吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 19-28.doi: 10.13229/j.cnki.jdxbgxb20190068

适用于高频激励的面内轮胎动态模型

- 吉林大学 汽车仿真与控制国家重点实验室, 长春 130022

In⁃plane dynamic tire model for high⁃frequency excitation

Kong-hui GUO( ),Shi-qing HUANG,Hai-dong WU(

),Shi-qing HUANG,Hai-dong WU( )

)

- State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

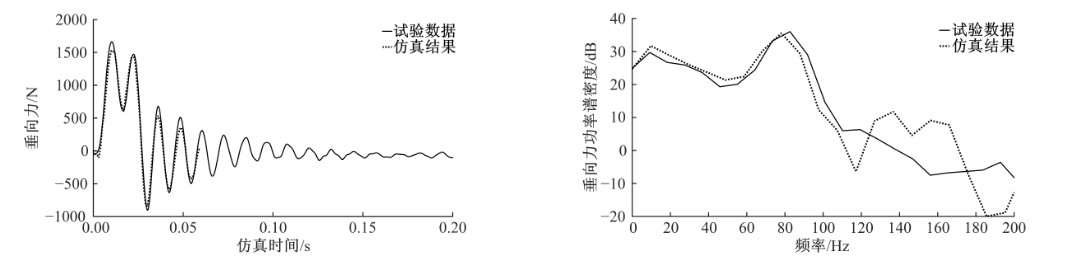

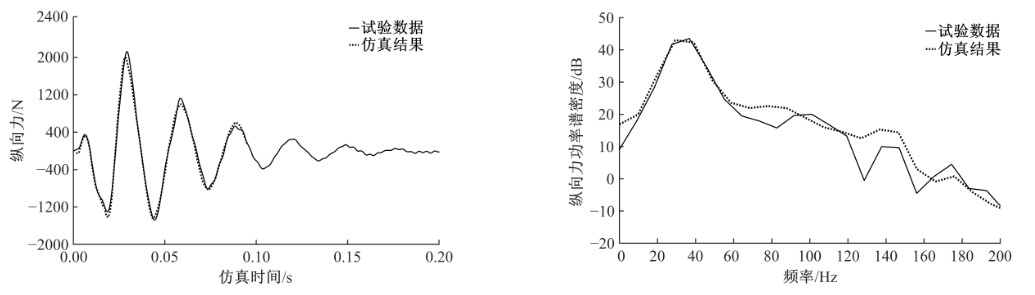

摘要:

