吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (5): 1622-1629.doi: 10.13229/j.cnki.jdxbgxb20180430

• • 上一篇

纤维增强复合材料应变率效应的数值仿真

- 吉林大学 汽车仿真与控制国家重点实验室,长春130022

Numerical simulation of strain rate effect of fiber reinforced composites

Hui YE( ),Yan-rong ZHU,Yong-feng PU

),Yan-rong ZHU,Yong-feng PU

- State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

摘要:

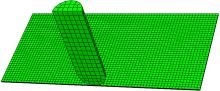

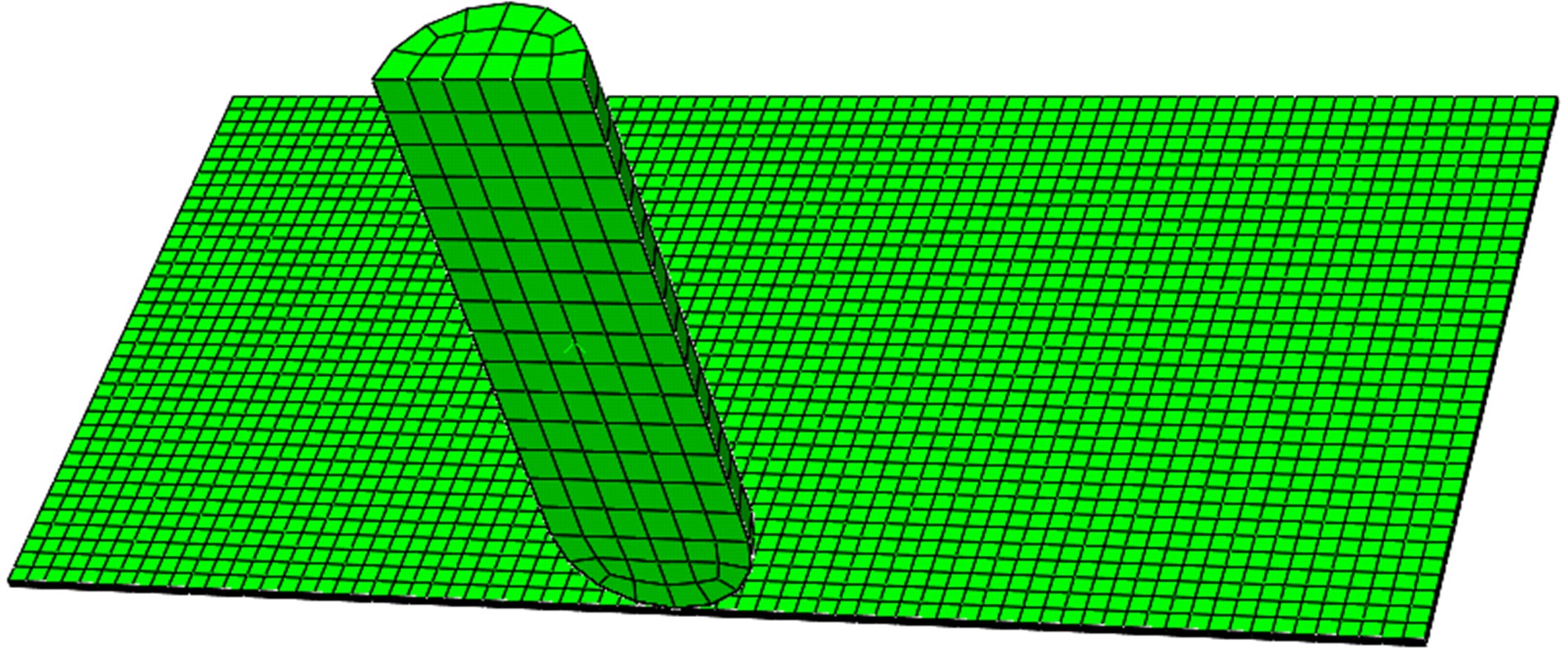

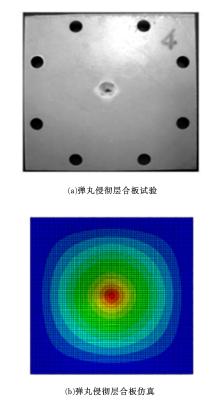

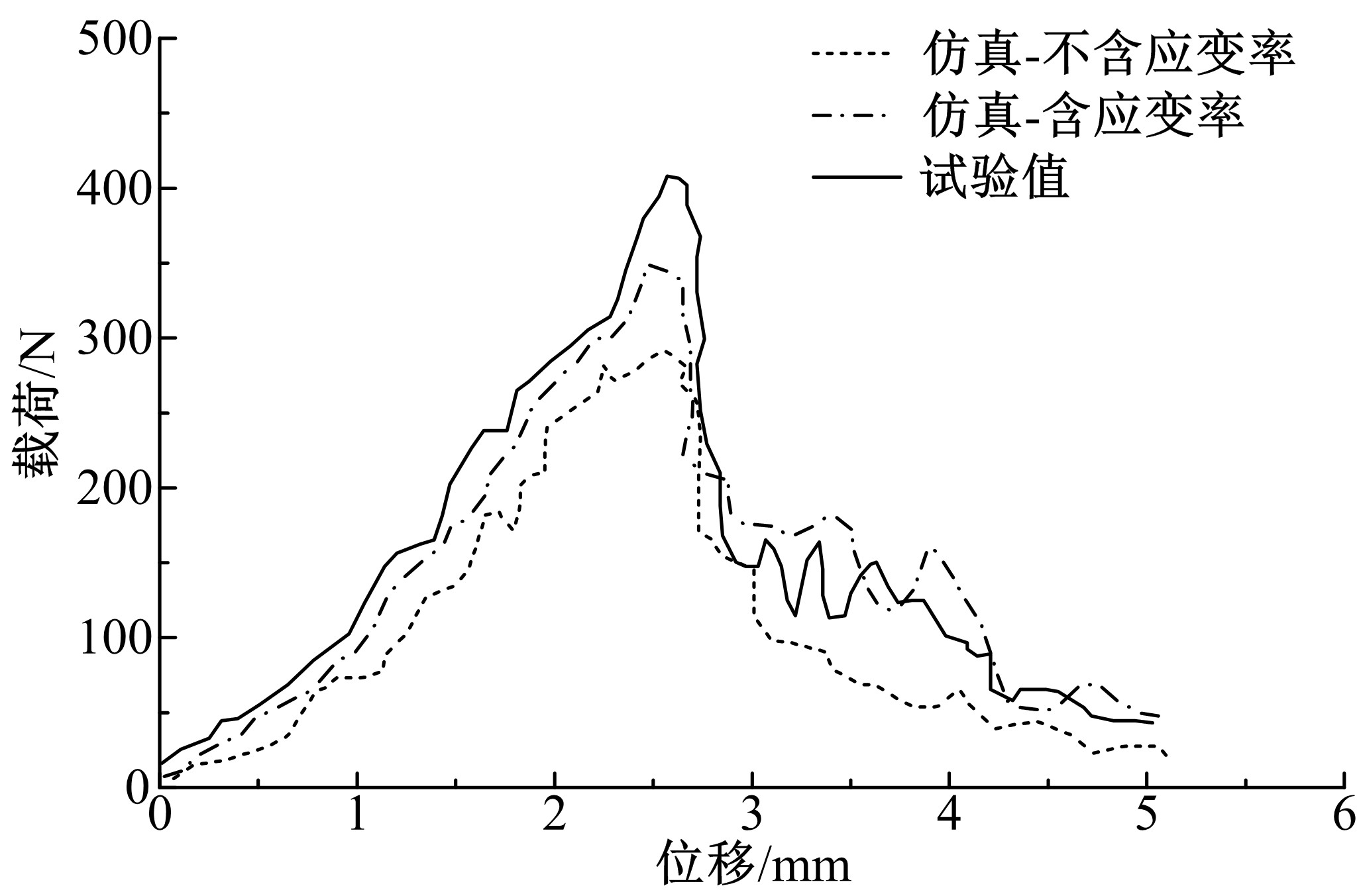

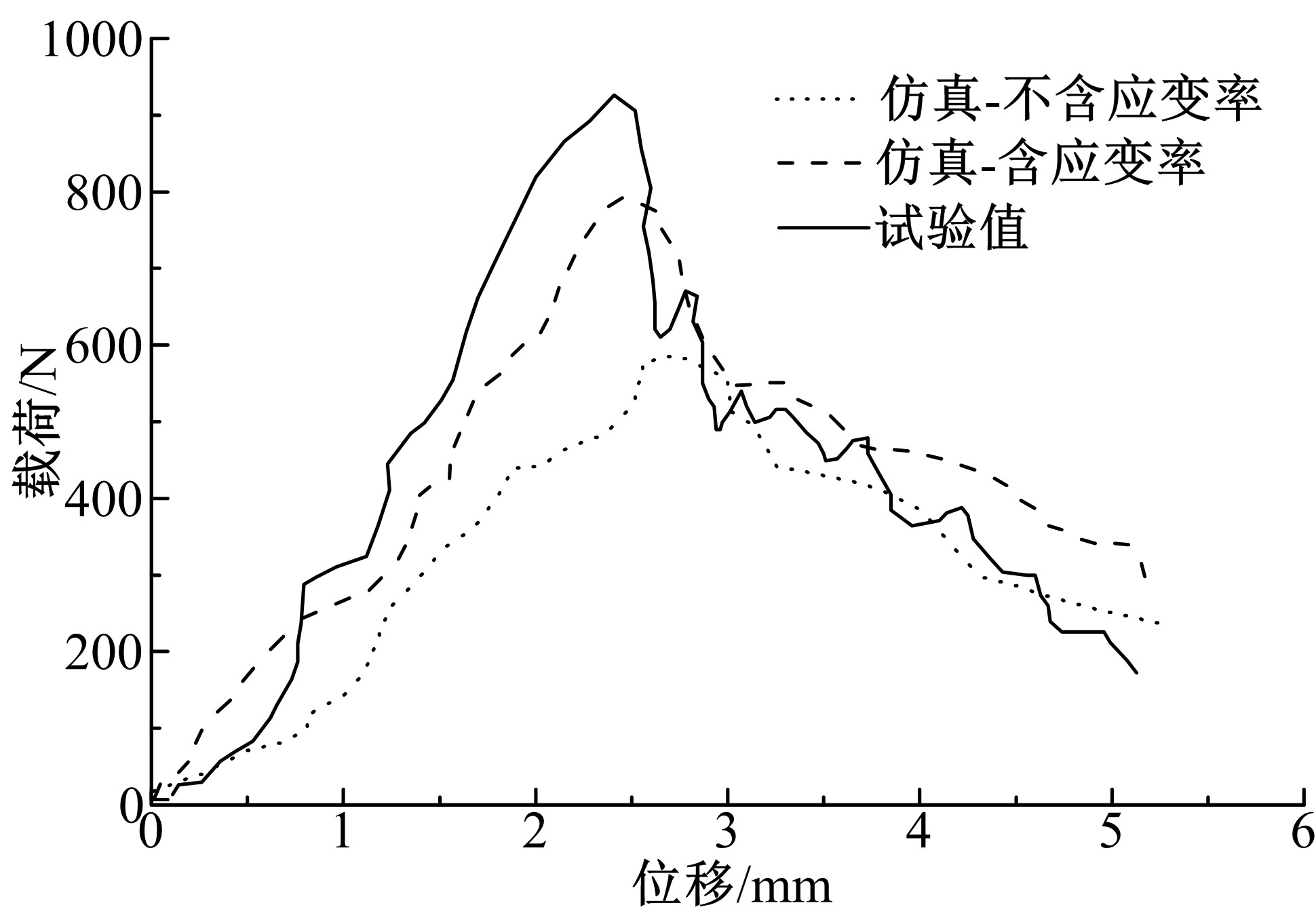

