吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1897-1907.doi: 10.13229/j.cnki.jdxbgxb20200487

• 农业工程·仿生工程 • 上一篇

油菜联合收获机筛下物组分质量比对清选性能的影响

袁佳诚1,2( ),王昌1,2,何坤1,2,万星宇1,2,廖庆喜1,2(

),王昌1,2,何坤1,2,万星宇1,2,廖庆喜1,2( )

)

- 1.华中农业大学 工学院,武汉 430070

2.农业农村部 长江中下游农业装备重点实验室,武汉 430070

Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester

Jia-cheng YUAN1,2( ),Chang WANG1,2,Kun HE1,2,Xing-yu WAN1,2,Qing-xi LIAO1,2(

),Chang WANG1,2,Kun HE1,2,Xing-yu WAN1,2,Qing-xi LIAO1,2( )

)

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-Lower Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

摘要:

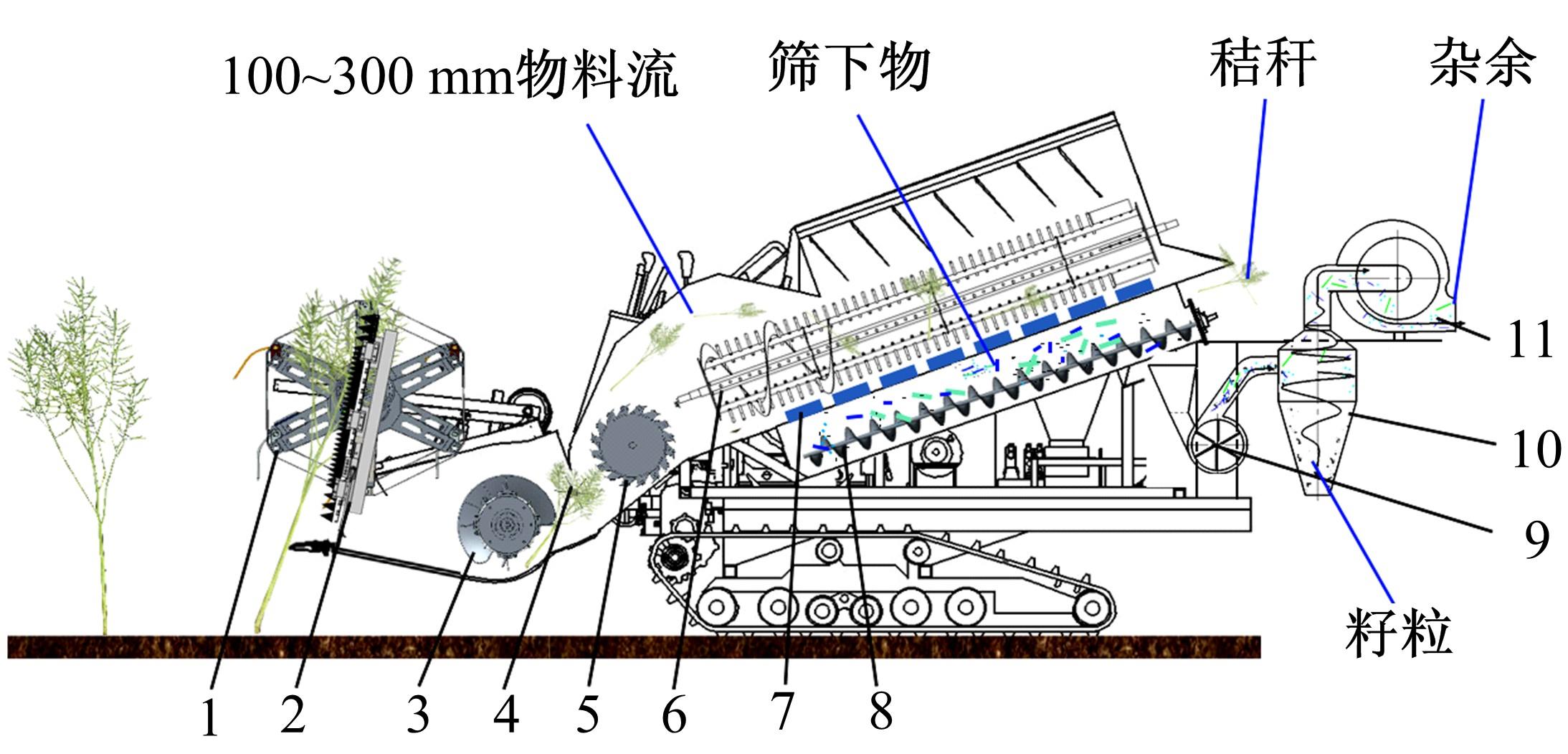

针对油菜联合收获机筛下物组分在不同质量比条件下,旋风分离清选系统性能差异较大的问题,开展了筛下物组分质量比对旋风分离清选系统性能影响的研究。基于自主研发的4LYZ-2.0型油菜联合收获机,开展了以切抛组合式纵轴流脱粒分离装置切碎滚筒和脱粒滚筒转速为因素的双因素试验;以筛下物组分质量比为因素开展了二次旋转正交组合试验,构建了荚壳、短茎秆质量比与清洁率、损失率之间的回归模型,基于多目标优化明确了荚壳、短茎秆质量比的较优变化区间。双因素试验表明:切碎滚筒转速为430~550 r/min、脱粒滚筒转速为450~650 r/min时,筛下物中荚壳、短茎秆、轻杂余、籽粒质量比变化区间分别为20.86%~31.68%、9.12%~16.47%、8.36%~11.27%、50.05%~51.93%;多目标优化结果表明:当荚壳质量比在20.00%~27.67%、短茎秆质量比在9.00%~12.08%时,旋风分离清选系统损失率低于6%、清洁率大于94%;田间试验表明:当切碎滚筒转速为550 r/min、脱粒滚筒转速为450 r/min时,脱粒装置夹带损失率为2.01%,旋风分离清选系统损失率为5.39%、清洁率为94.62%,为油菜联合收获机脱粒分离装置和清选系统的参数优化与匹配提供了参考。

中图分类号:

- S225.99

| 1 | 陈旭, 吴崇友, 张敏. 我国油菜联合收割机发展现状及趋势分析[J]. 中国农机化学报, 2018, 39(10): 28-31. |

| Chen Xu, Wu Chong-you, Zhang Min. Development status and trend analysis of rapeseed combine harvester in China[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(10): 28-31. | |

