吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1272-1279.doi: 10.13229/j.cnki.jdxbgxb20180146

• • 上一篇

基于增量控制的型材拉弯轨迹设计及有限元仿真

- 1. 中车长春轨道客车股份有限公司 工程规划发展部,长春 130051

2. 吉林大学 辊锻工艺研究所,长春 130022

3. 吉林交通职业技术学院 汽车工程学院,长春 130012

Trajectory design and FE simulation for profile stretch bending based on incremental control method

Xue⁃guang ZHANG1,2( ),Ming⁃meng JIA3,Chun⁃guo LIU2,Guang⁃zhong HE1

),Ming⁃meng JIA3,Chun⁃guo LIU2,Guang⁃zhong HE1

- 1. Engineering Planning and Development Department, CRRC Changchun Railway Vehicles Co. , Ltd. , Changchun 130051, China

2. Rolling Forming Research Institute, Jilin University, Changchun 130022, China

3. College of Automotive Engineering, Jilin Communication Polytechnic, Changchun 130012, China

摘要:

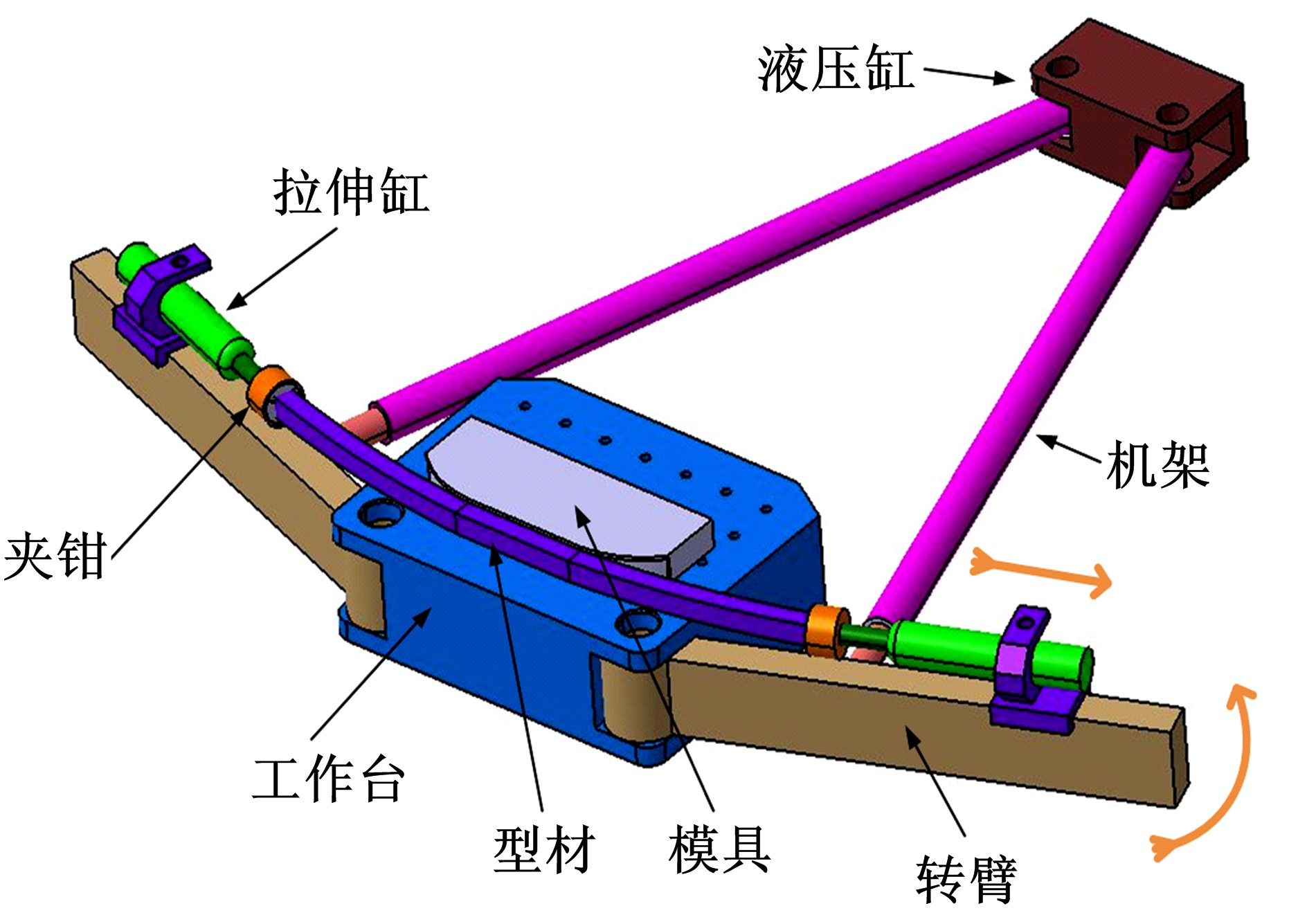

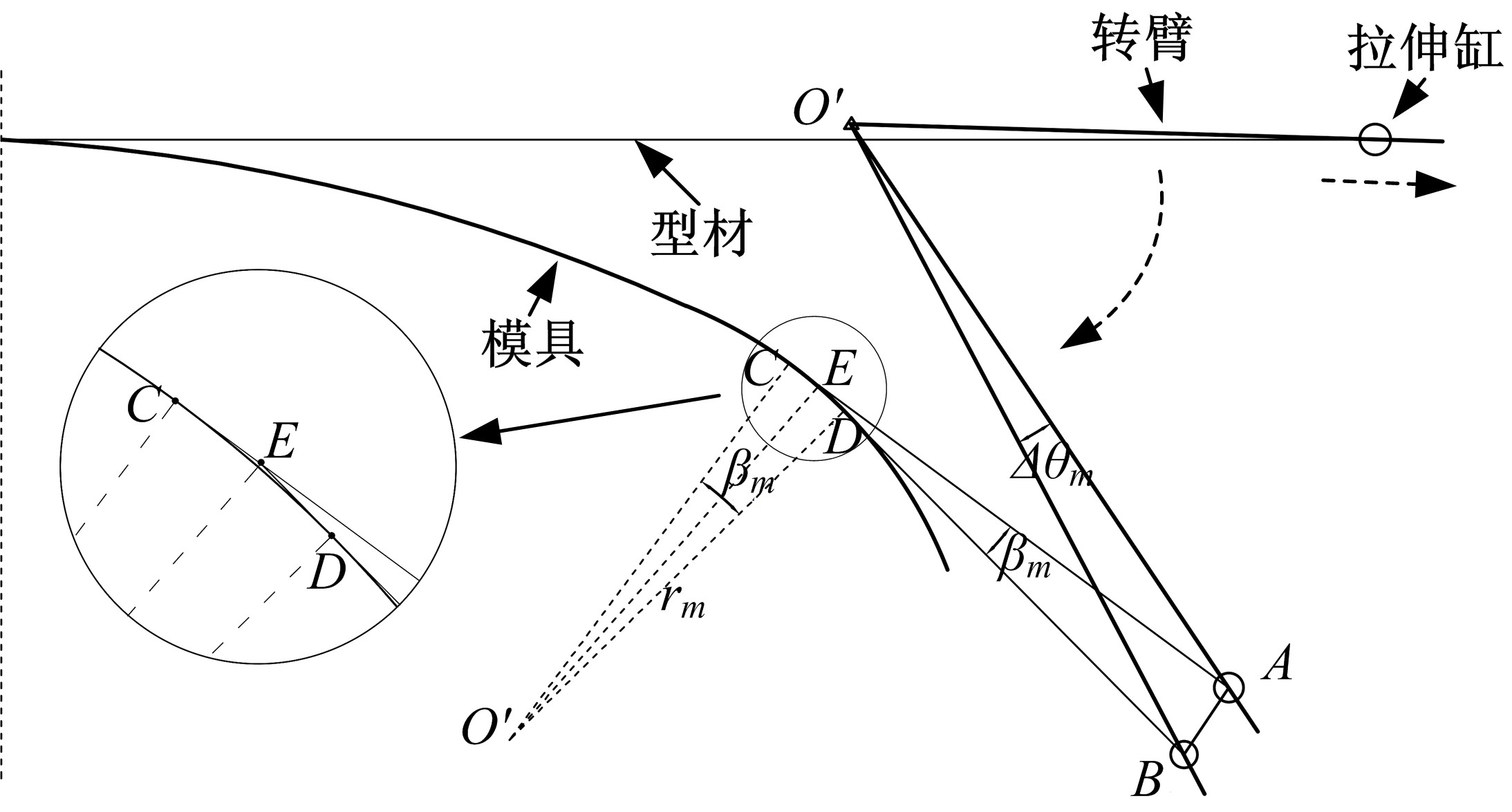

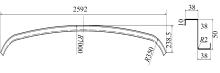

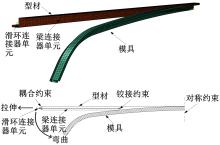

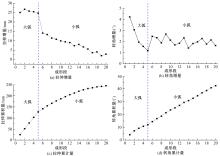

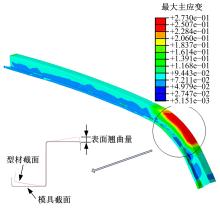

