吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (12): 2883-2891.doi: 10.13229/j.cnki.jdxbgxb20210420

钢箱梁横隔板-纵肋疲劳裂纹气动冲击维修试验

- 河海大学 土木与交通学院,南京 210098

Pneumatic impact test on rib⁃to⁃diaphragm fatigue crack of steel box girder

Zhi-yuan YUANZHOU( ),Bo-hai JI(

),Bo-hai JI( ),Jun-yuan XIA,Tong SUN

),Jun-yuan XIA,Tong SUN

- College of Civil and Transportation Engineering,Hohai University,Nanjing 210098,China

摘要:

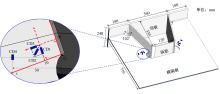

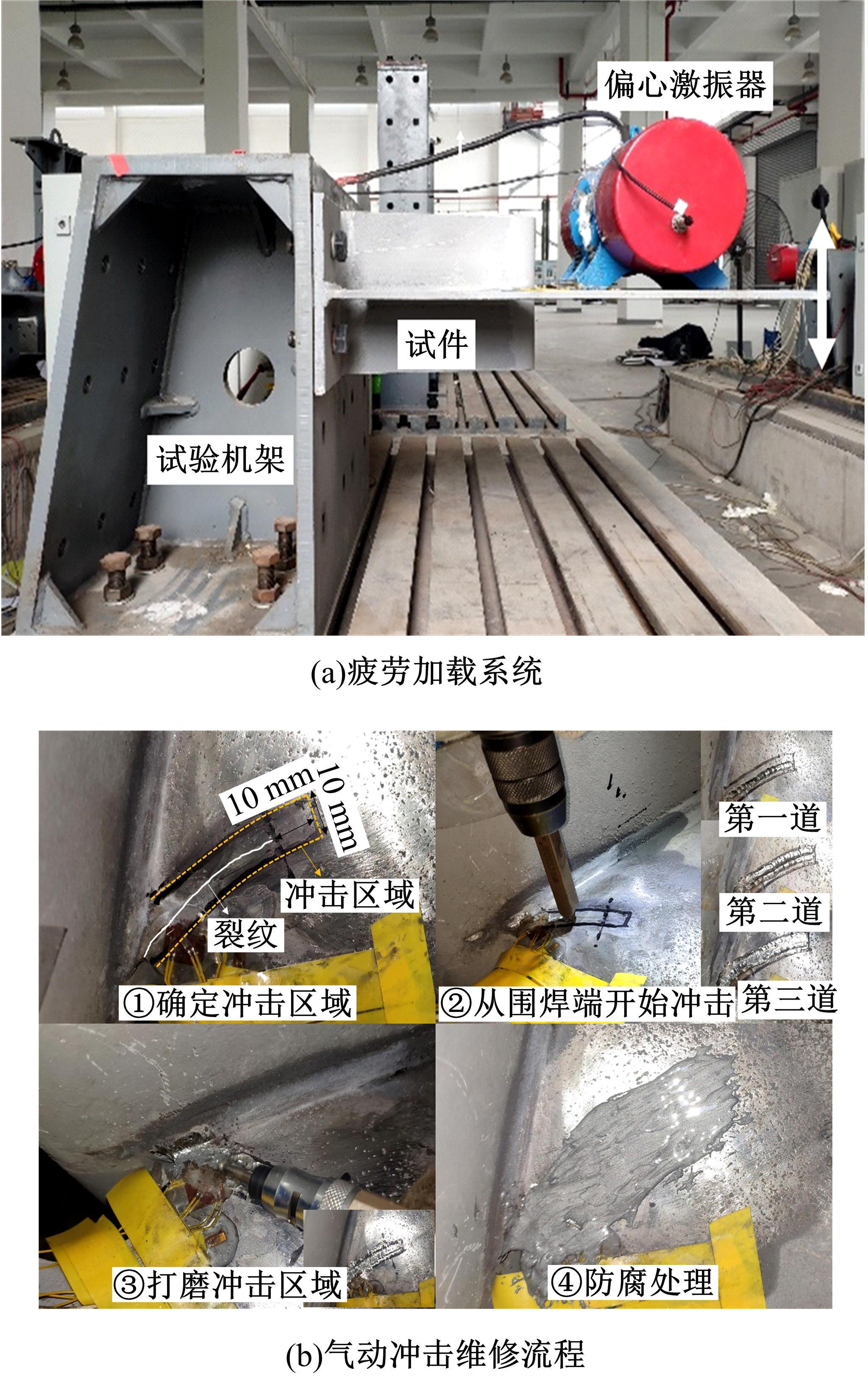

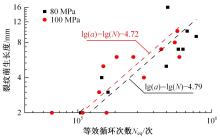

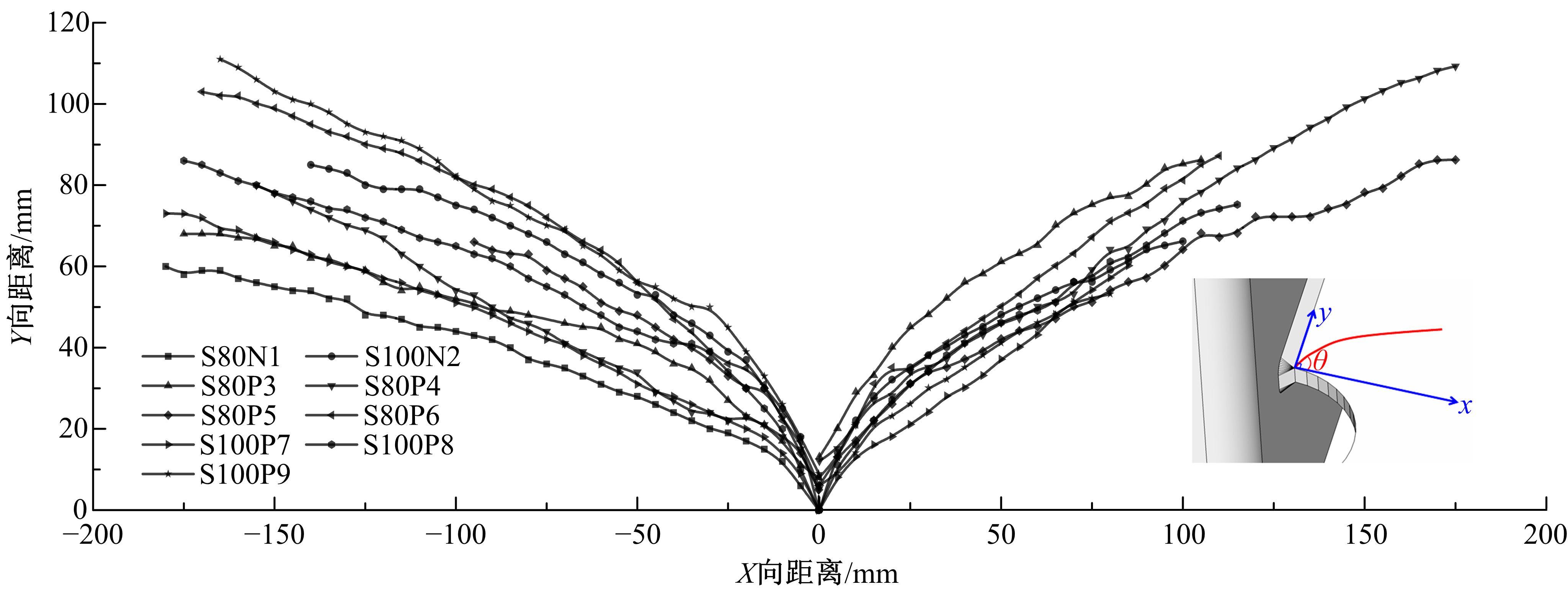

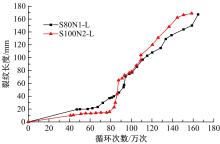