| 2 | 吴崇友, 肖圣元, 金梅. 油菜联合收获与分段收获效果比较[J]. 农业工程学报, 2014, 30(17): 10-16. |

| Wu Chong-you, Xiao Sheng-yuan, Jin Mei. Comparation on rape combine harvesting and two-stage harvesting[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(17): 10-16. | |

| 3 | 吴崇友, 王积军, 廖庆喜, 等. 油菜生产现状与问题分析[J]. 中国农机化学报, 2017, 38(1): 124-131. |

| Wu Chong-you, Wang Ji-jun, Liao Qing-xi, et al. Current status and problems of rapeseed production[J]. Journal of Chinese Agricultural Mechanization, 2017, 38(1): 124-131. | |

| 4 | 黄小毛, 宗望远. 油菜联合收获的研究现状及发展趋势[J]. 农业工程, 2012, 2(1): 14-19. |

| Huang Xiao-mao, Zong Wang-yuan. Research status and development trend of rape combine harvest[J]. Agricultural Engineering, 2012, 2(1): 14-19. | |

| 5 | 吴福良. 多功能油菜联合收获机的现状及发展方向[J]. 农业装备与车辆工程, 2007(4): 3-5. |

| Wu Fu-liang. The existing state and developing direction of multifunction rape combine-harveste[J]. Agricultural Equipment&Vehicle Engineering, 2007(4): 3-5. | |

| 6 | 李耀明, 邓玲黎, 丁为民, 等. 小型联合收割机清选装置的技术分析[J]. 农机化研究, 2004(3): 55-56. |

| Li Yao-ming, Deng Ling-li, Ding Wei-min, et al. Analysis and improvement design on the cleaning mechanism of small grain combine[J]. Journal of Agricultural Mechanization Research, 2004(3): 55-56. | |

| 7 | 汤庆, 吴崇友, 王素珍, 等. 谷物清选装置研究现状及发展趋势[J]. 农机化研究, 2013(12): 225-228. |

| Tang Qing, Wu Chong-you, Wang Su-zhen, et al. Research advances and prospects in cleaning device of grain[J]. Journal of Agricultural Mechanization Research, 2013(12): 225-228. | |

