吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (5): 1809-1817.doi: 10.13229/j.cnki.jdxbgxb20190577

• 计算机科学与技术 • 上一篇

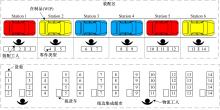

基于线边集成超市的混流装配线动态物料配送调度

- 同济大学 机械与能源工程学院, 上海 201804

Dynamic material handling scheduling for mixed⁃model assembly lines based on line⁃integrated supermarkets

- College of Mechanical Engineering, Tongji University, Shanghai 201804, China

摘要:

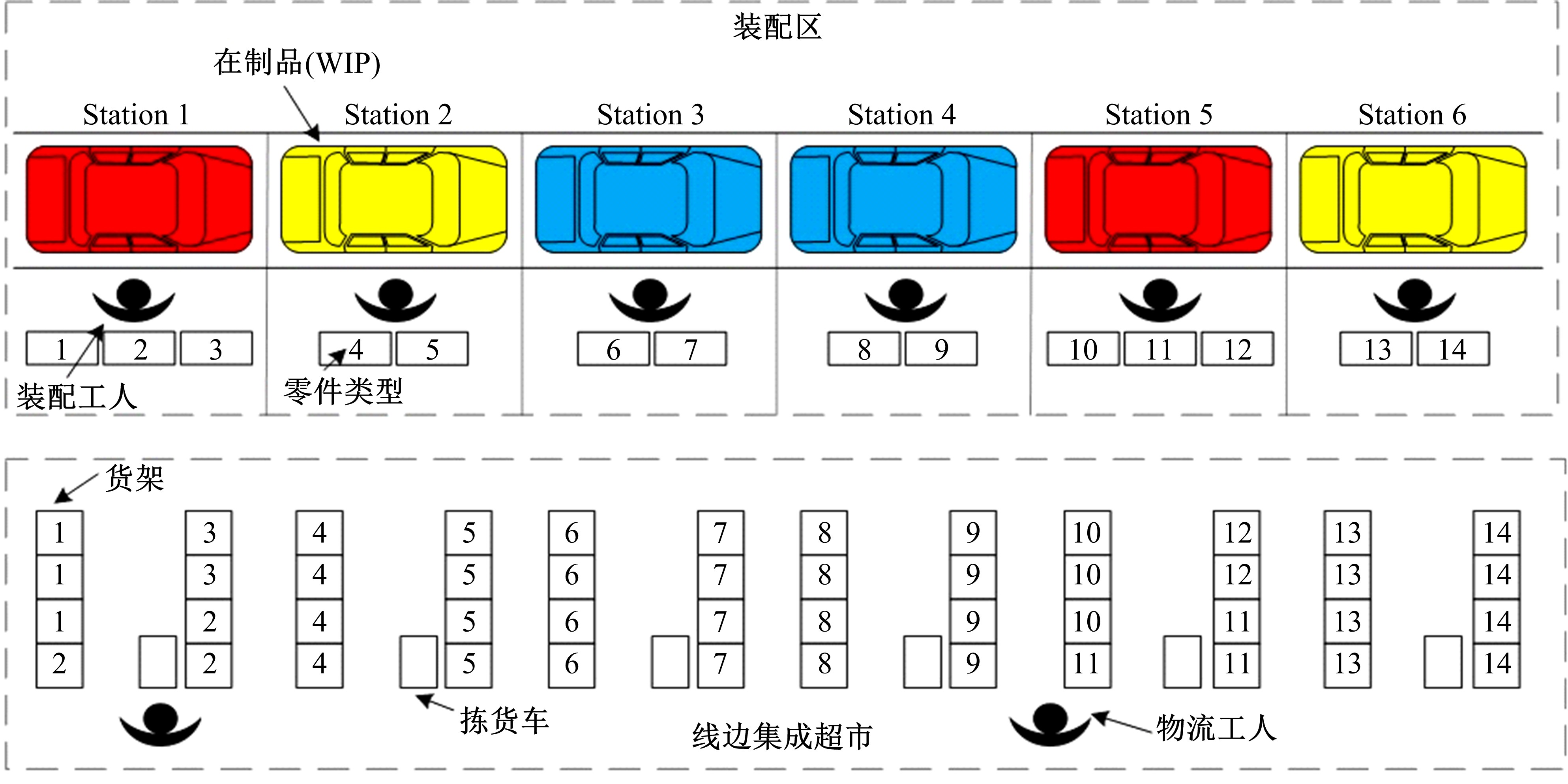

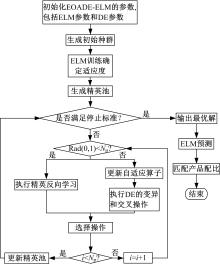