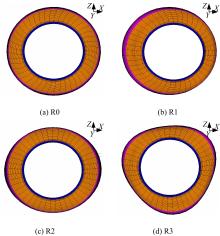

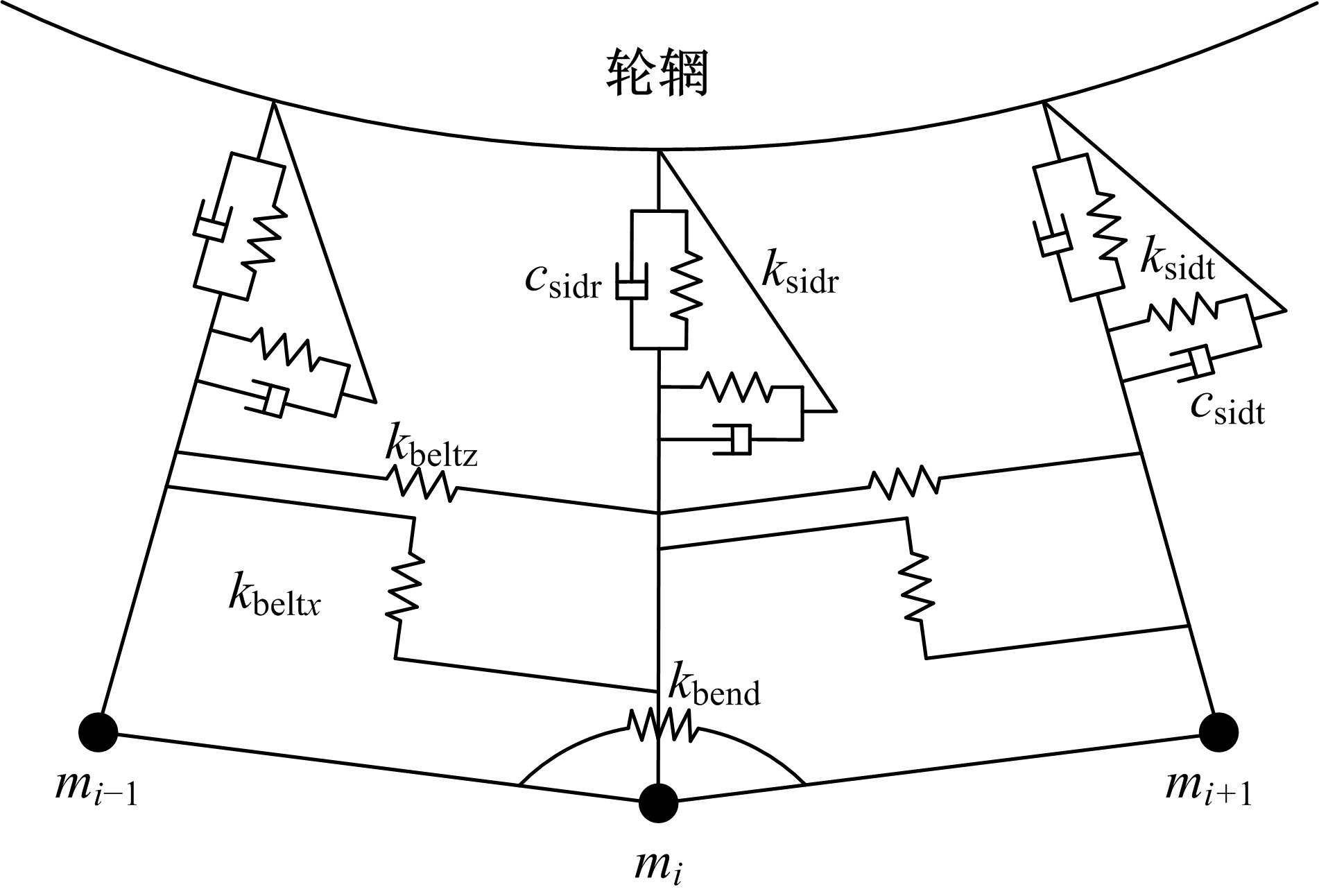

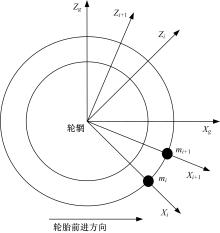

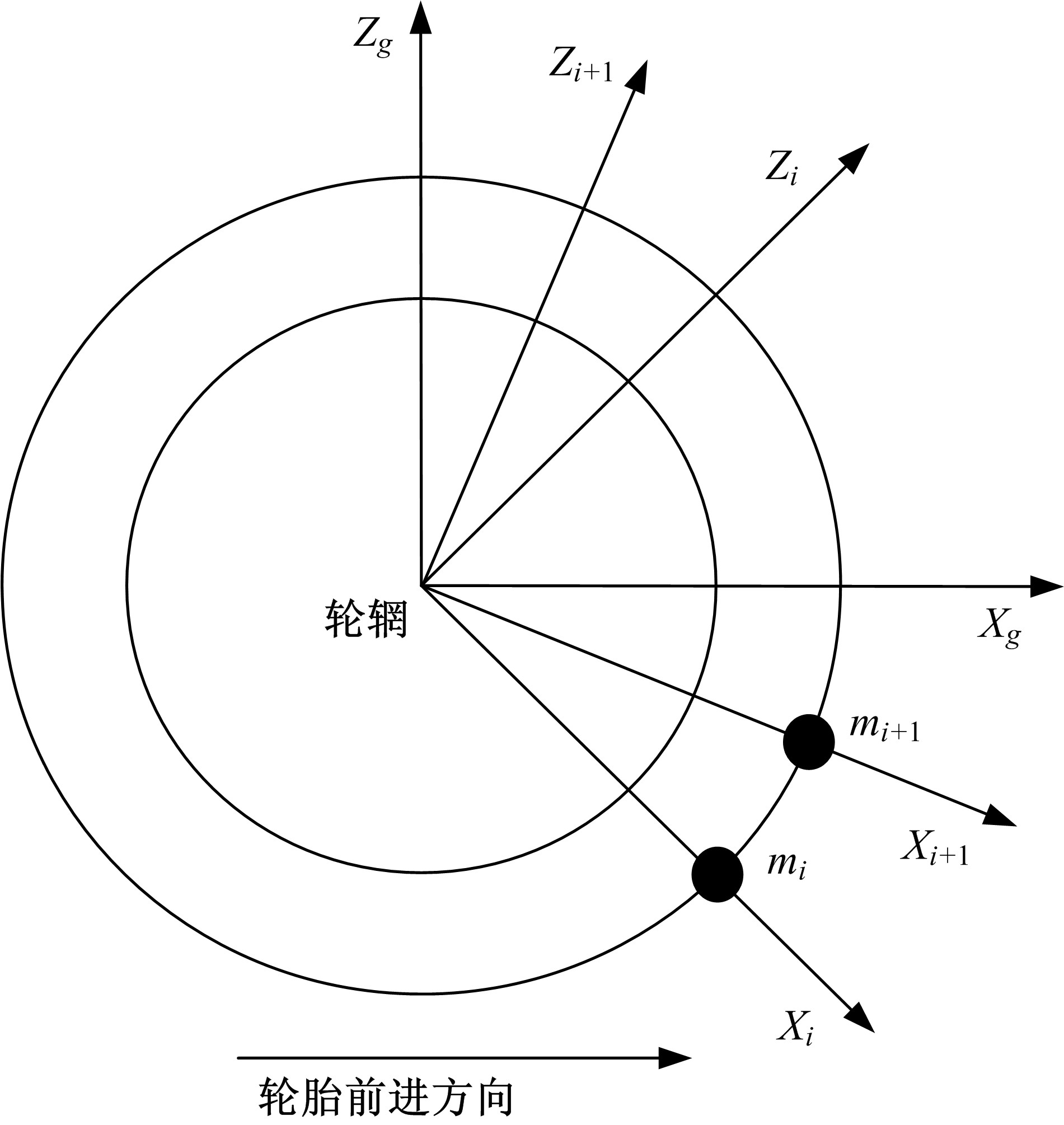

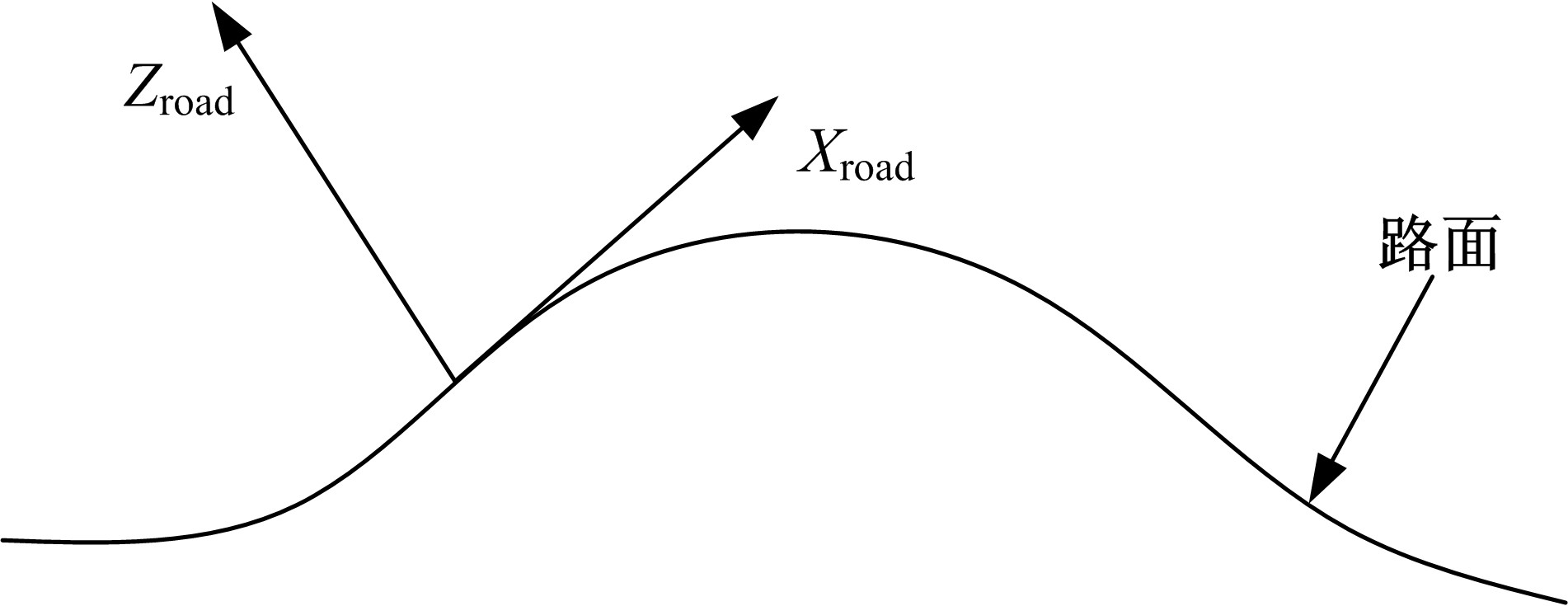

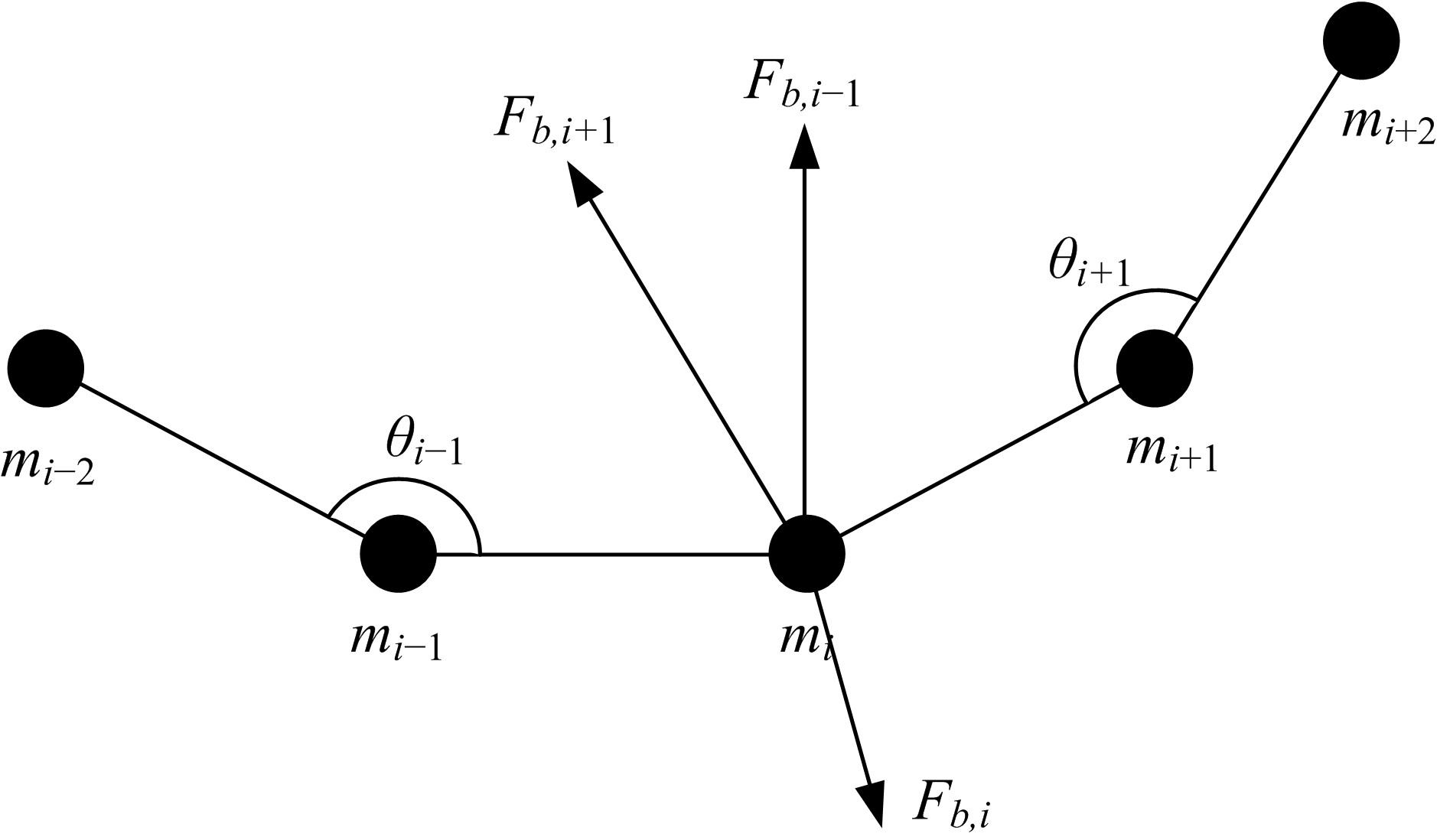