| 8 | 李洋, 徐立章, 周蓥, 等. 脱出物喂入量对多风道清选装置内部气流场的影响[J]. 农业工程学报, 2017, 33(12): 48-55. |

| Li Yang, Xu Li-zhang, Zhou Ying, et al. Effect of extractions feed-quantity on airflow field in multi-ducts cleaning device[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(12): 48-55. | |

| 9 | 徐立章, 李洋, 李耀明, 等. 谷物联合收获机清选技术与装置研究进展[J]. 农业机械学报, 2019, 50(10): 1-16. |

| Xu Li-zhang, Li Yang, Li Yao-ming, et al. Research progress on cleaning technology and device of grain combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50 (10): 1-16. | |

| 10 | 程超, 付君, 陈志, 等. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报: 工学版, 2021, 51(2): 761-771. |

| Cheng Chao, Fu Jun, Chen Zhi, et al. Sieve blocking laws and stripping test of corn grain harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 761-771. | |

| 11 | 刘大为, 卢伟, 王修善, 等. 联合收割机旋风分离清选装置研究现状及发展趋势[J]. 农业装备与车辆工程, 2016, 54(5): 8-13. |

| Liu Da-wei, Lu Wei, Wang Xiu-shan, et al. Research status and development trend of cyclone separating cleaning unit of combine harvesters[J]. Agricultural Equipment&Vehicle Engineering, 2016, 54(5): 8-13. | |

| 12 | 刘正怀, 郑一平, 王志明, 等. 微型稻麦联合收获机气流式清选装置研究[J]. 农业机械学报, 2015, 46(7): 102-108. |

| Liu Zheng-huai, Zheng Yi-ping, Wang Zhi-ming, et al. Design on air-flowing cleaning unit of micro rice-wheat combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 102-108. | |

| 13 | 李杰, 闫楚良, 杨方飞. 联合收割机振动筛的动态仿真与参数优化[J]. 吉林大学学报: 工学版, 2006(5): 701-704. |

| Li Jie, Yan Chu-liang, Yang Fang-fei. Dynamic simulation and parameter optimization of the combine harvester vibration sieve[J]. Journal of Jilin University(Engineering and Technology Edition), 2006, 36(5): 701-704. | |

| 14 | 曹成茂, 罗坤, 彭美乐, 等. 山核桃物料风选机理与风选性能试验研究[J]. 农业机械学报, 2019, 50(9): 105-112. |

| Cao Cheng-mao, Luo Kun, Peng Mei-le, et al. Experiment on winnowing mechanism and winnowing performance of hickory material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(9): 105-112. | |

| 15 | 陈立, 廖庆喜, 宗望远, 等. 油菜联合收获机脱出物空气动力学特性测定[J]. 农业机械学报, 2012, 43(): 125-130. |

| Chen Li, Liao Qing-xi, Zong Wang-yuan, et al. Aerodynamic characteristics measurement of extraction components for rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Sup.1): 125-130. | |

| 16 | 廖庆喜, 陈立, 李海同, 等. 油菜联合收获机脱出物清选试验台[J]. 农业机械学报, 2013, 44(10): 80-85, 79. |

| Liao Qing-xi, Chen Li, Li Hai-tong, et al. Cleaning unit test-bed of extraction components for rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(10): 80-85, 79. | |

| 17 | 刘师多, 张利娟, 师清翔, 等. 微型小麦联合收获机旋风分离清选系统研究[J]. 农业机械学报, 2006, 37(6): 45-48. |

| Liu Shi-duo, Zhang Li-juan, Shi Qing-xiang, et al. Experimental research on cyclone separating cleaning system used on micro-combine harvester of wheat[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(6): 45-48. | |

| 18 | 高连兴, 赵学观, 杨德旭, 等. 大豆脱粒机气力清选循环装置研制与性能试验[J]. 农业工程学报, 2012, 28(24): 22-27. |

| Gao Lian-xing, Zhao Xue-guan, Yang De-xu, et al. Development and performance test on pneumatic cleaning-circulatory device of soybean thresher[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(24): 22-27. | |

