吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1212-1220.doi: 10.13229/j.cnki.jdxbgxb20180200

• • 上一篇

基于多尺度理论的栓接结合部动力学建模

- 北京工业大学 先进制造技术北京市重点实验室, 北京 100124

Stiffness model of bolted joint based on multi⁃scale theory

Cheng YANG( ),Yong⁃sheng ZHAO,Zhi⁃feng LIU,Li⁃gang CAI

),Yong⁃sheng ZHAO,Zhi⁃feng LIU,Li⁃gang CAI

- Beijing Key Laboratory of Advanced Manufacturing Technology, Beijing University of Technology, Beijing 100124, China

摘要:

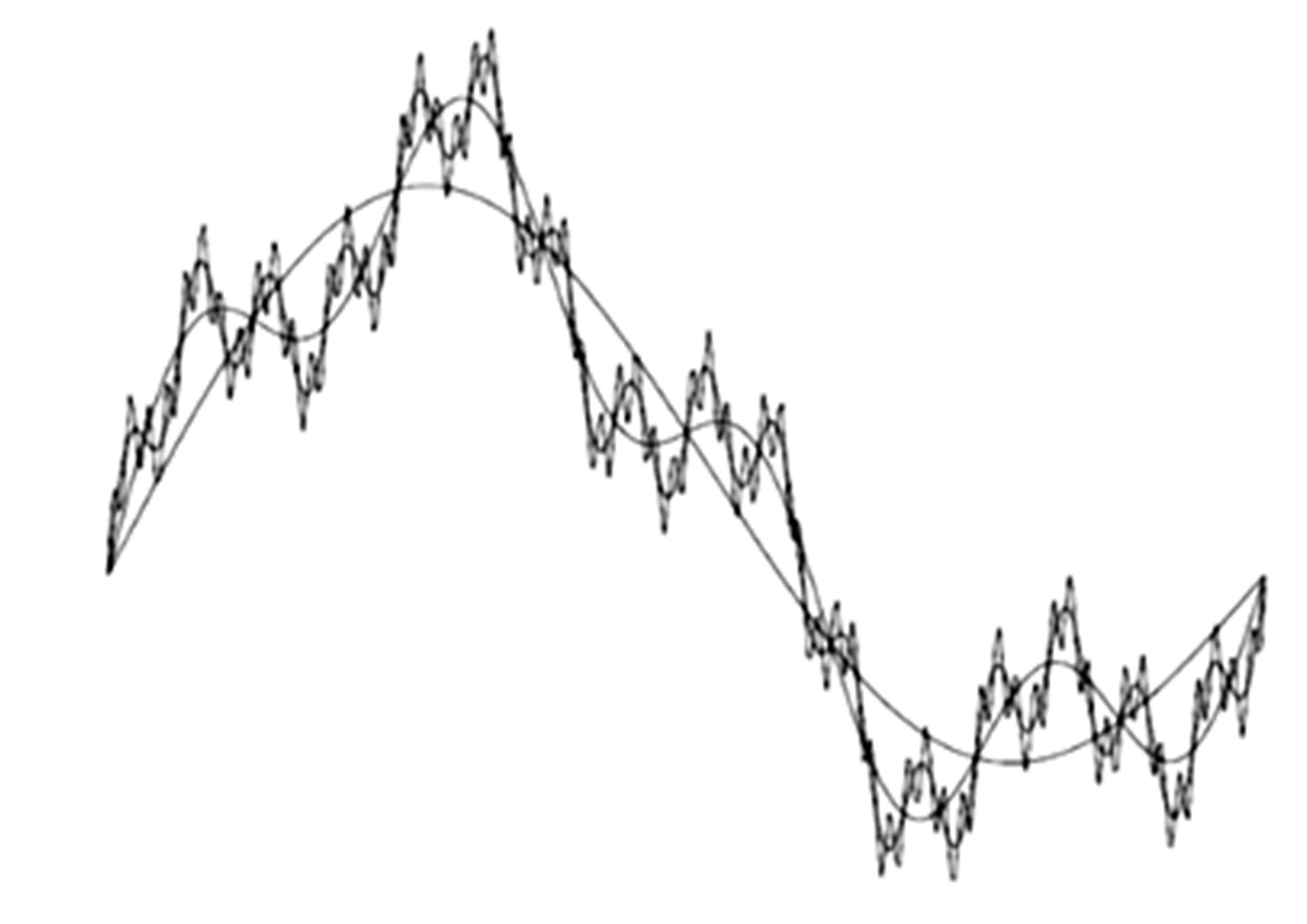

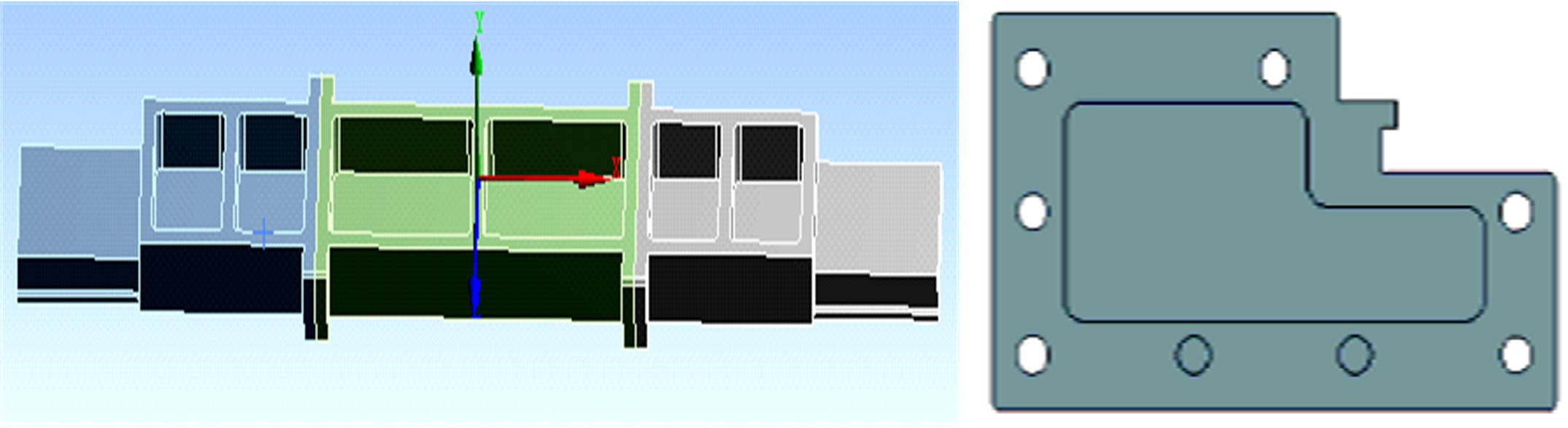