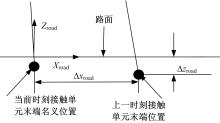

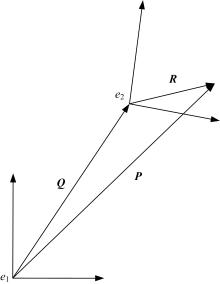

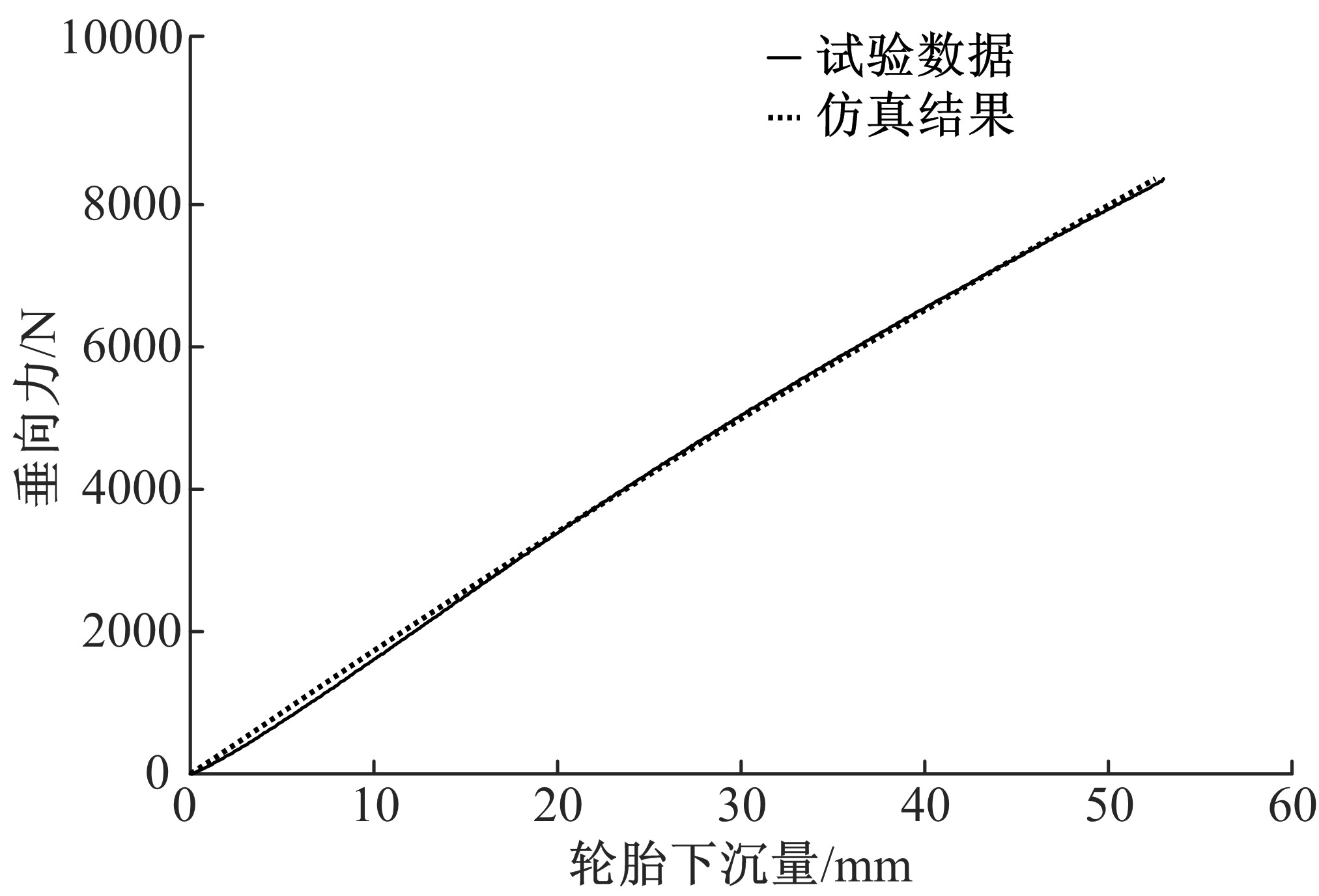

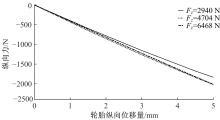

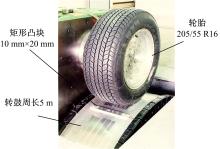

