吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (7): 1709-1718.doi: 10.13229/j.cnki.jdxbgxb20210103

• 农业工程·仿生工程 • 上一篇

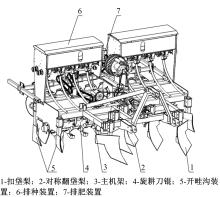

油菜直播机扣垡犁体参数分析与试验

魏国粱1,2( ),张青松1,2,王彪1,2,何坤1,2,廖庆喜1,2(

),张青松1,2,王彪1,2,何坤1,2,廖庆喜1,2( )

)

- 1.华中农业大学 工学院,武汉 430070

2.华中农业大学 农业农村部长江中下游农业装备重点实验室,武汉 430070

Analysis and experiment on parameters of plough body of rapeseed direct seeder

Guo-liang WEI1,2( ),Qing-song ZHANG1,2,Biao WANG1,2,Kun HE1,2,Qing-xi LIAO1,2(

),Qing-song ZHANG1,2,Biao WANG1,2,Kun HE1,2,Qing-xi LIAO1,2( )

)

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid?lower Yangtze River,Ministry of Agriculture and Rural Affairs,Huazhong Agricultural University,Wuhan 430070,China

摘要:

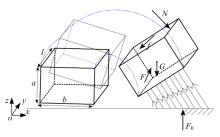

