吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (4): 1317-1330.doi: 10.13229/j.cnki.jdxbgxb20200427

• 交通运输工程·土木工程 • 上一篇

RC类活性粉末混凝土钢筋粘结-滑移本构模型

- 东北林业大学 土木工程学院,哈尔滨 150040

Bond-slip constitutive model of steel bars and reactive powder concrete under standard curing

Dong-hui CHENG( ),Yong-xuan FAN,Yan-song WANG

),Yong-xuan FAN,Yan-song WANG

- School of Civil Engineering,Northeast Forestry University,Harbin 150040,China

摘要:

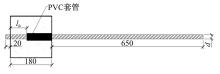

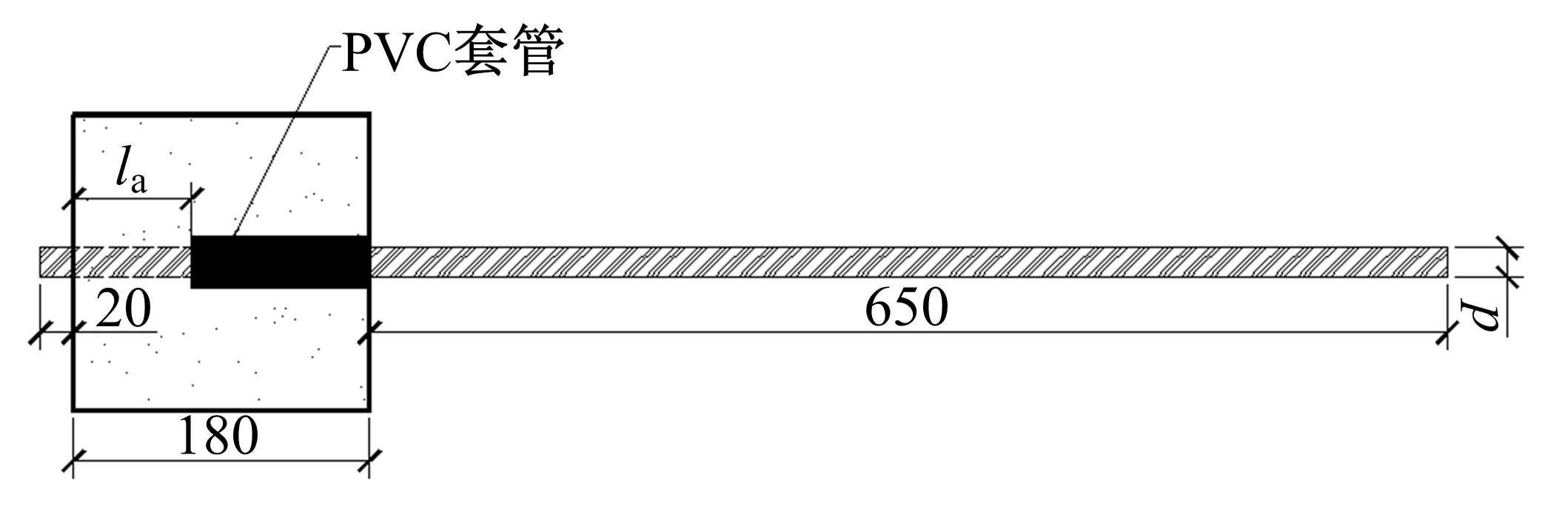

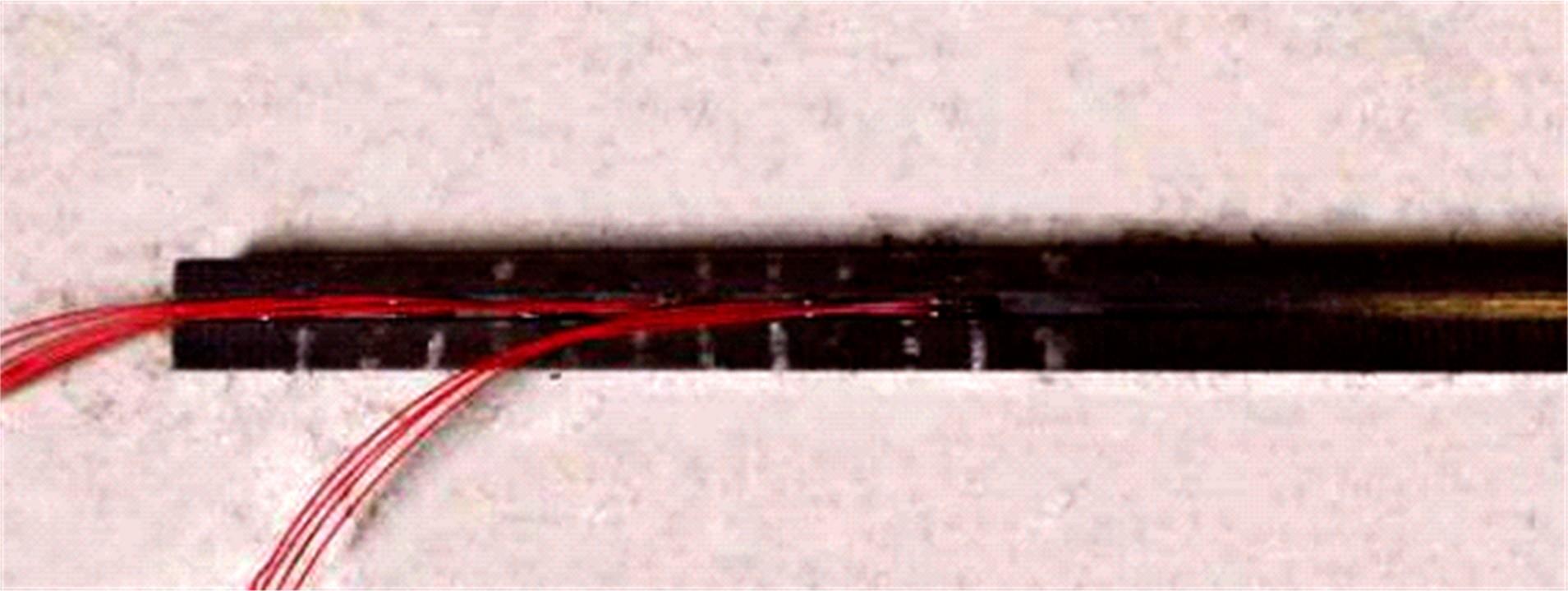

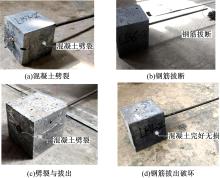