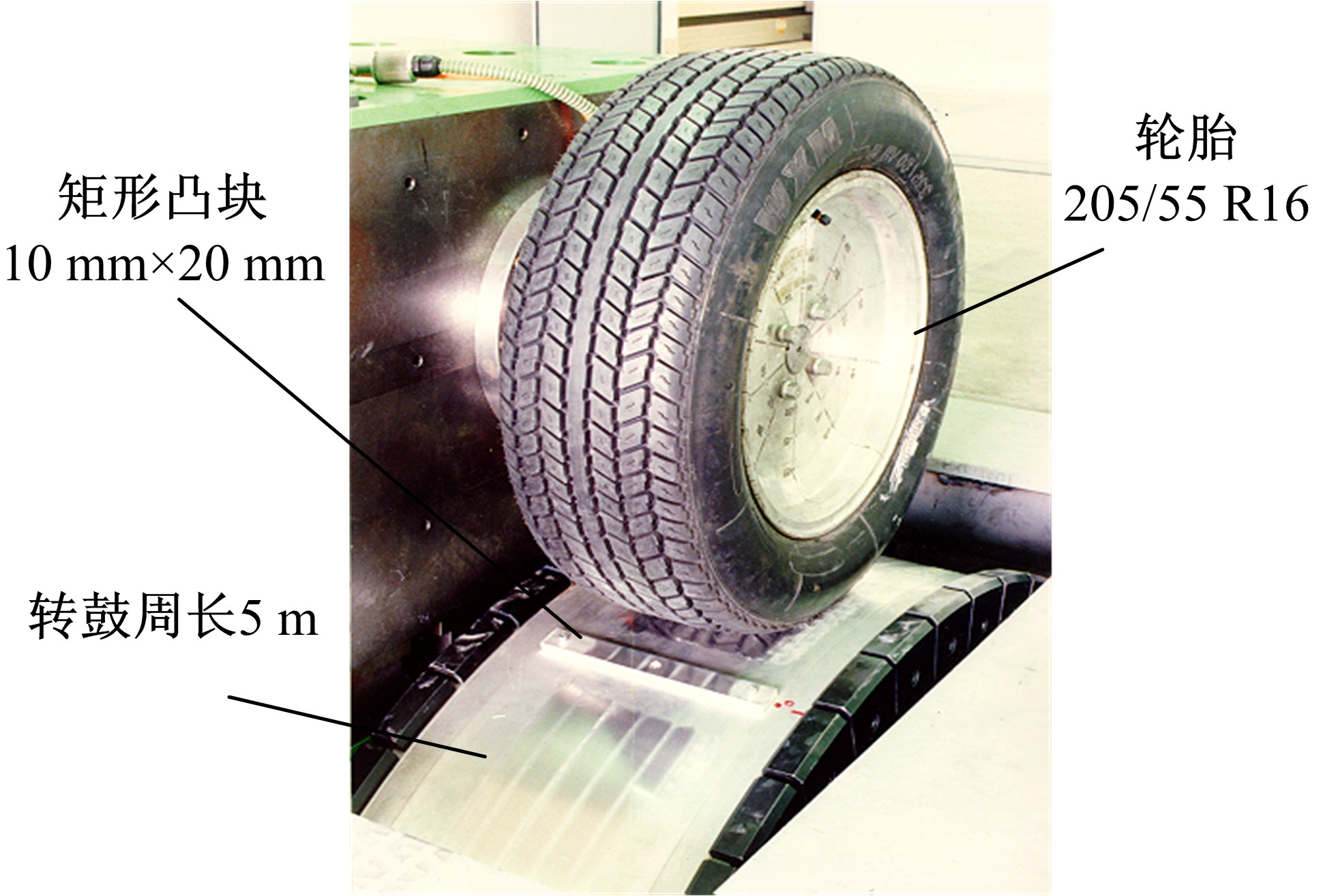

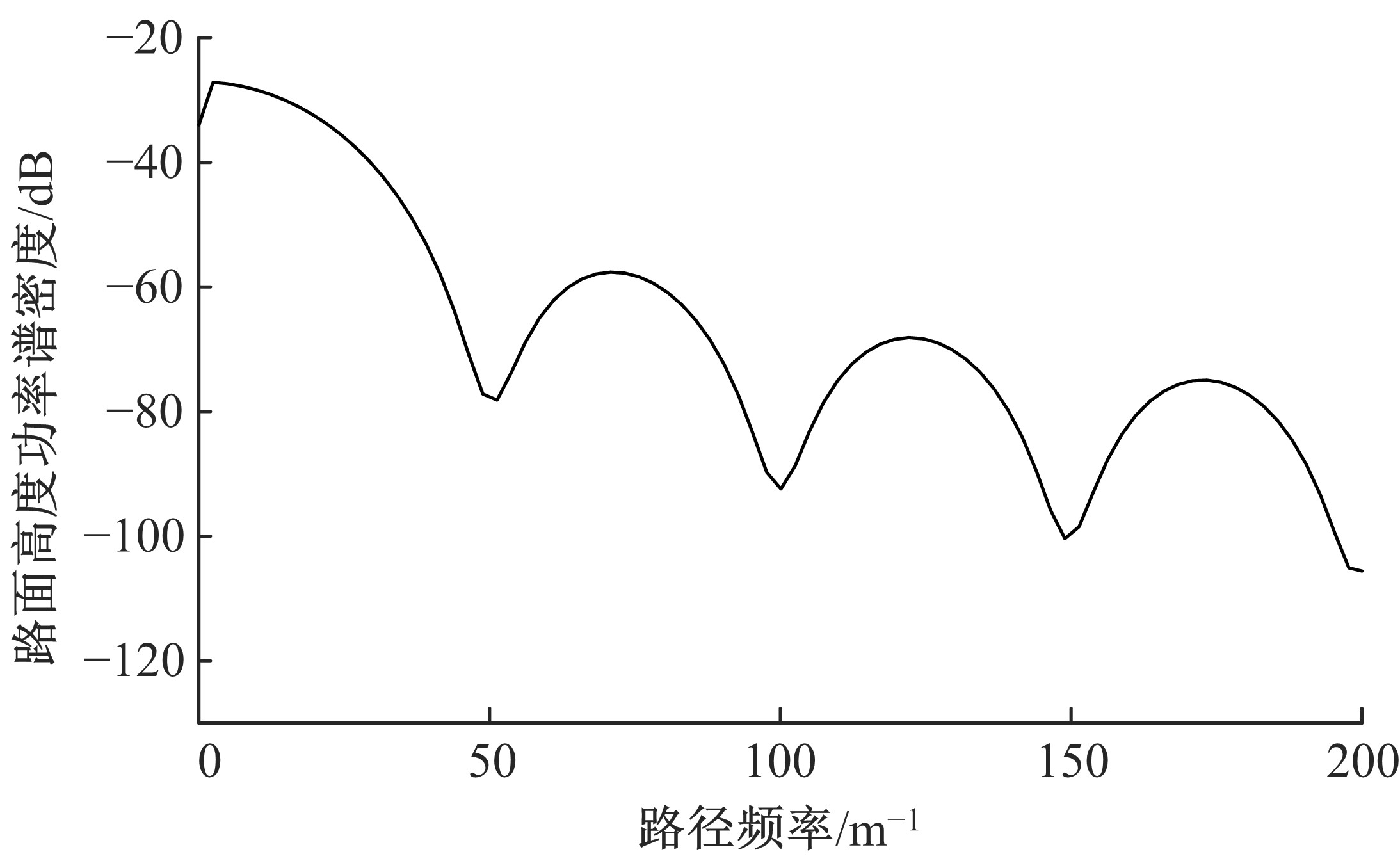

为了合理表达轮胎在高频激励工况下的动态力学特性,建立了一种将轮胎连续物理结构离散化处理的轮胎动态模型。该模型将胎侧部分以及胎内压缩空气离散成一系列弹簧阻尼单元,带束部分离散成沿带束圆周方向均匀分布的多个质量点,质量点之间由代表带束拉伸和弯曲特性的弹性单元相连。在相邻质量点之间引入若干个无质量接触单元进行轮胎与路面之间接触力计算。利用TMPT试验数据对所建立的轮胎动态模型进行参数辨识和精度验证。对比结果表明,本文建立的轮胎动态模型不仅能够准确地表达轮胎静态力学特性,也能够很好地表达轮胎在典型不平路面上的高频动态力学特性。

中图分类号:

- U463.34

| 1 | Pacejka H B . Tyre and Vehicle Dynamics[M]. Oxford: Butterworth-Heinemann, 2002. |

| 2 | Guo K H , Liu Q . Modeling and simulation of non-steady state cornering properties and identification of structure parameters of tyres[J]. Vehicle System Dynamics, 1997, 27(Sup.1): 80-93. |

| 3 | Guo K H , Lu D , Chen S , et al . The UniTire model: a nonlinear and non-steady-state tyre model for vehicle dynamics simulation[J]. Vehicle System Dynamics, 2005, 43(Sup.1): 341-358. |

| 4 | Guo K H , Lu D . UniTire: unified tire model for vehicle dynamic simulation[J]. Vehicle System Dynamics, 2007, 45(Sup.1): 79-99. |