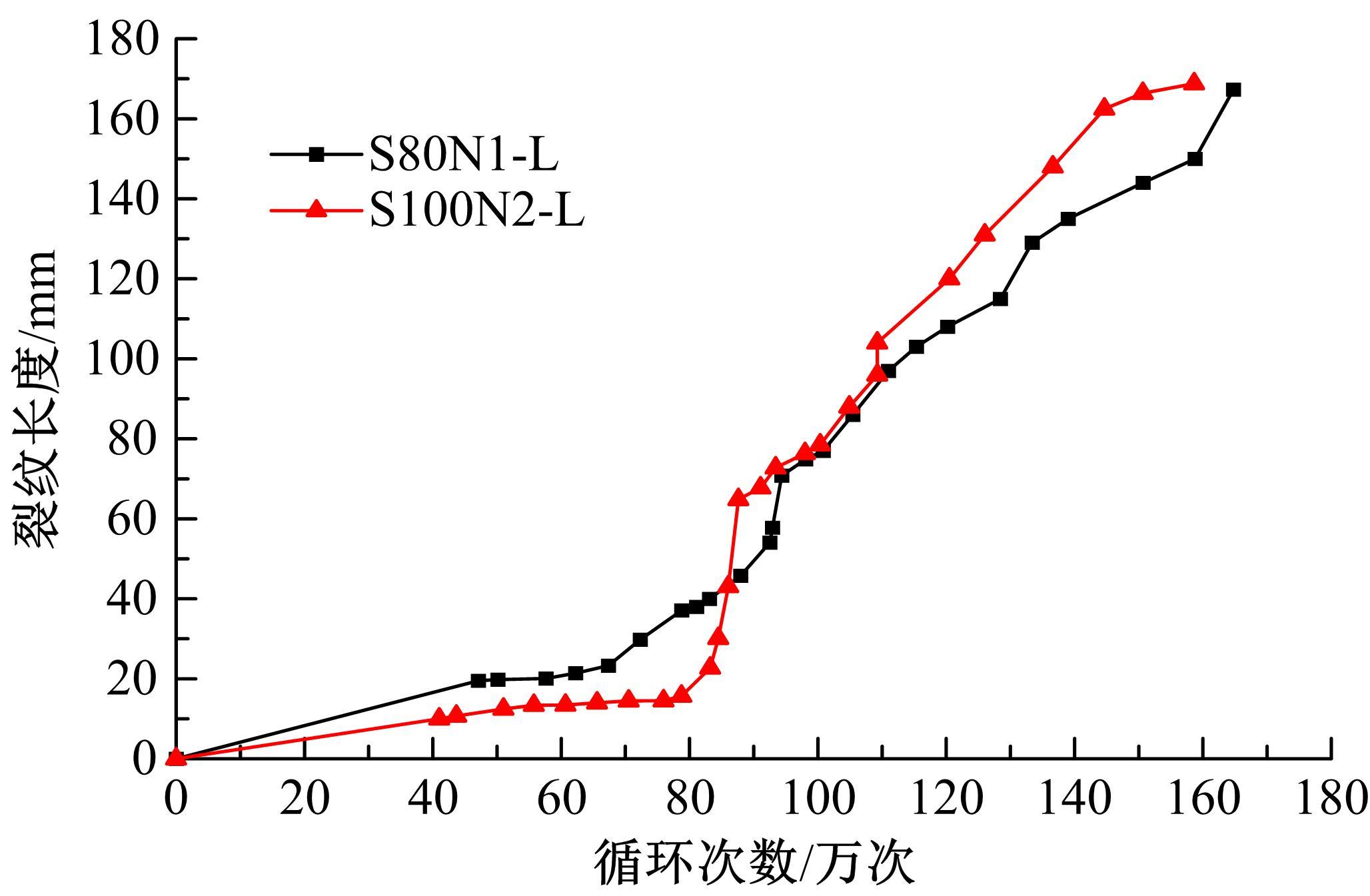

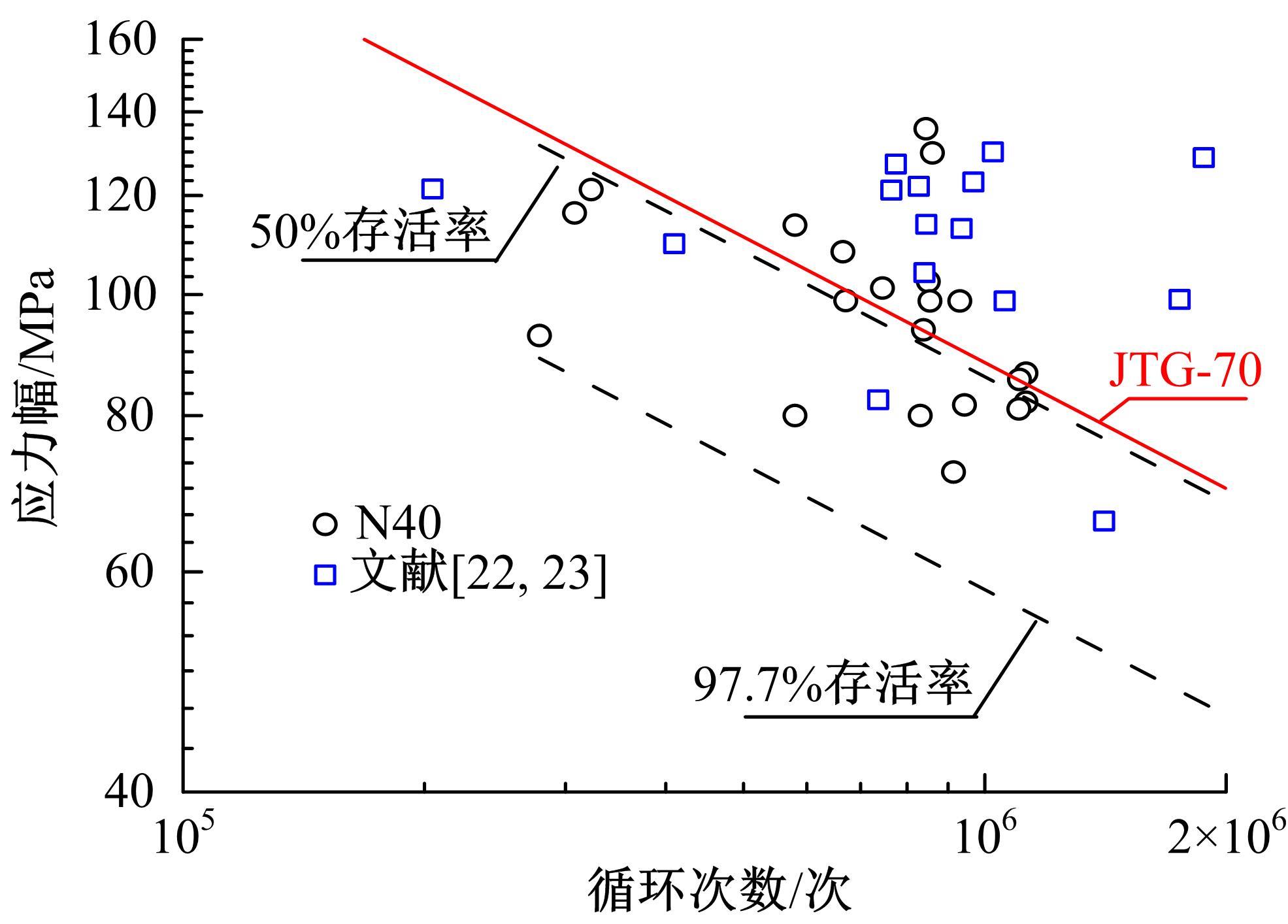

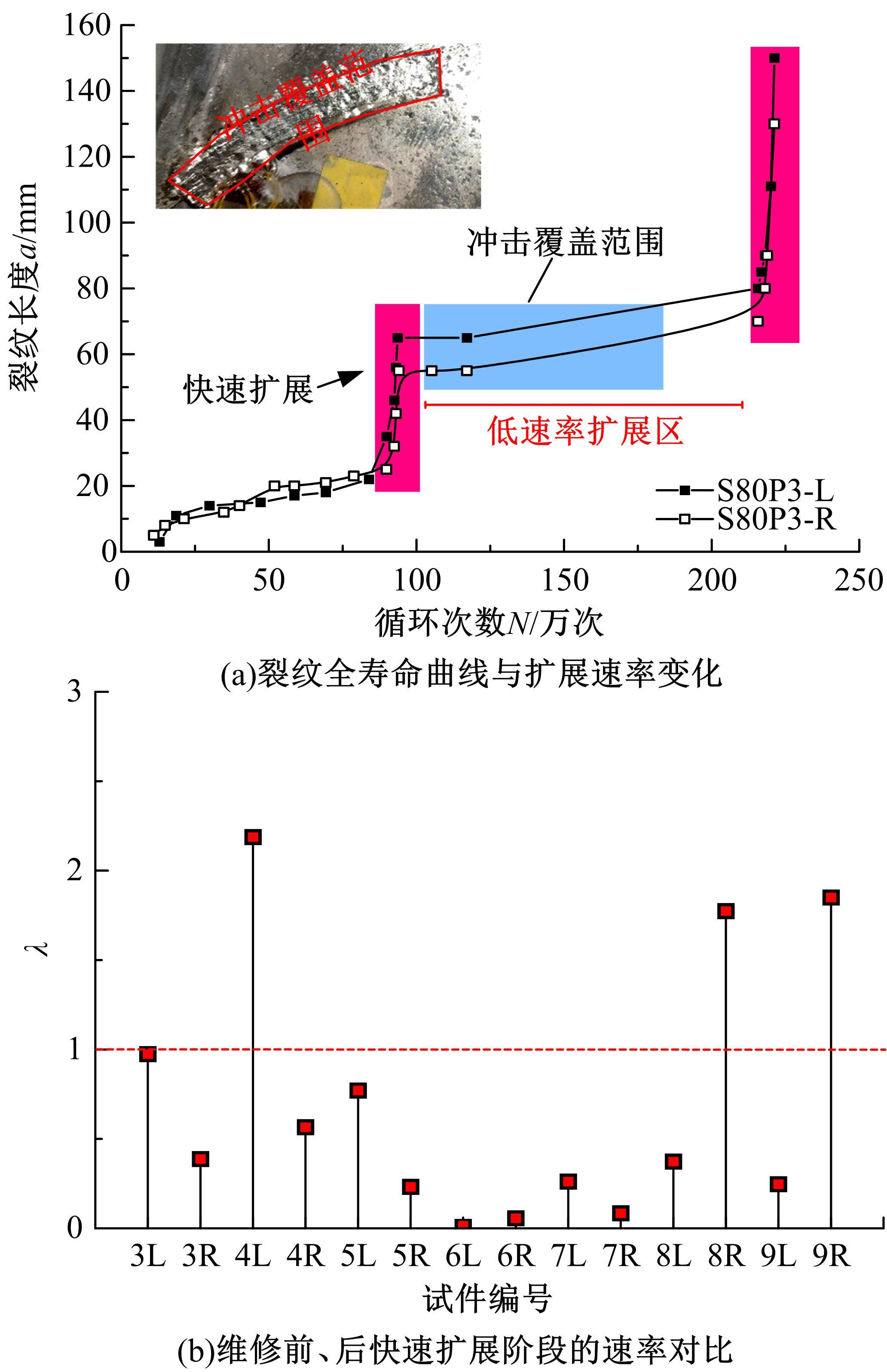

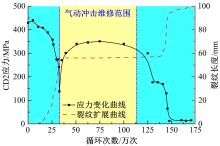

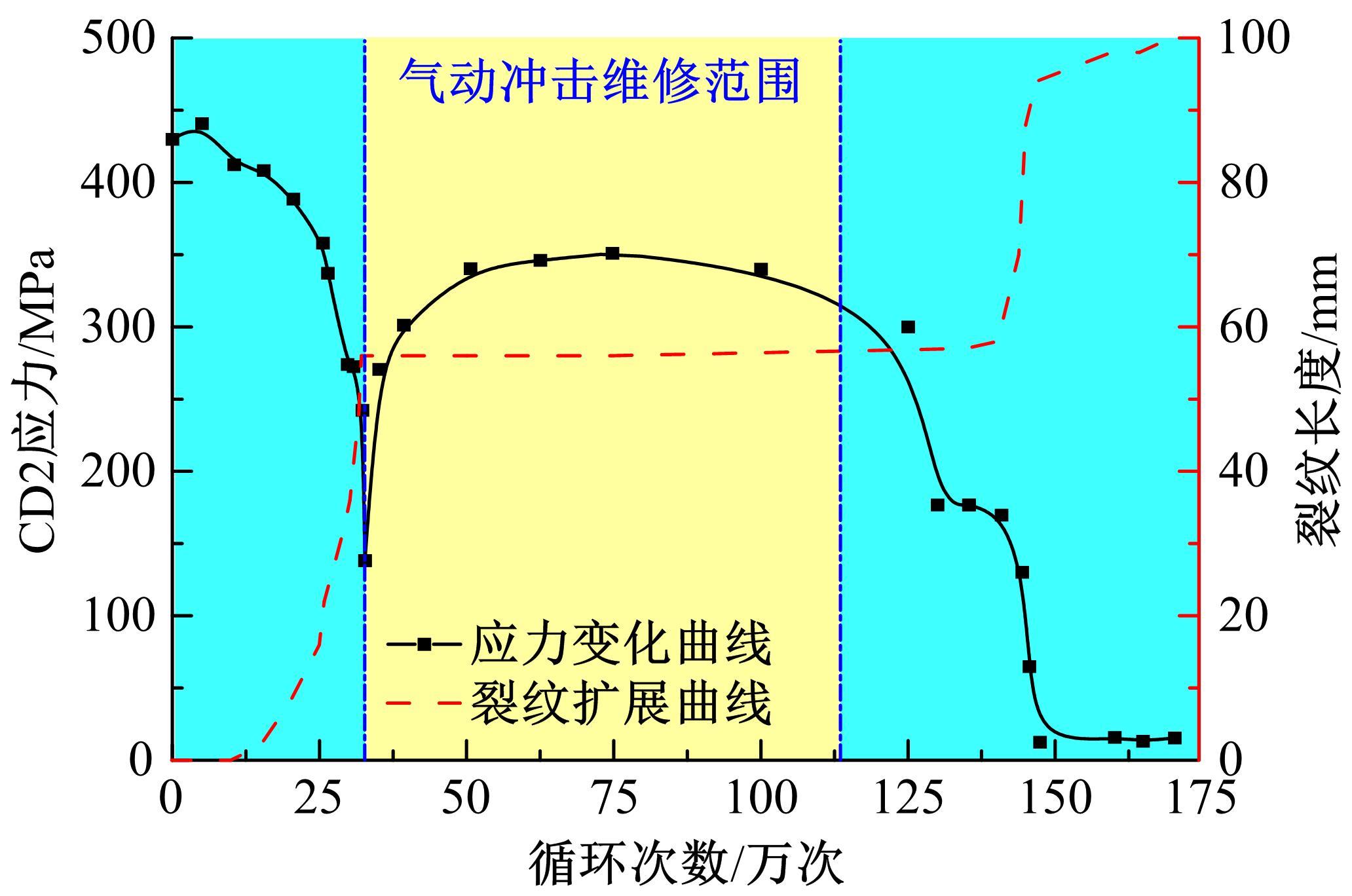

