吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (6): 1686-1694.doi: 10.13229/j.cnki.jdxbgxb.20230085

• 交通运输工程·土木工程 • 上一篇

超高性能玻璃砂混凝土-高强钢筋粘结滑移特性及其声发射参数表征

- 1.兰州交通大学 土木工程学院,兰州 730070

2.甘肃省公路航空旅游投资集团有限公司,兰州 730030

3.北京工业大学 城市与工程安全减灾教育部重点实验室,北京 100124

Bond⁃slip characterization between ultra⁃high performance glass sand concrete and high⁃strength reinforcement based on acoustic emission parameters

Ya-na MAO1,2( ),Shi-zhong LIU1,Jian XING3,Hua YANG3,Yu-bo JIAO3(

),Shi-zhong LIU1,Jian XING3,Hua YANG3,Yu-bo JIAO3( )

)

- 1.School of Civil Engineering,Lanzhou Jiaotong University,Lanzhou 730070,China

2.Gansu Province Highway Aviation Tourism Investment Group Co. ,Ltd. ,Lanzhou 730030,China

3.Key Laboratory of Urban Security and Disaster Engineering of Ministry of Education,Beijing University of Technology,Beijing 100124,China

摘要:

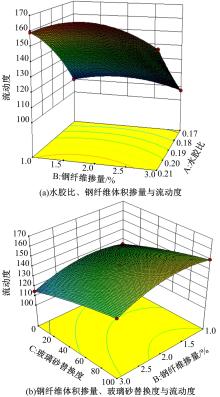