| 19 | 戴飞, 赵武云, 刘国春, 等. 胡麻脱粒物料分离清选机设计与试验[J]. 农业机械学报, 2019, 50(8): 140-147. |

| Dai Fei, Zhao Wu-yun, Liu Guo-chun, et al. Design and experiment of separating and cleaning machine for flax threshing material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(8): 140-147. | |

| 20 | 倪长安, 张利娟, 刘师多, 等. 无导向片旋风分离清选系统的试验分析[J]. 农业工程学报, 2008,24(8): 135-138. |

| Ni Chang-an, Zhang Li-juan, Liu Shi-duo, et al. Experimental analysis on cyclone separating cleaning system of no-guide vanes[J]. Transactions of the Chinese Society of Agricultural Engineering, 2008, 24(8): 135-138. | |

| 21 | 敬志臣, 韩正晟, 高爱民, 等. 基于Fluent软件的旋风分离清选系统仿真研究[J]. 机械研究与应用, 2014, 27(6): 25-27, 30. |

| Jing Zhi-chen, Han Zheng-sheng, Gao Ai-min, et al. Simulation study on cyclone separation cleaning system based on Fluent[J]. Mechanical Research & Application, 2014, 27(6): 25-27, 30. | |

| 22 | 廖庆喜, 万星宇, 李海同, 等. 油菜联合收获机旋风分离清选系统设计与试验[J]. 农业工程学报, 2015, 31(14): 24-31. |

| Liao Qing-xi, Wan Xing-yu, Li Hai-tong, et al. Design and experiment on cyclone separating cleaning system for rape combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(14): 24-31. | |

| 23 | 陈翠英, 王志华, 李青林. 油菜脱出物在气流中的运动分析[J]. 农业机械学报, 2004, 35(5): 90-93. |

| Chen Cui-ying, Wang Zhi-hua, Li Qing-lin. Analysis of aerodynamic properties of rape extractions[J]. Transactions of the Chinese Society for Agricultural Machinery, 2004, 35(5): 90-93. | |

| 24 | 侯华铭, 崔清亮, 郭玉明. 全喂入谷子联合收获机脱出物含水率对其悬浮特性的影响[J]. 农业工程学报, 2018, 34(24): 29-35. |

| Hou Hua-ming, Cui Qing-liang, Guo Yu-ming. Effects of moisture contents of threshed materials from whole-feeding combine for foxtail millet on their suspension characteristics[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(24): 29-35. | |

| 25 | Huang A N, Ito K, Fukasawa T, et al. Effects of particle mass loading on the hydrodynamics and separation efficiency of a cyclone separator[J]. Journal of the Taiwan Institute of Chemical Engineers, 2018, 90: 61-67. |

| 26 | 程超, 付君, 郝付平, 等. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报: 工学版, 2020, 50(1): 351-360. |

| Cheng Chao, Fu Jun, Hao Fu-ping, et al. Effect of motion parameters of cleaning screen on corn cob blocking law[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 351-360. | |

| 27 | 廖庆喜, 徐阳, 袁佳诚, 等. 油菜联合收获机切抛组合式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2019, 50(7): 140-150. |

| Liao Qing-xi, Xu Yang, Yuan Jia-cheng, et al. Design and experiment of combined cutting and throwing vertical axial flow detachment device for rape combine harvester[J]. Transactions of the Chinese Society for Agricultura Machinery, 2019, 50(7): 140-150. | |

| 28 | 万星宇, 舒彩霞, 徐阳, 等. 油菜联合收获机分离清选差速圆筒筛设计与试验[J]. 农业工程学报, 2018, 34(14): 27-35. |

| Wan Xing-yu, Shu Cai-xia, Xu Yang, et al. Design and experiment on cylinder sieve with different rotational speed in cleaning system for rape combine harvesters[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(14): 27-35. |

| [1] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [2] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [3] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [4] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [5] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [6] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [7] | 付君,钱志辉,尹维,王甲甲,任露泉. 小麦摩擦与拉伸性能[J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

| [8] | 高印寒,陈王锋,程鹏,李振雷,池俊成,李强 . 旋风分离器两相三维流场仿真 [J]. 吉林大学学报(工学版), 2008, 38(增刊): 85-0089. |

|

||