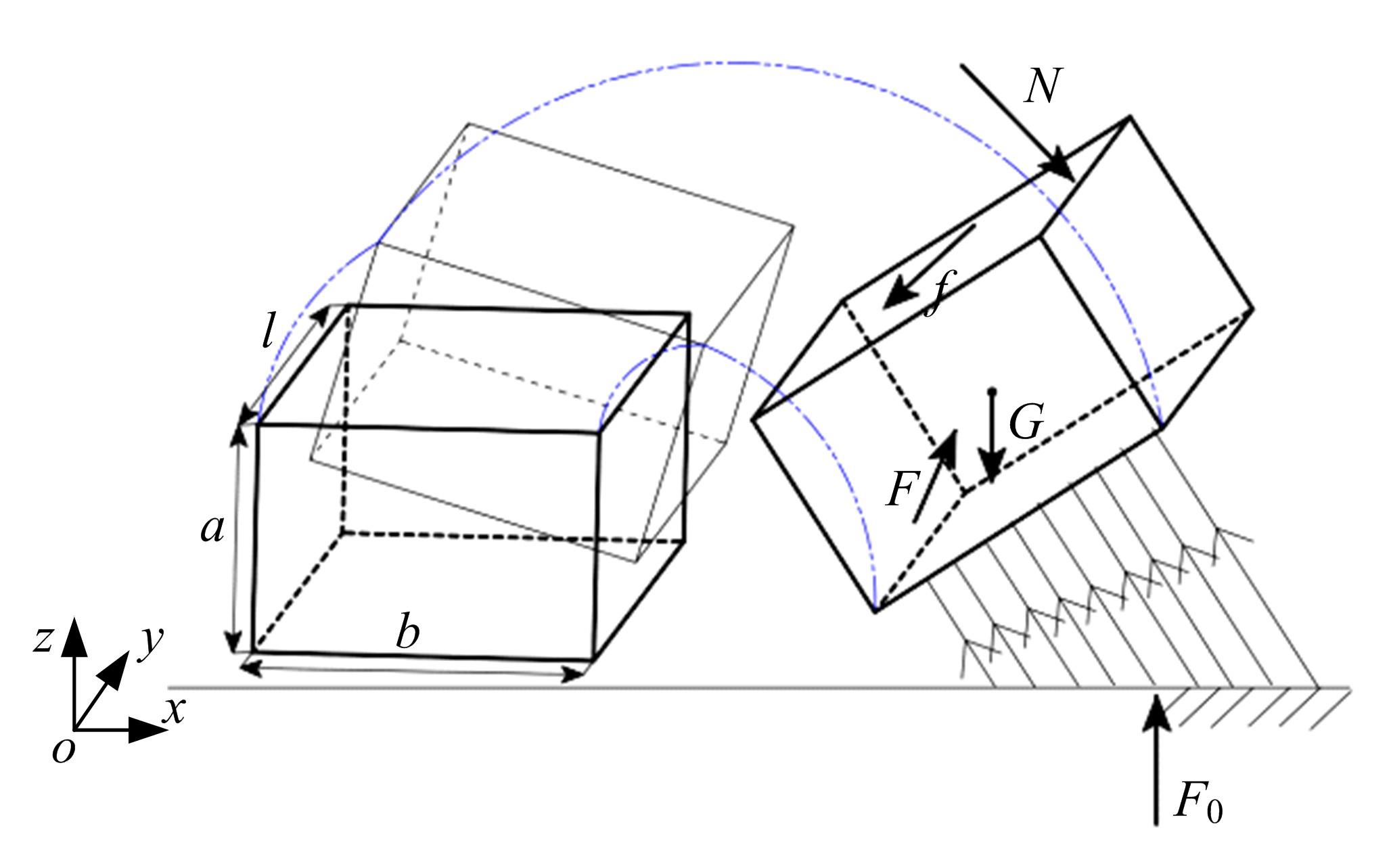

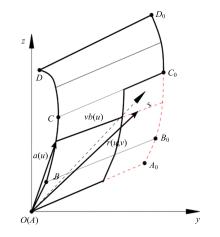

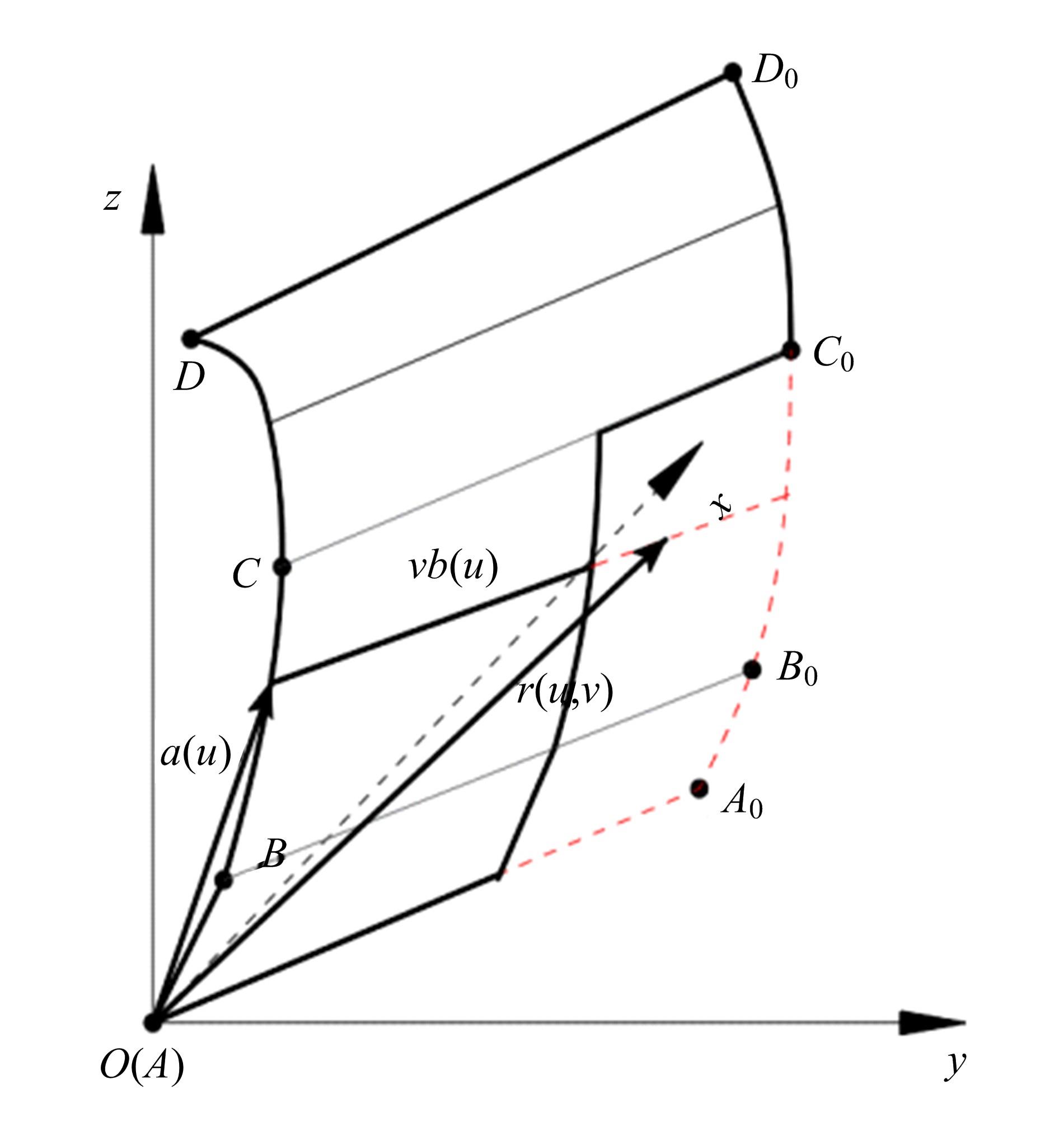

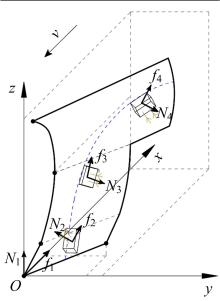

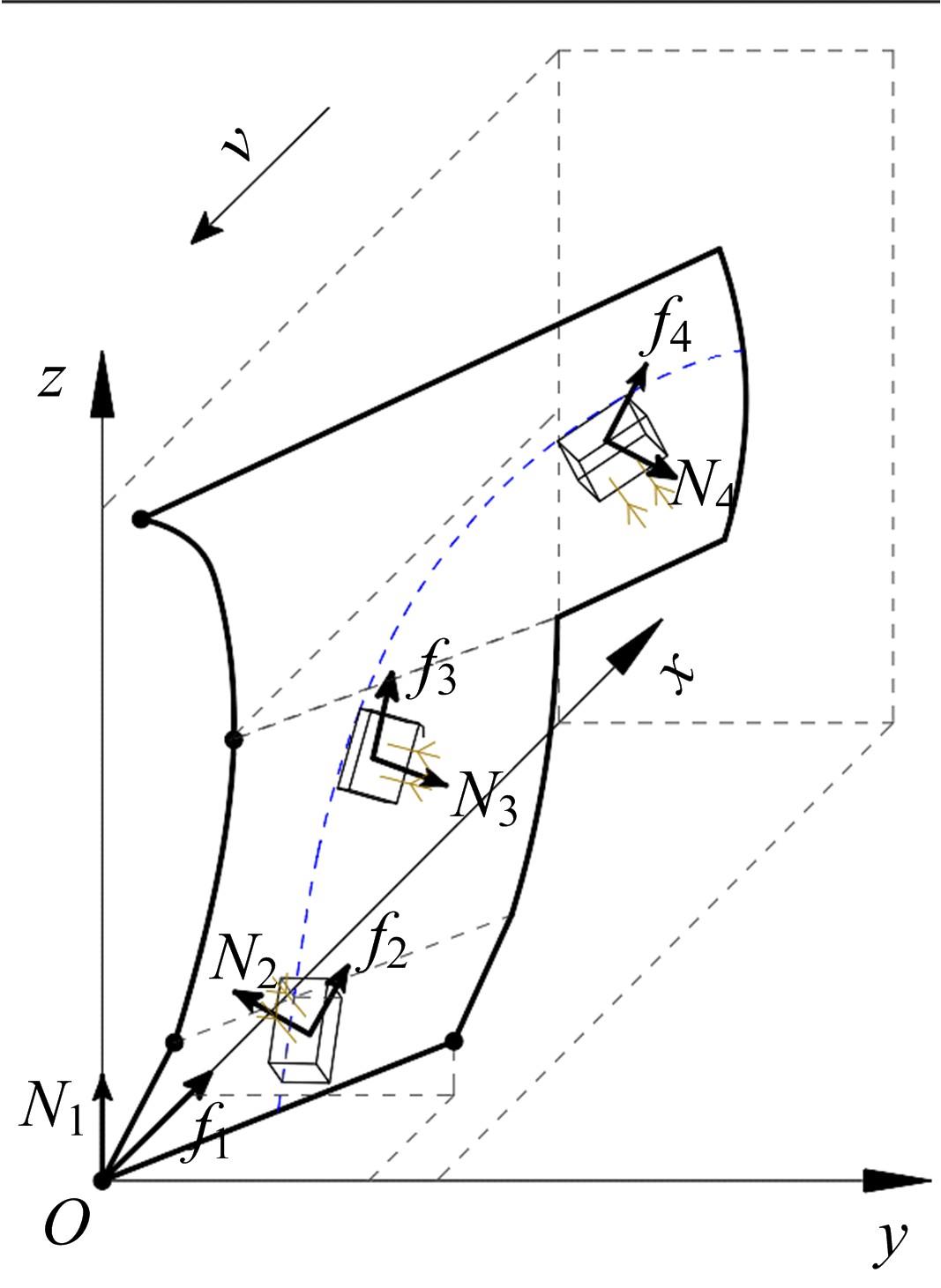

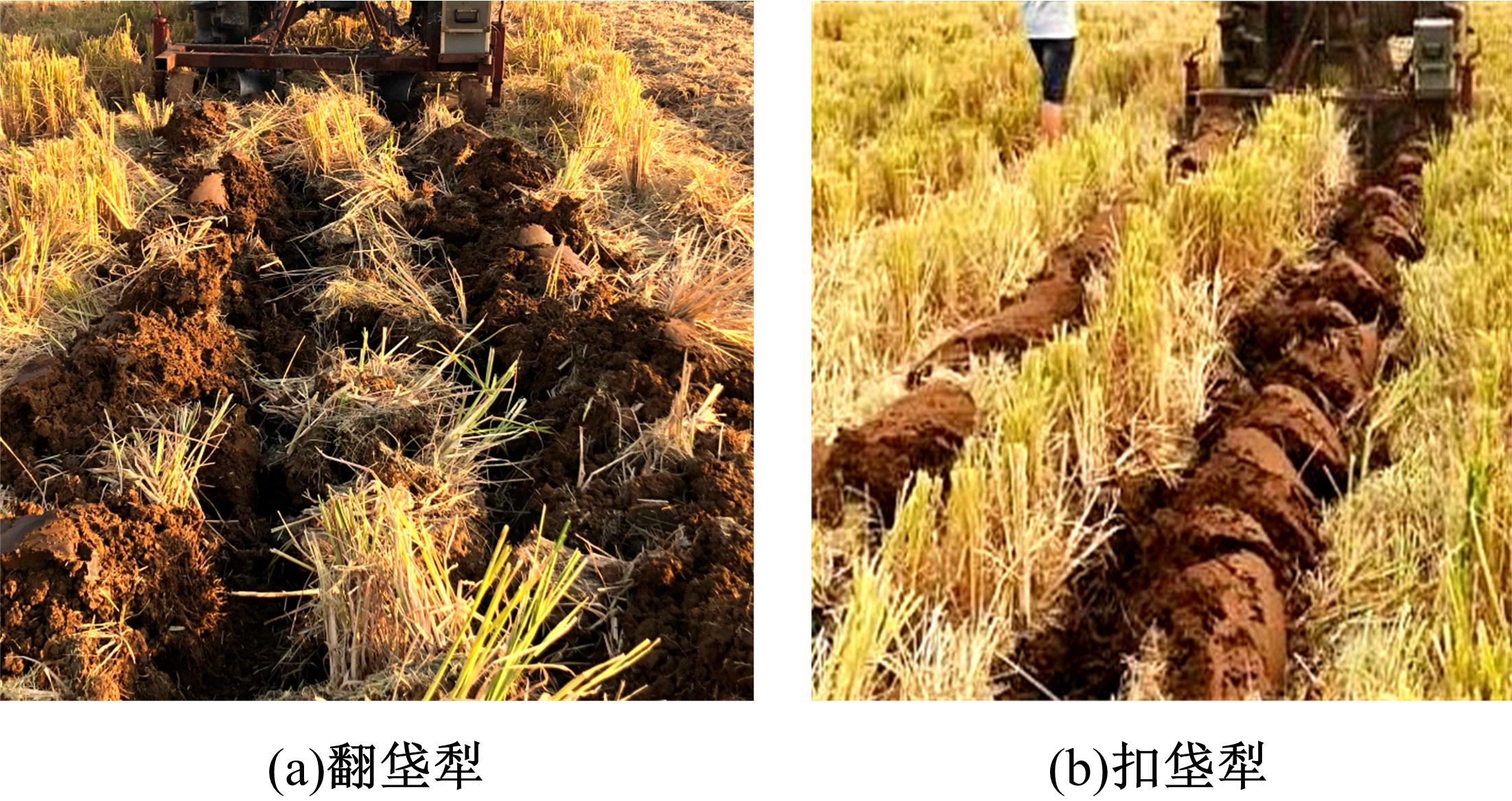

针对在长江中下游稻油轮作区秸秆量大、现有油菜直播机采用传统翻垡方式导致秸秆埋覆率低、回垡立垡现象突出的问题,提出了基于土垡先抬、后扣的侧边翻埋工艺方案,设计了一种与油菜直播机配套,能实现高茬水稻秸秆工况下的土垡侧边翻扣功能的扣垡犁。分析了扣垡犁主要结构和工作过程,构建土垡扣垡阶段力学模型,明确了扣垡犁的扣垡方式,确定了实现扣垡功能的扣垡犁宽深比为1.5~1.96。基于扣垡方式,确定了犁体曲面主要结构参数,并开展了作业阻力分析。扣垡犁田间作业性能表明,扣垡犁较优参数如下:犁铧宽度为150 mm,耕深为180 mm,此时扣垡犁作业阻力为5.54 kN,扣垡率为92.25%;扣垡犁与翻垡犁田间对比试验表明:扣垡犁相比翻垡犁扣垡率提高了34.54%,作业性能优于翻垡犁。以犁旋组合式油菜直播机为试验平台,扣垡犁较优参数下开展田间验证试验,结果表明:作业后地表平均秸秆埋覆率为91.41%,厢面平整度为16.22~21.05 mm,碎土率均高于90.89%,满足油菜种床耕整要求。该研究可为油菜直播秸秆翻埋装置和扣垡犁体曲面设计提供参考。

中图分类号:

- S222.12

| 1 | 吴崇友.稻油(麦)轮作机械化技术[M].北京: 中国农业出版社, 2013. |

