吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 100-106.doi: 10.13229/j.cnki.jdxbgxb20181206

• 材料科学与工程 • 上一篇

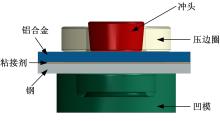

钢铝异质无铆钉粘铆复合连接胶层厚度分布

- 1. 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2. 一汽?大众汽车有限公司 技术开发部,长春 130011

3. 吉利汽车研究院(宁波)有限公司 整车工程中心,浙江 宁波 315336

Thickness distribution of adhesive layer in dissimilar clinch⁃adhesive hybrid joint with steel and aluminum alloy

Wei-min ZHUANG1( ),Hong-da SHI1,Dong-xuan XIE2,Guan-nan YANG3

),Hong-da SHI1,Dong-xuan XIE2,Guan-nan YANG3

- 1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2. Department of Technical Development, FAW?Volkswagen Automobile Co. Ltd. , Changchun 130011, China

3. Safety Technology Development Division, Geely Automobile Research Institute(Ningbo), Ningbo 315336, China

摘要:

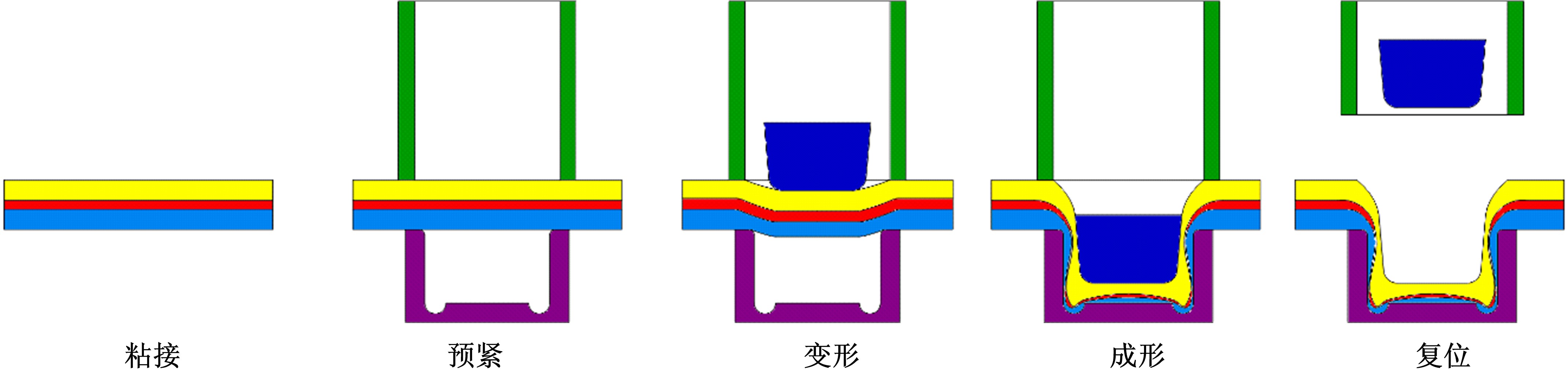

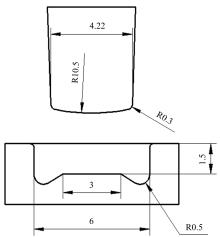

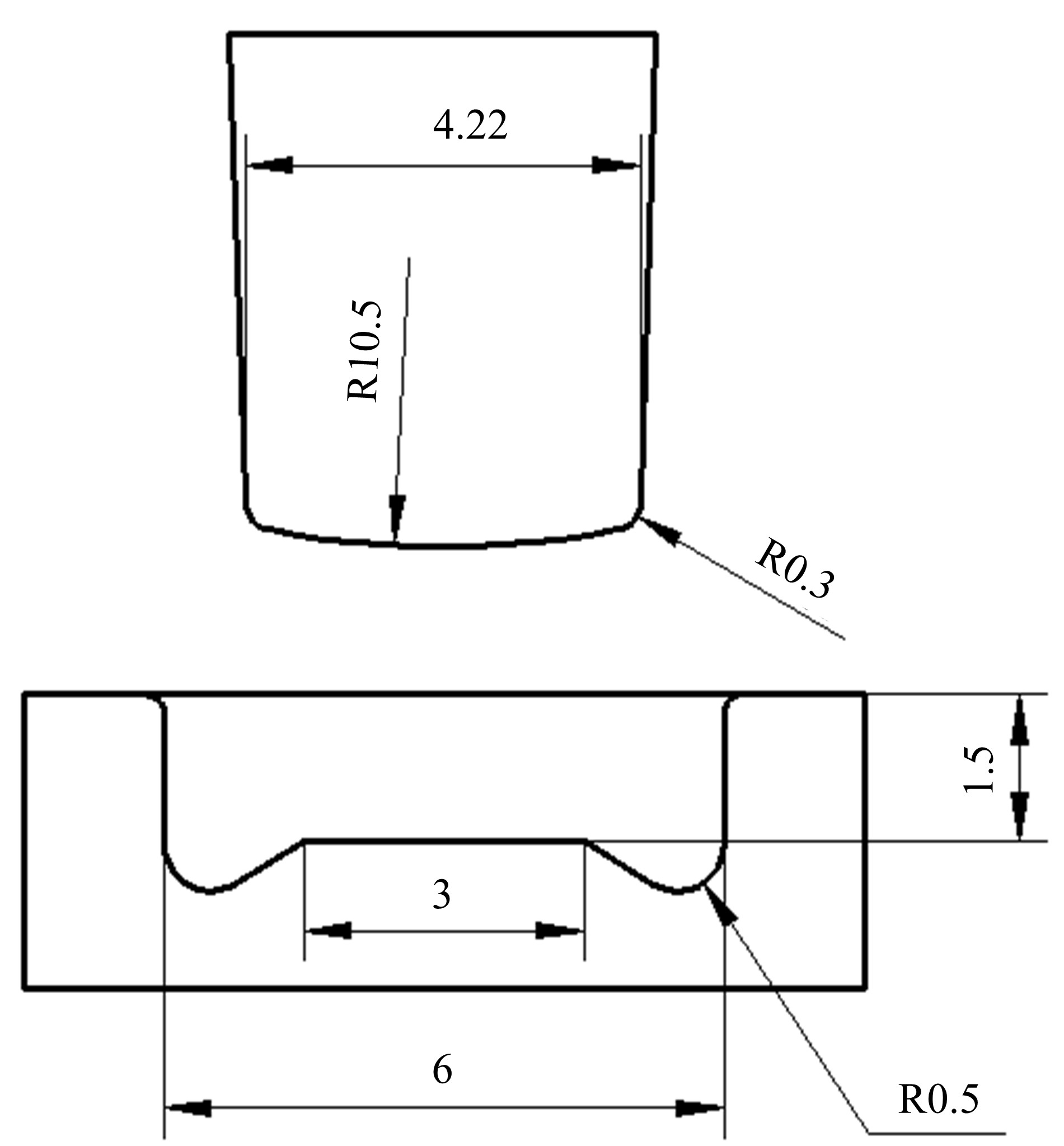

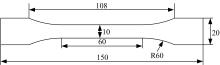

