吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (2): 583-596.doi: 10.13229/j.cnki.jdxbgxb20200018

• 交通运输工程·土木工程 • 上一篇

多车桥梁动态称重算法

宫亚峰1( ),宋加祥1,谭国金1(

),宋加祥1,谭国金1( ),毕海鹏1,刘洋2,3,4,单承新5

),毕海鹏1,刘洋2,3,4,单承新5

- 1.吉林大学 交通学院,长春 130022

2.中交第二航务工程局有限公司,武汉 430040

3.长大桥梁建设施工技术交通行业重点实验室,武汉 431400

4.交通运输行业交通基础设施智能制造研发中心,武汉 431400

5.长春空港翔悦投资有限公司,长春 130000

Multi⁃vehicle bridge weigh⁃in⁃motion algorithm

Ya-feng GONG1( ),Jia-xiang SONG1,Guo-jin TAN1(

),Jia-xiang SONG1,Guo-jin TAN1( ),Hai-peng BI1,Yang LIU2,3,4,Cheng-xin SHAN5

),Hai-peng BI1,Yang LIU2,3,4,Cheng-xin SHAN5

- 1.College of Transportation,Jilin University,Changchun 130022,China

2.China Communications Second Navigation Engineering Bureau Co. ,Ltd. ,Wuhan 430040,China

3.Changda Bridge Construction Technology Transportation Industry Key Laboratory,Wuhan 431400,China

4.Transportation Infrastructure Intelligent Manufacturing R&D Center for Transportation Infrastructure,Wuhan 431400,China

5.Changchun Airport Xiangyue Investment Co. ,Ltd. ,Changchun 130000,China

摘要:

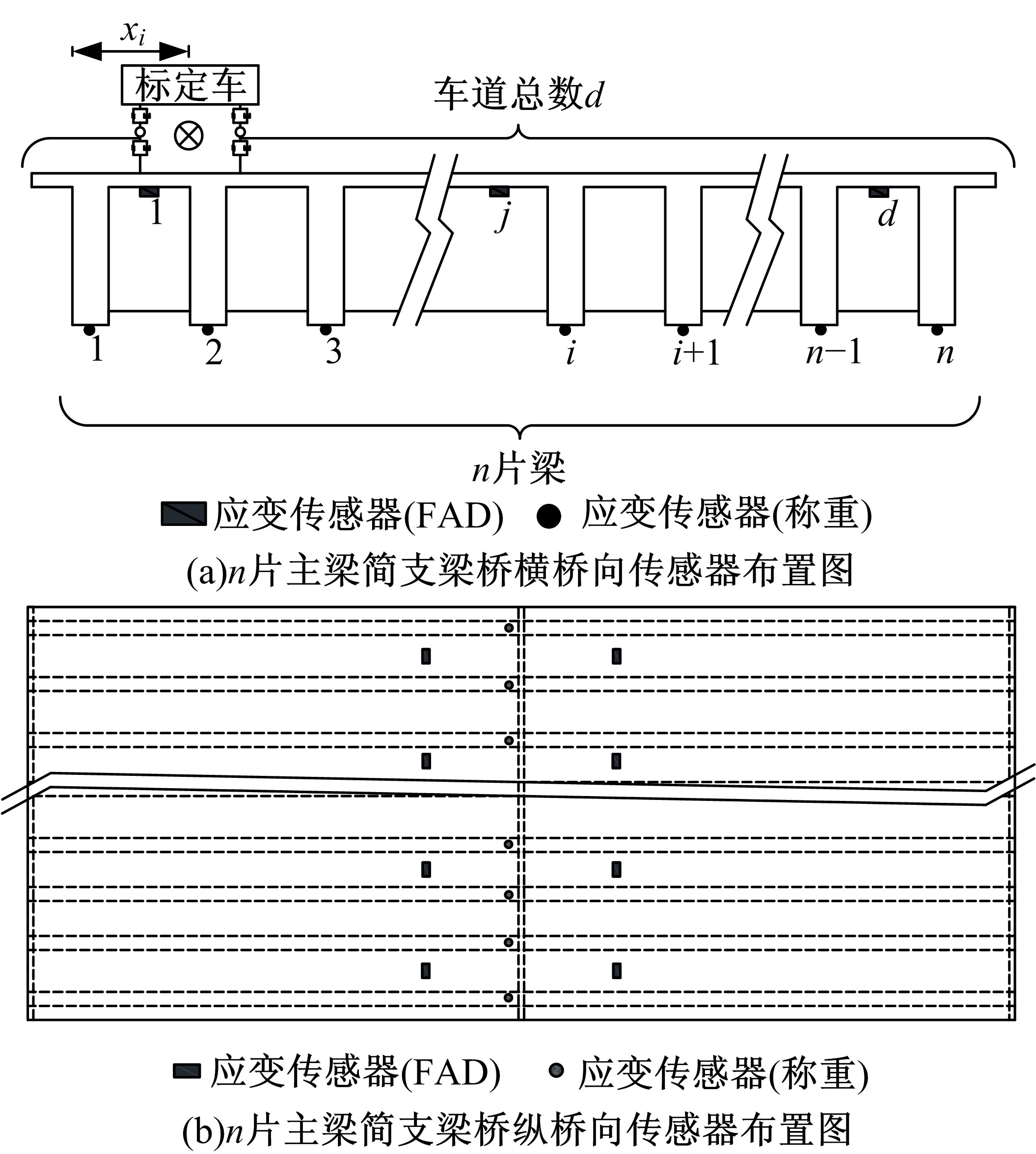

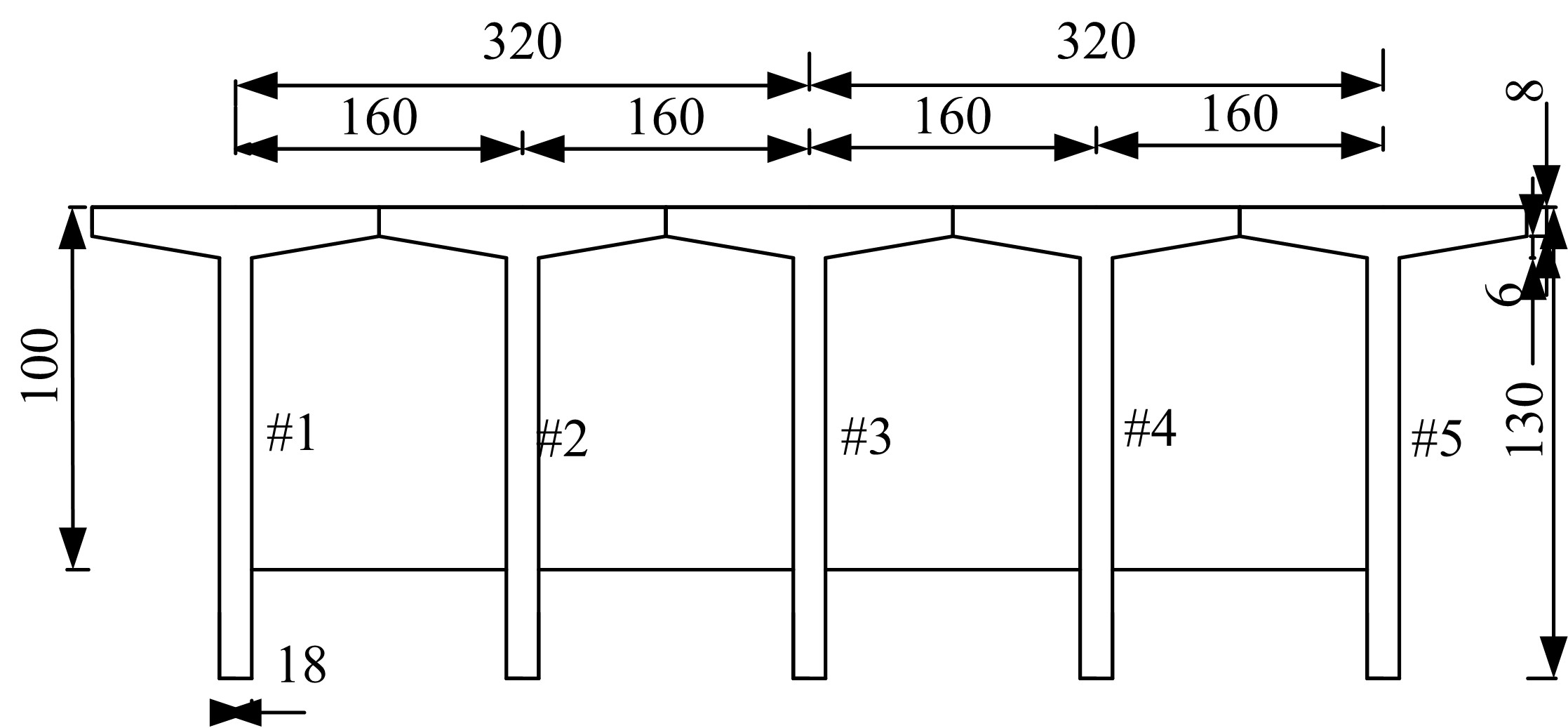

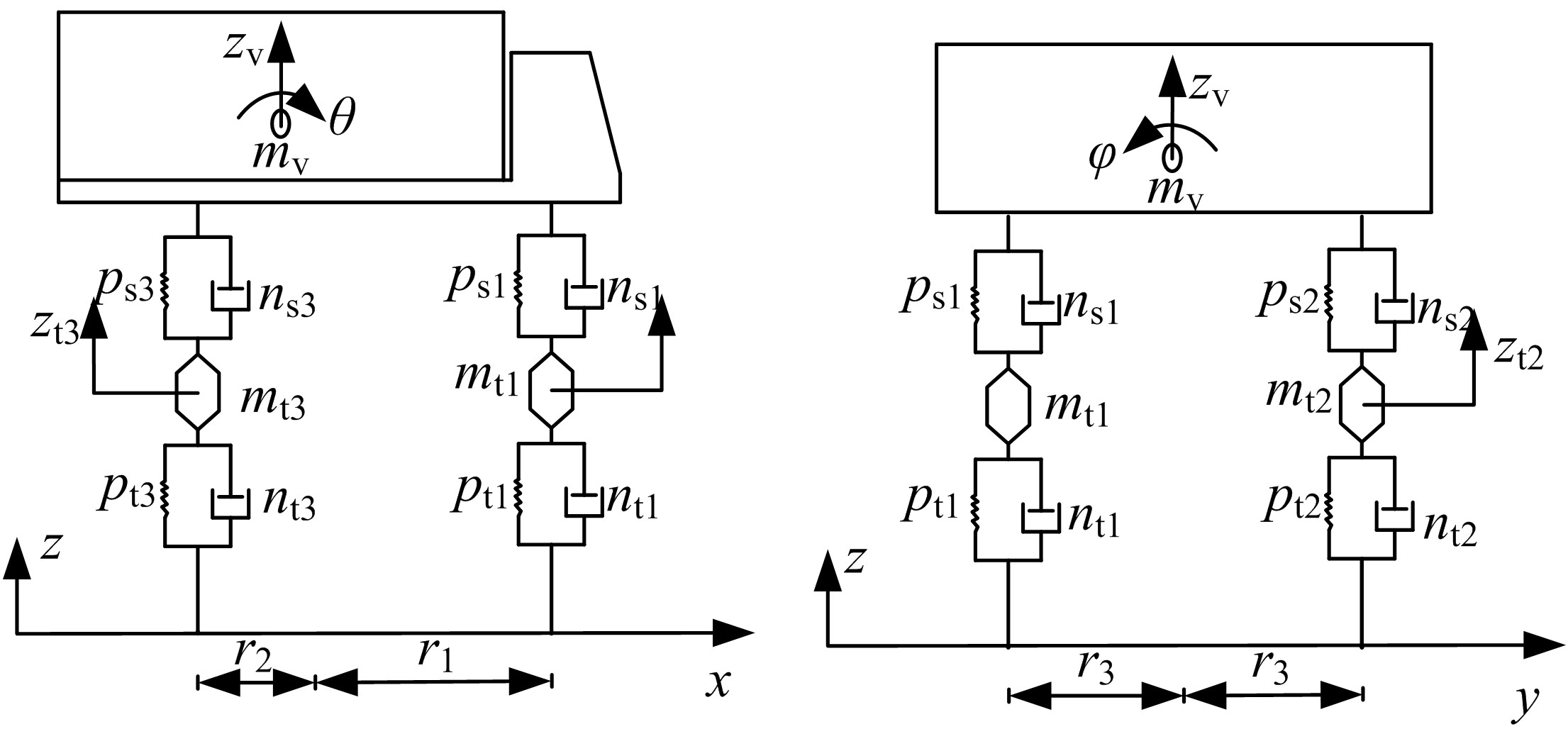

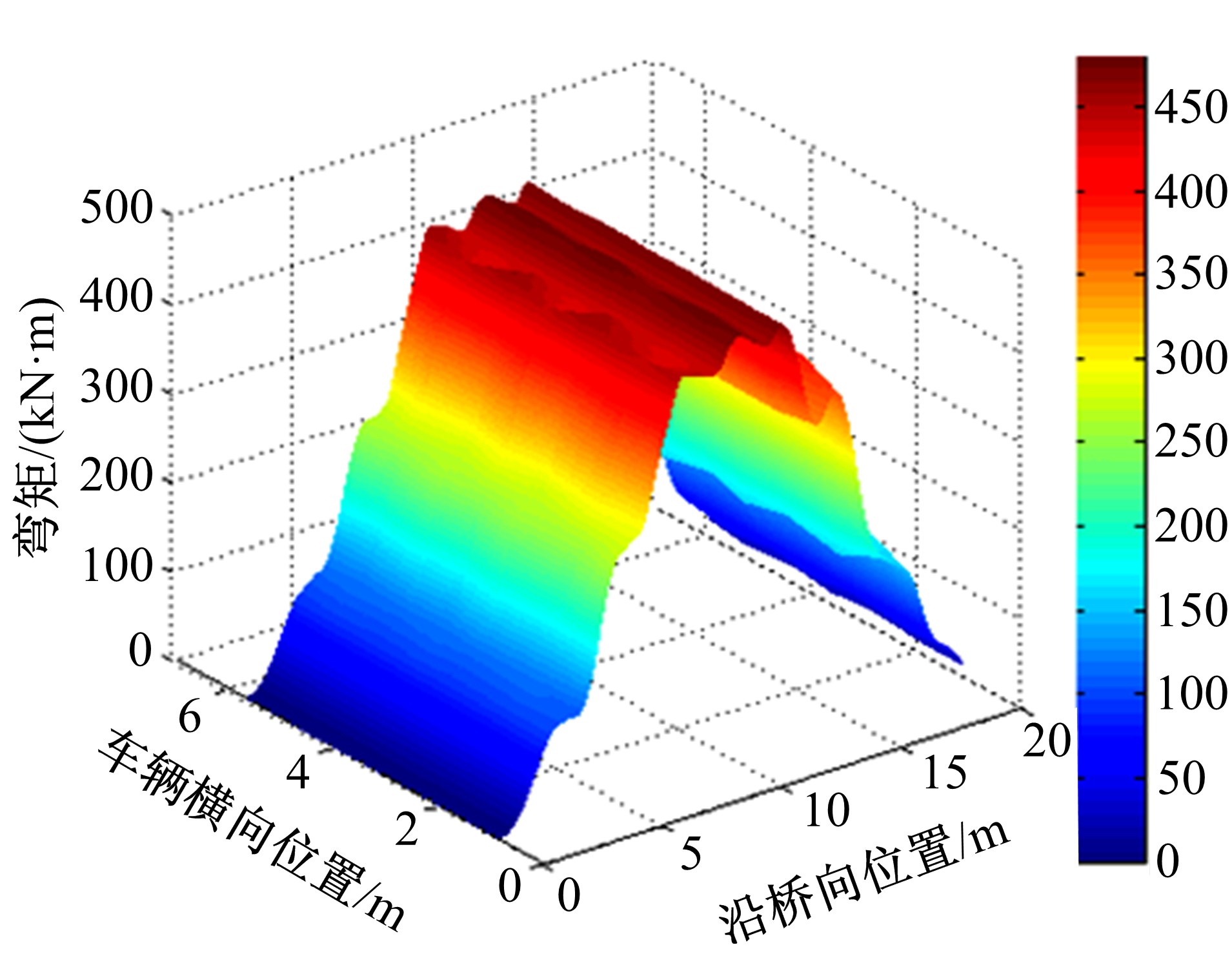

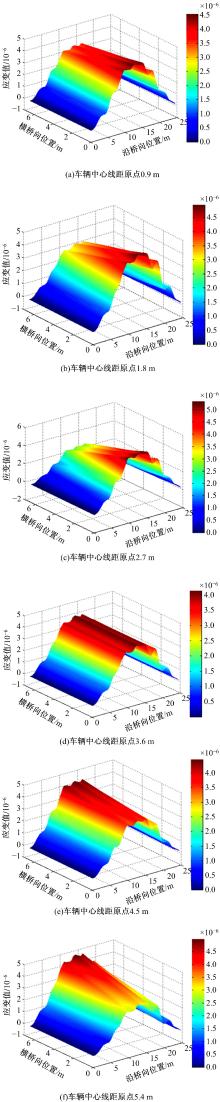