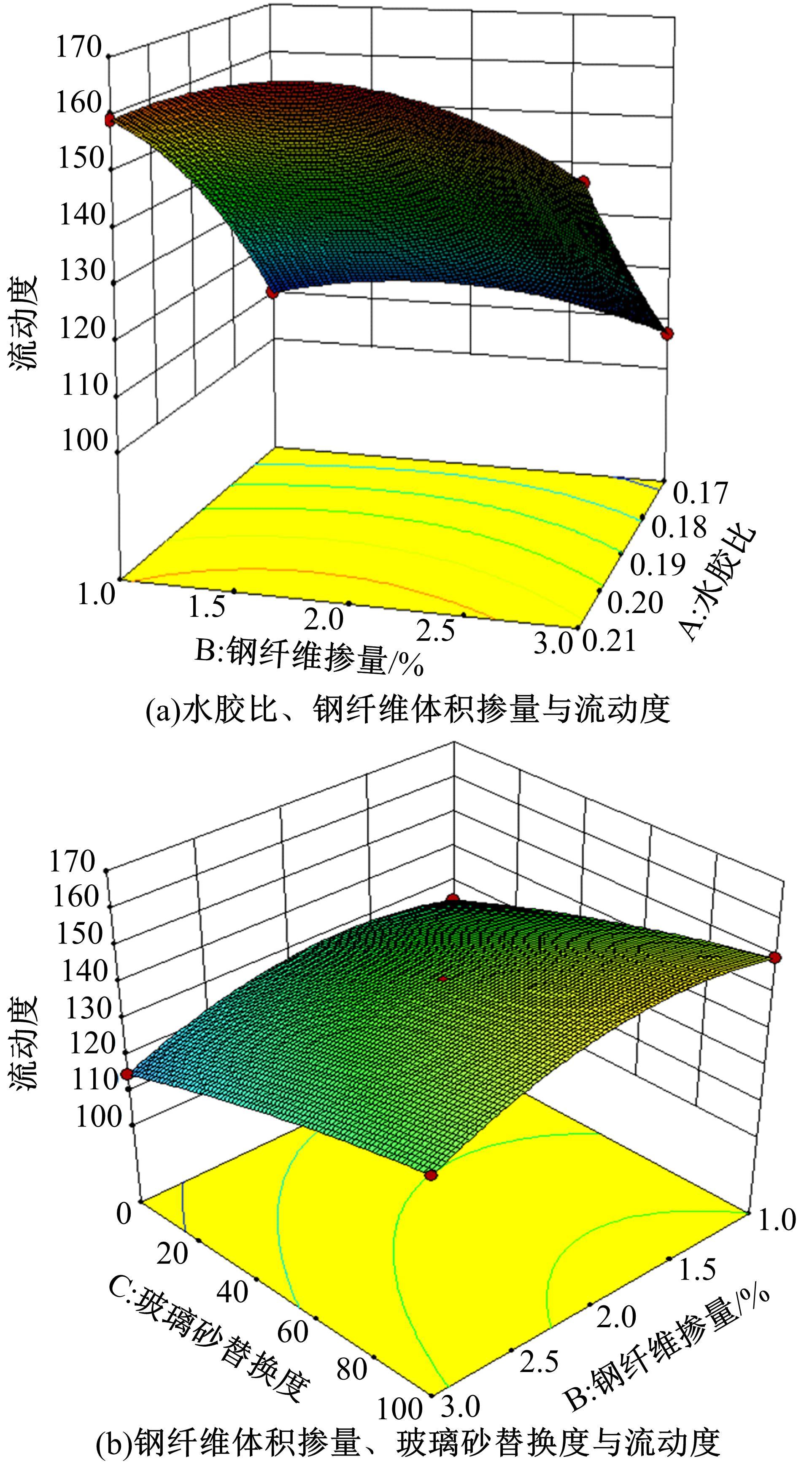

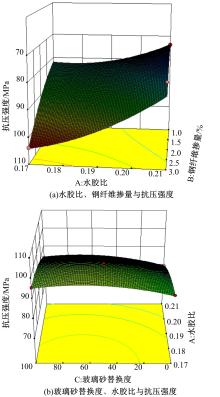

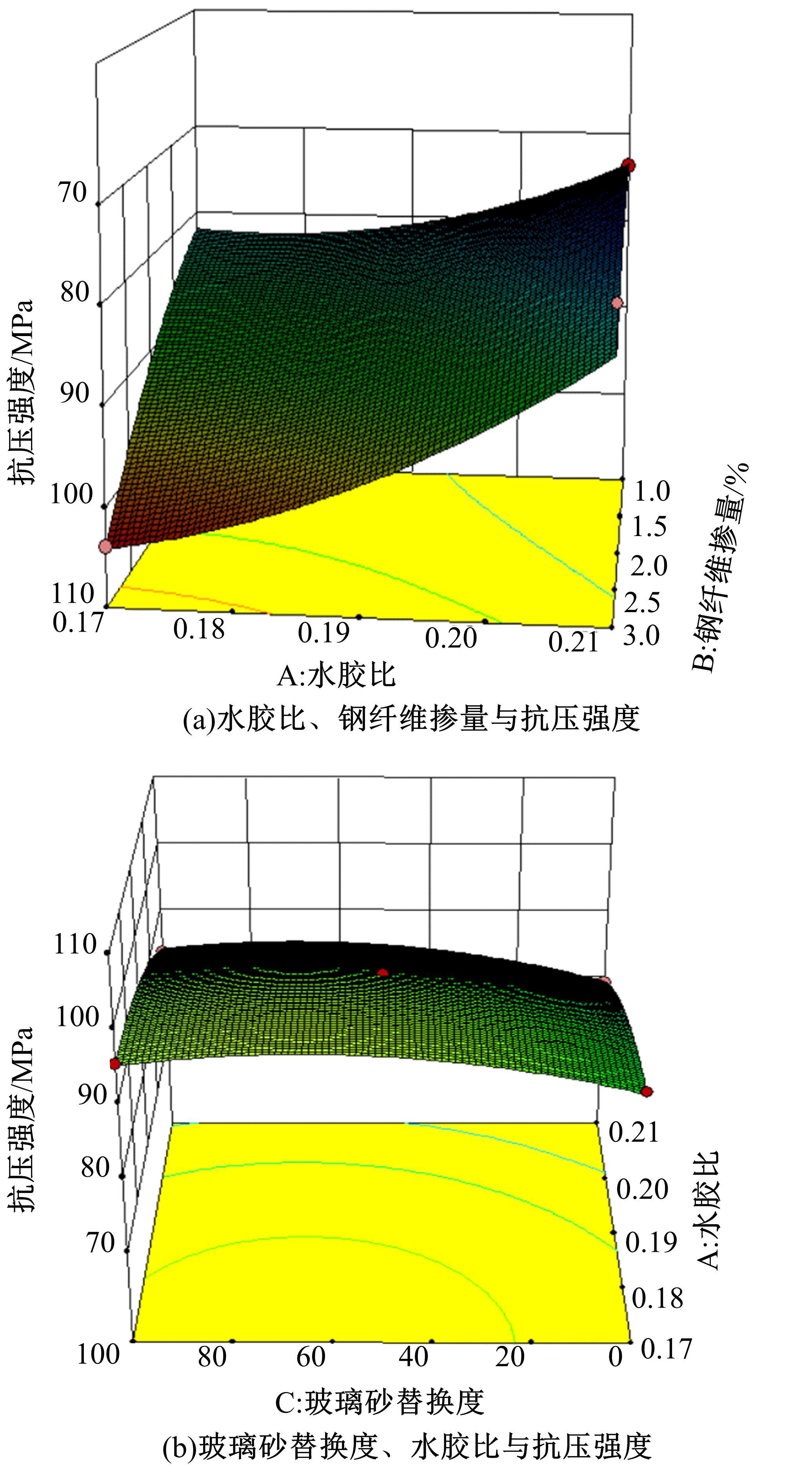

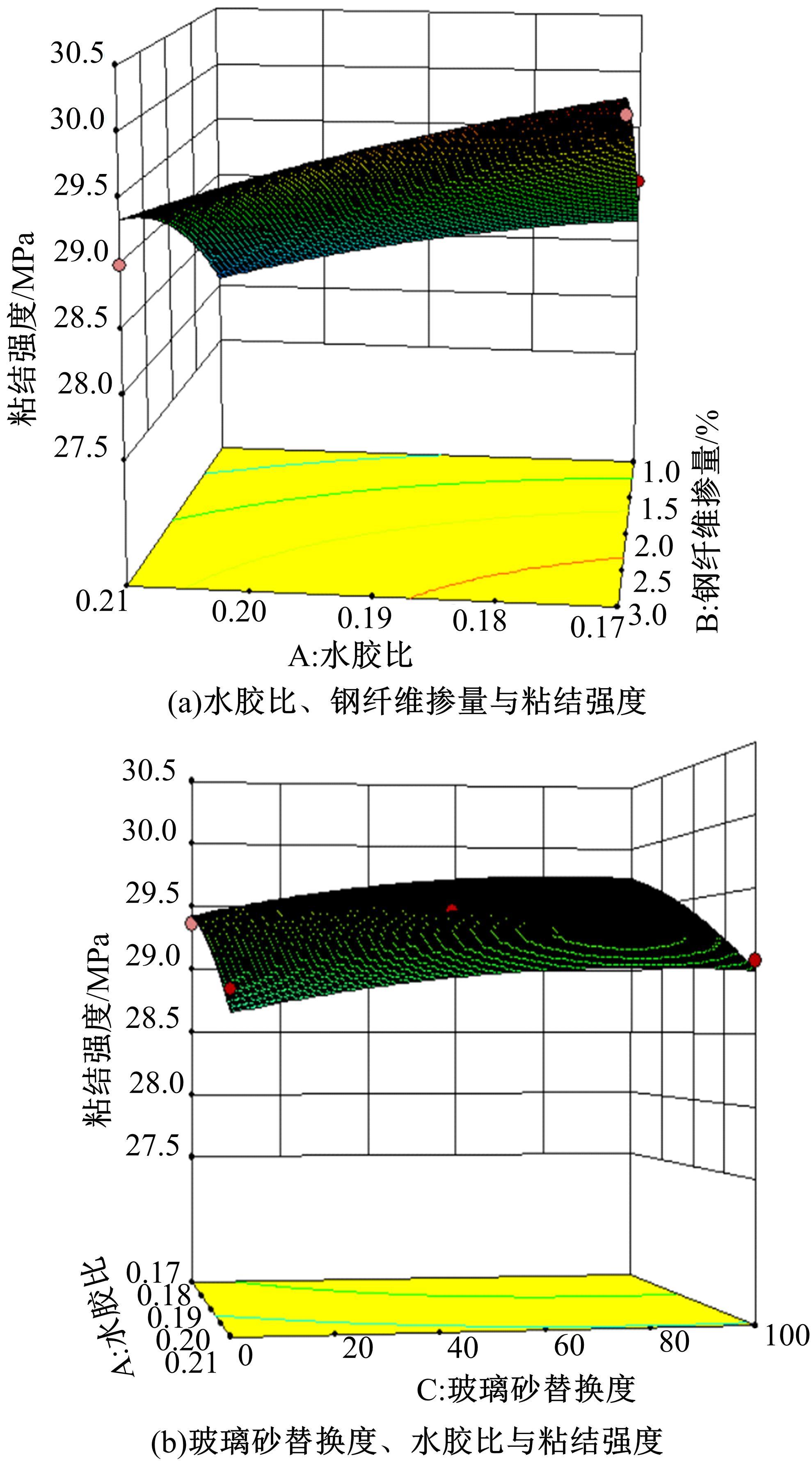

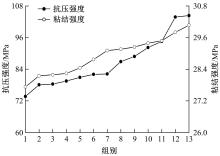

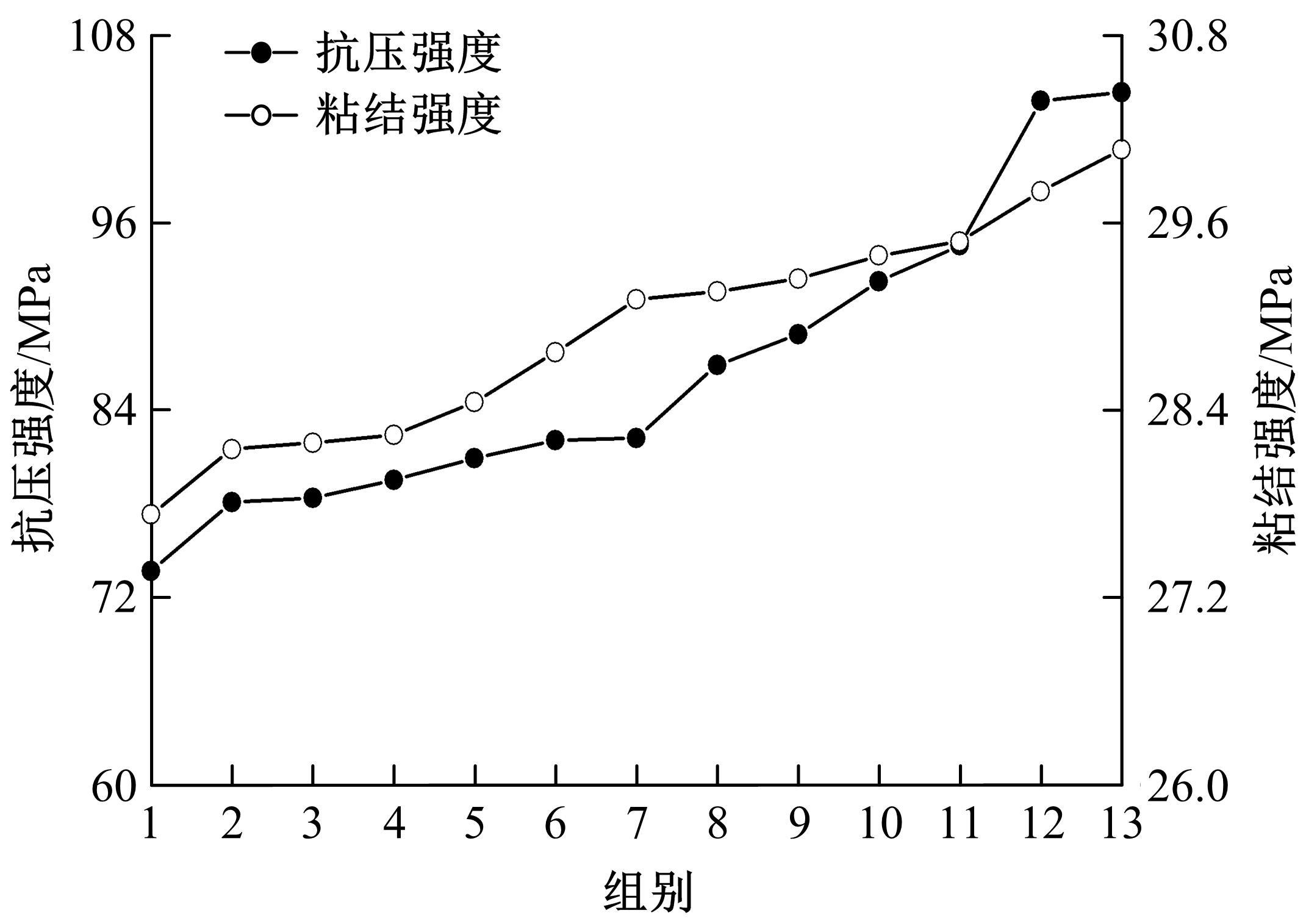

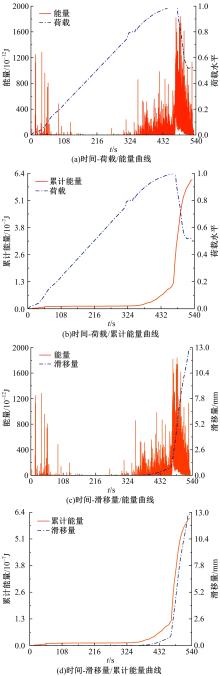

为研究超高性能玻璃砂混凝土(UHPGC)与HRB600高强钢筋的粘结性能,分析了水胶比(0.17、0.19、0.21)、钢纤维体积掺量(1%、2%、3%)和玻璃砂替换率(0%、50%、100%)对UHPGC工作及力学性能的影响规律。通过中心拉拔试验并结合声发射实时监测明确了UHPGC-HRB600高强钢筋粘结性能变化规律。结果表明:掺入玻璃砂能提高UHPGC的抗压强度,其最佳替换度为50%;粘结强度与水胶比和钢纤维掺量呈正相关关系,且随着玻璃砂替换度的增大呈先增长后减小的规律;UHPGC和HRB600粘结滑移破坏形式主要分为劈裂破坏和劈拉破坏两种;声发射参数呈现良好的粘结滑移表征能力。

中图分类号:

- U444

| 1 | Arora A, Almujaddidi A, Kianmofrad F, et al. Material design of economical ultra-high performance concrete (UHPC) and evaluation of their properties[J]. Cement and Concrete Composites, 2019, 104: No. 103346. |

| 2 | 朱劲松, 秦亚婷, 刘周强.预应力 UHPC-NC 组合梁截面优化设计[J/OL].[2023-01-15]. |

| 3 | Soliman N A, Omran A F, Tagnit-Hamou A. Laboratory characterization and field application of novel ultra-high-performance glass concrete[J]. Aci Materials Journal, 2016, 113(3): 307-316. |

| 4 | Soliman N A, Tagnit-Hamou A. Development of ultra-high-performance concrete using glass powder – towards ecofriendly concrete[J]. Construction and Building Materials, 2016,125:600-612. |

| 5 | Soliman N A, Tagnit-Hamou A. Partial substitution of silica fume with fine glass powder in UHPC: filling the micro gap[J]. Construction and Building Materials, 2017,139:374-383. |

| 6 | Vaitkevicius V, Šerelis E, Hilbig H. The effect of glass powder on the microstructure of ultra high performance concrete[J]. Construction and Building Materials, 2014, 68: 102-109. |

| 7 | Jiao Y B, Zhang Y, Guo M, et al. Mechanical and fracture properties of ultra-high performance concrete (UHPC) containing waste glass sand as partial replacement material[J]. Journal of Cleaner Production, 2020, 277: No. 123501. |

| 8 | 邓宗才,袁常兴. 高强钢筋与活性粉末混凝土黏结性能的试验研究[J]. 土木工程学报, 2014, 47(3): 69-78. |

| Deng Zong-cai, Yuan Chuang-xing. Experimental study on bond capability between high strength rebar and reactive powder concrete[J]. China Civil Engineering Journal, 2014, 47(3): 69-78. | |

| 9 | 黄政宇,岑小艳,柳红霞. 碳纤维筋与活性粉末混凝土粘结性能试验研究[J]. 铁道科学与工程学报, 2006(1): 65-69. |

| Huang Zheng-yu, Cen Xiao-yan, Liu Hong-xia. Experimental research on the bond performance between CFRP bars and reactive powder concrete[J]. Journal of Railway Science and Engineering, 2006(1): 65-69. | |

| 10 | Choi E S, Lee J W, Kim S J, et al. A Study on the Bond Strength between High Performance Concrete and Reinforcing Bar[J]. Engineering, 2015, 7(7): 373-378. |

| 11 | Gallego A, Senavent-Climent A, Suarez E. Concrete-galvanized steel pull-out bond assessed by acoustic emission[J]. Journal of Materials in Civil Engineering, 2016, 28(2): 1543-1552. |

| 12 | Abouhussien A A, Hassan A A. Acoustic emission-based analysis of bond behavior of corroded reinforcement in existing concrete structures[J/OL]. [2023-01-02]. |

| [1] | 卜建清,郭至博,张吉仁,荀敬川,黄晓明. 多损伤钢-混组合梁桥力学性能有限元分析方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1621-1637. |

| [2] | 韩智强,谢刚,周勇军,刘世忠,晋民杰. 曲线桥梁车桥耦合振动数值分析方法[J]. 吉林大学学报(工学版), 2023, 53(2): 515-522. |

| [3] | 杨国俊,田骐玮,吕明航,杜永峰,唐光武,韩宗健,伏一多. 大跨度悬索桥隧道式锚碇力学特性研究综述[J]. 吉林大学学报(工学版), 2022, 52(6): 1245-1263. |

| [4] | 袁周致远,吉伯海,夏俊元,孙童. 钢箱梁横隔板-纵肋疲劳裂纹气动冲击维修试验[J]. 吉林大学学报(工学版), 2022, 52(12): 2883-2891. |

| [5] | 王毅红,田桥罗,兰官奇,姚圣法,张建雄,刘喜. 630 MPa高强钢筋混凝土大偏压柱受力性能试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2626-2635. |

| [6] | 李春良,林志豪,赵珞珞. 铰缝及板损伤后对空心板桥横向受力的影响[J]. 吉林大学学报(工学版), 2021, 51(2): 611-619. |

| [7] | 李碧雄,廖桥,章一萍,周练,隗萍,刘侃. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版), 2019, 49(4): 1153-1161. |

|

||