为研究应变率效应对纤维增强复合材料仿真精度的影响,引入动态增强因子(DIF)对复合材料模量和强度进行修正,结合改进的Hashin失效准则,建立了可考虑应变率效应的复合材料三维渐进性损伤本构模型。将该模型通过VUMAT子程序嵌入Abaqus软件中,进行弹丸侵彻玻璃纤维增强复合材料层合板仿真,将仿真结果分别与试验结果和不考虑应变率效应的本构模型仿真结果进行了对比。结果表明:本文建立的含有应变率的本构模型,能较准确地模拟弹丸侵彻层合板过程;在1.8、3 m/s两种弹丸侵彻速度下,含应变率与不含应变率的仿真结果相比,精确度分别提高了14.1%、22.7%;对于不考虑应变率的本构模型,仿真误差随侵彻速度的增大而增加,由1.8 m/s的28.7%增大到3 m/s的36.9%,考虑应变率的本构模型仿真误差比较稳定。

中图分类号:

- U465.6

| 1 | 汤旭, 李征, 孙程阳, 等 . 先进复合材料在航空航天领域的应用[J]. 中国高新技术企业, 2016(13): 39-42. |

| Tang Xu , Li Zheng , Sun Cheng-yang , et al . Application of advanced composite materials in aerospace[J]. China High Technology Enterprises, 2016(13): 39-42. | |

| 2 | Abdul-Latif A , Man M H C , Mansor S . Inclusion of strain-rate effects in low velocity impact simulation of laminated composites[J]. Applied Mechanics & Materials, 2014, 465/466: 1395-1399. |

| 3 | Zhang X , Hao H , Shi Y , et al . Static and dynamic material properties of CFRP/epoxy laminates[J]. Construction & Building Materials, 2016, 114: 638-649. |

| 4 | 辛士红 . 纤维增强树脂基复合材料层合板抗侵彻性能数值模拟研究[D]. 合肥: 中国科学技术大学近代力学系, 2015. |

| Xin Shi-hong . Numerical study on the penetration resistence of fibre reinforced plastic laminates[D]. Hefei: Department of Modern Mechanics, University of Science and Technology of China, 2015. | |