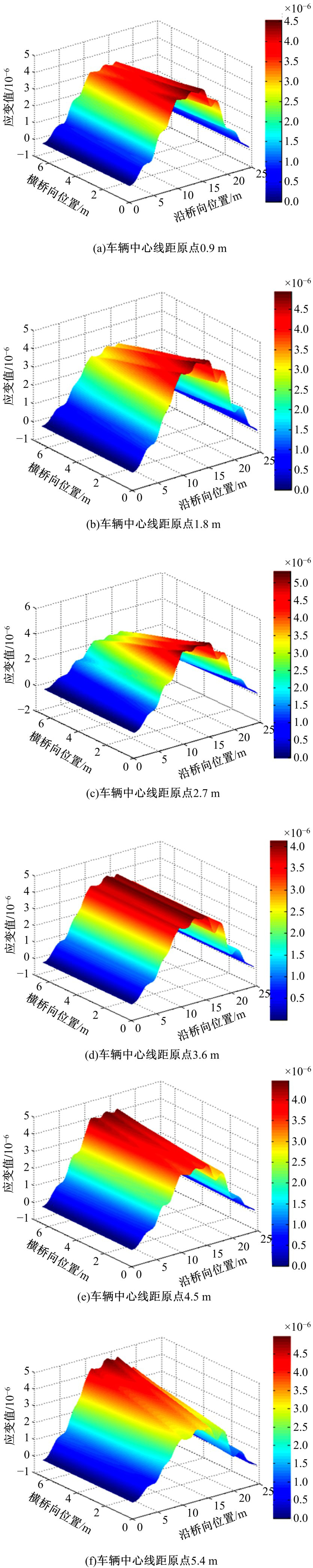

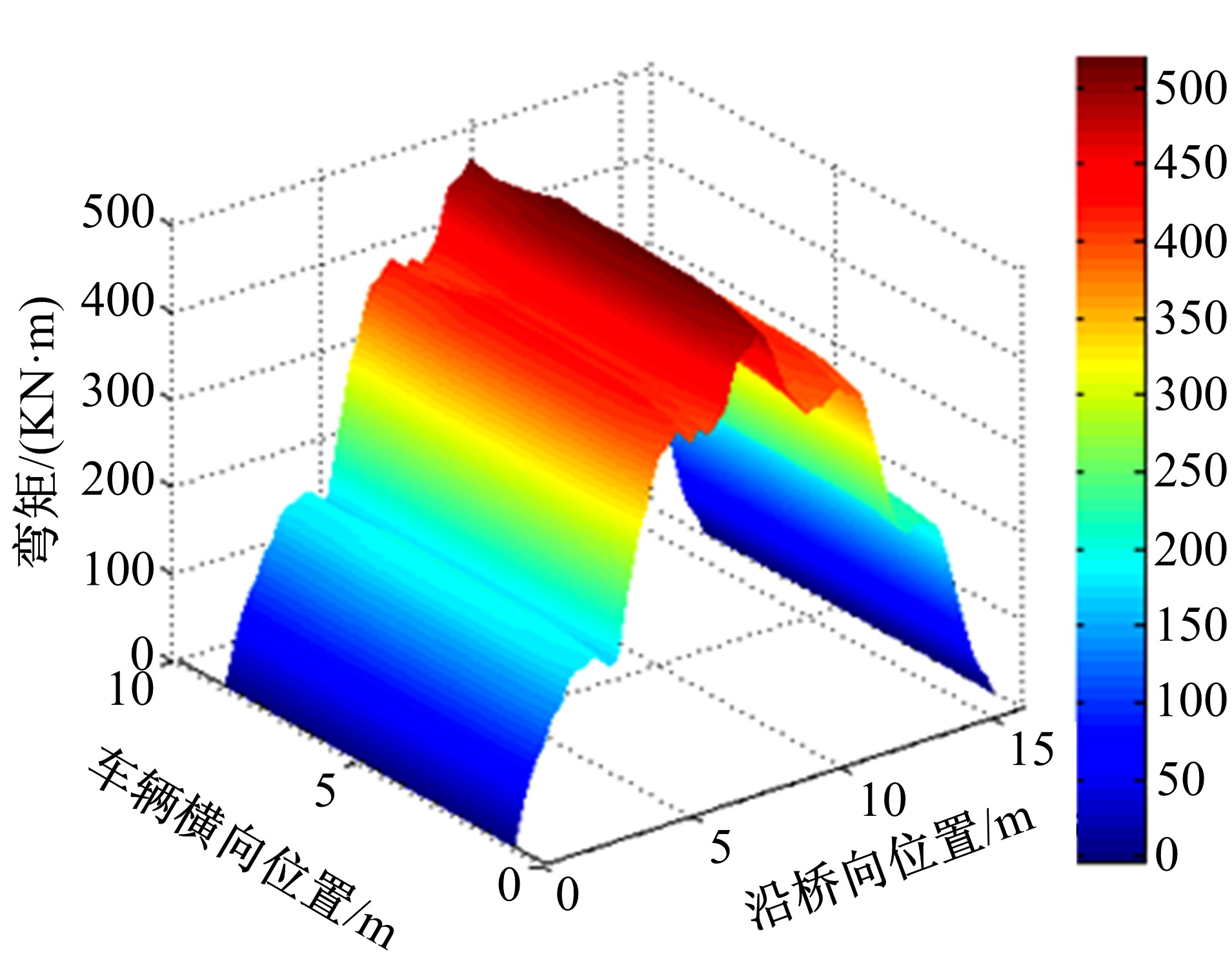

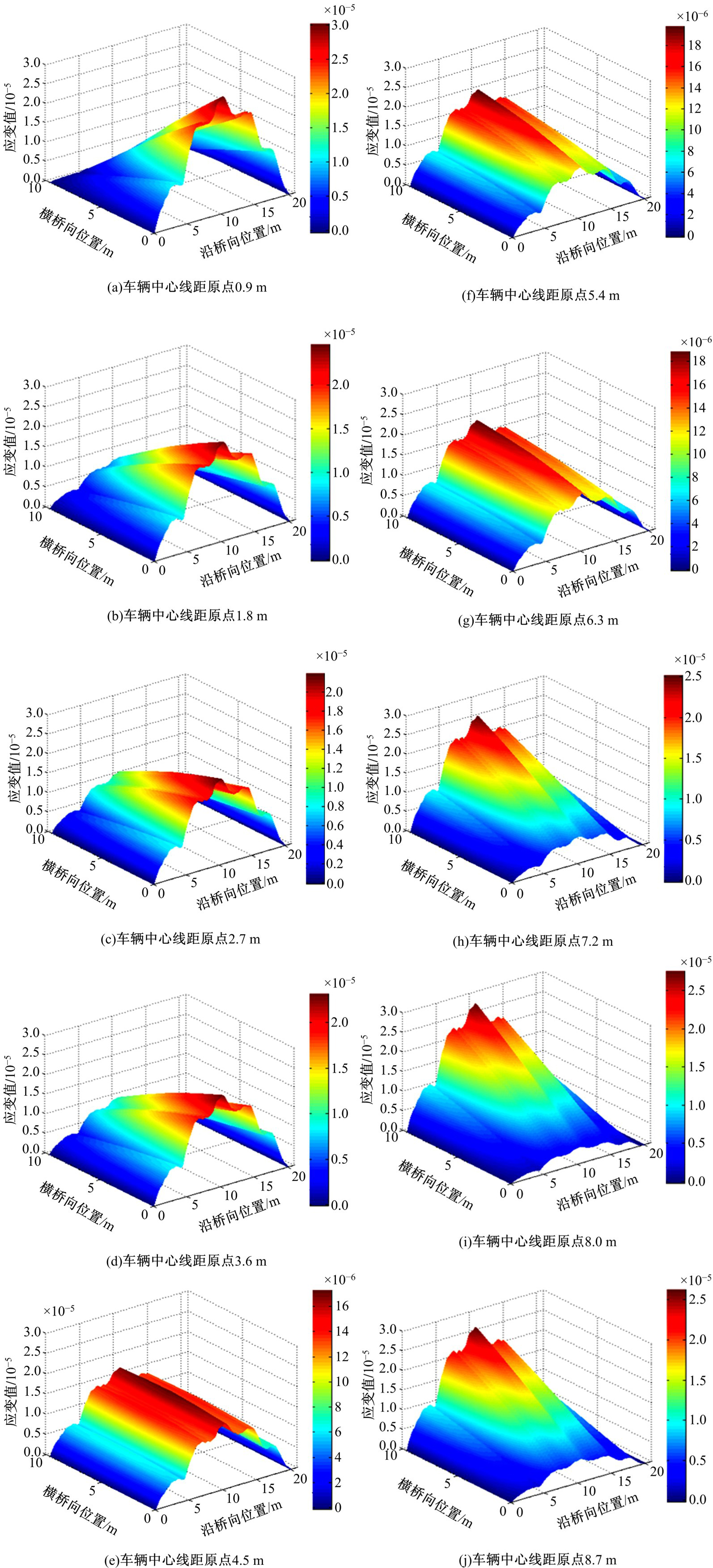

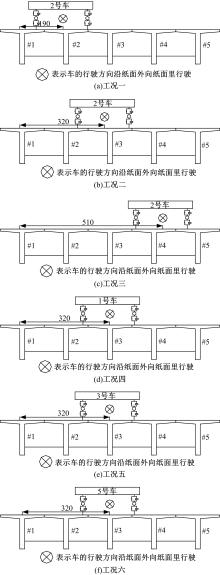