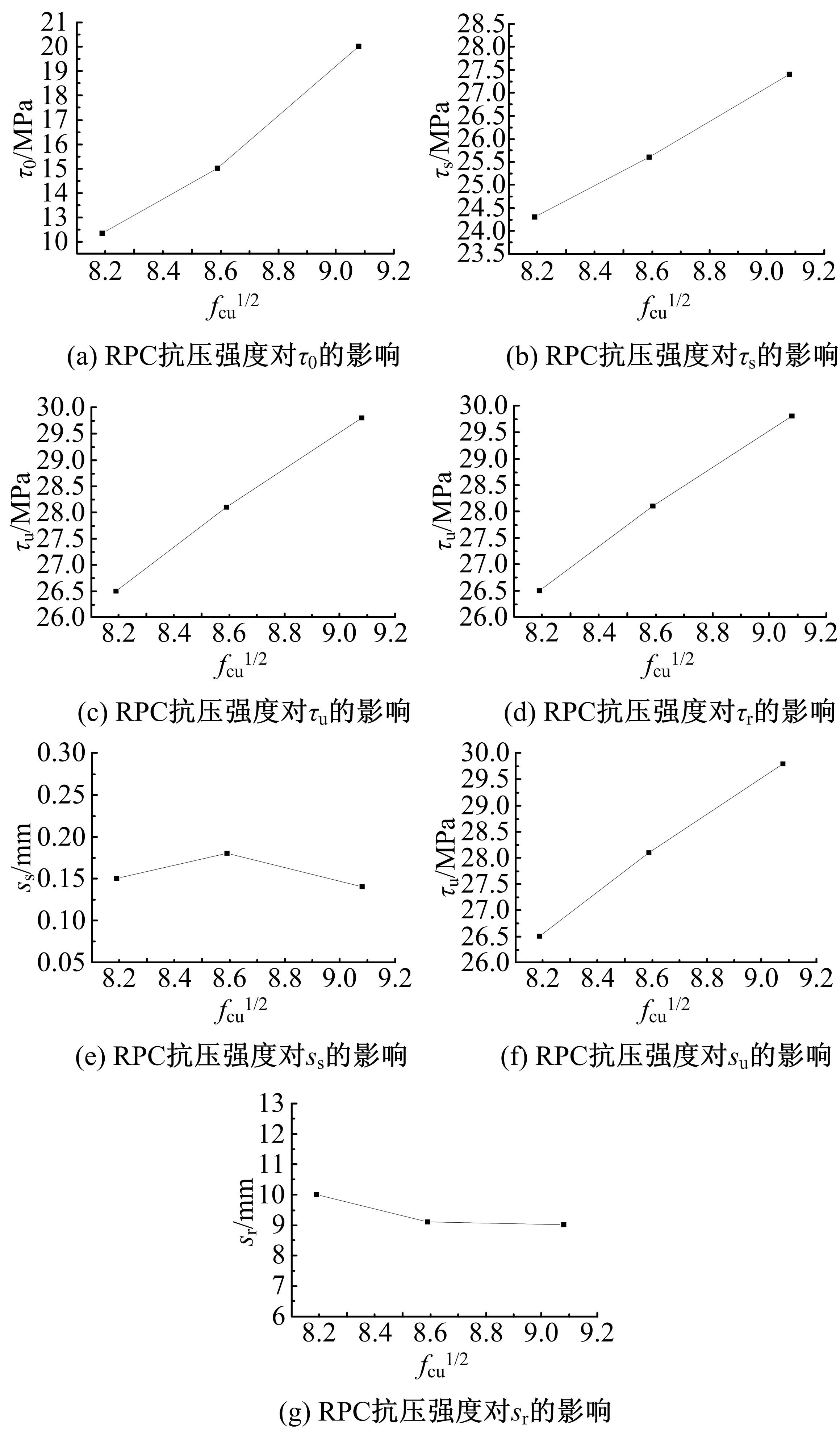

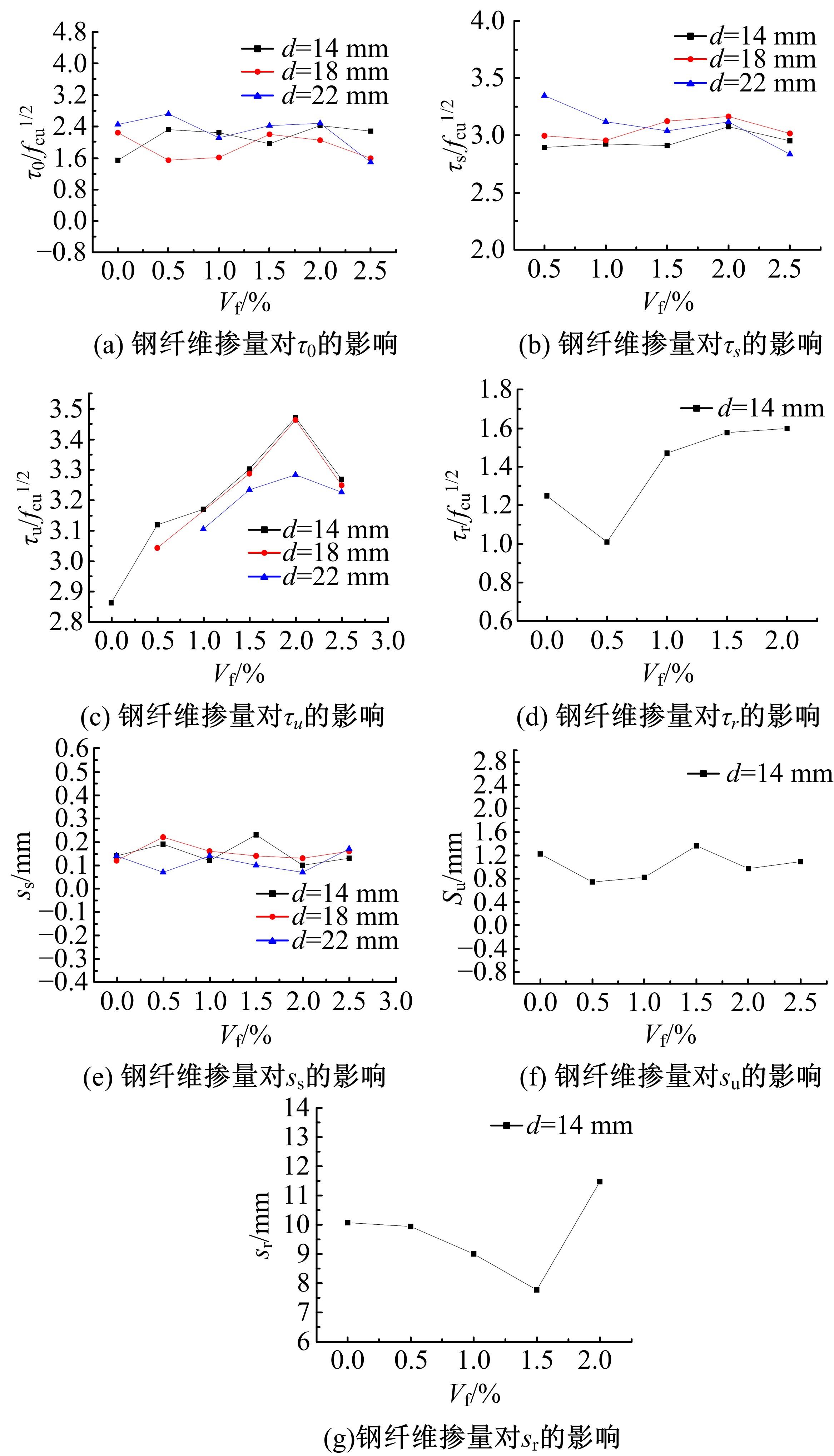

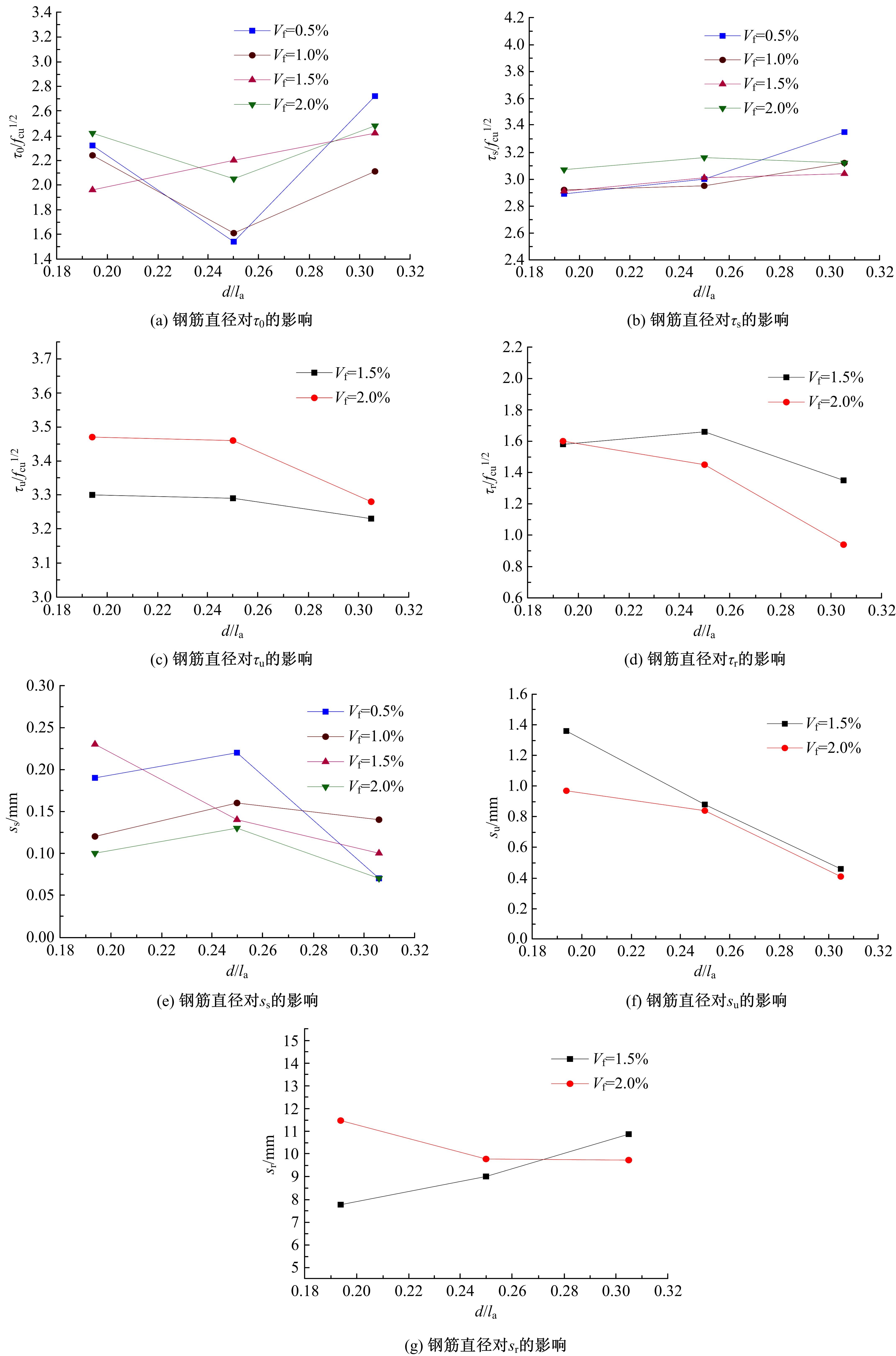

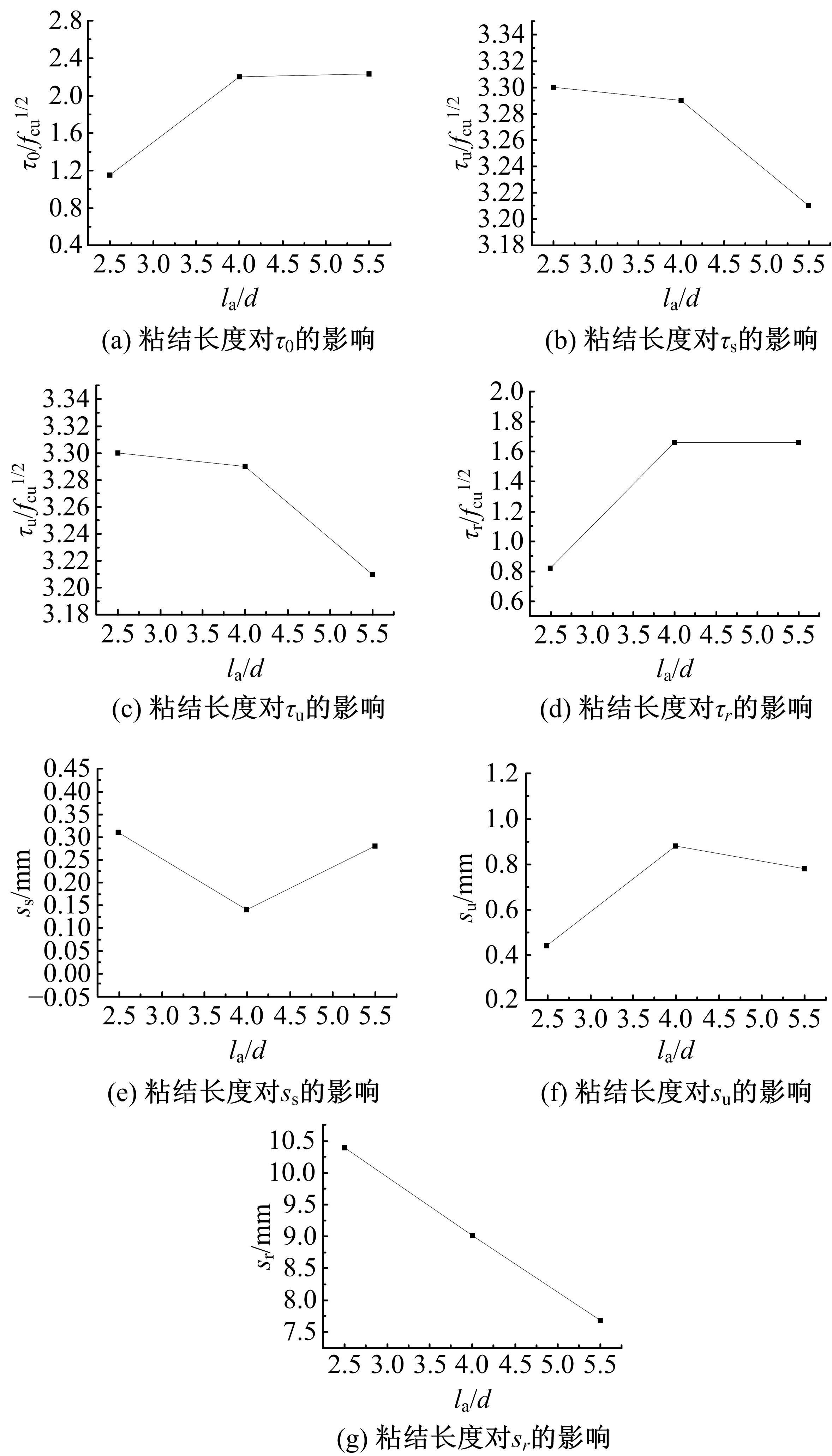

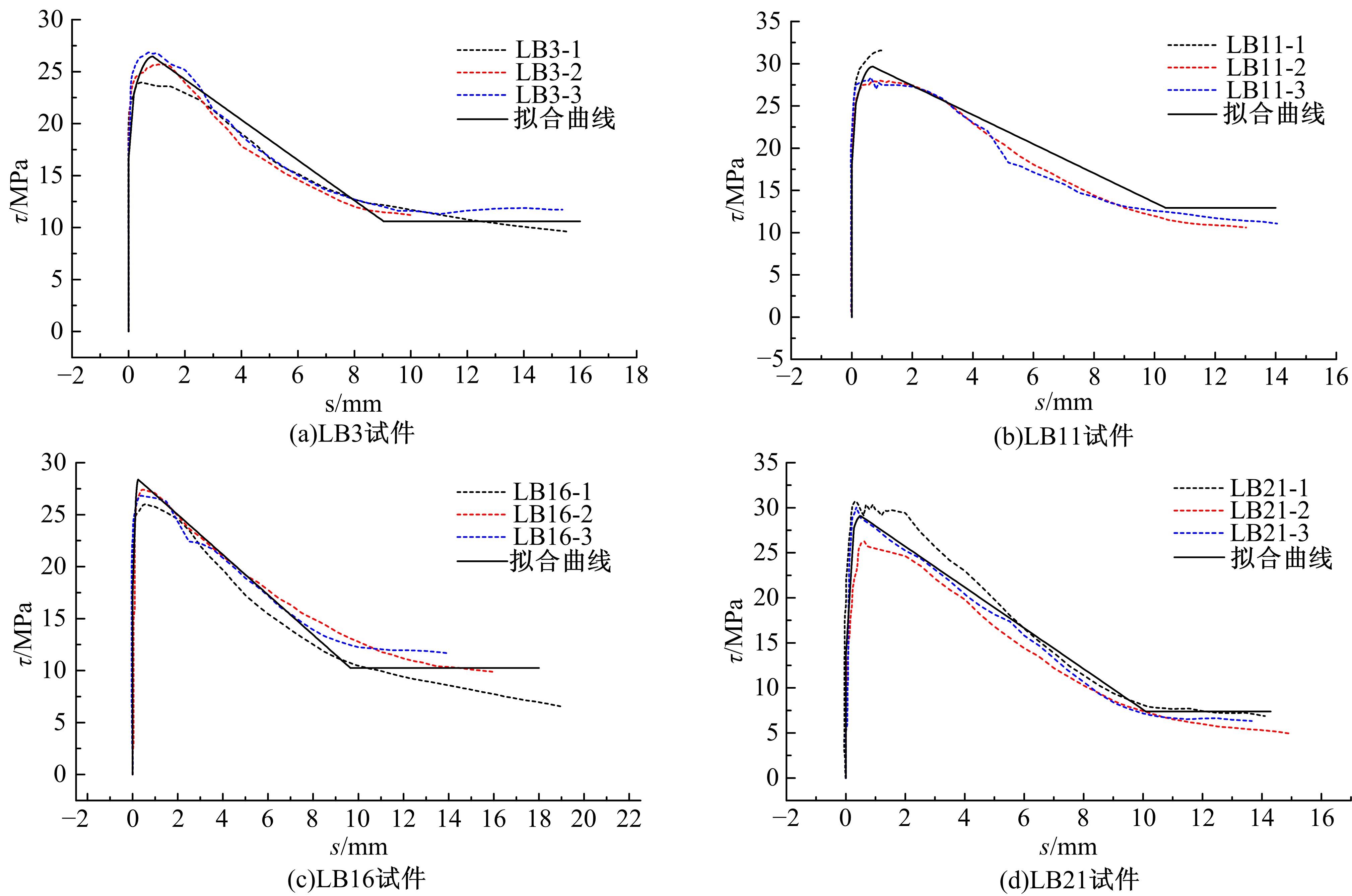