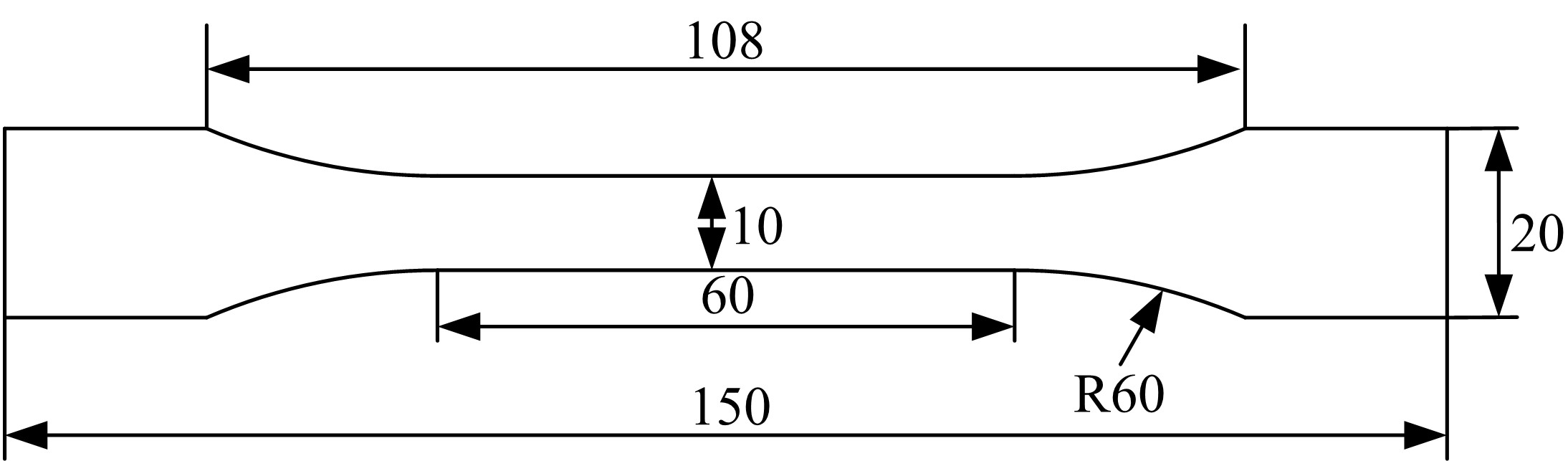

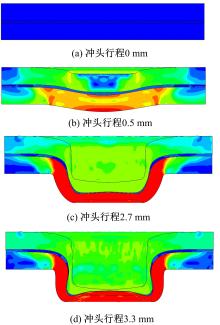

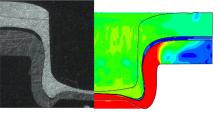

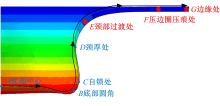

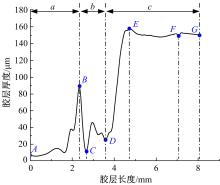

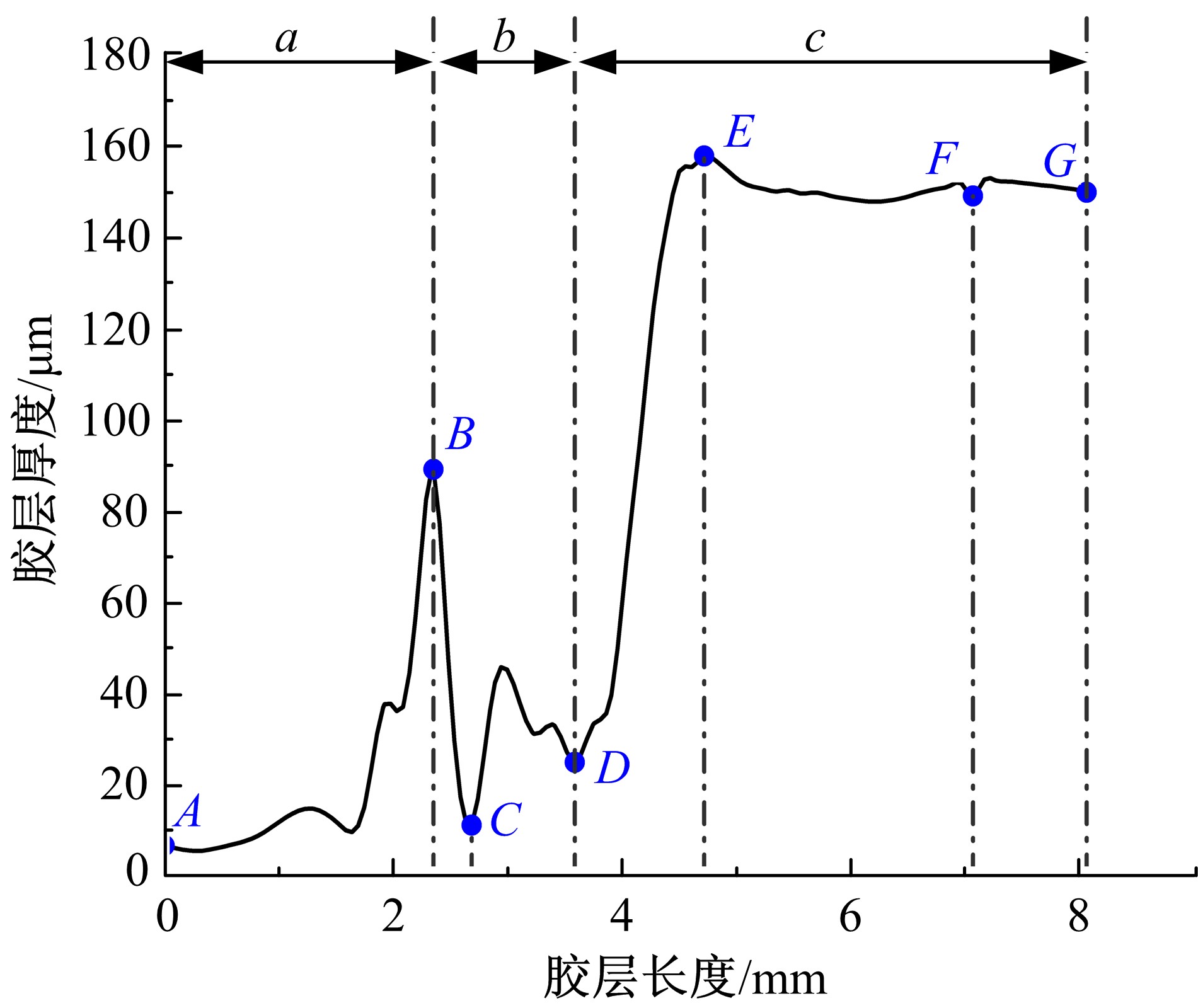