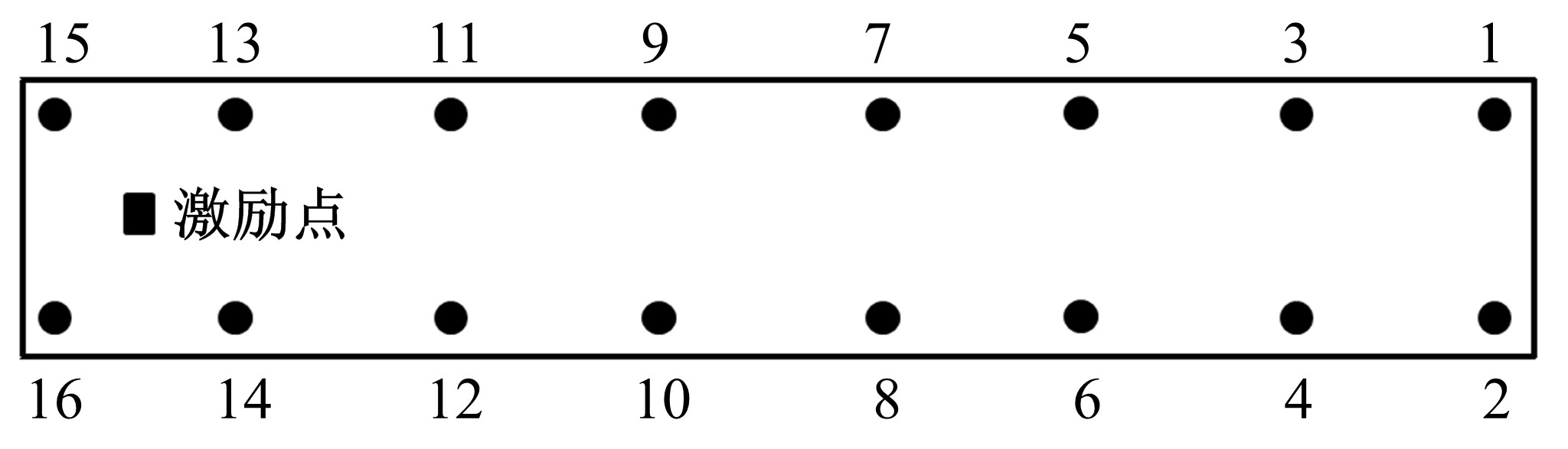

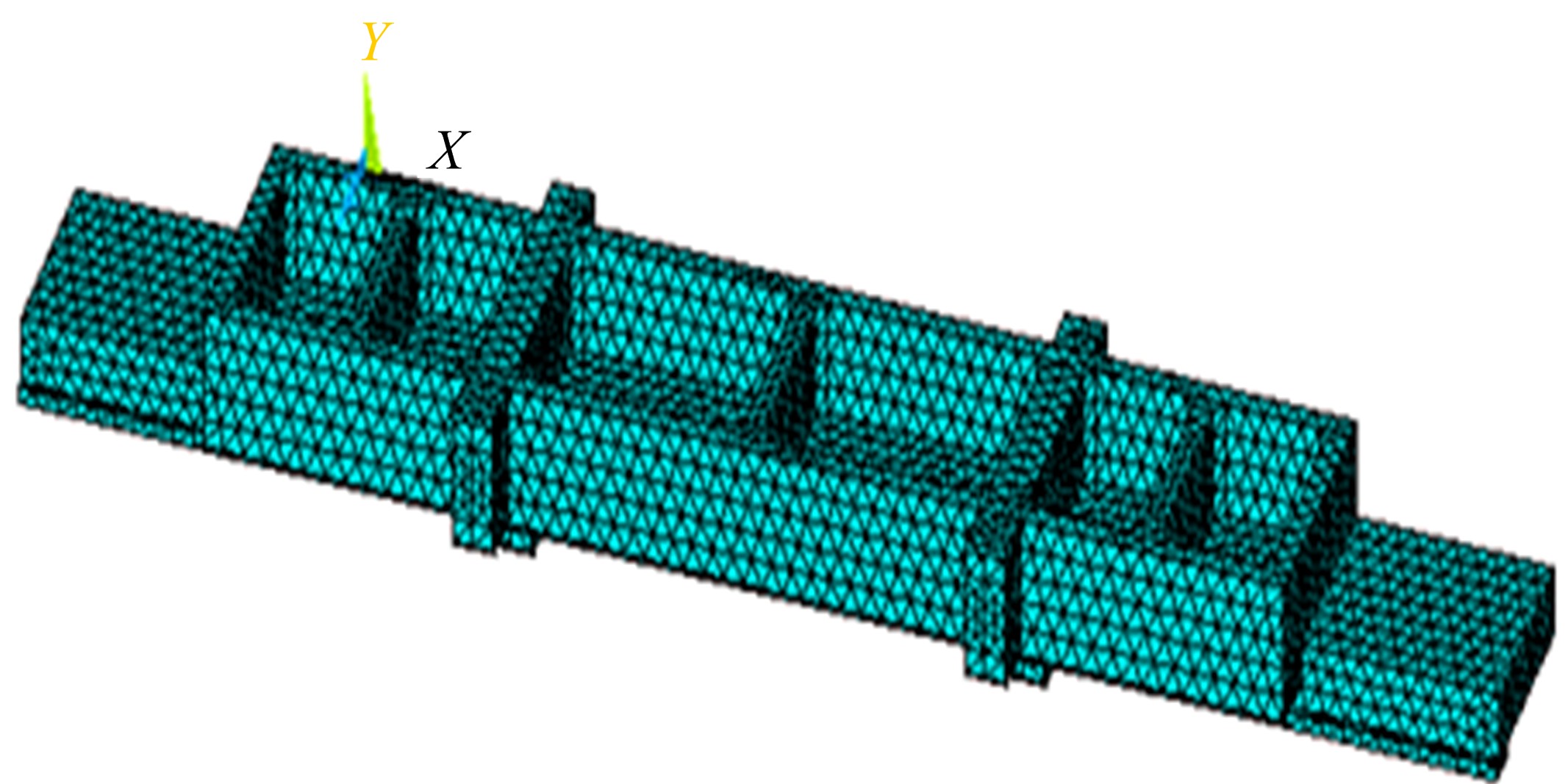

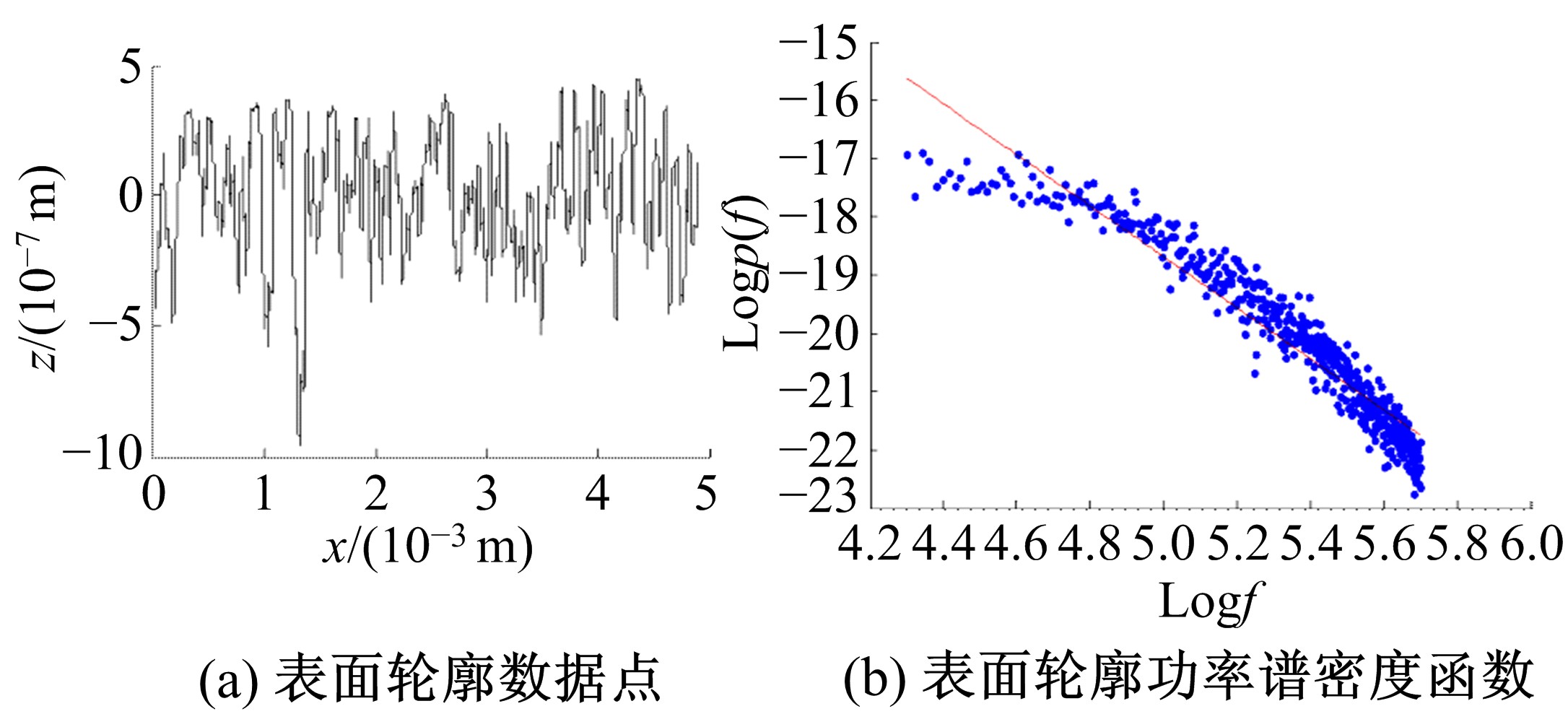

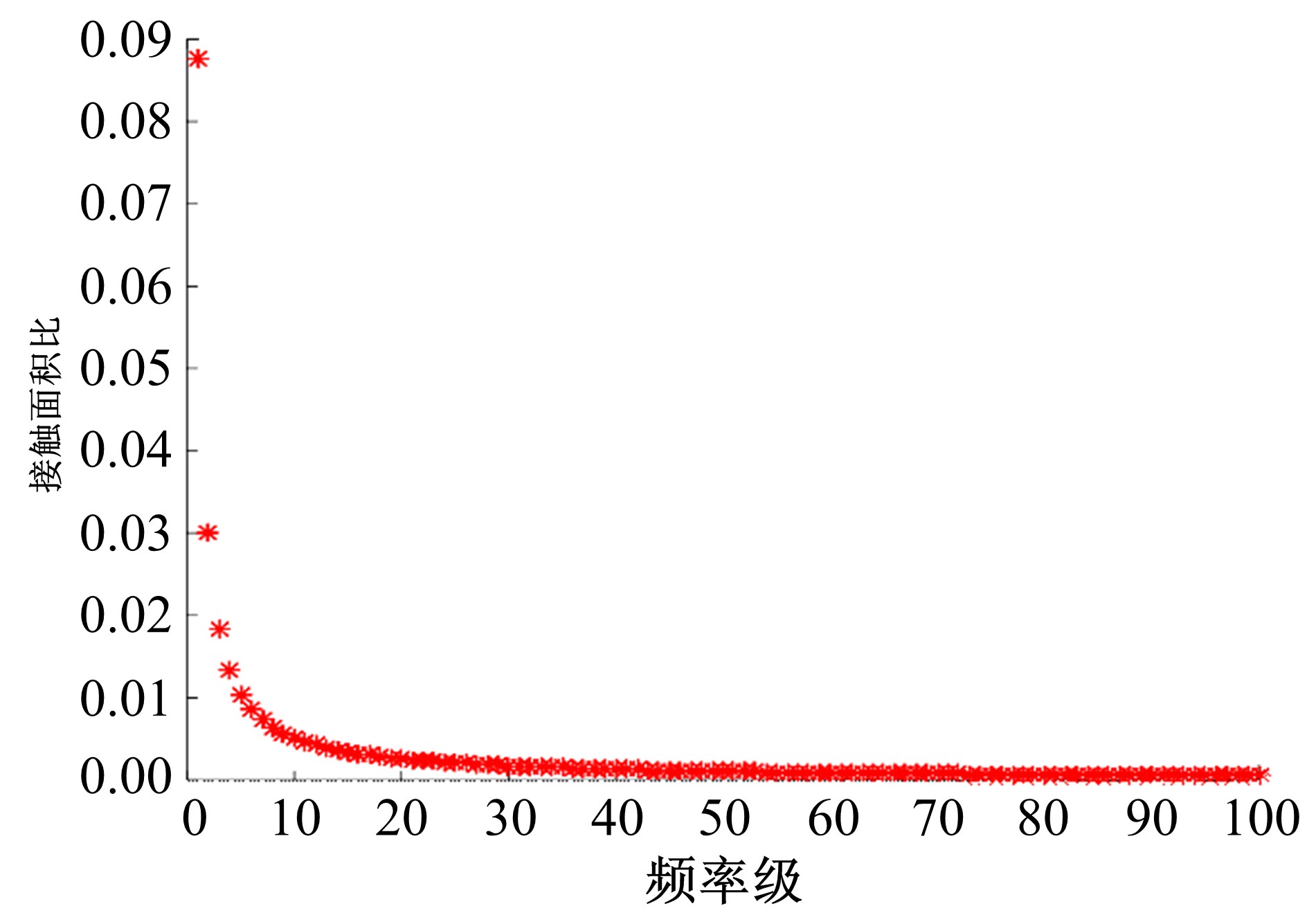

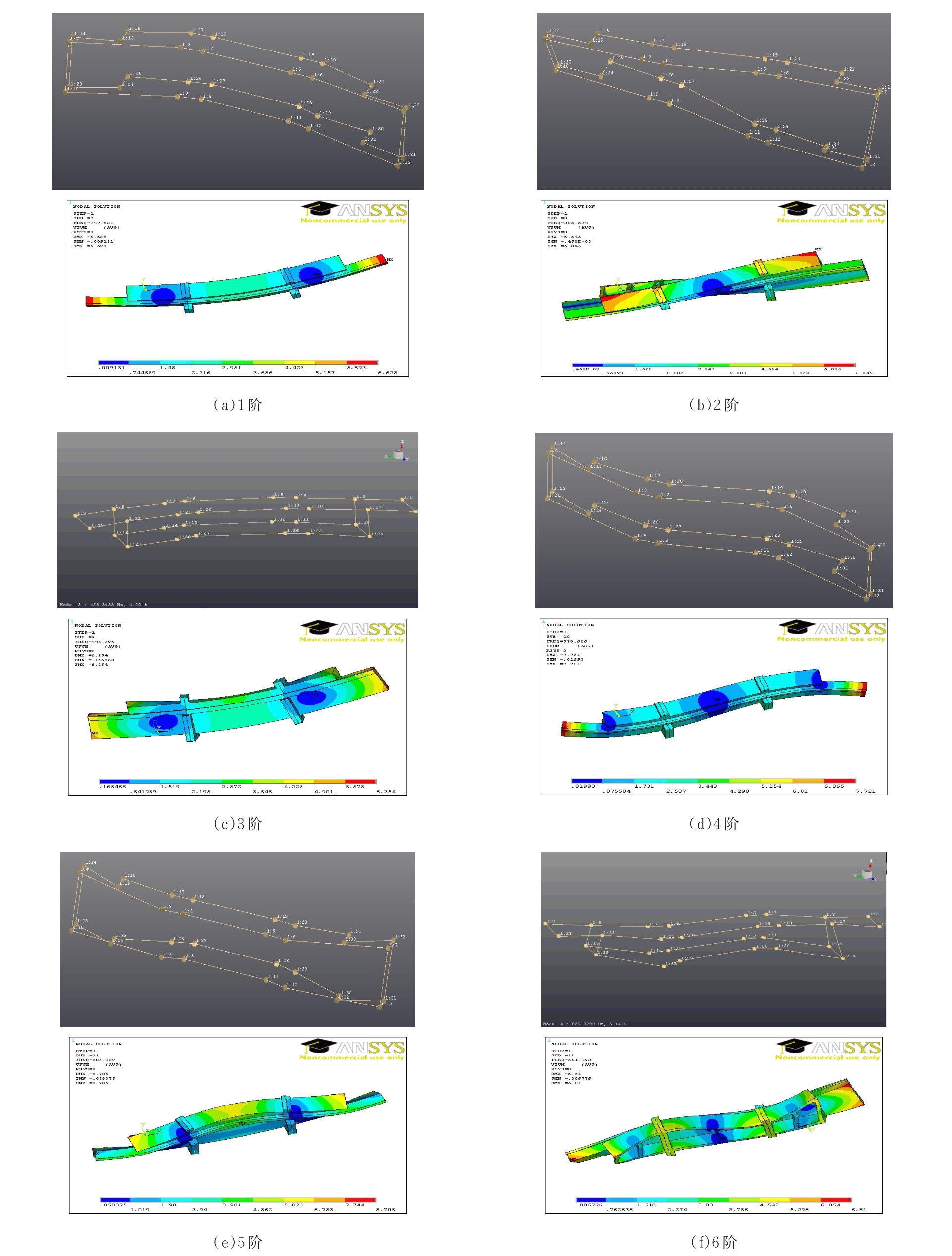

建立准确的栓接结合部接触刚度模型对预测数控机床的动态特性至关重要。本文提出了一种基于多尺度理论的栓接结合部刚度模型,首先使用一系列叠加的三维正弦波来描述粗糙接触表面多尺度特性,每个正弦波被认为是一层频率级,推导出接触面积比与频率级的函数关系,则整体刚度可以看作不同频率级串联的弹簧模型。然后,通过数值仿真分析了结合面法向接触载荷、材料特性参数以及多尺度参数对接触刚度模型的影响。最后,设计分段梁结构进行试验验证本文模型的准确性,通过力锤敲击试验获得栓接结合部在等同预紧力下的固有频率和振型,并与仿真结果对比,结果表明本文多尺度模型固有频率与试验频率之间的相对误差小于9.94%,表明多尺度模型可以有效地预测数控机床的动态特性。

