吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 288-295.doi: 10.13229/j.cnki.jdxbgxb20210657

• 车辆工程·机械工程 • 上一篇

基于子领域自适应的变工况下滚动轴承故障诊断

- 1.重庆交通大学 机电与车辆工程学院,重庆 400074

2.重庆工业大数据创新中心有限公司 重庆 404100

Fault diagnosis of rolling bearing under variable operating conditions based on subdomain adaptation

Shao-jiang DONG1( ),Peng ZHU1,Xue-wu PEI1,Yang LI1,Xiao-lin HU2

),Peng ZHU1,Xue-wu PEI1,Yang LI1,Xiao-lin HU2

- 1.School of Mechatronics and Vehicle Engineering,Chongqing Jiaotong University,Chongqing 400074,China

2.Chongqing Industrial Big Data Innovation Center Co. ,Ltd. ,Chongqing 404100,China

摘要:

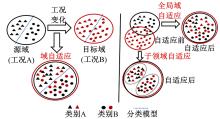

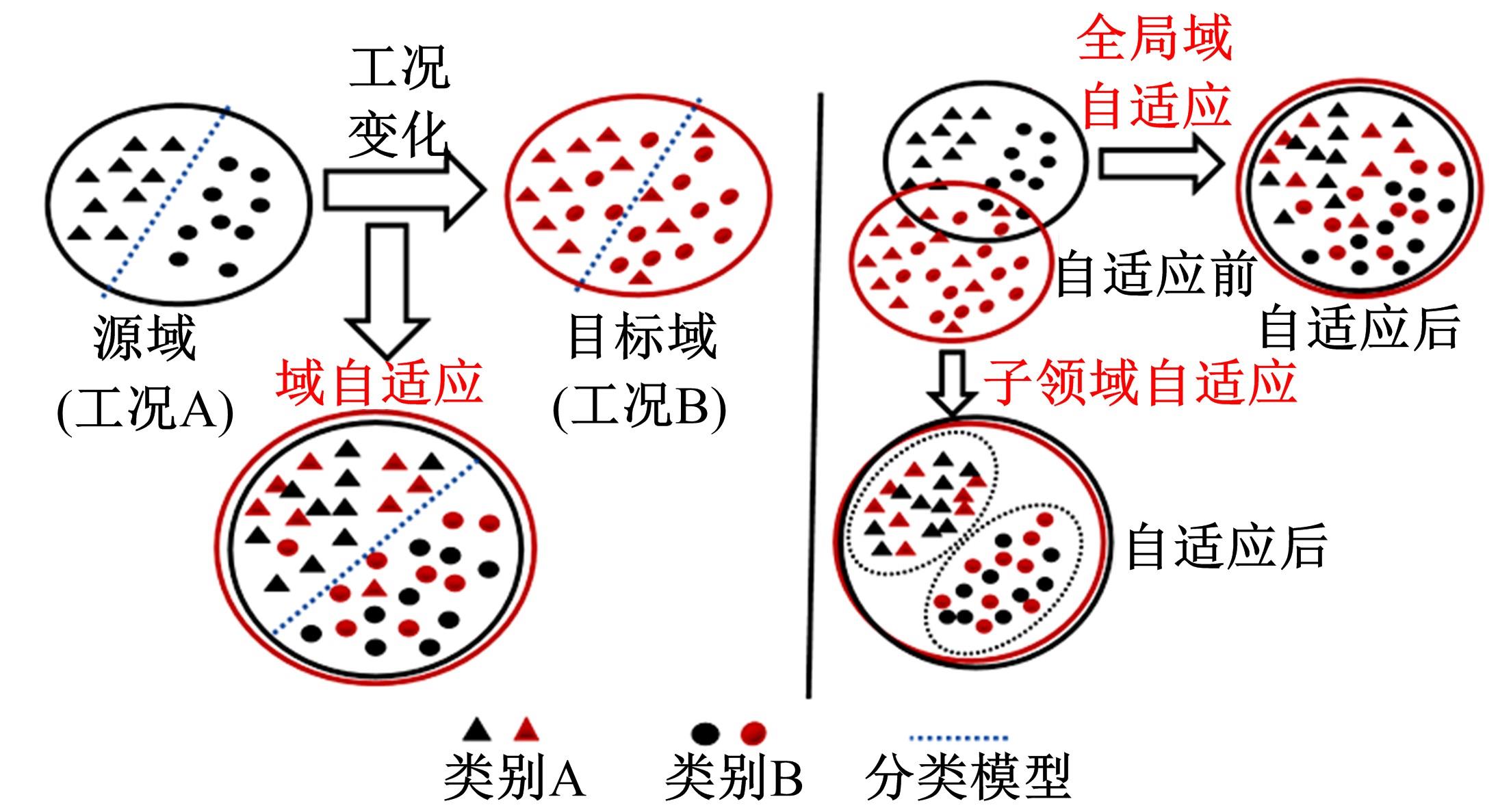

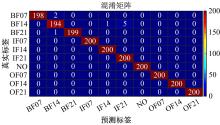

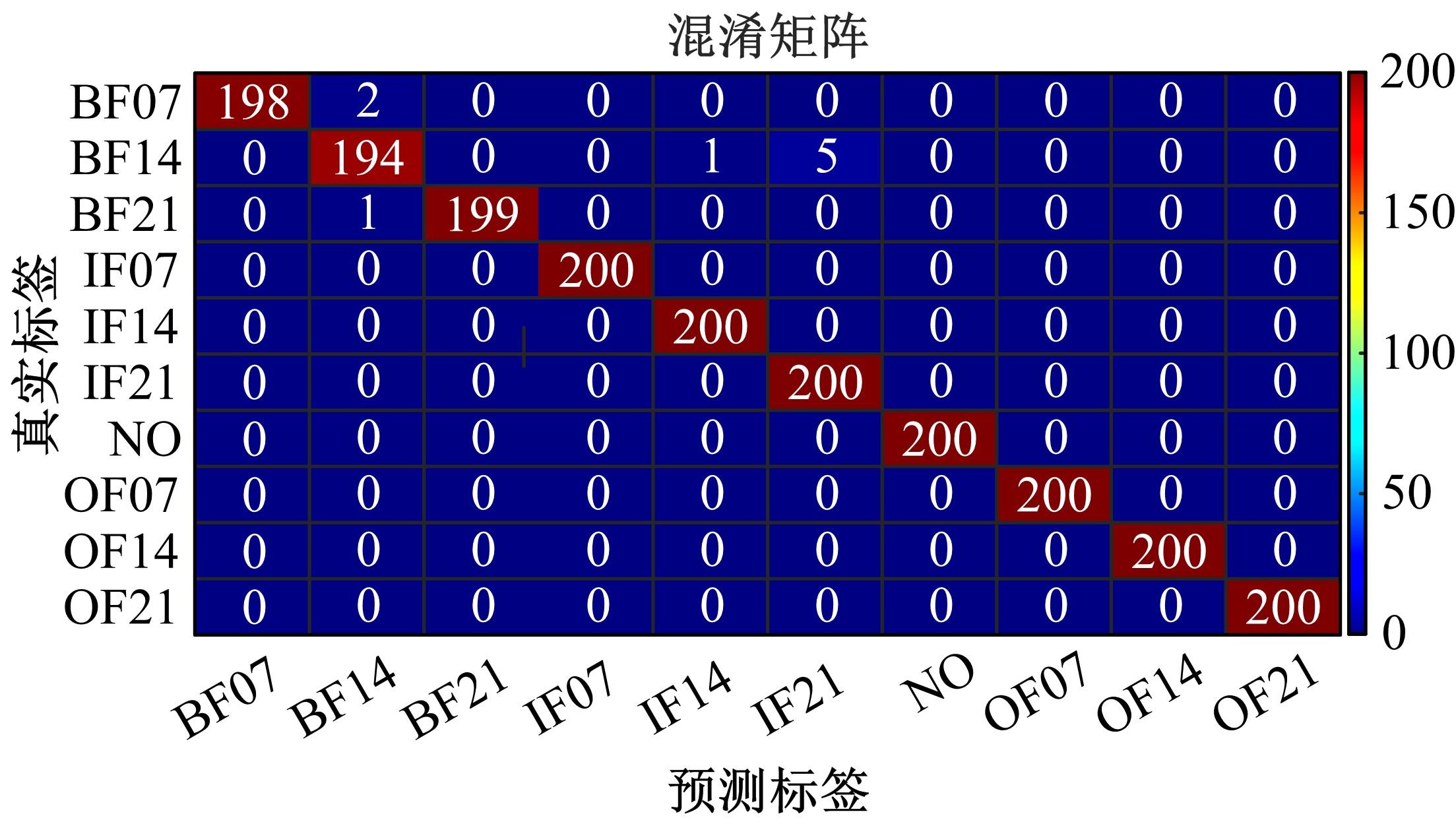

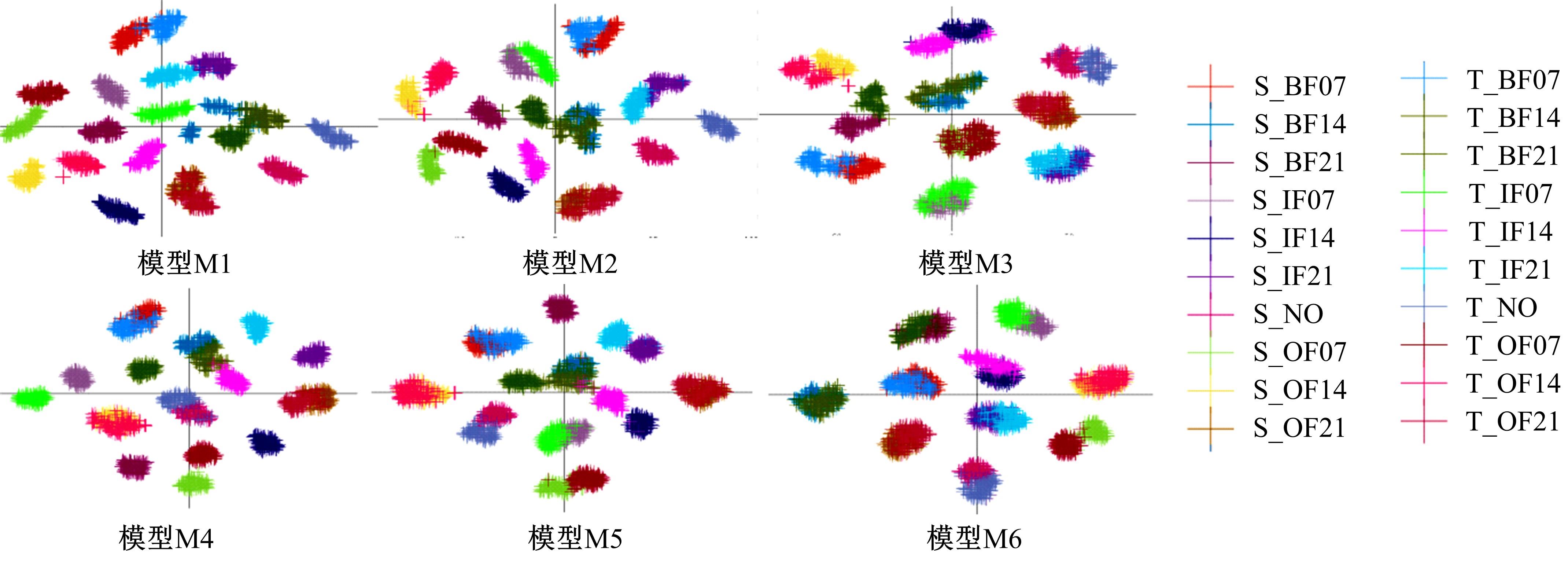

