吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 91-99.doi: 10.13229/j.cnki.jdxbgxb20180969

Cr8合金钢热变形行为及位错密度演变规律

- 河南科技大学 材料科学与工程学院,河南 洛阳 471023

Hot deformation behavior and dislocation density evolution regularity of Cr8 alloy

Xue-wen CHEN( ),Ji-ye WANG,Xi-qing YANG,Tao HUANG,Ke-xing SONG

),Ji-ye WANG,Xi-qing YANG,Tao HUANG,Ke-xing SONG

- School of Materials Science and Engineering,Henan University of Science and Technology,Luoyang 471023,China

摘要:

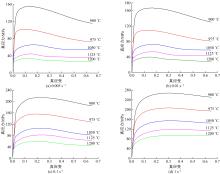

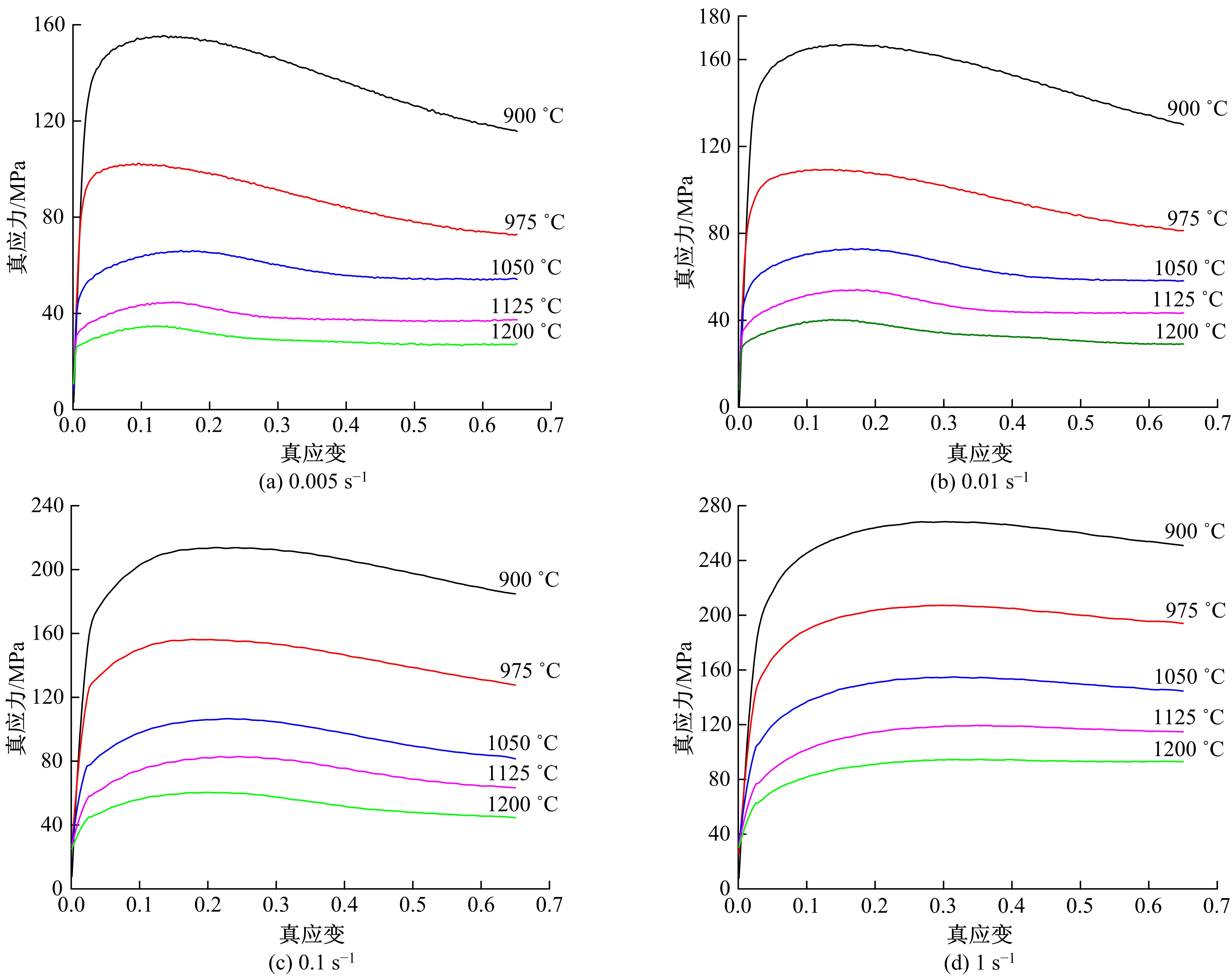

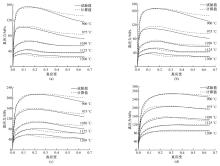

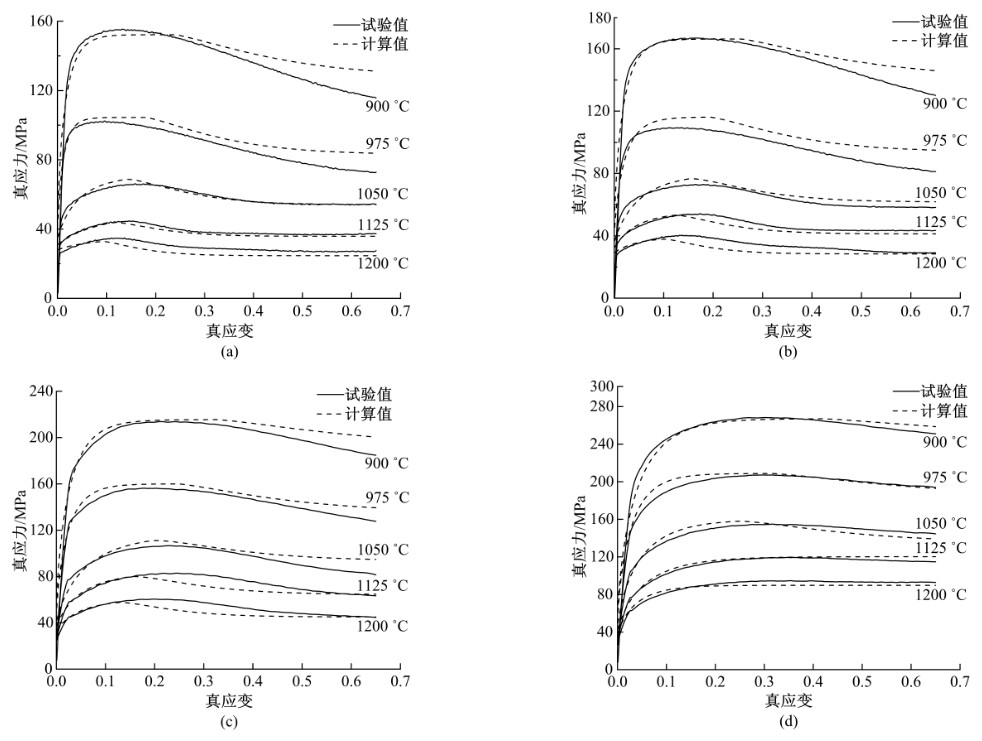

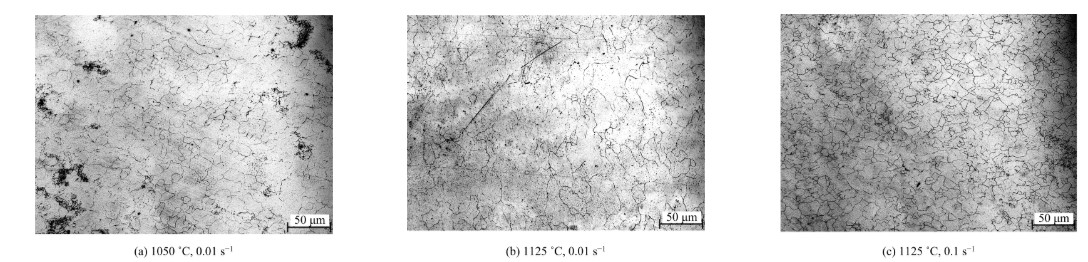

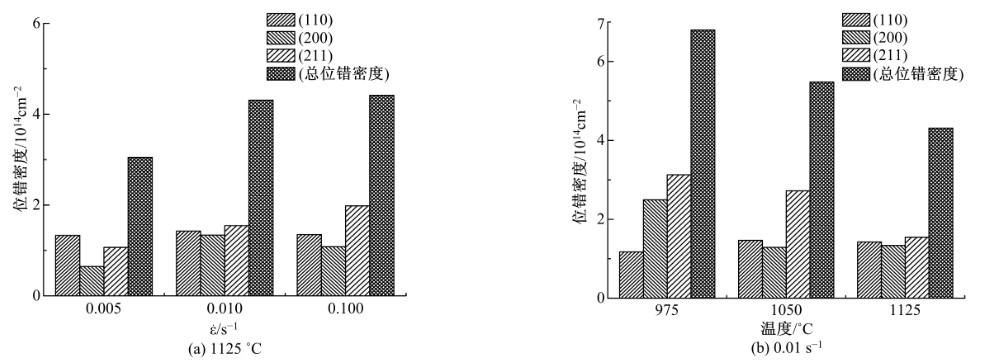