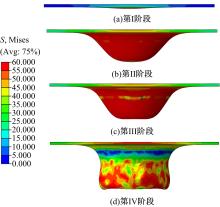

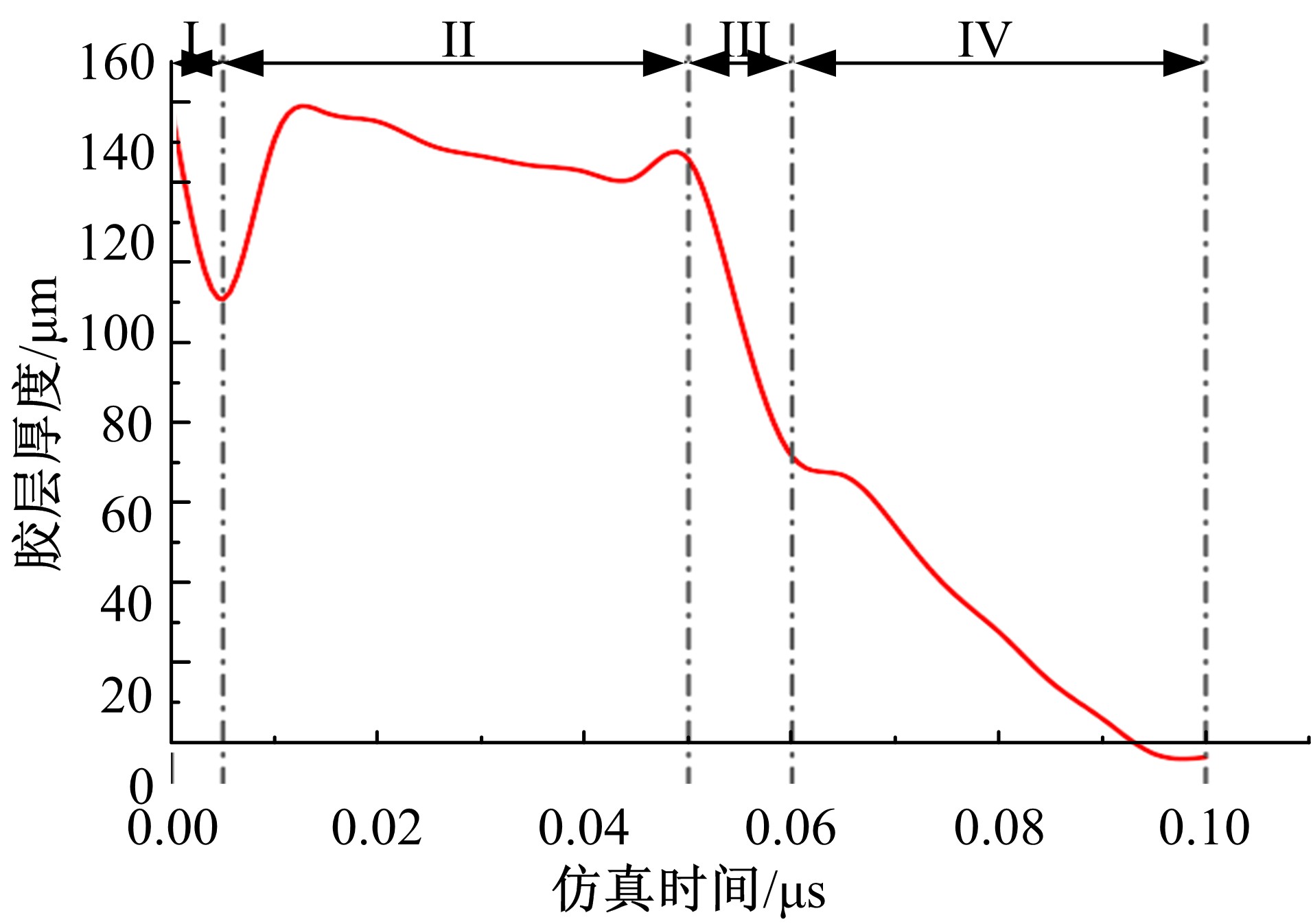

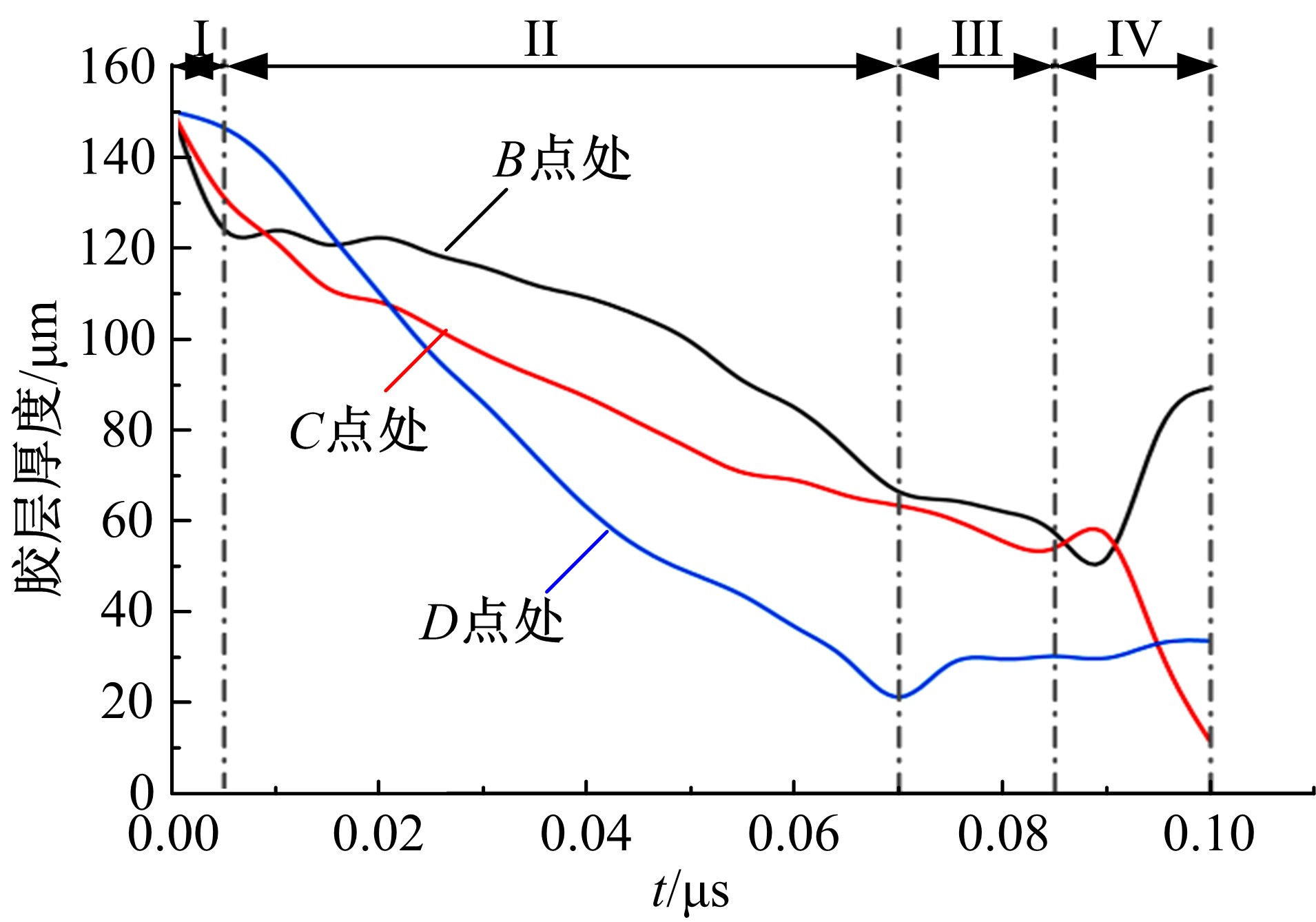

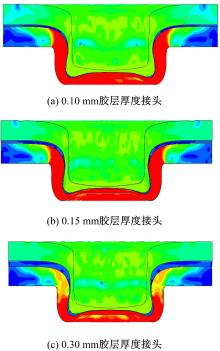

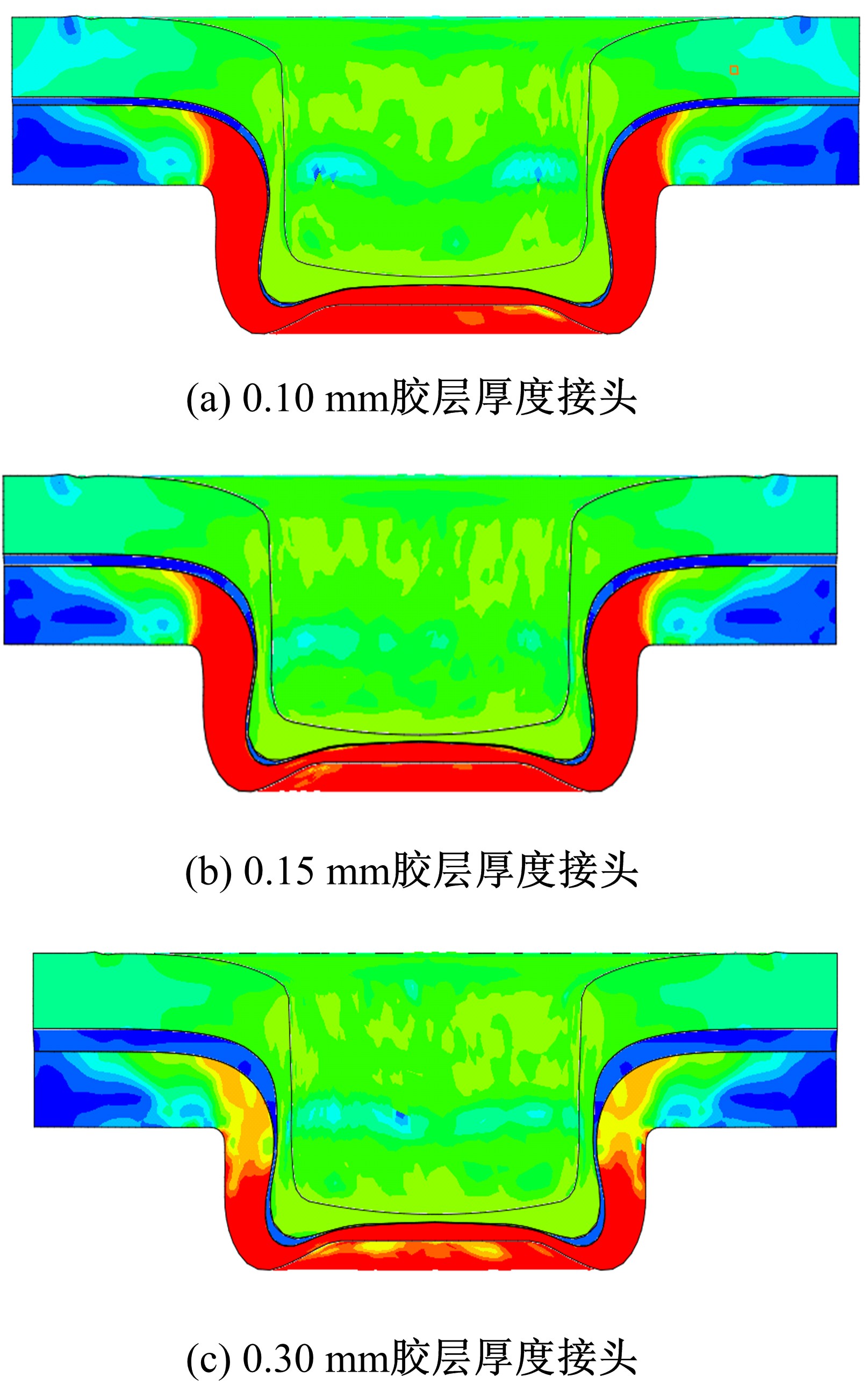

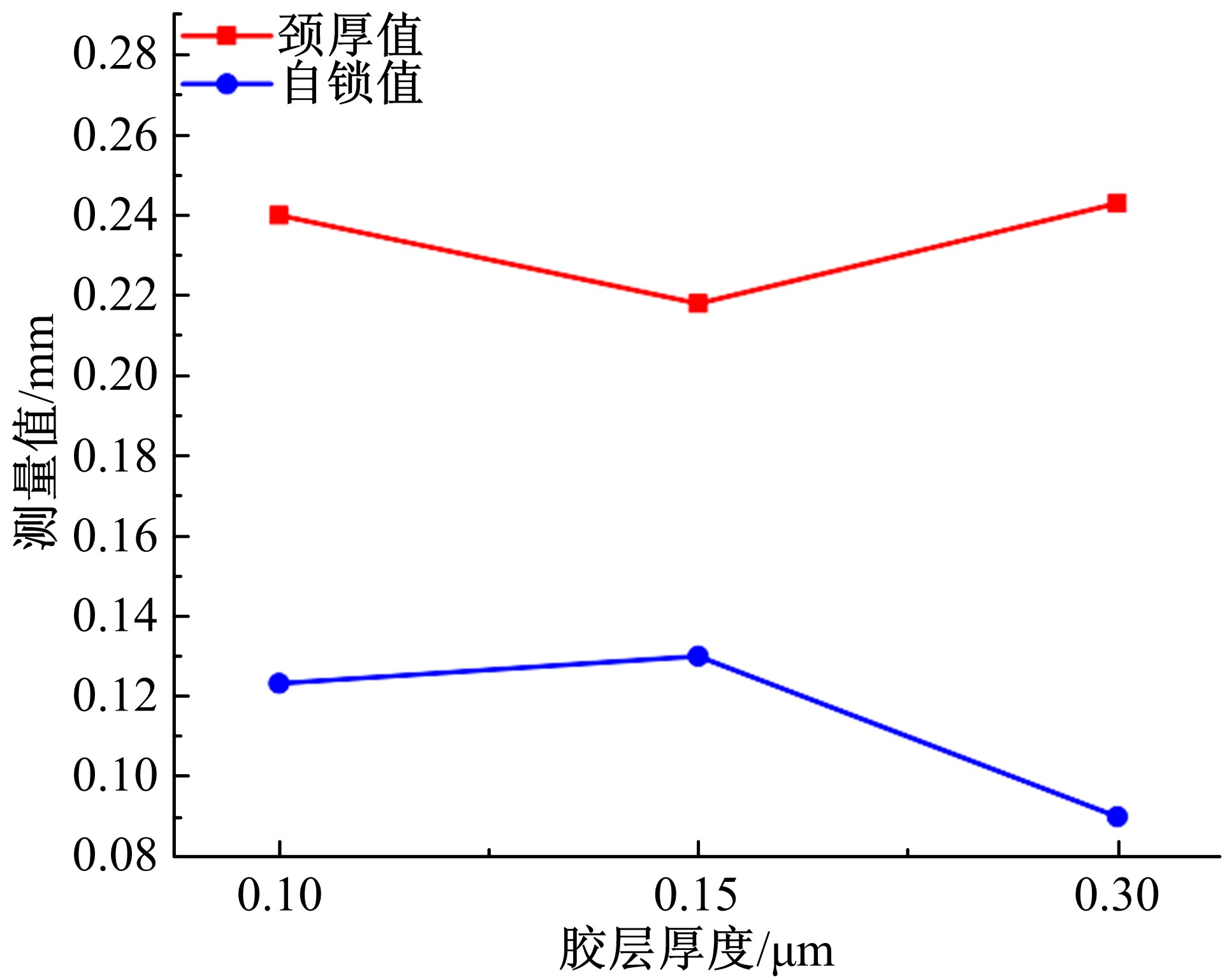