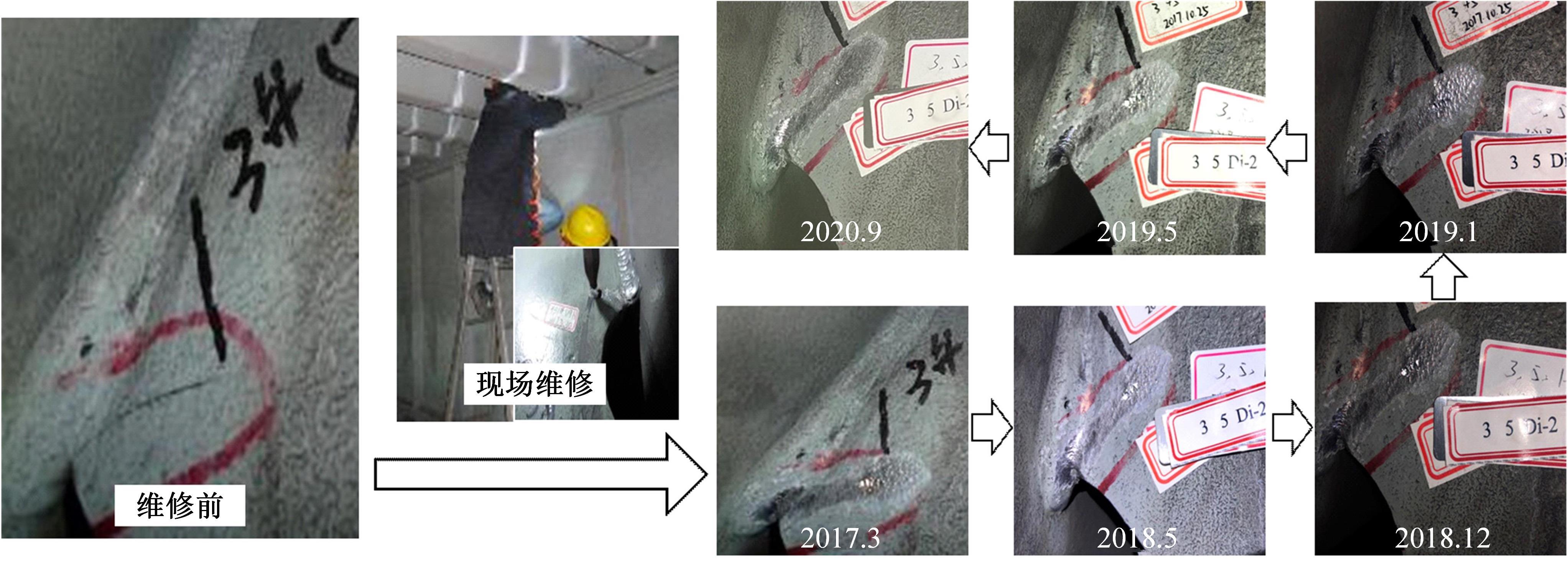

采用气动冲击维修技术对横隔板和纵肋弧形缺口部位疲劳裂纹实施维修,并结合疲劳试验对维修效果进行评估。先后累计开展了11个试件的弯曲疲劳试验,探讨了横隔板和纵肋弧形缺口部位焊缝疲劳性能以及裂纹扩展规律;对比分析了气动冲击维修前、后疲劳裂纹扩展速率以及局部承载能力的变化情况;揭示了气动冲击维修技术对于横隔板和纵肋弧形缺口部位疲劳裂纹的维修效果。研究结果表明:在面外变形作用下,横隔板和纵肋弧形缺口部位的疲劳强度约为46 MPa,低于我国现有规范(JTG D64—2015)中的建议值,并且疲劳裂纹易萌生于焊缝包脚处,主要沿着横隔板母材扩展,呈现出复合型裂纹扩展特征。气动冲击维修后,裂纹均出现了明显的扩展迟滞现象,表明气动冲击维修技术对于抑制该部位疲劳裂纹扩展有显著效果。4年多的工程应用结果也充分验证了本文方法在横隔板和纵肋弧形缺口部位疲劳裂纹维修工作中的有效性。

中图分类号:

- U443.32

| 1 | Pfeil M S, Battista R C, Mergulhao A J R. Stress concentration in steel bridge orthotropic decks[J]. Journal of Constructional Steel Research, 2005, 61(8): 1172-1184. |

| 2 | Xiao Z G, Yamada K, Inoue J, et al. Fatigue cracks in longitudinal ribs of steel orthotropic deck[J]. International Journal of Fatigue, 2006, 28(4): 409-416. |

| 3 | Guo T, Li A Q, Li J H. Fatigue life prediction of welded joints in orthotropic steel decks considering temperature effect and increasing traffic flow[J]. Structural Health Monitoring, 2008, 7(3): 189-202. |

| 4 | Fisher J W, Barsom J M. Evaluation of cracking in the rib-to-deck welds of the bronx—whitestone bridge[J]. Journal of Bridge Engineering, 2015, 21(3): 1-10. |

| 5 | 张允士, 李法雄, 熊锋, 等. 正交异性钢桥面板疲劳裂纹成因分析及控制[J]. 公路交通科技, 2013, 30(8): 75-80. |

| Zhang Yun-shi, Li Fa-xiong, Xiong Feng, et al. Cause analysis and control measures of fatigue cracks in orthotropic steel deck[J]. Highway Traffic Science and Technology, 2013, 30(8): 75-80. | |

| 6 | 李传习, 李游, 陈卓异, 等. 基于实测车流的钢箱梁横隔板疲劳特性[J]. 长安大学学报:自然科学版, 2019, 39(5): 48-58. |

| Li Chuan-xi, Li You, Chen Zhuo-yi, et al. Fatigue characteristics of steel box girder based on measured vehicle flow[J]. Journal of Chang'an University(Natural Science Edition), 2019, 39(5): 48-58. | |

| 7 | 刘益铭, 张清华, 崔闯, 等. 正交异性钢桥面板三维疲劳裂纹扩展数值模拟方法[J]. 中国公路学报, 2016, 29(7): 89-95. |

| Liu Yi-ming, Zhang Qing-hua, Cui Chuang, et al. Numerical simulation method for 3D fatigue crack propagation of orthotropic steel bridge deck[J]. China Journal of Highway and Transport, 2016, 29(7): 89-95. | |

| 8 | 汪珍, 王莹. 正交异性钢桥面板的疲劳裂纹扩展规律[J]. 中南大学学报:自然科学版, 2020, 51(7): 1873-1882. |

| Wang Zhen, Wang Ying. Analysis of fatigue crack propagation on orthotropic steel bridge deck[J]. Journal of Central South University(Science and Technology), 2020, 51(7): 1873-1882. | |

| 9 | Choi J H, Kim D H. Stress characteristics and fatigue crack behaviour of the longitudinal rib-to-cross beam joints in an orthotropic steel deck[J]. Advances in Structural Engineering, 2008, 11(2): 189-198. |

| 10 | Gao W, Dai S, Xiao T, et al. Failure process of rock slopes with cracks based on the fracture mechanics method[J]. Engineering Geology, 2017, 231:190-199. |

| 11 | Patel A B, Pandey R K. Fatigue crack growth under mixed-mode loading[J]. Fatigue & Fracture of Engineering Materials & Structures, 2007, 4(1): 65-77. |

| 12 | 马世骧, 胡泓. CTS试件中复合型疲劳裂纹扩展[J]. 力学学报, 2006, 38(5): 698-704. |

| Ma Shi-xiang, Hu Hong. Compound fatigue crack propagation in CTS specimen[J]. Chinese Journal of Theoretical and Applied Mechanics, 2006, 38(5): 698-704. | |

| 13 | 房亮, 傅中秋, 王益逊, 等. 钢桥面板横隔板疲劳裂纹维修对未开裂侧的影响[J]. 南昌大学学报:工科版, 2019, 41(4): 336-344. |

| Fang Liang, Fu Zhong-qiu, Wang Yi-xun, et al. Effect of fatigue crack maintenance on uncracked side stress of steel bridge deck diaphragm[J]. Journal of Nanchang University (Engineering & Technology), 2019, 41(4): 336-344. | |

| 14 | 陈卓异, 李传习, 柯璐, 等. 某悬索桥钢箱梁疲劳病害及处治方法研究[J]. 土木工程学报, 2017, 50(3): 91-100. |

| Chen Zhuo-yi, Li Chuan-xi, Ke Lu, et al. Study on fatigue damages and retrofit methods of steel box girder in a suspension bridge[J]. China Civil Engineering Journal, 2017, 50(3): 91-100. | |

| 15 | Yuanzhou Z Y, Ji B H, Fu Z Q, et al. Retarding effects on crack propagation by closing crack surface using ICR treatment[J]. Journal of Constructional Steel Research, 2018, 143: 11-17. |