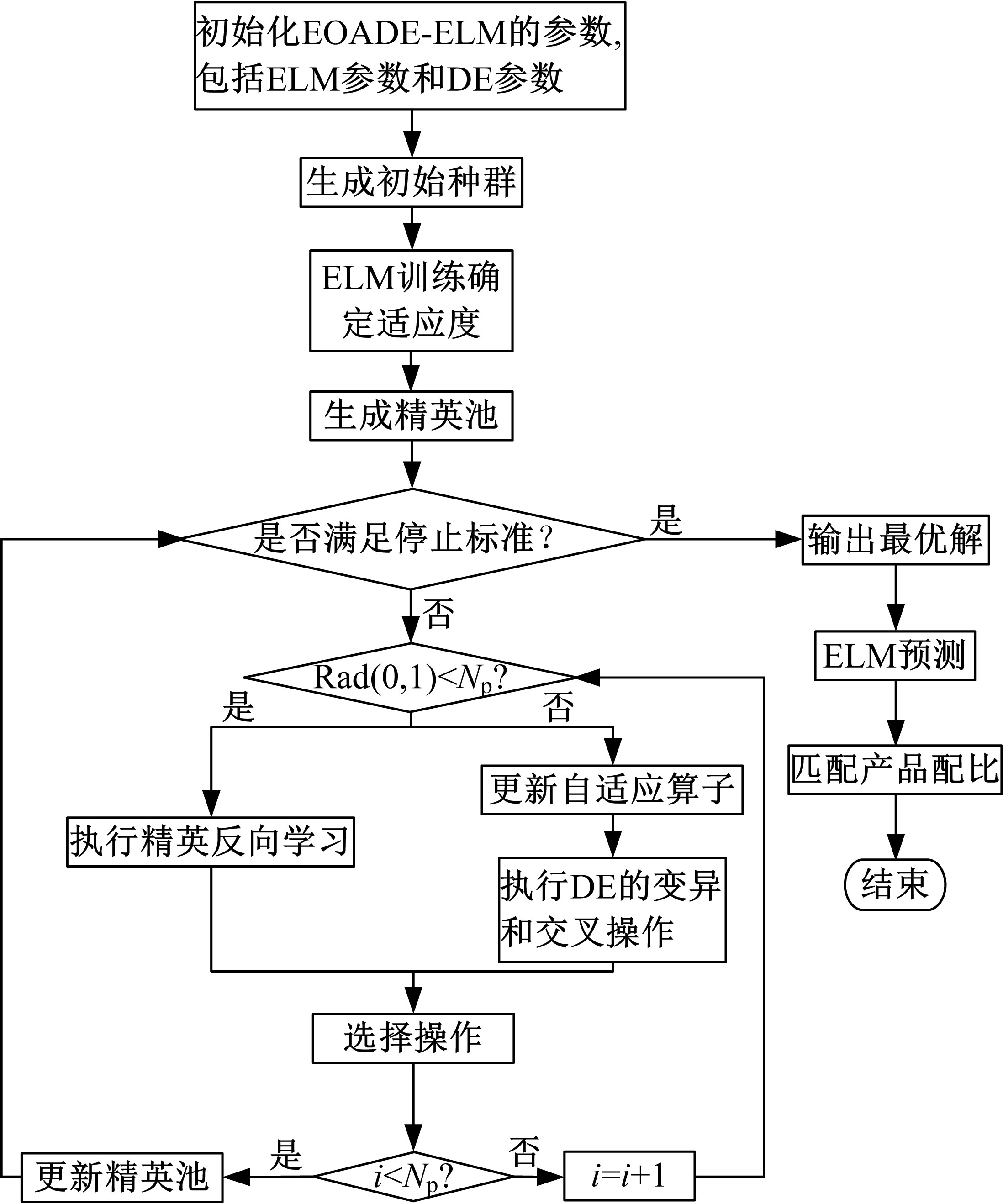

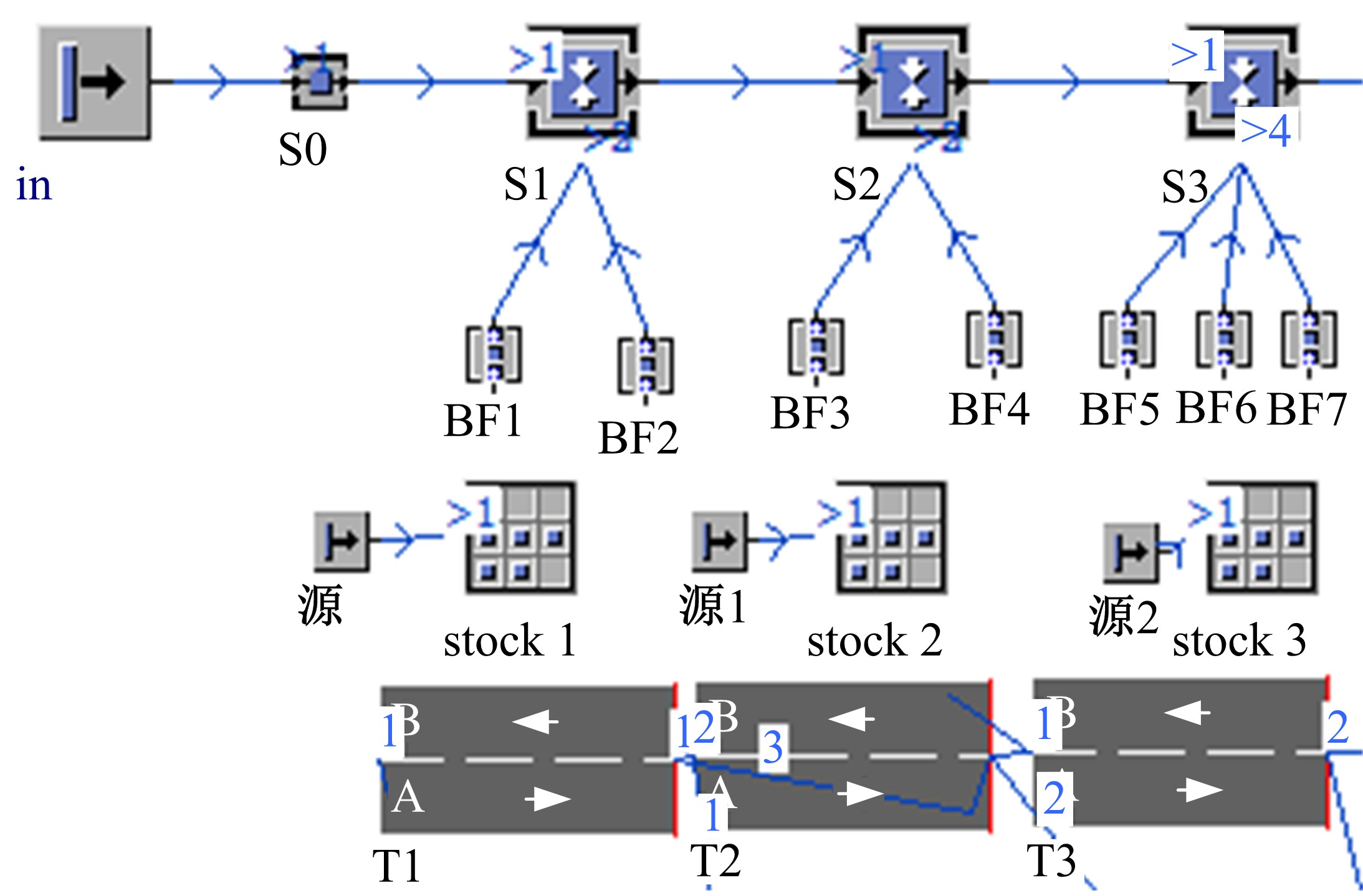

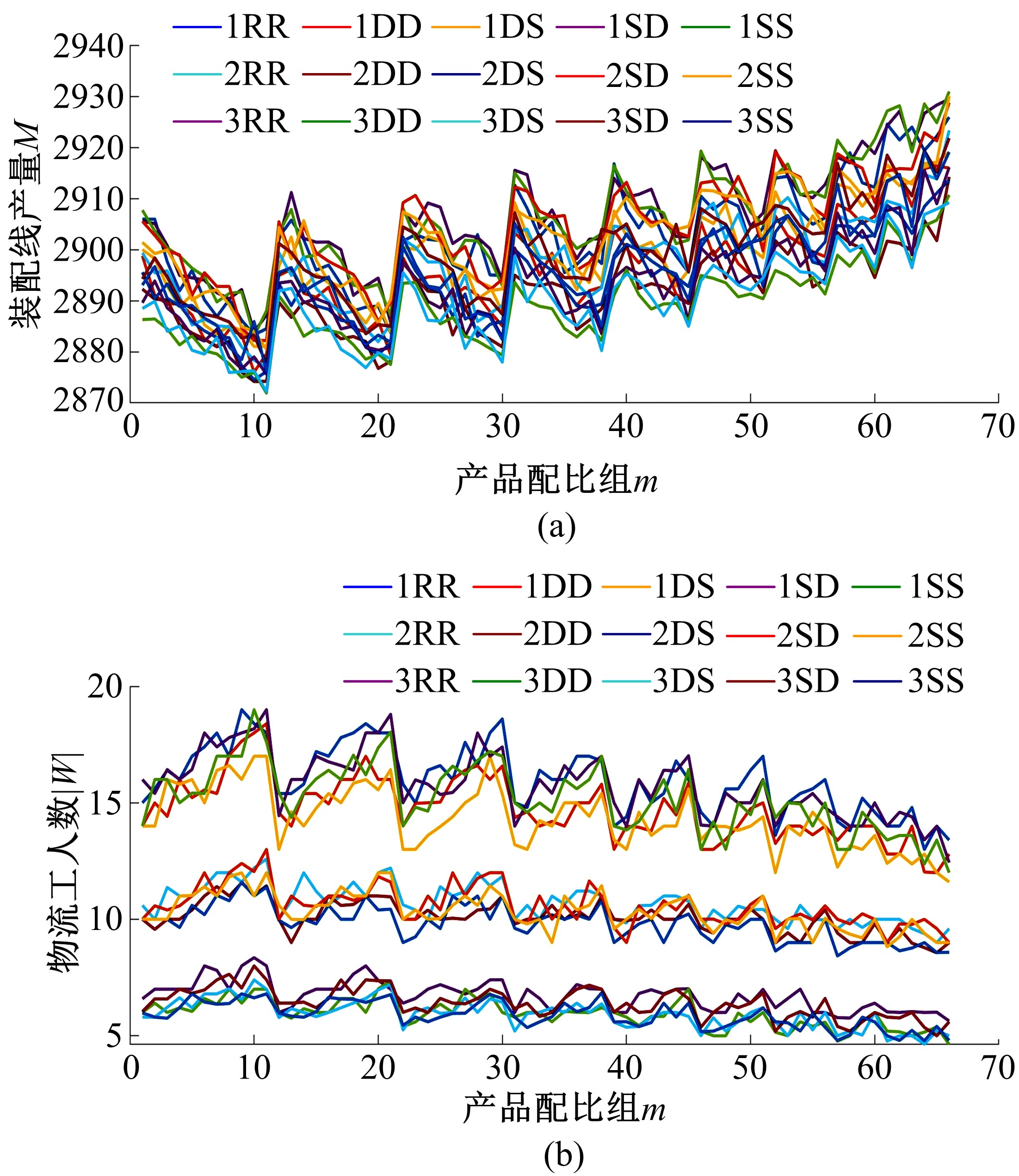

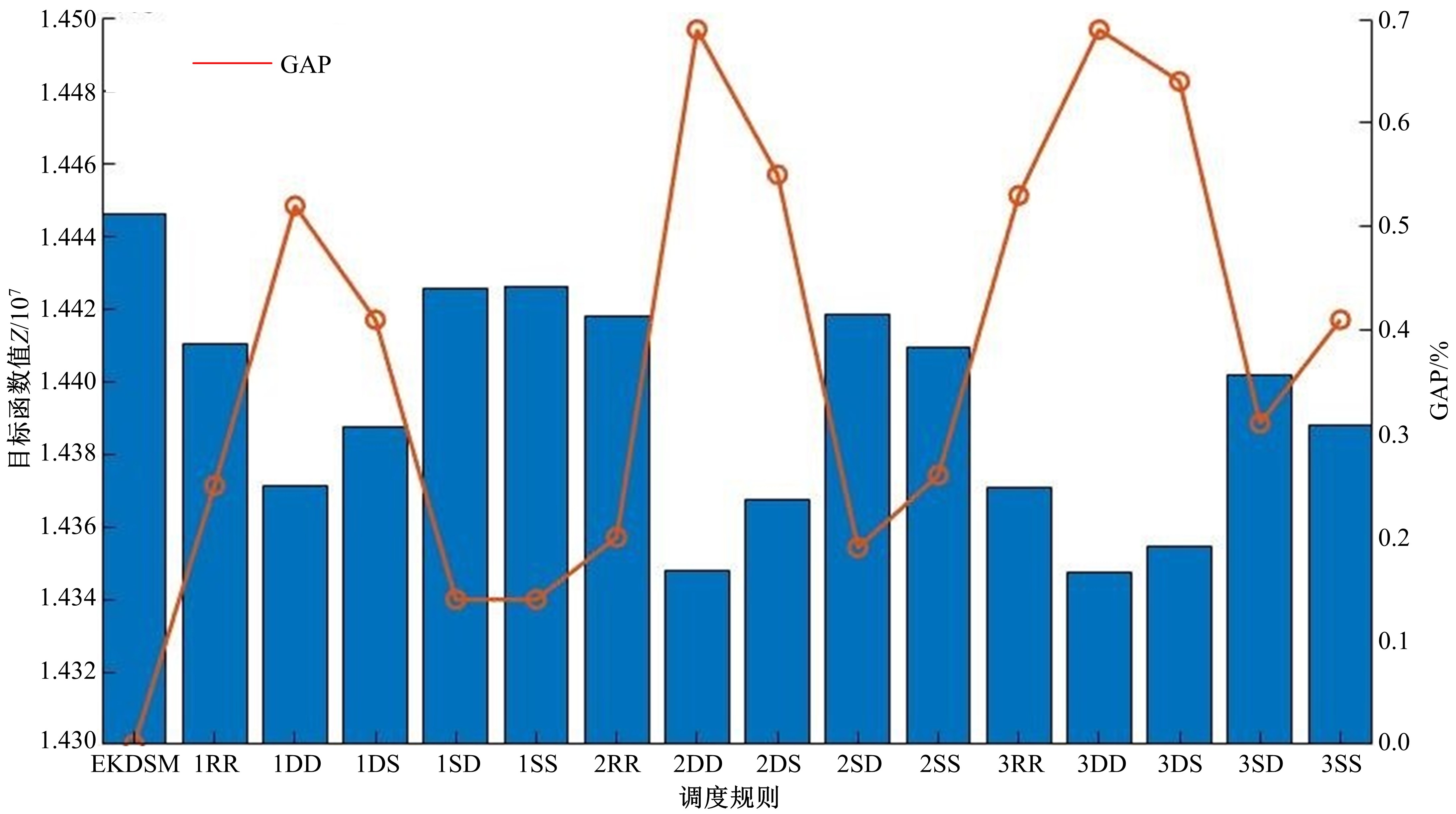

针对基于线边集成超市的混流装配线物料配送调度问题,提出了一种基于极限学习机和知识库的动态调度方法。首先,对动态物料配送调度问题进行描述,建立了数学模型,考虑设备的随机故障和装配时间的不稳定性,在产品配比和调度目标权重可变的条件下,最大化装配线产量和物流工人数的权重和;然后,构建了基于极限学习机和知识库的动态调度方法,考虑到极限学习机的缺陷,提出了基于精英反向学习的自适应差分进化算法优化极限学习机;最后,仿真实验结果证明了本文动态调度方法在动态调度过程中的可行性和有效性。

中图分类号:

- TP29