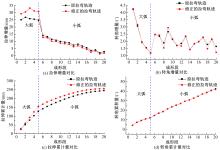

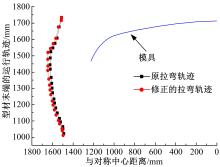

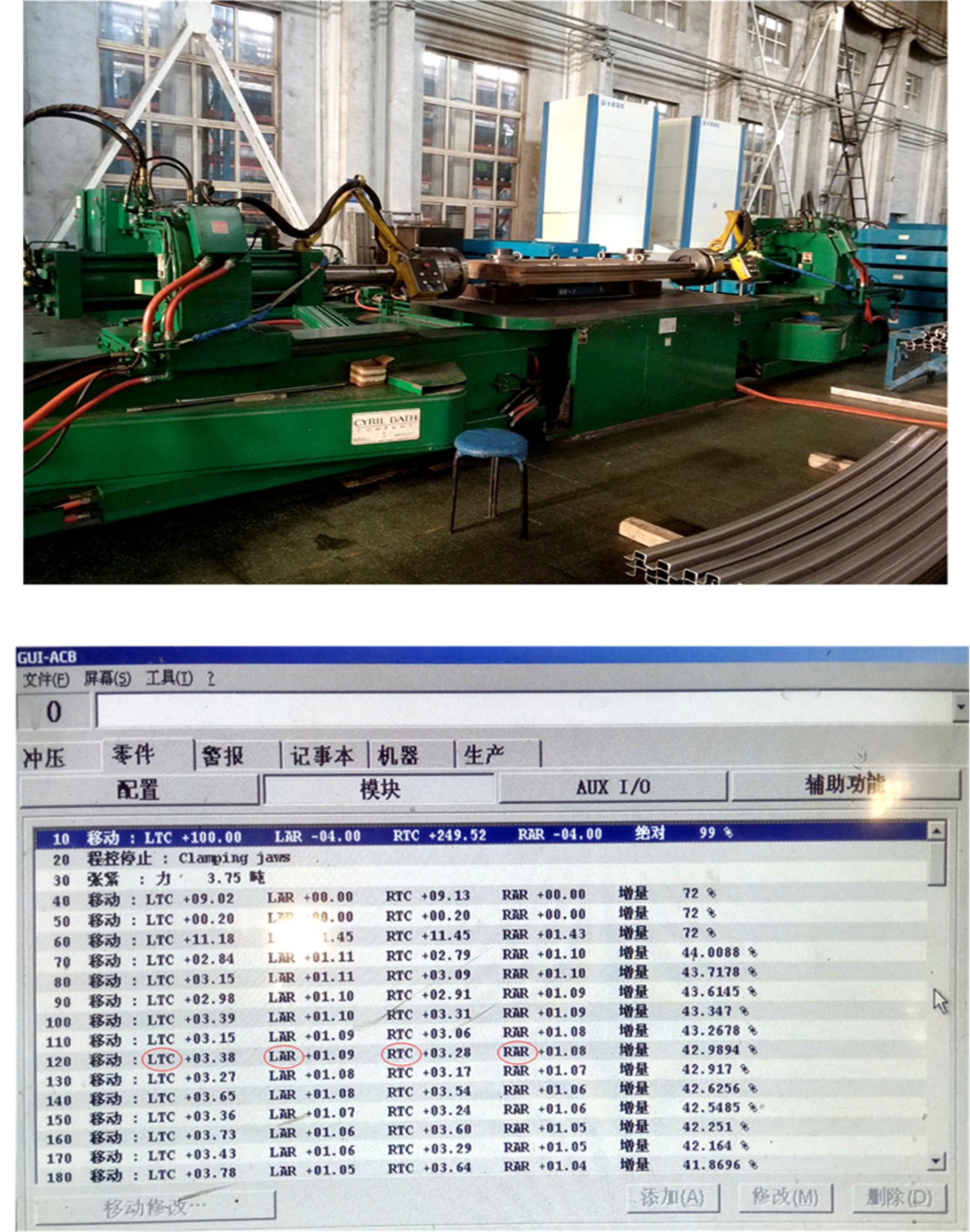

根据型材拉弯设备结构和成形工况,将夹钳加载量等效为拉伸缸沿转臂的拉伸量和转臂的转角,并提出了一种基于增量控制的型材拉弯轨迹设计方法。通过沿轴线方向将型材目标形状划分成多个成形段,并求解出每个成形段对应的拉伸增量和转角增量,实现型材拉弯成形中加载量的独立分配与控制。以轨道车辆车顶乙形不锈钢弯梁作为研究对象,建立了一种基于连接器单元的型材拉弯有限元模型,并将计算得到的加载增量应用于工件成形效果仿真中,实现了拉弯轨迹的参数化调控。根据仿真结果中工件的形状误差与表面翘曲量分析了拉弯缺陷的成因,并对拉弯轨迹进行了针对性的修正,提升了工件成形效果。采用修正后的拉弯轨迹进行工件成形试验,仿真结果与试验结果相吻合。

中图分类号:

- TG386

| 1 | 薛克仲 . 城市轨道车辆车体材料选择[J]. 城市轨道交通研究, 2003, 6(1): 14⁃19. |

| Xue Ke⁃zhong . Selection of car body materials for urban railway vechiles[J]. Urban Mass Transit, 2003, 6(1): 14⁃19. | |

| 2 | 王胜满 . 用于地铁车辆的不锈钢型材拉弯成形缺陷[J]. 吉林大学学报: 工学版, 2013, 43(6): 1546⁃1550. |

| Wang Sheng-man . Stretch bend forming defects of stainless steel profile of metro vechile[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(6): 1546⁃1550. | |

| 3 | 谷诤巍, 吕萌萌, 李欣, 等 . 数控拉弯工艺中型材变形量的影响因素[J]. 吉林大学学报:工学版, 2016, 46(4): 1190⁃1196. |