| 16 | Yamada K, Ishikawa T, Kakiichi T. Rehabilitation and improvement of fatigue life of welded joints by ICR treatment[J]. Advanced Steel Construction, 2015, 11(3): 294-304. |

| 17 | Yuanzhou Z Y, Ji B H, Fu Z Q, et al. Fatigue performance of cracked rib-deck welded joint retrofitted by ICR technique[J]. International Journal of Steel Structures, 2016, 16(3): 735-742. |

| 18 | Wang Q D, Ji B H, Fu Z Q, et al. Effect of crack-closure treatment on fatigue durability of cracked rib-to-deck welded joints in steel bridge decks[J]. Journal of Central South University, 2019, 26(9): 2554-2568. |

| 19 | . 桥梁用结构钢 [S]. |

| 20 | 孔祥明, 吉伯海, 傅中秋, 等. 钢桥面板典型细节疲劳应力及变形特征分析[J]. 工业建筑, 2017, 47(5):6-11. |

| Kong Xiang-ming, Ji Bo-hai, Fu Zhong-qiu, et al. Research on fatigue stress and deformation characteristics of typical details of steel bridge deck[J]. Industrial Construction, 2017, 47(5):6-11. | |

| 21 | . 公路桥梁钢箱梁疲劳裂纹检测、评定与维护规范 [S]. |

| 22 | 宗亮. 基于断裂力学的钢桥疲劳裂纹扩展与寿命评估方法研究[D]. 北京: 清华大学土木水利学院, 2015: 73-74. |

| Zong Liang. Investigation on fatigue crack propagation and life prediction of steel bridges based on fracture mechanics[D]. Beijing: School of Civil Engineering, Tsinghua University, 2015: 73-74. | |

| 23 | . 公路钢结构桥梁设计规范 [S]. |

| 24 | 陈一馨, 吕彭民, 李大涛. U肋与横隔板焊接构造细节疲劳强度研究[J]. 桥梁建设, 2014, 44(3): 63-68. |

| Chen Yi-xin, Peng-min Lü, Li Da-tao. Study of fatigue strength of structural details of u-rib and diaphragm welding joints[J]. Bridge Construction, 2014, 44(3): 63-68. | |

| 25 | 陈念念. 钢箱梁U肋与横隔板连接部位疲劳开裂钢板加固技术研究[D]. 南京: 河海大学土木与交通学院,2021. |

| Chen Nian-nian. Study on fatigue cracking steel plate reinforcement technology of connection between u-rib and diaphragm on steel box girder[D]. Nanjing: College of Civil and Transportation Engineering, Hohai University, 2021. |

| [1] | 韩智强,谢刚,周勇军,刘世忠,晋民杰. 曲线桥梁车桥耦合振动数值分析方法[J]. 吉林大学学报(工学版), 2023, 53(2): 515-522. |

| [2] | 杨国俊,田骐玮,吕明航,杜永峰,唐光武,韩宗健,伏一多. 大跨度悬索桥隧道式锚碇力学特性研究综述[J]. 吉林大学学报(工学版), 2022, 52(6): 1245-1263. |

| [3] | 严庆光,冯梓轩,李湘吉,王瑛玮. 一机六件等应力三点弯曲疲劳试验机的研制[J]. 吉林大学学报(工学版), 2021, 51(6): 2013-2020. |

| [4] | 李春良,林志豪,赵珞珞. 铰缝及板损伤后对空心板桥横向受力的影响[J]. 吉林大学学报(工学版), 2021, 51(2): 611-619. |

| [5] | 于天来, 刘兴国, 姚爽, 穆罕默德马苏. 碳纤维筋体外预应力加固钢筋混凝土梁的疲劳性能[J]. 吉林大学学报(工学版), 2016, 46(6): 1867-1873. |

| [6] | 刘震涛, 孙朝晖, 潘俊, 黄瑞, 陈俊玄, 俞小莉. 机械约束对缸盖热疲劳模拟试验的影响[J]. 吉林大学学报(工学版), 2015, 45(5): 1450-1454. |

| [7] | 刘克格, 闫楚良. 结构疲劳试验寿命数据分布类型对其使用寿命的影响[J]. 吉林大学学报(工学版), 2011, 41(02): 419-0423. |

| [8] | 陈俊, 黄晓明. 基于离散元法的沥青混合料虚拟疲劳试验方法[J]. 吉林大学学报(工学版), 2010, 40(02): 435-0440. |

| [9] | 石启印, 陆鸣,张庆宗 ,李爱群,惠卓 . 碳纤维布加固的钢筋砼吊车梁的抗弯疲劳性能[J]. 吉林大学学报(工学版), 2008, 38(01): 99-104. |

|