D B , Pedersen H C , et al . Analytical thermal field theory applicable to oil hydraulic fluid film lubrication[C]∥Proceedings of the ASME/BATH Symposium on Fluid Power and Motion Control, Bath, England, 2014:1-8. |

| 6 | 彭育志, 明越, 肖金生, 等 . 活性炭/沸石层状床氢气纯化穿透曲线热效应[J]. 工程热物理学报, 2016, 37(7): 1511-1518. |

| Peng Yu-zhi , Ming Yue , Xiao Jin-sheng , et al . Thermal effects on hydrogen purification breakthrough curves of activated carbon/zeolite layered bed[J]. Journal of Engineering Thermophysics, 2016, 37(7): 1511-1518. | |

| 7 | 孟曙光, 熊万里, 王少力, 等 . 小孔节流深浅腔动静压轴承承载特性解析研究[J]. 机械工程学报, 2015, 51(22): 191-201. |

| Meng Shu-guang , Xiong Wan-li , Wang Shao-li , et al . Analytical research on characteristics of deep-shallow journal bearings with orifice restrictors[J]. Journal of Mechanical Engineering, 2015, 51(22): 191-201. | |

| 8 | 于晓东, 耿磊, 郑小军, 等 . 恒流环形腔多油垫静压推力轴承油膜刚度特性[J]. 哈尔滨工程大学学报, 2017, 38(12):1-6. |

| Yu Xiao-dong , Geng Lei , Deng Xiao-jun , et al . Oil film stiffness characteristics of constant fluid hydrostatic thrust bearing with annular cavity multi-pads[J]. Journal of Harbin Engineering University, 2017, 38(12):1-6. | |

| 9 | 于晓东, 高春丽, 邱志新, 等 . 高速重载静压推力轴承润滑性能研究[J].中国机械工程, 2013, 24(23): 3230-3234. |

| Yu Xiao-dong , Gao Chun-li , Qiu Zhi-xin , et al . Research on lubrication performance of high-speed heavy-duty hydrostatic thrust bearings[J]. China Mechanical Engineering, 2013, 24(23): 3230-3234. | |

| 10 | 于晓东, 孙丹丹, 吴晓刚, 等 . 环形腔多油垫静压推力轴承膜厚高速重载特性[J]. 推进技术, 2016, 37(7): 1350-1355. |

| Yu Xiao-dong , Sun Dan-dan , Wu Xiao-gang , et al . High speed and heavy load characteristic on oil film thickness of annular recess multi-pad hydrostatic thrust bearing[J]. Journal of Propulsion Technology, 2016, 37(7): 1350-1355. | |

| 11 | 谢方伟, 侯友夫, 张立强, 等 . 液粘传动变形界面间油膜温度场实验研究[J]. 中南大学学报, 2015, 34(11): 1733-1737. |

| Xie Fang-wei , Hou You-fu , Zhang Li-qiang , et al . Experimental research on oil film temperature field of hydro-viscous drive between deformed interfaces[J]. Journal of Central South University, 2015, 34(11): 1733-1737. | |

| 12 | Zhang Yan-qin , Fan Li-guo , Yu Xiao-dong , et al . Simulation and experimental analysis on supporting characteristics of multiple oil pad hydrostatic bearing disk[J]. Journal of Hydrodynamics, 2013, 25(2): 236-241. |

| 13 | Zhang Yan-qin , Fan Li-guo , Chen Yao . Simulation and experimental study of lubrication characteristics of vertical hydrostatic guide rail[J]. High Technology Letters, 2014, 20(3): 315-320. |

| 14 | Zhang Yan-qin , Fan Li-guo . Simulation and experimental analysis of influence of inlet flow on heavy hydrostatic bearing temperature field[J]. Asian Journal of Chemistry, 2014, 26(17): 5478-5482. |

| 15 | 张艳芹 . 重型静压推力轴承综合物理场研究[D]. 哈尔滨:哈尔滨理工大学机械动力工程学院, 2009. |

| Zhang Yan-qin . Integrated physical field research of heavy hydrostatic thrust bearing[D]. Harbin: School of Mechanical and Power Engineering, Harbin University of Science and Technology, 2009. | |

| 16 | 李海宁, 张晓青, 李奎, 等 . 动磁直线压缩机气体轴承特性的CFD模拟[J]. 工程热物理学报, 2013, 34(6): 1026-1030. |

| Li Hai-ning , Zhang Xiao-qing , Li Kui , et al . CFD simulation of gas bearing characteristic for a moving-magnet linear compressor[J]. Journal of Engineering Hermophysics, 2013, 34(6): 1026-1030. | |

| 17 | Yadav S K , Sharma S C . Performance of hydrostatic tilted thrust pad bearings of various recess shapes operating with non-Newtonian lubricant[J]. Finite Elements in Analysis and Design, 2014, 87: 43-55. |

| [1] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [2] | 刘坤,吉硕,孙震源,徐洪伟,刘勇,赵静霞. 多功能坐站辅助型如厕轮椅机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(3): 872-880. |

| [3] | 王兴野,张进秋,李国强,彭志召. 惯性质量对齿轮齿条式作动器阻尼特性的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 881-887. |

| [4] | 王家序,倪小康,韩彦峰,向果,肖科. 轴向往复运动下微槽轴承混合润滑数值模型[J]. 吉林大学学报(工学版), 2019, 49(3): 888-896. |

| [5] | 毕秋实,王国强,黄婷婷,毛瑞,鲁艳鹏. 基于DEM-FEM耦合的双齿辊破碎机辊齿强度分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1770-1776. |

| [6] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

| [7] | 刘建芳, 王记波, 刘国君, 李新波, 梁实海, 杨志刚. 基于PMMA内嵌三维流道的压电驱动微混合器[J]. 吉林大学学报(工学版), 2018, 48(5): 1500-1507. |

| [8] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [9] | 王涛, 伞晓刚, 高世杰, 王惠先, 王晶, 倪迎雪. 光电跟踪转台垂直轴系动态特性[J]. 吉林大学学报(工学版), 2018, 48(4): 1099-1105. |

| [10] | 贺继林, 陈毅龙, 吴钪, 赵喻明, 汪志杰, 陈志伟. 起重机卷扬系统能量流动分析及势能回收系统实验[J]. 吉林大学学报(工学版), 2018, 48(4): 1106-1113. |

| [11] | 谢传流, 汤方平, 孙丹丹, 张文鹏, 夏烨, 段小汇. 立式混流泵装置压力脉动的模型试验分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1114-1123. |

| [12] | 孙秀荣, 董世民, 王宏博, 李伟成, 孙亮. 整体抽油杆柱在油管内空间屈曲的多段式仿真模型对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1124-1132. |

| [13] | 吉野辰萌, 樊璐璐, 闫磊, 徐涛, 林烨, 郭桂凯. 基于MBNWS算法的假人胸部结构多目标优化设计[J]. 吉林大学学报(工学版), 2018, 48(4): 1133-1139. |

| [14] | 刘坤, 刘勇, 闫建超, 吉硕, 孙震源, 徐洪伟. 基于体外传感检测的人体站起动力学分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1140-1146. |

| [15] | 刘志峰, 赵代红, 王语莫, 浑连明, 赵永胜, 董湘敏. 重载静压转台承载力与油垫温度场分布的关系[J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

|

||