| Gu Zheng⁃wei , Meng⁃meng Lyu , Li Xin , et al . Influence factors of profile deformation in NC stretch bending[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(4): 1190⁃1196. | |

| 4 | 梁继才,李义,高嵩,等 .型材多点柔性拉弯成形回弹预测[J].吉林大学学报:工学版,2017,47(1):185⁃190. |

| Liang Ji⁃cai , Li Yi , Gao Song , et al . Springback prediction for multi⁃point 3D stretch bending profile[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(1): 185⁃190. | |

| 5 | Yu C L , Li X Q . Theoretical analysis on springback of L⁃section extrusion in rotary stretch bending process[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(12): 2705⁃2710. |

| 6 | 王永军, 黄云华, 王俊彪, 等 . 数控转台拉弯机切点跟踪轨迹生成算法[J]. 机械工程学报, 2005, 41(10): 123⁃127. |

| Wang Yong⁃jun , Huang Yun⁃hua , Wang Jun⁃biao , et al . Algorithm of generating the tracking locus of the tangent point for NC rotary stretch-bending former[J]. Chinese Journal of Mechanical Engineering, 2005, 41(10): 123⁃127. | |

| 7 | 刘志军, 金朝海, 李东升, 等 . 基于 PSBPD 的 T 型材拉弯夹钳加载轨迹设计及有限元模拟[J]. 塑性工程学报, 2012, 19(6): 109⁃113. |