| 5 | Fan J , Guan Z , Cantwell W J . Modeling perforation in glass fiber reinforced composites subjected to low velocity impact loading[J]. Polymer Composites, 2011, 32(9): 1380-1388. |

| 6 | 王正浩, 赵桂平, 马君峰, 等 . 碳/环氧树脂复合材料应变率效应的实验研究[J]. 复合材料学报, 2007, 24(2): 113-119. |

| Wang Zheng-hao , Zhao Gui-ping , Ma Jun-feng , et, al . Experiment study on the strain rate behavior of carbon/epoxy composite materials[J]. Acta Materiae Compositae Sinica, 2007, 24(2): 113-119. | |

| 7 | Gebbeken N , Greulich S . A new material model for SFRC under high dynamic loadings[C]∥International Confernce on Interaction of the Effects of Munitions with Structures, Mannheim, Germany, 2003: 1-16. |

| 8 | Gama B Z , Stanton R J , Gillespie J W . Perforation mechanics of thin composites[C]∥International SAMPE Technical Conference, Long Beach, 2013: 6-9. |

| 9 | 汪凌云 . 论纤维增强复合材料的失效准则[J]. 纤维复合材料, 1995(1): 1-8. |

| Wang Ling-yun . The failure criterion of fiber reinforced composite[J]. Fiber Composites, 1995(1): 1-8. | |

| 10 | Gama B A , Bogetti T A . Progressive damage modeling of plain-weave composites using LS-Dyna composite damage model MAT162[ EB/OL ]. [2009-01-15]. https:∥ |

| 11 | Jordan J B , Naito C J , Haque B Z . Progressive damage modeling of plain weave E-glass/phenolic composites[J]. Composites Part B: Engineering, 2014, 61: 315-323. |

| 12 | Naik N K , Sekher Y C , Meduri S . Damage in woven-fabric composites subjected to low-velocity impact[J]. Composites Science & Technology, 2000, 60(5): 731-744. |

| [1] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [2] | 李碧雄,廖桥,章一萍,周练,隗萍,刘侃. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版), 2019, 49(4): 1153-1161. |

| [3] | 胡志清, 郑会会, 徐亚男, 张春玲, 党停停. 表面微沟槽对Al/CFRP胶结性能的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [4] | 刘耀辉, 陈乔旭, 宋雨来, 沈艳东. 火山灰-SBS、胶粉-SBS和SBS改性沥青压缩变形行为及机理[J]. 吉林大学学报(工学版), 2017, 47(6): 1861-1867. |

| [5] | 杨越东, 陈吉清, 兰凤崇, 周云郊. 基于焊点参数识别的白车身动态特性[J]. 吉林大学学报(工学版), 2017, 47(5): 1379-1386. |

| [6] | 李静, 王哲. 真三轴加载条件下混凝土的力学特性[J]. 吉林大学学报(工学版), 2017, 47(3): 771-777. |

| [7] | 杨悦, 李雪, 徐晓丹. Ti-B-C-N粉末烧结的微观组织及其性能[J]. 吉林大学学报(工学版), 2017, 47(2): 552-556. |

| [8] | 陈江义, 刘保元. 纤维断裂损伤对复合材料板中导波频散特性的影响[J]. 吉林大学学报(工学版), 2017, 47(1): 180-184. |

| [9] | 关庆丰, 黄尉, 李怀福, 龚晓花, 张从林, 吕鹏. 强流脉冲电子束诱发的Cu-C扩散合金化[J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

| [10] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [11] | 彭爱东, 刘贺男. 基于水包油微乳液法的方形苝纳米颗粒的合成与荧光性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1583-1586. |

| [12] | 刘利萍, 刘勇兵, 姬连峰, 曹占义, 杨晓红. 原位颗粒增强钛基复合材料高温流变行为[J]. 吉林大学学报(工学版), 2016, 46(4): 1197-1201. |

| [13] | 赵刚, 孙壮志, 郭华君, 隋志阳, 李芳, 赵华兴. 基于离子聚合物金属基复合材料线性驱动单元的性能[J]. 吉林大学学报(工学版), 2016, 46(1): 221-227. |

| [14] | 闫光,韩小进,闫楚良,祝连庆. 含口盖复合材料圆柱壳轴压屈曲性能分析[J]. 吉林大学学报(工学版), 2015, 45(1): 187-192. |

| [15] | 王国林, 傅乃霁, 张建, 裴紫嵘. 基于K-R动力学模型的子午线轮胎硫化过程仿真[J]. 吉林大学学报(工学版), 2013, 43(03): 659-664. |

|

||