利用Gleeble-1500D热模拟试验机对Cr8合金钢在变形温度为900~1200 ℃、应变速率为0.005~5 s-1条件下进行热压缩试验,并对热变形后的试样进行X射线衍射试验,研究了Cr8合金钢的热变形行为及位错密度演变规律。基于试验得到的数据,建立了考虑位错密度演变及包含多参数的两段式本构模型。结果表明:在低应变速率下,Cr8合金钢真应力-真应变曲线具有典型的动态再结晶特征;Cr8合金钢热变形激活能Q act为423.41 kJ/mol,本构模型的计算值与试验值数据吻合较好;在试验条件下,Cr8合金钢的总位错密度均达到1014 cm-2以上,总位错密度随应变速率增加、变形温度减小而增加。

中图分类号:

- TG142.33

| 1 | 孙秀华, 汝亚彬, 刘宝石 . 新型冷作模具钢Cr8的开发[J].机械工程材料, 2008, 32(增刊1): 42-43. |

| Sun Xiu-hua , Ru Ya-bin , Liu Bao-shi . Development of Cr8 new-type cold work die steel[J]. Materials for Mechanical Engineering, 2008, 32(Sup.1): 42-43. | |

| 2 | 常旭东 . Cr8钢工作辊淬火过程数值模拟与工艺优化[D].秦皇岛:燕山大学机械工程学院, 2016. |

| Chang Xu-dong . Numerical simulation and process optimization of the Cr8 steel working roll quenching process[D]. Qinhuangdao: Shool of Mechnology Engineering, Yanshan University, 2016. | |

| 3 | Chi H X , Ma D S , Yong Q L , et al . Effect of cryogenic treatment on properties of Cr8-type cold work die steel[J]. Journal of Iron and Steel Research (International), 2010, 17(6): 43-46, 59. |

| 4 | Li C H , Wu X C , Xie C ,et al . Investigation on wear resistance of Cr8 tool steels[J]. Tribology, 2013, 33(1):36-43. |

| 5 | Wang G , Wang D R , Liu L G ,et al . Austenite grain growth behavior of Cr8 steel[J]. Transactions of Materials & Heat Treatment,2014,35(2):94-99. |

| 6 | 张岩, 赵爱民, 何建国, 等 . 热处理工艺对Cr8钢组织与性能的影响[J]. 金属热处理, 2016, 41(1): 79-84. |

| Zhang Yan , Zhao Ai-min , He Jian-guo , et al . Effect of heat treatment on microstructure and properties of Cr8 steel[J]. Heat Treatment of Metals, 2016, 41(1): 79-84. | |