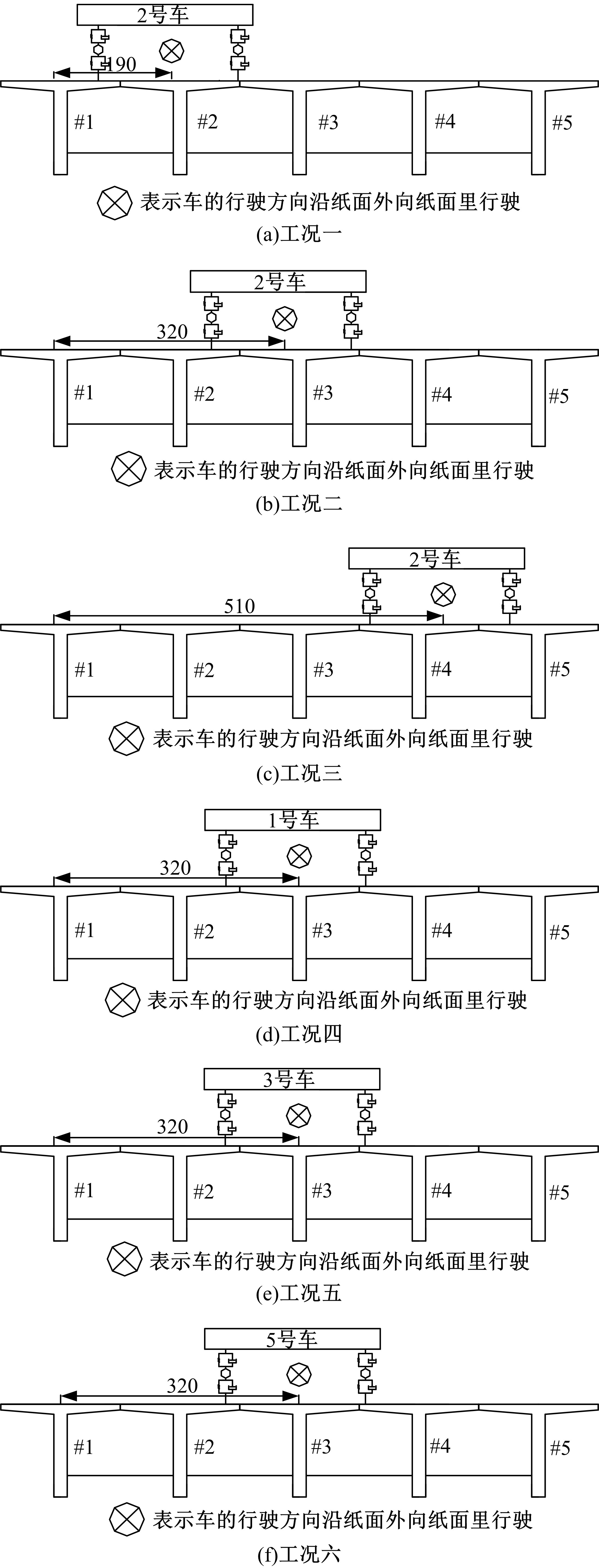

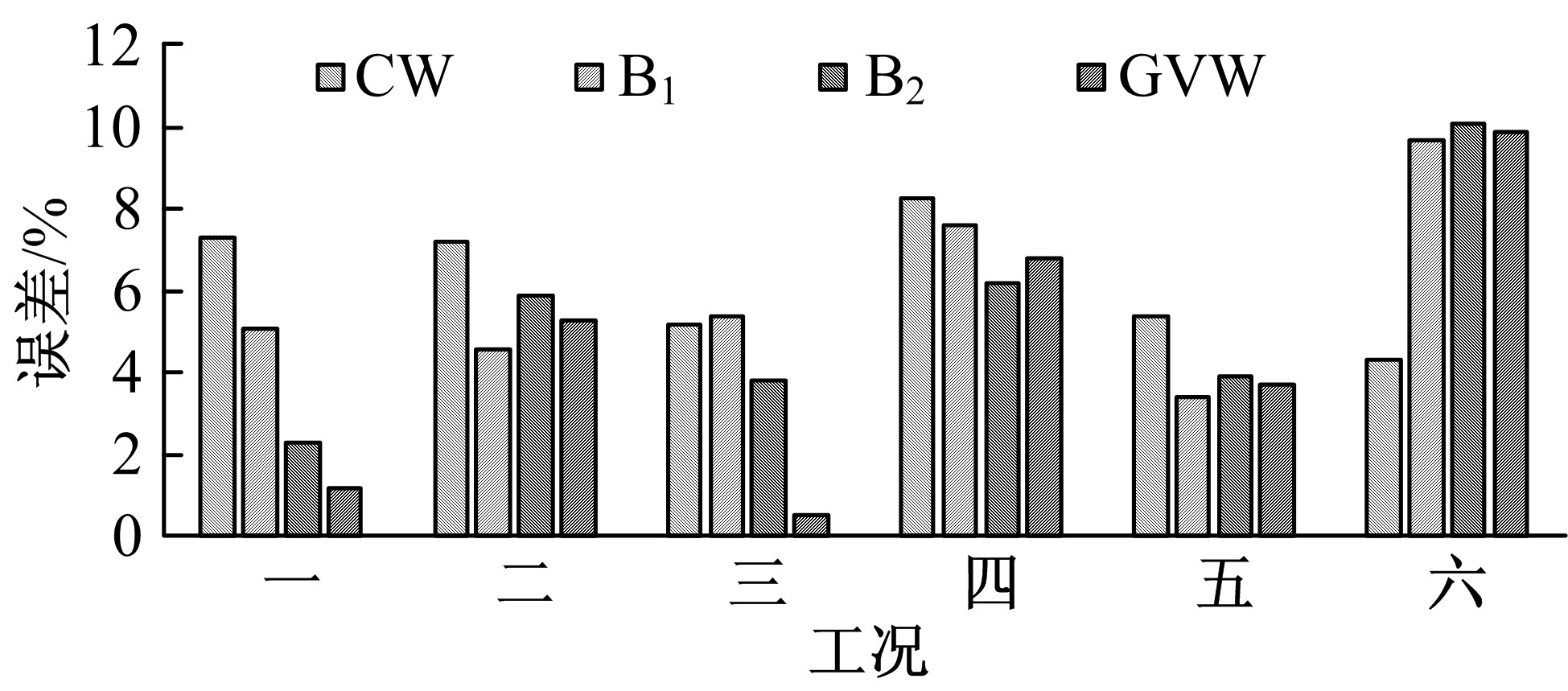

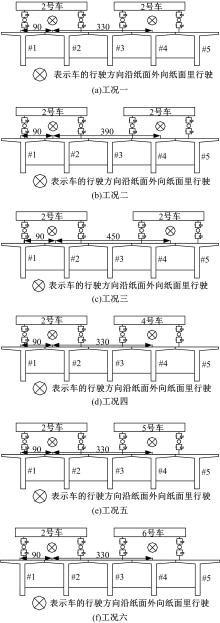

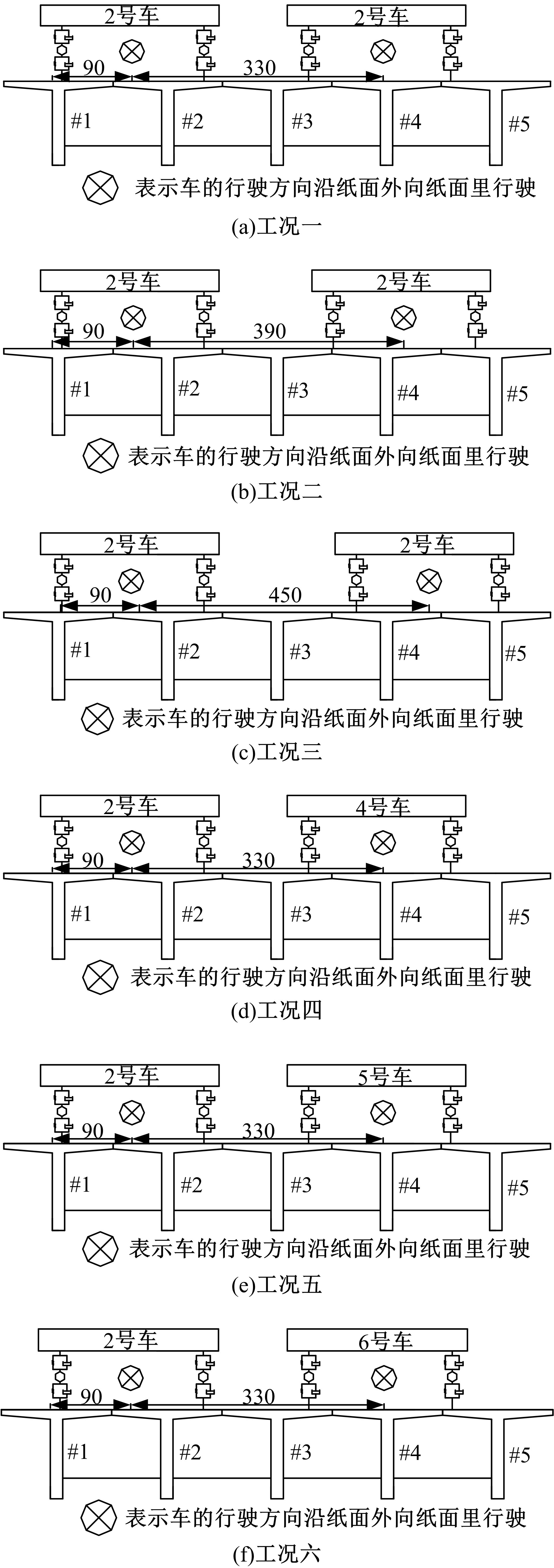

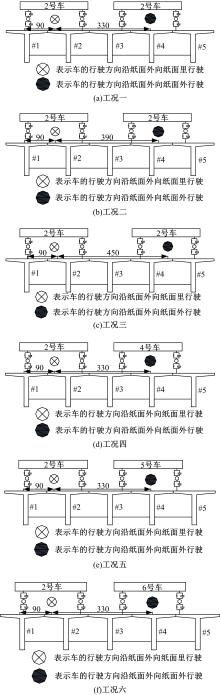