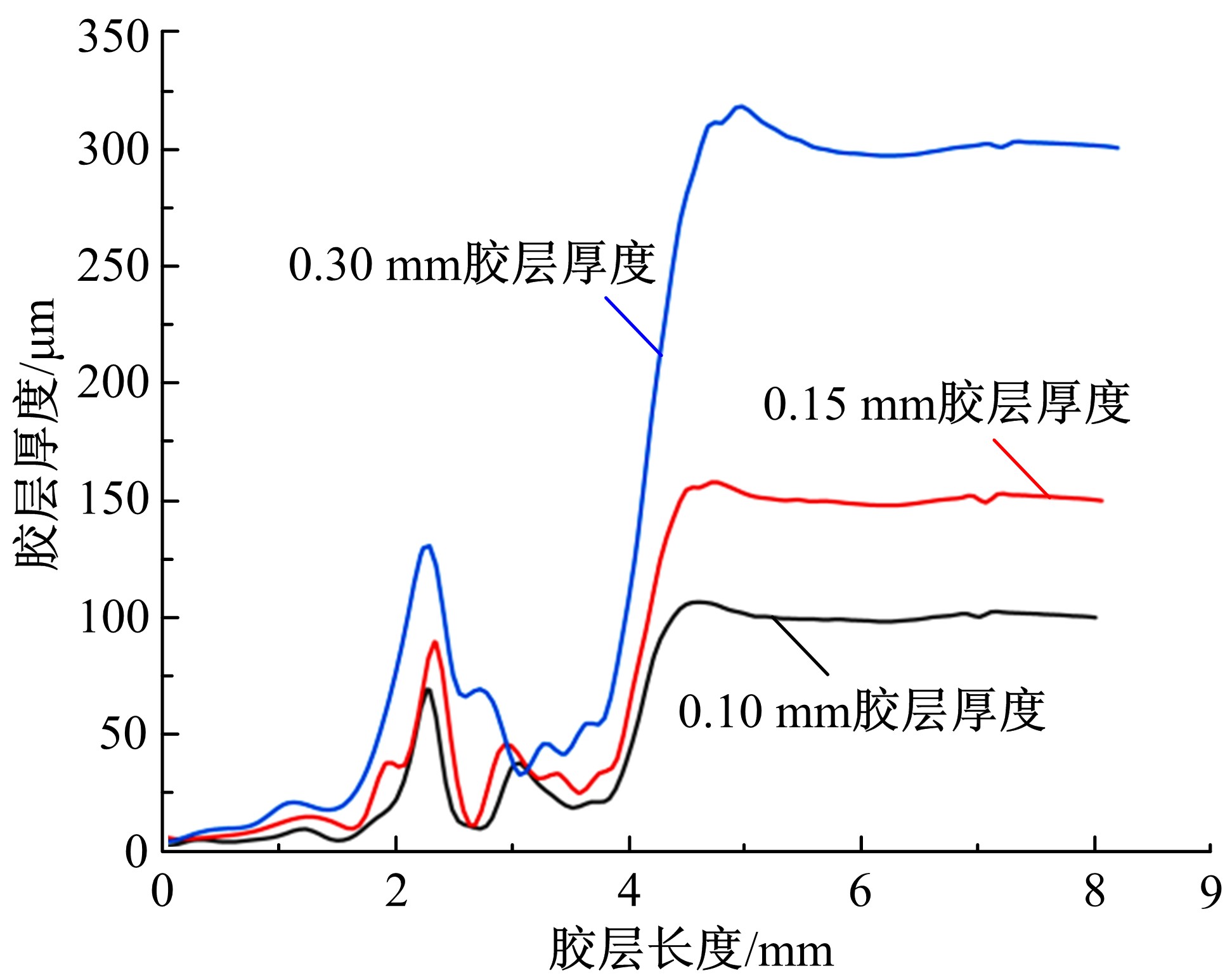

为了研究粘铆复合接头的胶层厚度对接头的成形质量和服役性能的影响,建立了无铆钉粘铆成形有限元模型,并通过实验验证有限元模型的有效性。利用有限元模型分析了接头成形后胶层的分布规律及接头成形过程中胶层的变化趋势,研究胶层厚度对接头成形的影响。结果表明:胶层厚度从接头底部中心到自锁处呈先增大后减小的趋势,其中底部圆角处胶层厚度最大;铆接过程中胶层厚度随冲头行程增加而变化;胶层厚度影响接头的自锁值与颈厚值。