| 1 | Kilic H S, Durmusoglu M B. Advances in assembly line parts feeding policies: a literature review[J]. Assembly Automation, 2015, 35(1): 57-68. |

| 2 | Hua S Y, Johnson D J. Research issues on factors influencing the choice of kitting versus line stocking[J]. International Journal of Production Research, 2010, 48(3): 779-800. |

| 3 | Boysen N, Emde S. Scheduling the part supply of mixed-model assembly lines in line-integrated supermarkets[J]. European Journal of Operational Research, 2014, 239(3): 820-829. |

| 4 | 周炳海, 徐佳惠, 彭涛. 基于新型线边集成超市的周期性物料配送优化[J]. 吉林大学学报: 工学版, 2018, 48(2): 588-595. |

| Zhou Bing-hai, Xu Jia-hui, Peng Tao. Optimization of cyclic part feeding with novel line-integrated supermarket[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(2): 588-595. | |

| 5 | 周炳海, 沈诚怡. 基于改进齐套零件策略的车辆装配线新型物料配送调度[J]. 系统工程理论与实践, 2018, 38(7): 1870-1876. |

| Zhou Bing-hai, Shen Cheng-yi. A new part supply scheduling method of automotive assembly lines based on improved kitting strategy[J]. Systems Engineering-Theory & Practice, 2018, 38(7): 1870-1876. | |

| 6 | Dong J T, Zhang L X, Xiao T Y, et al. A dynamic delivery strategy for material handling in mixed-model assembly lines using decentralized supermarkets[J]. International Journal of Modeling, Simulation & Scientific Computing, 2015, 6(4): 1-19. |

| 7 | 刘明周, 卢佳, 葛茂根, 等. 基于实时工况的动态物料搬运路径规划[J]. 合肥工业大学学报: 自然科学版, 2008, 31(12): 1948-1952. |

| Liu Ming-zhou, Lu Jia, Ge Mao-gen, et al. Dynamic material handling route planning based on real-time operation conditions[J]. Journal of Hefei University of Technology(Natural Science), 2008, 31(12): 1948-1952. | |

| 8 | Gola A, Klosowski G. Development of computer-controlled material handling model by means of fuzzy logic and genetic algorithms[J]. Neurocomputing, 2019, 338: 381-392. |

| 9 | Rajendran C, Holthaus O. A comparative study of dispatching rules in dynamic flowshops and jobshops[J]. European Journal of Operational Research, 1999, 116(1): 156-170. |