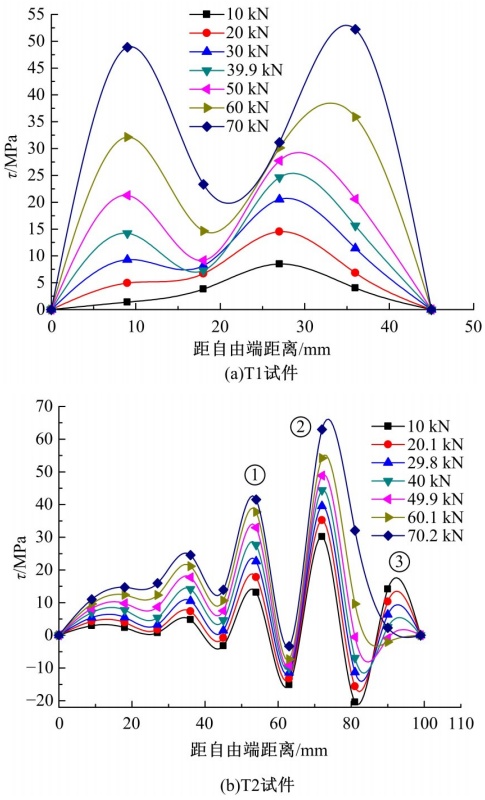

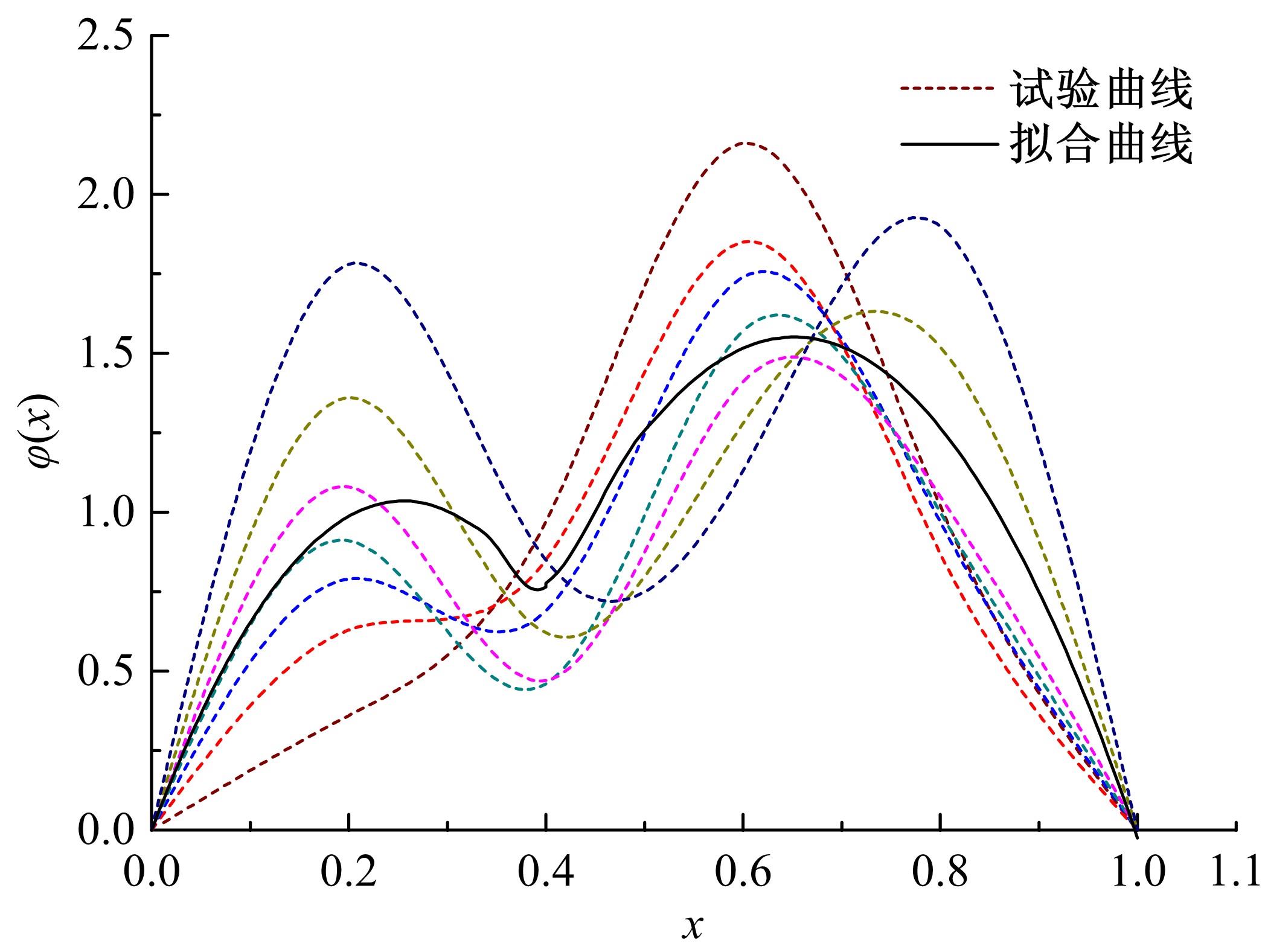

通过22组活性粉末混凝土中心拔出试验,分析了混凝土抗压强度、钢纤维体积掺量、钢筋直径和钢筋与RPC粘结长度对变形钢筋与RC类活性粉末混凝土粘结性能的影响,总结了钢筋拔出破坏、混凝土劈裂破坏以及钢筋拔出与混凝土劈裂破坏同时发生等3种破坏模式的发生条件,结合试验数据拟合得到RC类养护模式下各粘结锚固特征值计算公式,建立了RC类活性粉末混凝土钢筋平均粘结应力-滑移本构模型,并利用该模型与试验结果进行验证,效果较好;通过钢筋内贴应变片中心拔出试验,分析粘结应力分布规律,拟合得到粘结位置函数。试验结果表明:变形钢筋与活性粉末混凝土粘结强度随混凝土抗压强度的增大而增大;随着钢纤维掺量增加,极限粘接强度τu和残余粘接强度τr呈增大的趋势;随着钢筋直径的增大,初始粘接强度τ0先减小后增大,τu和τr减小;随着钢筋粘结长度的增大,τ0和τr增大,而τu呈减小趋势;随荷载增加,粘结应力峰值从加载端向自由端移动;粘结长度越长,粘结应力分布越不均匀;结合平均粘结应力-滑移本构模型和粘贴位置函数得到的公式能较为充分地反映RC类活性粉末混凝土与变形钢筋的粘结应力-滑移本构模型。

中图分类号:

- TU378

| 1 | Richard P, Cheyrezy M H.Composition of reactive powder concretes[J]. Cement and Concrete Research, 1995, 25(7) : 1501-1511. |

| 2 | Richard Pierre. Reactive powder concrete: a new ultra high strength cementitious Material[C]∥The 4th International Symposium On Utilization of High Strength High Performance Concrete, Paris,France,1996:1343-1349. |

| 3 | 吴中伟,廉慧珍. 高性能混凝土[M].北京:中国铁道出版社,1999. |

| 4 | 柯开展,蔡文尧. 活性粉末混凝士(RPC)在工程结构中的应用与前景[J].福建建材, 2006,24(2): 17-19. |

| Ke Kai-zhan,Cai Wen-yao. Application and prospect of reactive powder concrete (RPC) in engineering structure[J]. Fujian Building Materials, 2006,24(2): 17-19. | |

| 5 | 杨志慧.不同钢纤维掺量活性粉末混凝土的抗拉力学特性研究[D]. 北京:北京交通大学土木工程学院,2006. |

| Yang Zhi-hui. Study on tensile mechanical properties of reactive steel reinforced concrete with different steel fibers[D]. Beijing: School of Civil Engineering,Beijing Jiaotong University,2006. | |

| 6 | 周一桥,杜亚凡. 世界上第一座预制预应力活性粉混凝土结构—舍布鲁克人行桥[J].国外桥梁,2000,27(3):18-23. |

| Zhou Yi-qiao, Du Ya-fan. The world's first precast prestressed reactive powder concrete structure - Sherbrooke footbridge[J]. Foreign Bridges, 2000,27(3): 18-23. | |

| 7 | Adeline R, Lachemi M, Blais P. Design and behaviour of the Sherbrooke Footbridge[C]∥Proceedings of International Symposium on High-performance and Reactive Powder Concrete,Sherbrooke,Canada,1998:89-97. |

| 8 | 贾方方. 钢筋与活性粉末混凝土粘结性能的试验研究[D].北京:北京交通大学土木工程学院,2013. |

| Jia Fang-fang. Experimental study on the bonding properties of steel bars and reactive powder concrete[D]. Beijing:School of Civil Engineering,Beijing Jiaotong University, 2013. | |

| 9 | An Ming-zhe,Ji Wen-yu,Zhong Tie-yi,et al. Application of UHPC in railway construction[C]∥International Workshop on Sustainable and Science-Driven Engineering of Cement-based Materials,Beijing,China,2011:141-148. |

| 10 | . 活性粉末混凝土[S]. |

| 11 | 李新星. 大流动性活性粉末混凝土与钢筋的粘结滑移本构理论及试验研究[D].湘潭:湘潭大学土木工程与力学学院,2019. |

| Li Xin-xing. The theory and experimental study of the adhesion slip structure of large liquid active powder concrete and steel bar[D]. Xiangtan:School of Civil Engineering and Mechanics, Xiangtan University, 2019. | |

| 12 | 赵北祥,王晓慧,张延亿.钢筋与活性粉末混凝土粘结滑移本构关系研究[J].科技资讯,2011,8(22):85-88. |

| Zhao Bei-xiang,Wang Xiao-hui,Zhang Yan-yi. A study on the relationship between rebar and active powder concrete bond slip[J]. Science & Technology Information,2011,8(22):85-88. | |

| 13 | CECS13:89 钢纤维混凝土试验方法[M].北京:中国建筑工业出版社,1989. |

| 14 | Xiao Jian-zhuang, Falkner H. Bond behavior between recycled aggregate concrete and steel rebars[J]. Construction and Building Materials,2007,21(2):395-401. |

| 15 | 徐有邻,沈文都. 钢筋外形对粘结性能的影响[J]. 工业建筑, 1987, 17(3): 26-30. |

| Xu You-lin, Shen Wen-du. Effect of reinforcement shape on bonding properties[J]. Industrial Construction, 1987, 17(3): 26-30. | |

| 16 | 卫军,王艺霖,罗晓辉.钢筋拉拔试验中粘结应力分布的曲线拟合[J].铁道科学与工程学报,2005(2):22-24. |

| Wei Jun,Wang Yi-lin,Luo Xiao-hui. Curve fitting of bond stress distribution in steel bar drawing test[J]. Journal of Railway Science and Engineering,2005(2):22-24. | |

| 17 | 徐有邻.变形钢筋-混凝土粘结锚固性能的试验研究[D]. 北京:清华大学土木工程学院,1990. |

| Xu You-lin. Experimental study on the anchoring performance of deformed steel-concrete bonding[D]. Beijing: School of Civil Engineering and Engineering,Tsinghua University, 1990. |

| [1] | 庄蔚敏,王鹏跃,高瑞娟,解东旋. 温热成形对AA5754铝合金静态力学性能的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 847-854. |

| [2] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [3] | 叶辉,朱艳荣,蒲永锋. 纤维增强复合材料应变率效应的数值仿真[J]. 吉林大学学报(工学版), 2019, 49(5): 1622-1629. |

|

||