针对变工况环境下采集到的滚动轴承振动数据特征分布不一致及待诊断样本标签较难获取的问题,提出了一种子领域自适应的深度迁移学习故障诊断方法。首先,为充分利用卷积神经网络图像特征提取能力,将滚动轴承振动信号采用连续小波变换生成图像数据集;其次,源域与目标域通用特征提取采用改进图像集预训练的ResNet-50网络结构,子领域自适应度量引入局部最大均值差异(LMMD)准则,该度量准则通过计算目标域伪标签以匹配条件分布距离来进行子领域自适应,从而减小不同工况下的子类故障特征分布差异,提高模型诊断精度;最后,在两个公开变工况滚动轴承故障数据集上进行试验验证,结果表明,本文方法平均识别准确率为99%左右,并将其与不同诊断方法进行了对比分析,说明了本文方法的有效性与优越性。

中图分类号:

- TH17

| 1 | Zhao Z B,Wu J Y,Li T F, et al. Challenges and opportunities of AI-enabled monitoring, diagnosis & prognosis: a review[J]. Chinese Journal of Mechanical Engineering, 2021, 34(1): 34-56. |

| 2 | 吴晨芳, 杨世锡, 黄海舟, 等. 一种基于改进的LeNet-5模型滚动轴承故障诊断方法研究[J]. 振动与冲击, 2021, 40(12): 55-61. |

| Wu Chen-fang, Yang Shi-xi, Huang Hai-zhou, et al. Research on fault diagnosis method of rolling bearing based on improved LeNet-5 model[J]. Vibration and Shock, 2021, 40(12): 55-61. | |

| 3 | 张弘斌, 袁奇, 赵柄锡, 等. 采用多通道样本和深度卷积神经网络的轴承故障诊断方法[J]. 西安交通大学学报, 2020, 54(8): 58-66. |