| 7 | 黄顶俊, 杨弋涛 . Cr8型刃具钢热处理工艺优化[J]. 金属热处理, 2016, 41(3): 43-48. |

| Huang Ding-jun , Yang Yi-tao . Heat treatment process optimization of Cr8 cutting-tool steel[J]. Heat Treatment of Metals, 2016, 41(3): 43-48. | |

| 8 | 王葛, 刘智超, 常旭东, 等 . Cr8钢轧辊最终热处理过程数值模拟与实验研究[J]. 材料热处理学报, 2016, 37(6): 241-248. |

| Wang Ge , Liu Zhi-chao , Chang Xu-dong , et al . Numerical simulation and experimental research on final heat treatment process of a Cr8 steel roll[J]. Transactions of Materials and Heat Treatment, 2016, 37(6): 241-248. | |

| 9 | Ferdowsi M R G , Nakhaie D , Benhangi P H , et al . Modeling the high temperature flow behavior and dynamic recrystallization kinetics of a medium carbon microalloyed steel[J]. Journal of Materials Engineering and Performance, 2014, 23(3): 1077-1087. |

| 10 | Zhang D , Liu Y Z , Zhou L Y , et al . Dynamic recrystallization behavior of GCr15SiMn bearing steel during hot deformation[J]. Journal of Iron and Steel Research (International), 2014, 21(11): 1042-1048. |

| 11 | Pu E X , Feng H , Liu M , et al . Constitutive modeling for flow behaviors of superaustenitic stainless steel S32654 during hot deformation[J]. Journal of Iron and Steel Research (International), 2016, 23(2): 178-184. |

| 12 | 刘利萍, 刘勇兵, 姬连峰, 等 . 原位颗粒增强钛基复合材料高温流变行为[J]. 吉林大学学报:工学版, 2016, 46(4): 1197-1201. |

| Liu Li-ping , Liu Yong-bing , Ji Lian-feng ,et al . Flow stress behavior of in situ particulate reinforced titanium matrix composite at elevated temperature[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(4): 1197-1201. | |

| 13 | Laasraoui A , Jonas J J . Prediction of steel flow stresses at high temperatures and strain rates[J]. Metallurgical and Materials Transactions A, 1991, 22(7): 1545-1558. |

| 14 | 何运斌, 潘清林, 覃银江, 等 . ZK60镁合金热变形过程中的动态再结晶动力学[J]. 中国有色金属学报, 2011, 21(6): 1205-1213. |

| He Yun-bin , Pan Qing-lin , Qin Yin-jiang , et al . The dynamic recrystallization kinetics of ZK60 magnesium alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1205-1213. | |

| 15 | 陈飞 . 热锻非连续变形过程微观组织演变的元胞自动机模拟[D]. 上海:上海交通大学材料科学与工程学院, 2012. |

| Chen Fei . Simulation of microstructure evolution during discontinuous hot forging processes using cellular automaton method[D]. Shanghai: College of Materials and Science Engineering, Shanghai Jiaotong University, 2012. | |

| 16 | 齐珂 . 核电用钢316LN动态再结晶行为实验研究与数值模拟[D]. 上海:上海交通大学材料科学与工程学院, 2014. |

| Qi Ke . Experimental and numerical study on dynamic recrystallization of 316LN nuclear power steel[D]. Shanghai: College of Materials and Science Engineering, Shanghai Jiaotong University, 2014. | |

| 17 | Dini G , Ueji R , Najafizadeh A , et al . Flow stress analysis of TWIP steel via the XRD measurement of dislocation density[J]. Materials Science & Engineering A, 2010, 527(10/11): 2759-2763. |

| 18 | 闻瑶 . TA15钛合金形变过程的微观机理研究及其介观晶体塑性有限元模拟[D]. 合肥:合肥工业大学材料科学与工程学院, 2015. |

| Wen Yao . Microscopic mechanism and crystal plasticity finite element simulation of TA15 titanium alloy at deformation process[D]. Hefei:College of Materials Science and Engineering, Hefei University of Technology, 2015. | |

| 19 | Mathis K , Farkas G , Garces G , et al . Evolution of dislocation density during compression of a Mg-Zn-Y alloy with long period stacking ordered structure[J]. Materials Letters, 2017, 190: 86-89. |