中图分类号:

- TG146

| 1 | Sadowski T, Balawender T, Golewski P. Technological Aspects of Manufacturing and Numerical Modelling of Clinch-Adhesive Joints[M]. Berlin: Springer International Publishing, 2015. |

| 2 | Gómez S, Oñoro J, Pecharromán J. A simple mechanical model of a structural hybrid adhesive/riveted single lap joint[J]. International Journal of Adhesion & Adhesives, 2007, 27(4):263-267. |

| 3 | Balawender T, Sadowski T, Golewski P. Numerical analysis and experiments of the clinch-bonded joint subjected to uniaxial tension[J]. Computational Materials Science, 2012, 64:270-272. |

| 4 | Sadowski T, Kneć M, Golewski P. Experimental investigations and numerical modelling of steel adhesive joints reinforced by rivets[J]. International Journal of Adhesion & Adhesives, 2010, 30(5):338-346. |

| 5 | He X, Zhao L, Yang H, et al. Investigations of strength and energy absorption of clinched joints[J]. Computational Materials Science, 2014, 94(11):58-65. |

| 6 | 陈吉清, 邱泽鑫, 周云郊,等. 钢铝板材压-胶复合连接性能[J]. 哈尔滨工业大学学报, 2016, 48(7):169-175. |

| Chen Ji-qing, Qiu Ze-xin, Zhou Yun-jiao,et al. Performances of clinch-bonded hybrid joints between steel-aluminum sheets[J]. Journal of Harbin Institute of Technology, 2016, 48(7):169-175. | |

| 7 | 李龙, 胡平, 刘立忠. 不同胶层厚度单搭接接头剪切试验与强度预测[J]. 农业机械学报, 2010, 41(12):17-21. |

| Li Long, Hu Ping, Liu Li-zhong. Strength of adhesively bonded single lap for differential bondline thickness and tension loading prediction[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12):17-21. | |

| 8 | 杨辛. 胶焊接头在碰撞载荷下失效的模拟方法研究及其应用[D]. 北京:清华大学机械学院, 2010. |

| Yang Xin. Research and application of the simula- tion method for failure of adhesive welded joint under impact load[D]. Beijing: College of Mechanical Engineering, Tsinghua University, 2010. | |

| 9 | 庄蔚敏, 赵文增, 解东旋,等. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报:工学版, 2018,48(4): 1016-1022. |

| Zhuang Wei-min, Zhao Wen-zeng, Xie Dong-xuan, et al. Joint performance analysis on connection of ultrahigh-strength steel and aluminum alloy with hot riveting[J]. Journal of Jilin University(Engineering and Technology Edition), 2018,48(4): 1016-1022. | |

| 10 | Na Jing-xin, Mu Wen-long, Qin Guo-feng, et al. Effect of temperature on the mechanical properties of adhesively bonded basalt FRP-aluminum alloy joints in the automotive industry[J]. International Journal of Adhesion & Adhesives, 2018,85:138-148. |

| [1] | 关庆丰,姚欣雯,杨洋,张凌燕,刘迪,李晨,吕鹏. 强流脉冲电子束作用下TC4钛合金表面Cr合金层制备及性能[J]. 吉林大学学报(工学版), 2019, 49(6): 2002-2009. |

| [2] | 石舟,寇淑清. 36MnVS4裂解连杆性能分析及轻量化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1992-2001. |

| [3] | 依卓,付文智,李明哲. 双层剖分式超高压模具数值模拟及实验[J]. 吉林大学学报(工学版), 2019, 49(5): 1593-1599. |

| [4] | 谷晓燕,刘东锋,刘婧,孙大千,马会峰. 焊接能量对Cu/Al超声波焊接接头组织与性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1600-1607. |

| [5] | 李欣,孙延朋,王丹,陈军绪,谷诤巍,徐虹. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1608-1614. |

| [6] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [7] | 刘文权,盈亮,荣海,胡平. 基于损伤修正M⁃K模型的高强度钢成形极限预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1266-1271. |

| [8] | 张学广,贾明萌,刘纯国,何广忠. 基于增量控制的型材拉弯轨迹设计及有限元仿真[J]. 吉林大学学报(工学版), 2019, 49(4): 1272-1279. |

| [9] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [10] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [11] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [12] | 陈俊甫, 管志平, 杨昌海, 牛晓玲, 姜振涛, 宋玉泉. 金属棒试样拉伸和扭转试验应变范围和力学特性对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

| [13] | 梁晓波, 蔡中义, 高鹏飞. 夹芯复合板柱面成形的数值模拟及试验[J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [14] | 刘子武, 李剑峰. 叶片材料FV520B再制造熔覆层冲蚀损伤行为及评价[J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [15] | 刘纯国, 刘伟东, 邓玉山. 多点冲头主动加载路径对薄板拉形的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

|

||