| Zhang Hong-bin, Yuan Qi, Zhao Bing-xi, et al. Bearing fault diagnosis method using multi-channel samples and deep convolutional neural network[J]. Journal of Xi'an Jiaotong University, 2020, 54(8): 58-66. | |

| 4 | 张根保, 李浩, 冉琰, 等. 一种用于轴承故障诊断的迁移学习模型[J]. 吉林大学学报: 工学版, 2020, 50(5): 1617-1626. |

| Zhang Gen-bao, Li Hao, Ran Yan, et al. A transfer learning model for bearing fault diagnosis[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1617-1626. | |

| 5 | Wang H Q, Li S, Song L Y, et al. A novel convolutional neural network based fault recognition method via image fusion of multi-vibration-signals[J]. Computers in Industry, 2019, 105: 182-190. |

| 6 | Wen L, Li X Y, Gao L. A transfer convolutional neural network for fault diagnosis based on resnet-50[J]. Neural Computing and Applications,2019, 32(10): 6111-6124. |

| 7 | Wang X, Shen C Q, Xia M, et al. Multi-scale deep intra-class transfer learning for bearing fault diagnosis[J]. Reliability Engineering and System Safety, 2020,202: 107050. |

| 8 | Li X, Zhang W, Xu N X, et al. Deep learning-based machinery fault diagnostics with domain adaptation across sensors at different places[J]. IEEE Transactions on Industrial Electronics, 2020, 67(8): 6785-6794. |

| 9 | Zhu Y C, Zhuang F Z, Wang J D, et al. Deep subdomain adaptation network for image classification[J]. IEEE Transactions on Neural Networks and Learning Systems, 2020(99): 1-10. |

| 10 | Gretton A, Borgward K M, Rasch M J, et al. A kernel two-sample test[J]. Journal of Machine Learning Research, 2012, 13: 723-773. |

| 11 | Yosinski J, Clune J, Bengio Y, et al. How transferable are features in deep neural networks?[C]∥International Conference on Neural Information Processing Systems, Montreal Canada, 2014: 3320-3328. |

| 12 | He K M, Zhang X Y, Ren S Q, et al. Deep residual learning for image recognition[C]∥IEEE Conference on Computer Vision & Pattern Recognition, New York, 2016: 770-778. |