| 2 | 廖庆喜,雷小龙,廖宜涛,等.油菜精量播种技术研究进展[J].农业机械学报, 2017, 48(9):1-16. |

| Liao Qing-xi, Lei Xiao-long, Liao Yi-tao, et al. Research progress of precision seeding for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 1-16. | |

| 3 | Zhou Hua, Zhang Chun-ling, Zhang Wen-liang, et al. Evaluation of straw spatial distribution after straw incorporation into soil for different tillage tools[J]. Soil and Tillage Research, 2020, 196: 104440. |

| 4 | 肖文芳,舒彩霞,廖庆喜,等.犁旋组合式稻茬全量还田油菜直播种床整理机设计与试验[J].华中农业大学学报, 2019, 38(6):139-146. |

| Xiao Wen-fang, Shu Cai-xia, Liao Qing-xi, et al. Design and test of tillage machine combined with plough and rotary for managing seedbed before planting rapeseed by burying of rice straw incorporated into soil[J]. Journal of Huazhong Agriculture University, 2019, 38(6): 139-146. | |

| 5 | 秦宽,丁为民,方志超,等.犁翻旋耕复试作业耕整机的设计与试验[J]. 农业工程学报, 2016, 32(16): 7-16. |

| Qin Kuan, Ding Wei-min, Fang Zhi-chao, et al.Design and experiment of plowing and rotary tillage combined machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(16): 7-16. | |

| 6 | 魏国粱,张青松,刘立超,等.犁旋组合式油菜直播机扣垡装置设计与试验[J]. 农业机械学报, 2020, 51(6): 38-46. |

| Wei Guo-liang, Zhang Qing-song, Liu Li-chao, et al. Design and experiment of plowing and rotary tillage buckle device for rapeseed direct seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(6): 38-46. | |

| 7 | 余贵珍,吴成武,丁能根,等.犁体参数化设计系统的研究[J]. 农业机械学报, 2008, 39(3): 49-51. |

| Yu Gui-zhen, Wu Cheng-wu, Ding Neng-gen, et al. Research on parametric design system of plow[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(3): 49-51. | |

| 8 | 林静,张桐嘉,陈彬,等.深松灭茬旋耕起垄联合作业机设计与试验[J]. 农业机械学报, 2019, 50(2): 28-39. |

| Lin Jing, Zhang Tong-jia, Chen Bin, et al. Design and test of subsoiling rotary rilling and rilling combined operating machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(2): 28-39. | |

| 9 | 刘晓鹏,肖文立,马磊,等.油菜联合直播机组合式船型开沟器设计与开沟质量试验[J]. 农业机械学报, 2017, 48(11):79-87. |

| Liu Xiao-peng, Xiao Wen-li, Ma Lei, et al. Design and ditching quality experiment on combined ship type opener of direct rapeseed seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(11): 79-87. | |

| 10 | 翟力欣,姬长英,郁隐梅,等.犁体表面载荷分布的传感器阵列检测[J]. 农业机械学报, 2011, 42(8): 50-53. |

| Zhai Li-xin, Ji Chang-ying, Yu Yin-mei, et al. Arrayed sensors measurement for load distribution of plow[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(8): 50-53. | |