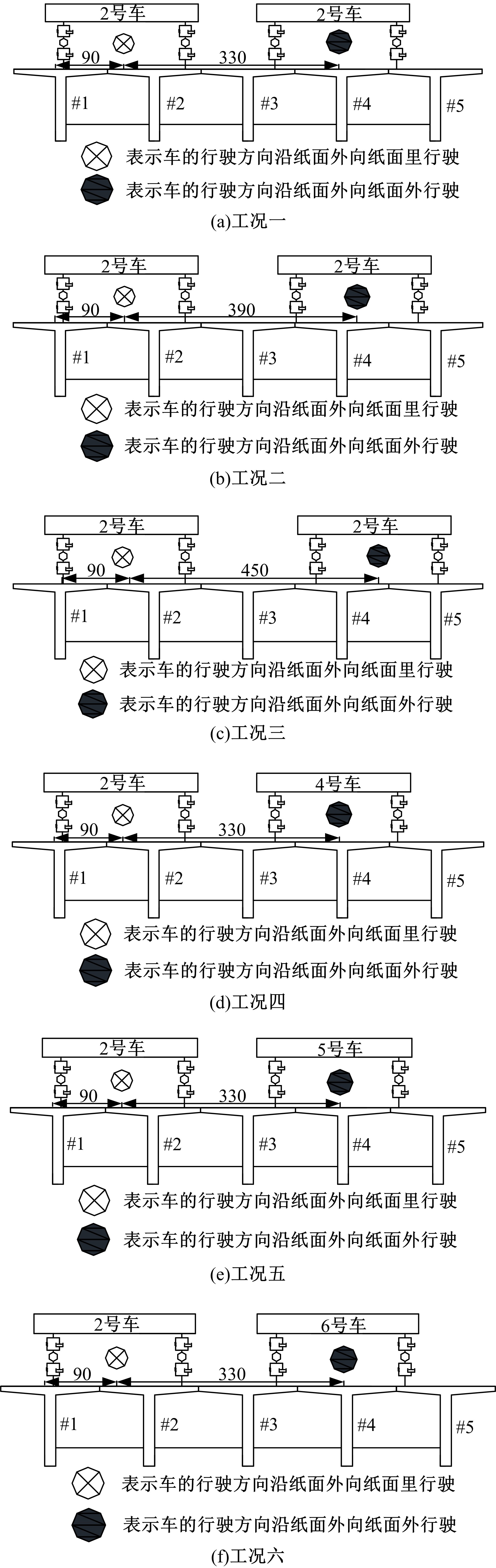

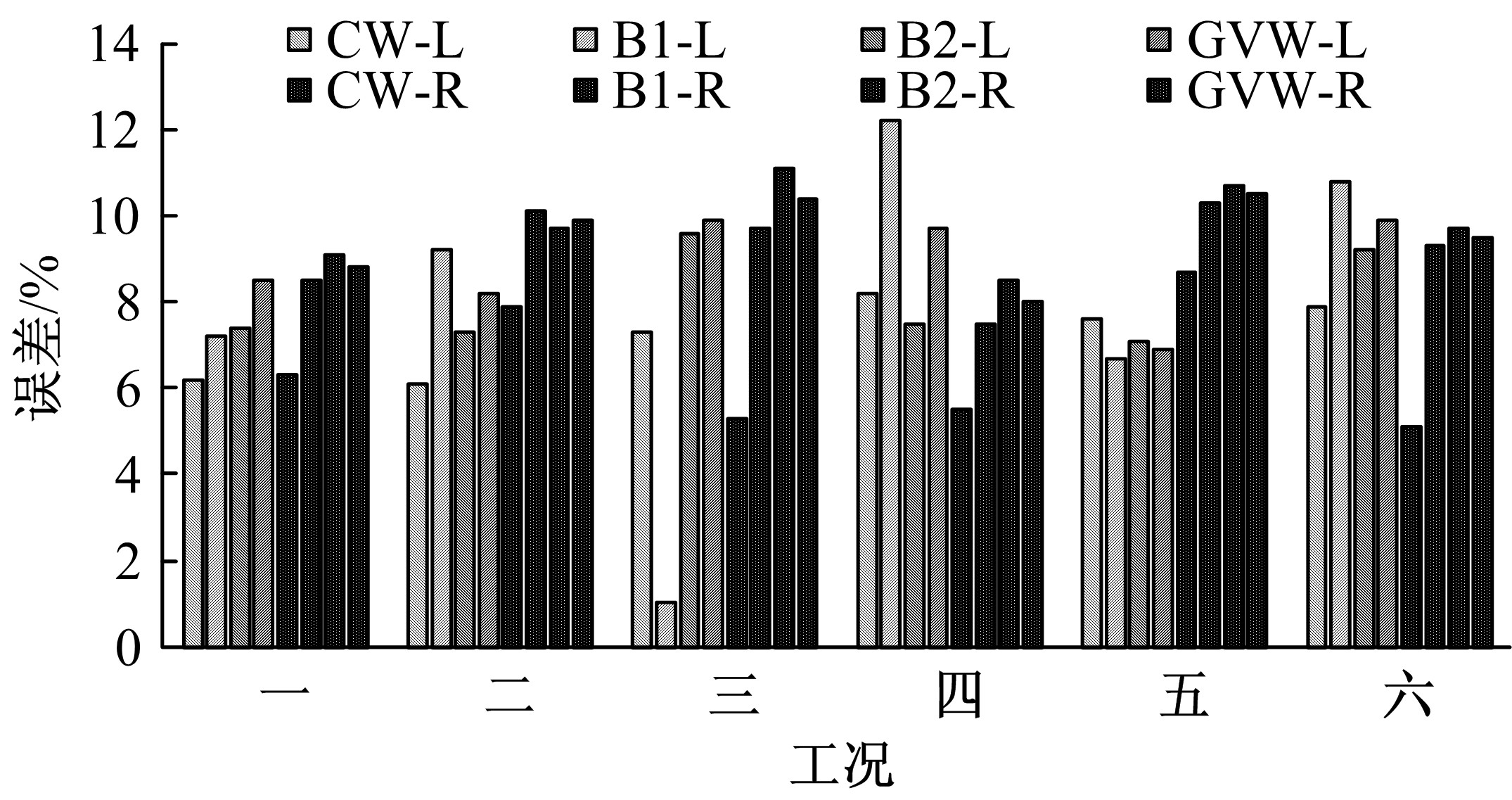

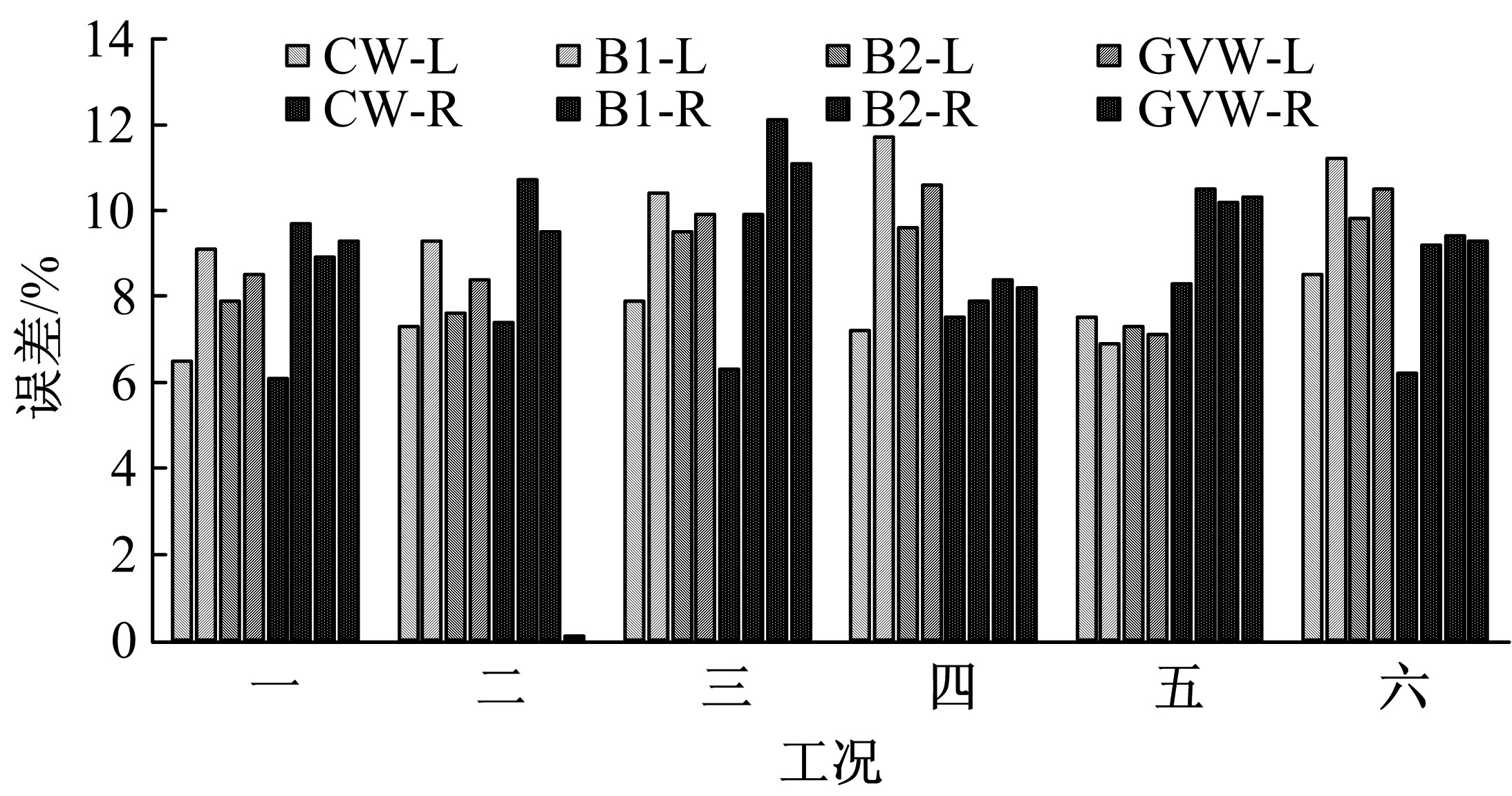

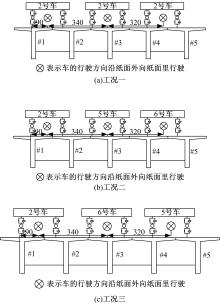

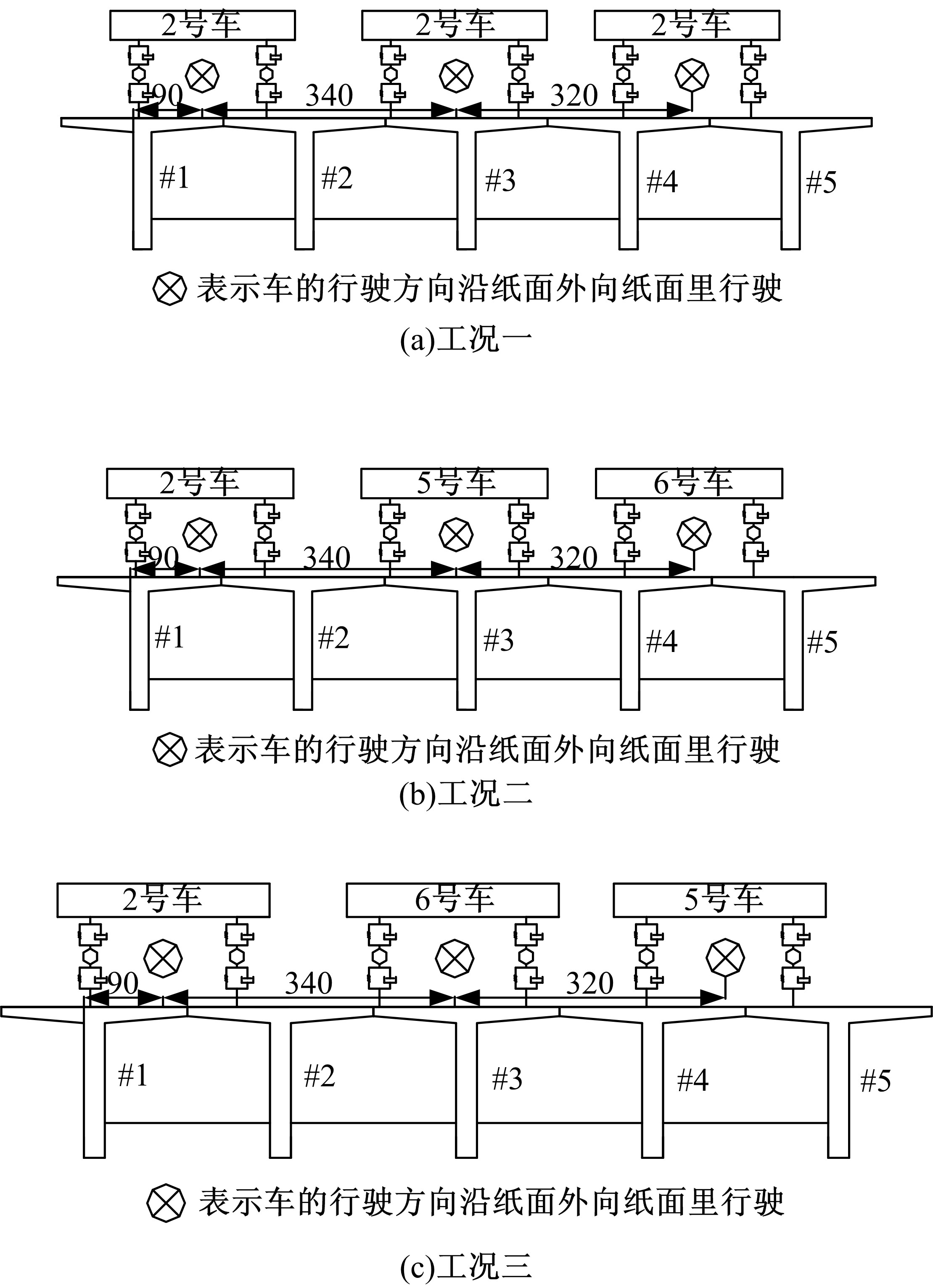