| Liu Zhi⁃jun , Jin Chao⁃hai , Li Dong⁃sheng , et al . PSBPD⁃based jaw trajectory design and numerical simulation for T⁃section profile during stretch⁃bending[J]. Journal of Plasticity Engineering, 2012, 19(6): 109⁃113. | |

| 8 | Reinhard L . Coupling of bending and stretching deformation in vehicle members[J]. Advances in Colloid and Interface Science, 2014, 208(1):14⁃24. |

| 9 | 李小强, 周贤宾, 金朝海, 等 . 基于有限元模拟的三维型材拉弯轨迹设计[J]. 航空学报, 2009, 30(3): 544⁃550. |

| Li Xiao⁃qiang , Zhou Xian⁃bin , Jin Chao⁃hai , et al . Design of stretch bending trajectory based on finite element simulation for three⁃dimensional profile parts[J]. Acta Aeronautica et Astronautica Sinica, 2009, 30(3): 544⁃550. | |

| 10 | 李小强, 周贤宾, 金朝海, 等 . 型材拉弯数值模拟夹钳边界条件的一种等效模型[J]. 塑性工程学报, 2009, 16(1): 64⁃69. |

| Li Xiao⁃qiang , Zhou Xian⁃bin , Jin Chao⁃hai , et al . An equivalent model of jaws boundary condition in numerical simulation of stretch bending for extrusions[J].Journal of Plasticity Engineering, 2009, 16(1): 64⁃69. | |