中图分类号:

- TH128

| 1 | LevinaZ M. Calculation of contact deformation in slideways[J]. Machine and Tooling, 1968, 36(1): 1⁃8. |

| 2 | LevinaZ M. Research on the static stiffness of joints in machine tools[J]. Advances in Machine Tool Design and Research, 1968: 737⁃758. |

| 3 | MajumdarA, BhushanB. Fractal model of elastic⁃plastic contact between rough surfaces[J]. Journal of Tribology, 1991, 113(1): 1⁃11. |

| 4 | GreenwoodJ A, WilliamsonJ B P. Contact of nominally flat surfaces[J]. Proceedings of the Royal Society of London, 1966, 295(1442): 300⁃319. |

| 5 | KashaniH, NobariA S. Identification of dynamic characteristics of nonlinear joint based on the optimum equivalent linear frequency response function[J]. Journal of Sound and Vibration, 2010, 329(9): 1460⁃1479. |

| 6 | WangL Y, YinG G, ZhangJ F. Joint identification of plant rational models and noise distribution function using binary⁃valued observation[J]. Automatica, 2006, 42(4): 535⁃547. |

| 7 | MajumdarA. Role of fractal geometry in roughness characterization and contact mechanics of surfaces[J]. Trans Asme J Tribology, 1990, 112(2): 205⁃216. |

| 8 | MajumdarA, TienC L. Fractal characterization and simulation of rough surfaces[J]. Wear, 1990, 136(2): 313⁃327. |

| 9 | 温淑花, 张学良, 武美先, 等. 结合部法向接触刚度分形模型建立与仿真[J]. 农业机械学报, 2009, 40(11): 197⁃202. |

| WenShu⁃hua, ZhangXue⁃liang, WuMei⁃xian, et al. Fractal model and simulation of normal contact stiffness of joint interfaces and its simulation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(11):197⁃202. | |

| 10 | 温淑花, 张学良, 文晓光, 等. 结合部切向接触刚度分形模型建立与仿真[J].农业机械学报, 2009, 40(12): 223⁃227. |

| WenShu⁃hua, ZhangXue⁃liang, WenXiao⁃guang, et al. Fractal model of tangential contact stiffness of joint interfaces and its simulation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(12): 223⁃227. | |

| 11 | ArchardJ F. Elastic deformation and the laws of friction[J]. Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, 1957, 243(1233): 190⁃205. |

| 12 | CiavarellaM. Linear elastic contact of the Weierstrass profile[J]. Proceedings Mathematical Physical and Engineering Sciences, 2000,456(1994): 387⁃405. |

| 13 | WilsonW E, AngadiS V, JacksonR L. Surface separation and contact resistance considering sinusoidal elastic⁃plastic multi⁃scale rough surface contact[J]. Wear, 2010, 268(1/2): 190⁃201. |

| 14 | JacksonR L, StreatorJ L. A multi⁃scale model for contact between rough surfaces[J]. Wear, 2006, 261(11): 1337⁃1347. |

| 15 | JacksonR L. An analytical solution to an Archard⁃type fractal rough surface contact model[J]. Tribology Transactions, 2010, 53(4): 543⁃553. |