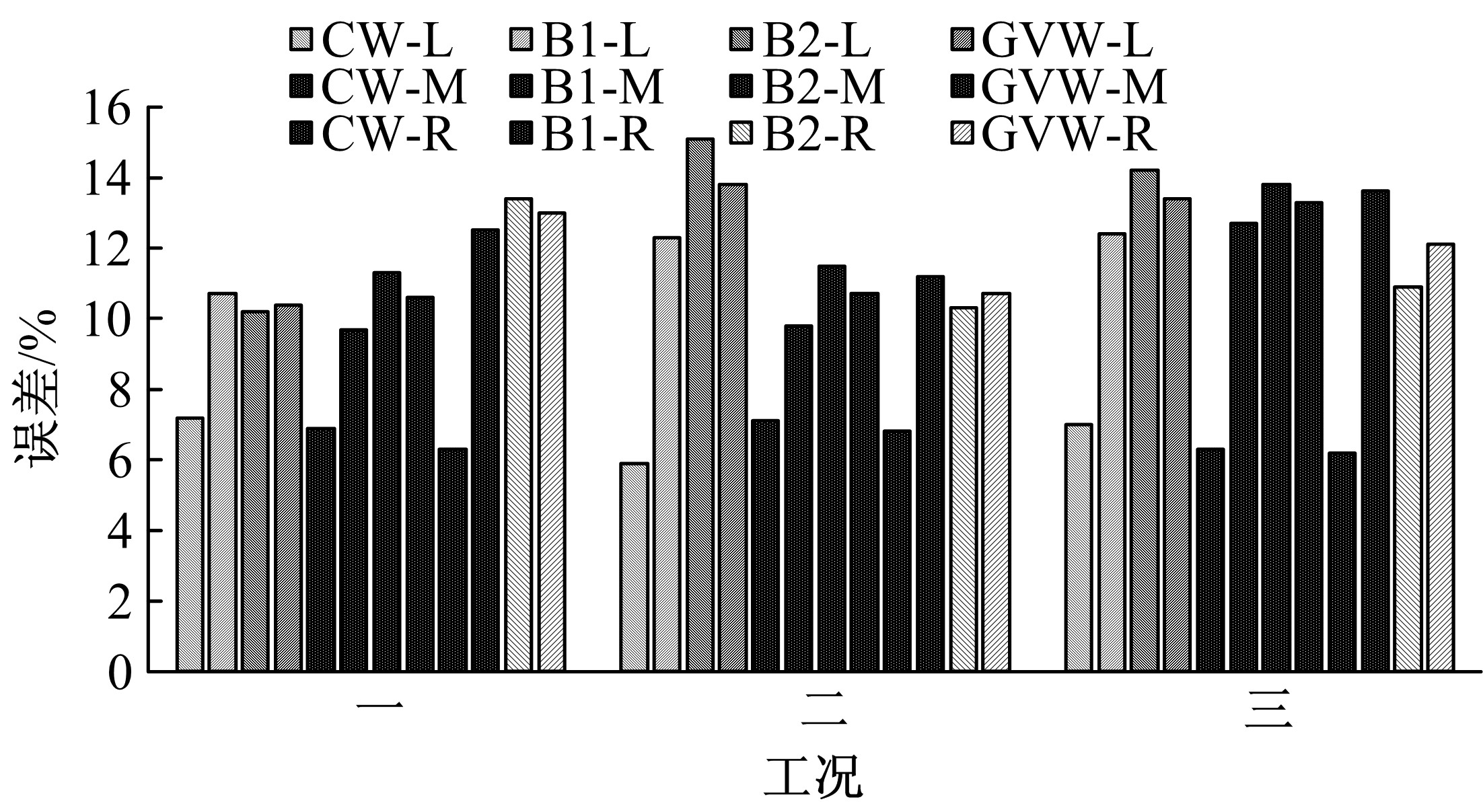

目前商用桥梁动态称重(BWIM)系统的研究主要集中在一维BWIM系统,多数只考虑单车过桥的情况,而实际交通中多车过桥的现象普遍存在。针对这一情况,提出了一种多车动态称重算法。以Moses轴重识别算法为基础,基于横桥向动力响应线和桥梁弯矩影响面,对单车以及多车过桥的横向位置及轴重等车辆信息进行识别,最后通过桥梁动态称重有限元仿真分析,研究单车过桥、两车过桥以及三车过桥等不同工况下本文算法的可靠性。结果表明:单车过桥、两车过桥以及三车过桥的情况下,随着车辆数目的增加,识别精度略有降低,车辆总重的识别最大误差在13%左右,车辆横向位置的识别误差在9%左右,识别精度满足工程实际需求,该算法可识别多车过桥时的车辆横向位置与轴重,具有发展成为商业BWIM系统的潜力。

中图分类号:

- U446.2

| 1 | Moses F. Weigh-in-motion system using instrumented Bridges[J]. Transportation Engineering Journal, 1979, 105(3): 233-249. |

| 2 | Peters R J. Axway―a system to obtain vehicle axle weights[J]. Australia Road Research, 1984, 12(2): 17-29. |

| 3 | Peters R J. An unmanned and undetectable highway speed vehicle weighing system[J]. Australian Road Research Board Proceedings, 1986, 1(1): 70-83. |

| 4 | Commission European. Weight-in-motion of axles and vehicles for Europe (WAVE): general report[R]. Paris: LCPC, 2001. |

| 5 | Commission European. Weight-in-motion of axles and vehicles for Europe (WAVE): report of work package 1.2-Bridge WIM systems (B-WIM)[R]. Dublin: University College Dublin, 2001. |

| 6 | Jacob B, O'Brien E J. Weigh-in-motion: recent developments in Europe[C]∥4th International Conference on Weigh-In-Motion, Taipei, 2005: 90-94. |

| 7 | Rowley C W, Gonz A A, O'Brien E J, et a1. Comparison of conventional and regularized bridge weigh-in-motion algorithms[C]∥5th International Conference on Weigh-in-Motion, Paris, 2008: 12-13. |

| 8 | 王林军. 正则化方法及其在动态载荷识别中的应用[D]. 长沙: 湖南大学机械与载运工程学院, 2011. |

| Wang Lin-jun. Regularization method and its application in dynamic load identification[D]. Changsha: School of Mechanical and Transportation Engineering, Hunan University, 2011. | |

| 9 | 龙波. 移动车辆轴重识别MOSES算法在宽桥中的应用研究[D]. 长沙: 湖南大学土木工程学院, 2014. |

| Long Bo. Application of MOSES algorithm for axle weight identification of moving vehicles in wide bridges[D]. Changsha: School of Civil Engineering, Hunan University, 2014. | |

| 10 | 邓露, 施海, 何维, 等. 基于虚拟简支梁法的桥梁动态称重研究[J]. 振动与冲击, 2018, 37(15): 209-215. |

| Deng Lu, Shi Hai, He Wei, et al. Research on dynamic weighing of bridges based on virtual simply supported beam method[J]. Vibration and Shock, 2018, 37(15): 209-215. | |

| 11 | Zolghadri N, Halling M W, Johnson N, et al. Field verification of simplified bridge weigh-in-motion techniques[J]. Journal of Bridge Engineering, 2016, 21(10): 4016063. |

| 12 | Quilligan M. Bridge weigh-in-motion: development of a 2-D multi-vehicle algorithm[J]. Trita-BKN Bulletin, 2003, 1(1): 23-35. |

| 13 | 刘洋. 基于Moses算法的单车及多车动态称重算法研究[D]. 长春: 吉林大学交通学院, 2019. |

| Liu Yang. Study on the BWIM algorithm of a vehicle or multi-vehicles based on the Moses algorithm[D]. Changchun: College of Transportation, Jilin University, 2019. | |

| 14 | Zhao H, Uddin N, O'Brien E J, et al. Identification of vehicular axle weights with a bridge weigh-in-motion system considering transverse distribution of wheel loads[J]. Journal of Bridge Engineering, 2013, 19(3): 04013008. |

| 15 | Tikhonov A N, Arsenin V Y. Solutions of ill-posed problems[J]. Mathematics of Computation, 1977, 32(144): 1-258. |

| 16 | 汤海燕, 蔡晶. 桥梁结构影响面与影响线的比较研究[C]∥江苏省力学学会青年力学论坛, 南京, 2005: 104-108. |

| 17 | 李希. 点云数据处理及规则曲面拟合[D]. 太原: 中北大学计算机科学与技术学院, 2017. |

| Li Xi. Point cloud data processing and regular surface fitting[D]. Taiyuan: College of Computer Science and Technology, North University of China, 2017. | |

| 18 | 刘福寿. 基于车桥耦合振动的混凝土简支梁桥动力特性研究[D]. 长春: 吉林大学交通学院, 2009. |

| Liu Fu-shou. Study on the dynamic characteristics of a simply supported concrete beam bridge based on vehicle-bridge coupling vibration[D]. Changchun: College of Transportation, Jilin University, 2009. | |

| 19 | Huang D, Wang T L. Impact analysis of cable-stayed bridge[J].Computers and Structures, 1992, 43(5): 897-908. |

| 20 | 谭国金, 刘子煜, 魏海斌, 等. 偏心直线预应力筋简支梁自振频率计算方法[J]. 吉林大学学报: 工学版, 2016, 46(3): 798-803. |

| Tan Guo-jin, Liu Zi-yu, Wei Hai-bin, et al. Calculation method of natural vibration frequency of simply supported beam with eccentric linear prestressed tendons[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(3): 798-803. | |

| 21 | 宫亚峰, 何钰龙, 谭国金, 等. 三跨独柱连续曲线梁桥抗倾覆稳定性分析[J]. 吉林大学学报: 工学版, 2018, 48(1): 113-120. |

| Gong Ya-feng, He Yu-long, Tan Guo-jin, et al. Three-span single-column continuous curve beam bridge anti-overturning stability analysis[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(1): 113-120. |

| [1] | 孔庆雯,谭国金,王龙林,王勇,魏志刚,刘寒冰. 基于有限元方法的裂缝箱梁桥自振特性分析[J]. 吉林大学学报(工学版), 2021, 51(1): 225-232. |

| [2] | 陈华,陈耀嘉,谢斌,王鹏凯,邓朗妮. CFRP筋粘结式锚固体系界面失效演化机制及粘结强度计算[J]. 吉林大学学报(工学版), 2020, 50(5): 1698-1708. |

| [3] | 宫亚峰,宋加祥,毕海鹏,谭国金,胡国海,林思远. 装配式箱涵结构缩尺模型静载试验及有限元分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1728-1738. |

| [4] | 高昊,王君杰,刘慧杰,王剑明. 连续梁桥地震行为可控设计准则及实用装置[J]. 吉林大学学报(工学版), 2020, 50(5): 1718-1727. |

| [5] | 蒲黔辉,刘静文,赵刚云,严猛,李晓斌. 高性能树脂混凝土加固混凝土偏压柱承载力理论分析[J]. 吉林大学学报(工学版), 2020, 50(2): 606-612. |

| [6] | 张云龙,郭阳阳,王静,梁东. 钢-混凝土组合梁的固有频率及其振型[J]. 吉林大学学报(工学版), 2020, 50(2): 581-588. |

| [7] | 王伯昕,杨海涛,王清,高欣,陈小旭. 基于补充改进集合经验模态分析法⁃多尺度排列熵分析桥梁振动信号优化滤波方法[J]. 吉林大学学报(工学版), 2020, 50(1): 216-226. |

| [8] | 张淼,钱永久,张方,朱守芹. 基于增大截面法的混凝土加固石拱桥空间受力性能试验分析[J]. 吉林大学学报(工学版), 2020, 50(1): 210-215. |

| [9] | 贾毅,赵人达,王永宝,李福海. 多跨长联连续梁桥粘滞阻尼器参数敏感性分析[J]. 吉林大学学报(工学版), 2019, 49(6): 1871-1883. |

| [10] | 钟春玲,梁东,张云龙,王静. 体外预应力加固简支梁自振频率计算[J]. 吉林大学学报(工学版), 2019, 49(6): 1884-1890. |

| [11] | 白伦华,沈锐利,张兴标,王路. 自锚式悬索桥的面内稳定性[J]. 吉林大学学报(工学版), 2019, 49(5): 1500-1508. |

| [12] | 赵金钢,张明,占玉林,谢明志. 基于塑性应变能密度的钢筋混凝土墩柱损伤准则[J]. 吉林大学学报(工学版), 2019, 49(4): 1124-1133. |

| [13] | 万世成,黄侨,关健,郭赵元. 预应力碳纤维板加固钢⁃混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1114-1123. |

| [14] | 李万恒,申林,王少鹏,赵尚传. 基于多阶段分区域动力测试的桥梁结构损伤评估[J]. 吉林大学学报(工学版), 2019, 49(3): 773-780. |

| [15] | 惠迎新,毛明杰,刘海峰,张尚荣. 跨断层桥梁结构地震响应影响[J]. 吉林大学学报(工学版), 2018, 48(6): 1725-1734. |

|

||