| 11 | 张学广, 刘纯国, 张石磊, 等 . 轴向非对称中空型材拉弯过渡区长度优化[J]. 哈尔滨工业大学学报, 2015, 47(10):85⁃87. |

| Zhang Xue⁃guang , Liu Chun⁃guo , Zhang Shi⁃lei , et al . Optimization of transition zone length in stretch bending of axially asymmetric hollow profiles[J]. Journal of Harbin Institute of Technology, 2015, 47(10): 85⁃87. | |

| 12 | 周苗苗, 王红建, 贺尔铭, 等 . 复杂截面型材3D拉弯数值模拟建模技术研究[J]. 机械科学与技术, 2012, 31(6): 888⁃892. |

| Zhou Miao⁃miao , Wang Hong⁃jian , He Er-ming , et al . Investion of numerical modeling techniques of 3D stretch bending for complex cross section[J]. Mechanical Science and Technology for Aerospace Engineering, 2012, 31(6): 888⁃892. | |

| 13 | 谷诤巍, 张文学, 吕萌萌, 等 . 宽翼边 U 型截面不锈钢型材拉弯成形缺陷控制[J]. 吉林大学学报: 工学版, 2017, 47(4): 1165⁃1170. |

| Gu Zheng⁃wei , Zhang Wen⁃xue , Meng⁃meng Lyu , et al . Stretch bending defect control of U-section stainless steel profile with wide flange[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(4): 1165⁃1170. | |

| 14 | Sushanta G , Kashi N S . An experimental study on stress concentration around a hole under combined bending and stretching stress field[J]. Procedia Technology, 2016, 23(1): 20⁃27. |

| 15 | 梁继业,邓钢,方斌 . L型截面铝型材拉弯成形截面畸变缺陷控制研究[J]. 锻压技术, 2016, 41(12): 42⁃45. |

| Liang Ji⁃ye , Deng Gang , Fang Bin . Section distortion control for L⁃section aluminium profile part in the strecth-bending process[J]. Foring and Stamping Tchnology, 2016, 41(12): 42⁃45. | |

| 16 | 刘天娇,王永军,夏晓娇,等 . 型材拉弯数值模拟轨迹建模方法[J]. 锻压技术, 2014, 39(7): 132⁃137. |

| Liu Tian⁃jiao , Wang Yong⁃jun , Xia Xiao⁃jiao , et al . Trajectory modeling of extrusion stretch bending simulation[J]. Forging and Stamping Technology, 2014, 39(7): 132⁃137. |

| [1] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [2] | 刘文权,盈亮,荣海,胡平. 基于损伤修正M⁃K模型的高强度钢成形极限预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1266-1271. |

| [3] | 郭昊添,徐涛,梁逍,于征磊,刘欢,马龙. 仿鲨鳃扰流结构的过渡段换热表面优化设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1793-1798. |

| [4] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [5] | 宫亚峰, 王博, 魏海斌, 何自珩, 何钰龙, 申杨凡. 基于Peck公式的双线盾构隧道地表沉降规律[J]. 吉林大学学报(工学版), 2018, 48(5): 1411-1417. |

| [6] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [7] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [8] | 陈俊甫, 管志平, 杨昌海, 牛晓玲, 姜振涛, 宋玉泉. 金属棒试样拉伸和扭转试验应变范围和力学特性对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

| [9] | 梁晓波, 蔡中义, 高鹏飞. 夹芯复合板柱面成形的数值模拟及试验[J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [10] | 刘子武, 李剑峰. 叶片材料FV520B再制造熔覆层冲蚀损伤行为及评价[J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [11] | 刘纯国, 刘伟东, 邓玉山. 多点冲头主动加载路径对薄板拉形的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [12] | 付文智, 刘晓东, 王洪波, 闫德俊, 刘晓莉, 李明哲, 董玉其, 曾振华, 刘桂彬. 关于1561铝合金曲面件的多点成形工艺[J]. 吉林大学学报(工学版), 2017, 47(6): 1822-1828. |

| [13] | 张志强, 刘从豪, 何东野, 李湘吉, 李纪萱. 基于性能梯度分布的硼钢热冲压工艺对形状精度的影响[J]. 吉林大学学报(工学版), 2017, 47(6): 1829-1833. |

| [14] | 吕萌萌, 谷诤巍, 徐虹, 李欣. 超高强度防撞梁热冲压成形工艺优化[J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [15] | 王辉, 周杰, 熊煜, 陶亚平, 向荣. 基于逆向工程的复杂曲面冲压件回弹补偿[J]. 吉林大学学报(工学版), 2017, 47(6): 1842-1847. |

|

||