| 11 | 张青松,汲文峰,廖宜涛,等.油菜直播机铧式开畦沟前犁曲面分析与阻力特性试验[J]. 农业机械学报, 2014, 45(2): 130-135. |

| Zhang Qing-song, Ji Wen-feng, Liao Yi-tao, et al. Surface analysis and resistance characteristics experiment on ditch plow ahead of direct rapeseed seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(2): 130-135. | |

| 12 | 张青松,廖庆喜,汲文峰,等.油菜直播机开沟犁体曲面优化与试验[J]. 农业机械学报, 2015, 46(1): 53-59. |

| Zhang Qing-song, Liao qing-xi, Ji Wen-feng, et al. Surface optimization and experiment on ditch plow of direct rapeseed seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(1): 53-59. | |

| 13 | 翟力欣,姬长英,丁启朔,等.犁体结构参数与工作参数优化设计[J]. 农业机械学报, 2013, 44(8): 57-62. |

| Zhai Li-xin, Ji Chang-ying, Ding Qi-shuo, et al. Research Optimized design of plough body structural and working parameters[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(8): 57-62. | |

| 14 | Volodymy B, Simone P, Valerii A, et al. A theoretical study of the limit path of the movement of a layer of soil along the plough mouldboard[J]. Soil and Tillage Research, 2019, 195: 104406. |

| 15 | Michele M, Massimiliano V, Giovanni M, et al. Influence of the speed on soil-pressure over a plough[J]. Biosystems Engineering, 2017, 156: 136-147. |

| 16 | 翟力欣,姬长英,丁启朔,等. 犁面前部土体表层位移场分布有限元分析[J]. 农业机械学报, 2011, 42(10): 45-50. |

| Zhai Li-xin, Ji Chang-ying, Ding Qi-shuo, et al. Analysis of distribution of displacement on soil surface in front of plow with FEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(10): 45-50. | |

| 17 | Gutiérrez D E, Jiménez-Hornero F J, Muñoz-Piorno J M, et al. The geometric characterization of mouldboard plough surfaces by using splines[J]. Soil and Tillage Research, 2011, 112: 98-105. |

| 18 | Mahmood M, Rahim E, Davood G, et al. Geometric characterization of moldboard plough using coupled close photography and surface fitting model[J]. Soil and Tillage Research, 2017, 170: 122-129. |

| 19 | 李宝筏.农业机械学[M]. 北京: 中国农业出版社, 2003. |

| 20 | 包攀峰,吴明亮,官青云,等.犁旋组合式油菜播种开沟起垄装置设计[J]. 农业工程学报, 2017, 33(20): 23-31. |

| Bao Pan-feng, Wu Ming-liang, Guan Qing-yun, et al. Design of plow-rotary style ditching and ridging device for rapeseed seeding[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(20): 23-31. | |

| 21 | 周华,李栋,刘政源,等.秸秆旋埋还田后空间分布效果仿真与试验[J]. 农业机械学报, 2019, 50(9): 69-77. |

| Zhou Hua, Li Dong, Liu Zheng-yuan,et al.Simulation and experiment of spatial distribution effect after straw incorporation into soil by rotary burial[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(9): 69-77. | |

| 22 | 中国农业机械化科学研究院. 农业机械手册(上)[M]. 北京: 中国农业机械出版社, 2007. |

| 23 | 周华,张居敏,祝英豪,等.秸秆还田深松旋埋联合耕整机设计与试验[J]. 农业工程学报, 2017, 33(22): 17-26. |

| Zhou Hua, Zhang Ju-min, Zhu Ying-hao, et al. Design and experiment of combined tillage machine for subsoiling and rotary burying of straw incorporated into soil[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(22): 17-26. | |

| 24 | 刘晓鹏,张青松,肖文立,等.稻油轮作区驱动圆盘犁对置组合式耕整机设计与试验[J]. 农业机械学报, 2017, 48(12): 33-41. |

| Liu Xiao-peng, Zhang Qing-song, Xiao Wen-li, et al. Design and experiment on symmetrical driven disc plows combined tillage machine for rice-rapeseed rotation area[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(12): 33-41. | |

| 25 | NT/Y 2709—2015. 油菜播种机作业质量 [S]. |

| [1] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [2] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [3] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [4] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [5] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [6] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [7] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [8] | 付君,钱志辉,尹维,王甲甲,任露泉. 小麦摩擦与拉伸性能[J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

|

||