| 5 | Pacejka H B , Bakker E . The magic formula tyre model[J]. Vehicle System Dynamics, 1992, 21(Sup.1): 1-18. |

| 6 | Pacejka H B . In-plane and out-of-plane dynamics of pneumatic tyres[J]. Vehicle System Dynamics, 1981, 10(4, 5): 221-251. |

| 7 | Gong S . A study of in-plane dynamics of tires[D]. Delft: College of Industrial Design Engineering, Delft University of Technology, 1993. |

| 8 | Gipser M . FTire:a physically based application-oriented tyre model for use with detailed MBS and finite-element sudpension models[J]. Vehicle System Dynamics, 2005, 43(Sup.1): 76-91. |

| 9 | Gipser M . FTire-the tire simulation model for all applications related to vehicle dynamics[J]. Vehicle System Dynamics, 2007, 45(Sup.1): 139-151. |

| 10 | Oertel C . On modeling contact and friction calculation of tyre response on uneven roads[J]. Vehicle System Dynamics, 1997, 27(Sup.1): 289-302. |

| 11 | Oertel C , Fandre A . Tire model RMOD-K 7 and misuse load case[J]. SAE Paper, 2009-01-0582. |

| 12 | Oertel C . Eigensystem of tangential contact in tyre models[J]. Vehicle System Dynamics, 2002, 38(4); 245-260. |

| 13 | Gallrein A , Bäcker M . CDTire: a tire model for comfort and durability applications[J]. Vehicle System Dynamics, 2007, 45(Sup.1): 69-77. |

| 14 | Baecke M , Gallrein A , Haga H . A tire models for very large tire deformation and its application in very severe events[J]. SAE International Journal of Materials and Manufacturing, 2010, 3(1): 142-151. |

| 15 | Gallrein A , Baecker M , Burger M , et al . An advanced flexible realtime tire model and its integration into fraunhofer’s driving simulator[C]∥SAE Paper, 2014-01-0861. |

| 16 | Li B , Yang X , Yang J , et al . In-plane parameters relationship between the 2D and 3D flexible ring tire models[C]∥SAE Paper, 2017-01-0414. |

| 17 | 马文俊 . 车轮动态载荷冲击过程建模研究[D]. 长春: 吉林大学汽车工程学院, 2015. |

| Ma Wen-jun . Study on tire dynamic force during impact process[D]. Changchun: College of Automotive Engineering, Jilin University, 2015. | |

| 18 | Guan Di-hua , Fan Cheng-jian , Xie Xian-hai . A dynamic tyre model of vertical performace rolling over cleats[J]. Vehicle System Dynamics, 2005, 43(Sup.1): 209-222. |

| 19 | Mlugner P , Plochl M . Specifications of the test procedures[J]. Vehicle System Dynamics, 2007, 45(Sup.1): 21-28. |

| [1] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [2] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [3] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

| [4] | 庄蔚敏,刘洋,王鹏跃,施宏达,徐纪栓. 钢铝异质自冲铆接头剥离失效仿真[J]. 吉林大学学报(工学版), 2019, 49(6): 1826-1835. |

| [5] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [6] | 李杰, 郭文翠, 赵旗, 谷盛丰. 基于车辆响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1810-1817. |

| [7] | 陈百超,邹猛,党兆龙,黄晗,贾阳,石睿杨,李建桥. CE-3月球车筛网轮月面沉陷行为试验[J]. 吉林大学学报(工学版), 2019, 49(6): 1836-1843. |

| [8] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [9] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [10] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [11] | 鄢挺,杨林,陈亮. AMT换挡执行机构自适应智能控制策略[J]. 吉林大学学报(工学版), 2019, 49(5): 1441-1450. |

| [12] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [13] | 张博,张建伟,郭孔辉,丁海涛,褚洪庆. 路感模拟用永磁同步电机电流控制[J]. 吉林大学学报(工学版), 2019, 49(5): 1405-1413. |

| [14] | 王鹏宇,赵世杰,马天飞,熊晓勇,程馨. 基于联合概率数据关联的车用多传感器目标跟踪融合算法[J]. 吉林大学学报(工学版), 2019, 49(5): 1420-1427. |

| [15] | 韩小健,赵伟强,陈立军,郑宏宇,刘阳,宗长富. 基于区域采样随机树的客车局部路径规划算法[J]. 吉林大学学报(工学版), 2019, 49(5): 1428-1440. |

|

||