| 20 | 余启航, 蒋显全, 佘欣未, 等 . 5182铸锭高温压缩流变行为与微观组织演变[J]. 西南大学学报:自然科学版, 2018, 40(1): 172-180. |

| Yu Qi-hang , Jiang Xian-quan , She Xin-wei , et al . High temperature rheologic behavior and microstructure evolution of 5182 alloy flat ingot[J]. Journal of Southwest University (Natural Science), 2018, 40(1): 172-180. | |

| 21 | Ding R , Guo Z X . Coupled quantitative simulation of microstructural evolution and plastic flow during dynamic recrystallization[J]. Acta Materialia, 2001, 49(16): 3163-3175. |

| 22 | Laasraoui A , Jonas J J . Recrystallization of austenite after deformation at high temperatures and strain rates-analysis and modeling[J]. Metallurgical transactions A, 1991, 22(1): 151-160. |

| 23 | Sellars C M , Whiteman J A . Recrystallization and grain growth in hot rolling[J]. Metal Science, 1979, 13(3/4): 187-194. |

| 24 | 陈学文, 王继业, 皇涛, 等 . 基于L-J位错密度模型模拟Cr8合金钢动态再结晶行为[J]. 钢铁, 2018, 53(7): 74-79. |

| Chen Xue-wen , Wang Ji-ye , Huang Tao , et al . Dynamic recrystallization behavior simulation for Cr8 alloy based on modified Laasraoui-Jonas dislocation density model[J]. Iron and Steel, 2018, 53(7): 74-79. | |

| 25 | Gay P , Hirsch P B , Kelly A . The estimation of dislocation densities in metals from X-ray data[J]. Acta Metallurgica, 1953, 1(3): 315-319. |

| [1] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [2] | 叶辉,朱艳荣,蒲永锋. 纤维增强复合材料应变率效应的数值仿真[J]. 吉林大学学报(工学版), 2019, 49(5): 1622-1629. |

| [3] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [4] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [5] | 关庆丰,张福涛,彭韬,吕鹏,李姚君,许亮,丁佐军. 含硼、钴9%Cr耐热钢的热变形行为[J]. 吉林大学学报(工学版), 2018, 48(6): 1799-1805. |

| [6] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [7] | 赵宇光, 杨雪慧, 徐晓峰, 张阳阳, 宁玉恒. Al-10Sr变质剂状态、变质温度及变质时间对ZL114A合金组织的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [8] | 汤华国, 马贤锋, 赵伟, 刘建伟, 赵振业. 高性能金属铝的制备、微观结构及其热稳定性[J]. 吉林大学学报(工学版), 2017, 47(5): 1542-1547. |

| [9] | 关庆丰, 张远望, 孙潇, 张超仁, 吕鹏, 张从林. 强流脉冲电子束作用下铝钨合金的表面合金化[J]. 吉林大学学报(工学版), 2017, 47(4): 1171-1178. |

| [10] | 杨晓红, 杭文先, 秦绍刚, 刘勇兵, 刘利萍. H13钢激光熔覆钴基复合涂层的组织及耐磨性[J]. 吉林大学学报(工学版), 2017, 47(3): 891-899. |

| [11] | 关庆丰, 黄尉, 李怀福, 龚晓花, 张从林, 吕鹏. 强流脉冲电子束诱发的Cu-C扩散合金化[J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

| [12] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [13] | 张学广, 刘纯国, 郑愿, 江仲海, 李湘吉. 基于延性损伤和剪切损伤的铝合金成形极限预测[J]. 吉林大学学报(工学版), 2016, 46(5): 1558-1566. |

| [14] | 李春玲, 樊丁, 王斌, 余淑荣. 5A06铝合金/镀锌钢预置涂粉对接激光熔钎焊组织与性能[J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [15] | 张家陶, 赵宇光, 谭娟. 初始组织对电脉冲处理逆变奥氏体晶粒细化效果的影响[J]. 吉林大学学报(工学版), 2016, 46(1): 193-198. |

|

||