| 10 | Chen C, Xi L F, Zhou B H, et al. A multiple-criteria real-time scheduling approach for multiple-load carriers subject to LIFO loading constraints[J]. International Journal of Production Research, 2011, 49(16): 4787-4806. |

| 11 | Chen R M. Reducing network and computation complexities in neural based real-time scheduling scheme[J]. Applied Mathematics and Computation, 2011, 217(13): 6379-6389. |

| 12 | 蒋舒宇. 基于Kohonen神经网络的晶圆光刻流程动态调度方法[D]. 上海: 上海交通大学机械与动力工程学院, 2009. |

| Jiang Shu-yu. Dynamic scheduling of photolithography process based on kohonen neural network[D]. Shanghai: School of Mechanical and Power Engineering, Shanghai Jiaotong University, 2009. |

| [1] | 赵宏伟,刘晓涵,张媛,范丽丽,龙曼丽,臧雪柏. 基于关键点注意力和通道注意力的服装分类算法[J]. 吉林大学学报(工学版), 2020, 50(5): 1765-1770. |

| [2] | 车翔玖,董有政. 基于多尺度信息融合的图像识别改进算法[J]. 吉林大学学报(工学版), 2020, 50(5): 1747-1754. |

| [3] | 刘洲洲,尹文晓,张倩昀,彭寒. 基于离散优化算法和机器学习的传感云入侵检测[J]. 吉林大学学报(工学版), 2020, 50(2): 692-702. |

| [4] | 王晓辉,吴禄慎,陈华伟. 基于法向量距离分类的散乱点云数据去噪[J]. 吉林大学学报(工学版), 2020, 50(1): 278-288. |

| [5] | 张笑东,夏筱筠,吕海峰,公绪超,廉梦佳. 大数据网络并行计算环境中生理数据流动态负载均衡[J]. 吉林大学学报(工学版), 2020, 50(1): 247-254. |

| [6] | 陈蔓,钟勇,李振东. 隐低秩结合低秩表示的多聚焦图像融合[J]. 吉林大学学报(工学版), 2020, 50(1): 297-305. |

| [7] | 金顺福,郄修尘,武海星,霍占强. 基于新型休眠模式的云虚拟机分簇调度策略及性能优化[J]. 吉林大学学报(工学版), 2020, 50(1): 237-246. |

| [8] | 邓钧忆,刘衍珩,冯时,赵荣村,王健. 基于GSPN的Ad⁃hoc网络性能和安全平衡[J]. 吉林大学学报(工学版), 2020, 50(1): 255-261. |

| [9] | 王铁君,王维兰. 基于本体的唐卡图像标注方法[J]. 吉林大学学报(工学版), 2020, 50(1): 289-296. |

| [10] | 李雄飞,王婧,张小利,范铁虎. 基于SVM和窗口梯度的多焦距图像融合方法[J]. 吉林大学学报(工学版), 2020, 50(1): 227-236. |

| [11] | 王洪雁,邱贺磊,郑佳,裴炳南. 光照变化下基于低秩稀疏表示的视觉跟踪方法[J]. 吉林大学学报(工学版), 2020, 50(1): 268-277. |

| [12] | 周柚,杨森,李大琳,吴春国,王岩,王康平. 基于现场可编程门电路的人脸检测识别加速平台[J]. 吉林大学学报(工学版), 2019, 49(6): 2051-2057. |

| [13] | 赵宏伟,王鹏,范丽丽,胡黄水,刘萍萍. 相似性保持实例检索方法[J]. 吉林大学学报(工学版), 2019, 49(6): 2045-2050. |

| [14] | 沈军,周晓,吉祖勤. 服务动态扩展网络及其结点系统模型的实现[J]. 吉林大学学报(工学版), 2019, 49(6): 2058-2068. |

| [15] | 周炳海,吴琼. 考虑工具和空间约束的机器人装配线平衡优化[J]. 吉林大学学报(工学版), 2019, 49(6): 2069-2075. |

|

||