| 16 | JacksonR L, AshurstW R, FlowersG T, et al. The effect of initial connector insertions on electrical contact resistance[C]∥Electrical Contacts⁃2007 Proceedings of the 53rd IEEE Holm Conference on Electrical Contacts,Pittsburgh, PA, USA, 2007: 17⁃24. |

| 17 | PerssonB. N. J. Theory of rubber friction and contact mechanics[J]. The Journal of Chemical Physics, 2001, 115(8): 3840⁃3861. |

| 18 | JohnsonK L, GreenwoodJ A, HigginsonJ G. The contact of elastic regular wavy surfaces[J]. International Journal of Mechanical Sciences, 1985, 27(6): 383⁃396. |

| 19 | JacksonR L, GreenI. A finite element study of elastopastic hemispherical contact against a rigid flat[J]. Journal of Tribology, 2005, 127(2):343⁃354. |

| 20 | ZhangX L, HuangY M, HanY. Fractal model of the normal contact stiffness of machine joint surfaces based on the fractal contact theory[J]. China Mechanical Engineering, 2000, 11(7): 727⁃729. |

| 21 | KogutL, EtsionI. Elastic⁃plastic contact analysis of a sphere and a rigid flat[J]. Journal of Applied Mechanics, 2002, 69(5): 657⁃662. |

| [1] | 张艳芹,冯雅楠,孔鹏睿,于晓东,孔祥滨. 基于热油携带的静压支承油膜温度场及试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1203-1211. |

| [2] | 刘坤,吉硕,孙震源,徐洪伟,刘勇,赵静霞. 多功能坐站辅助型如厕轮椅机械结构设计与优化[J]. 吉林大学学报(工学版), 2019, 49(3): 872-880. |

| [3] | 王兴野,张进秋,李国强,彭志召. 惯性质量对齿轮齿条式作动器阻尼特性的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 881-887. |

| [4] | 王家序,倪小康,韩彦峰,向果,肖科. 轴向往复运动下微槽轴承混合润滑数值模型[J]. 吉林大学学报(工学版), 2019, 49(3): 888-896. |

| [5] | 毕秋实,王国强,黄婷婷,毛瑞,鲁艳鹏. 基于DEM-FEM耦合的双齿辊破碎机辊齿强度分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1770-1776. |

| [6] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

| [7] | 刘建芳, 王记波, 刘国君, 李新波, 梁实海, 杨志刚. 基于PMMA内嵌三维流道的压电驱动微混合器[J]. 吉林大学学报(工学版), 2018, 48(5): 1500-1507. |

| [8] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [9] | 王涛, 伞晓刚, 高世杰, 王惠先, 王晶, 倪迎雪. 光电跟踪转台垂直轴系动态特性[J]. 吉林大学学报(工学版), 2018, 48(4): 1099-1105. |

| [10] | 贺继林, 陈毅龙, 吴钪, 赵喻明, 汪志杰, 陈志伟. 起重机卷扬系统能量流动分析及势能回收系统实验[J]. 吉林大学学报(工学版), 2018, 48(4): 1106-1113. |

| [11] | 谢传流, 汤方平, 孙丹丹, 张文鹏, 夏烨, 段小汇. 立式混流泵装置压力脉动的模型试验分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1114-1123. |

| [12] | 孙秀荣, 董世民, 王宏博, 李伟成, 孙亮. 整体抽油杆柱在油管内空间屈曲的多段式仿真模型对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1124-1132. |

| [13] | 吉野辰萌, 樊璐璐, 闫磊, 徐涛, 林烨, 郭桂凯. 基于MBNWS算法的假人胸部结构多目标优化设计[J]. 吉林大学学报(工学版), 2018, 48(4): 1133-1139. |

| [14] | 刘坤, 刘勇, 闫建超, 吉硕, 孙震源, 徐洪伟. 基于体外传感检测的人体站起动力学分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1140-1146. |

| [15] | 刘志峰, 赵代红, 王语莫, 浑连明, 赵永胜, 董湘敏. 重载静压转台承载力与油垫温度场分布的关系[J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

|

||