| 13 | Long M S, Cao Y, Cao Z J,et al. Transferable representation learning with deep adaptation networks[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2018, 41(12): 3071-3085. |

| 14 | 院老虎, 连冬杉, 张亮, 等. 基于密集连接卷积网络和支持向量机的飞行器机械部件故障诊断[J]. 吉林大学学报: 工学版, 2021, 51(5): 1635-1641. |

| Yuan Lao-hu, Lian Dong-shan, Zhang Liang, et al. Fault diagnosis of aircraft mechanical components based on densely connected convolutional networks and support vector machines[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1635-1641. | |

| 15 | Lessmeier C, Kimotho J K, Zimmer D, et al. Condition monitoring of bearing damage in electromechanical drive systems by using motor current signals of electric motors: a benchmark data set for data-driven classification[C]∥European Conference of the Prognostics and Health Management Society, Bilbao Spain, 2016: 1-17. |

| [1] | 欧阳丹彤,张必歌,田乃予,张立明. 结合格局检测与局部搜索的故障数据缩减方法[J]. 吉林大学学报(工学版), 2021, 51(6): 2144-2153. |

| [2] | 院老虎,连冬杉,张亮,刘义. 基于密集连接卷积网络和支持向量机的飞行器机械部件故障诊断[J]. 吉林大学学报(工学版), 2021, 51(5): 1635-1641. |

| [3] | 李伟,陈剑,陶善勇. 自适应耦合周期势系统随机共振信号增强方法[J]. 吉林大学学报(工学版), 2021, 51(3): 1091-1096. |

| [4] | 欧阳丹彤,刘扬,刘杰. 故障响应指导下基于测试集的故障诊断方法[J]. 吉林大学学报(工学版), 2021, 51(3): 1017-1025. |

| [5] | 潘凤文,弓栋梁,高莹,徐明伟,麻斌. 基于锂离子电池线性化模型的电流传感器故障诊断[J]. 吉林大学学报(工学版), 2021, 51(2): 435-441. |

| [6] | 张根保,李浩,冉琰,李裘进. 一种用于轴承故障诊断的迁移学习模型[J]. 吉林大学学报(工学版), 2020, 50(5): 1617-1626. |

| [7] | 马子骥,卢浩,董艳茹. 双通道单图像超分辨率卷积神经网络[J]. 吉林大学学报(工学版), 2019, 49(6): 2089-2097. |

| [8] | 王德军, 魏薇郦, 鲍亚新. 考虑侧风干扰的电子稳定控制系统执行器故障诊断[J]. 吉林大学学报(工学版), 2018, 48(5): 1548-1555. |

| [9] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [10] | 宋大凤, 李广含, 张琳, 潘冰, 曾小华, 彭宇君, 王庆年. 模糊逻辑在混合动力汽车电机故障检测中的应用[J]. 吉林大学学报(工学版), 2016, 46(2): 354-359. |

| [11] | 欧阳丹彤,迟晋进,王晓宇,赵相福,孟祥宇. 一种高阶离散事件系统的诊断方法[J]. 吉林大学学报(工学版), 2015, 45(2): 562-568. |

| [12] | 陶涛,徐洪泽. 高速列车浸入与不变自适应容错控制方法[J]. 吉林大学学报(工学版), 2015, 45(2): 554-561. |

| [13] | 宋宝玉,解志杰,张锋,王瑞泽,郝明晖,苏代忠. 基于角度域同步平均和阶次分析的低速斜齿轮故障诊断[J]. 吉林大学学报(工学版), 2015, 45(2): 454-459. |

| [14] | 吴坚, 赵阳, 何睿. 基于支持向量机回归算法的电子机械制动传感器系统故障诊断[J]. 吉林大学学报(工学版), 2013, 43(05): 1178-1183. |

| [15] | 郝研, 王太勇, 万剑, 张攀, 刘路. 基于经验模式分解和广义维数的机械故障诊断[J]. 吉林大学学报(工学版), 2012, 42(02): 392-396. |

|

||