吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (4): 1153-1165.doi: 10.13229/j.cnki.jdxbgxb.20220687

• 农业工程·仿生工程 • 上一篇

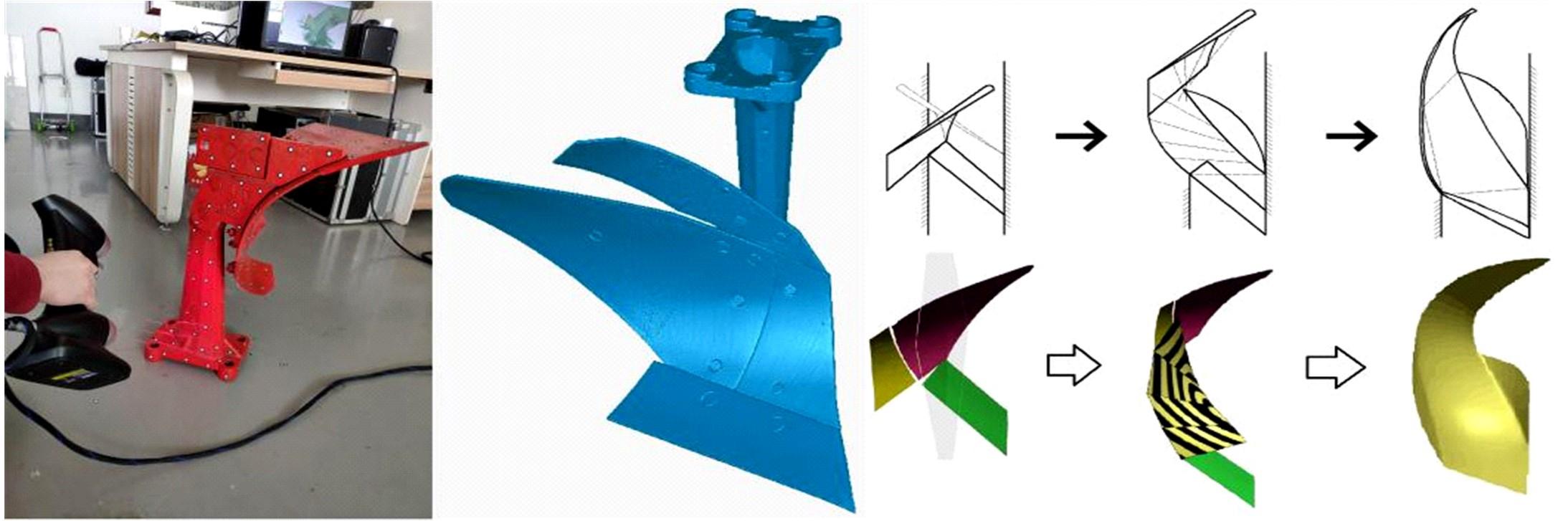

基于离散元的设施农业就地翻土犁的研究与试验

- 1.山东理工大学 农业工程与食品科学学院,山东 淄博 255000

2.西安交通大学 机械制造系统国家重点实验室,西安 710054

Experimental study on in-situ tilling plow in facility agriculture based on discrete element method

Yuan-yi LIU1( ),Sheng-jie YU1,Bei XU1,Xian-liang WANG1,Fa-cheng SONG2

),Sheng-jie YU1,Bei XU1,Xian-liang WANG1,Fa-cheng SONG2

- 1.College of Agricultural Engineering and Food Science, Shandong University of Technology, Zibo 255000, China

2.State Key Laboratory for Manufacturing Systems Engineering, Xi′an jiaotong University, Xi′an 710054, China

摘要:

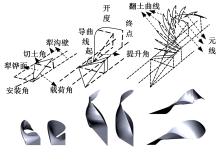

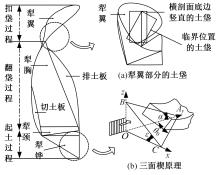

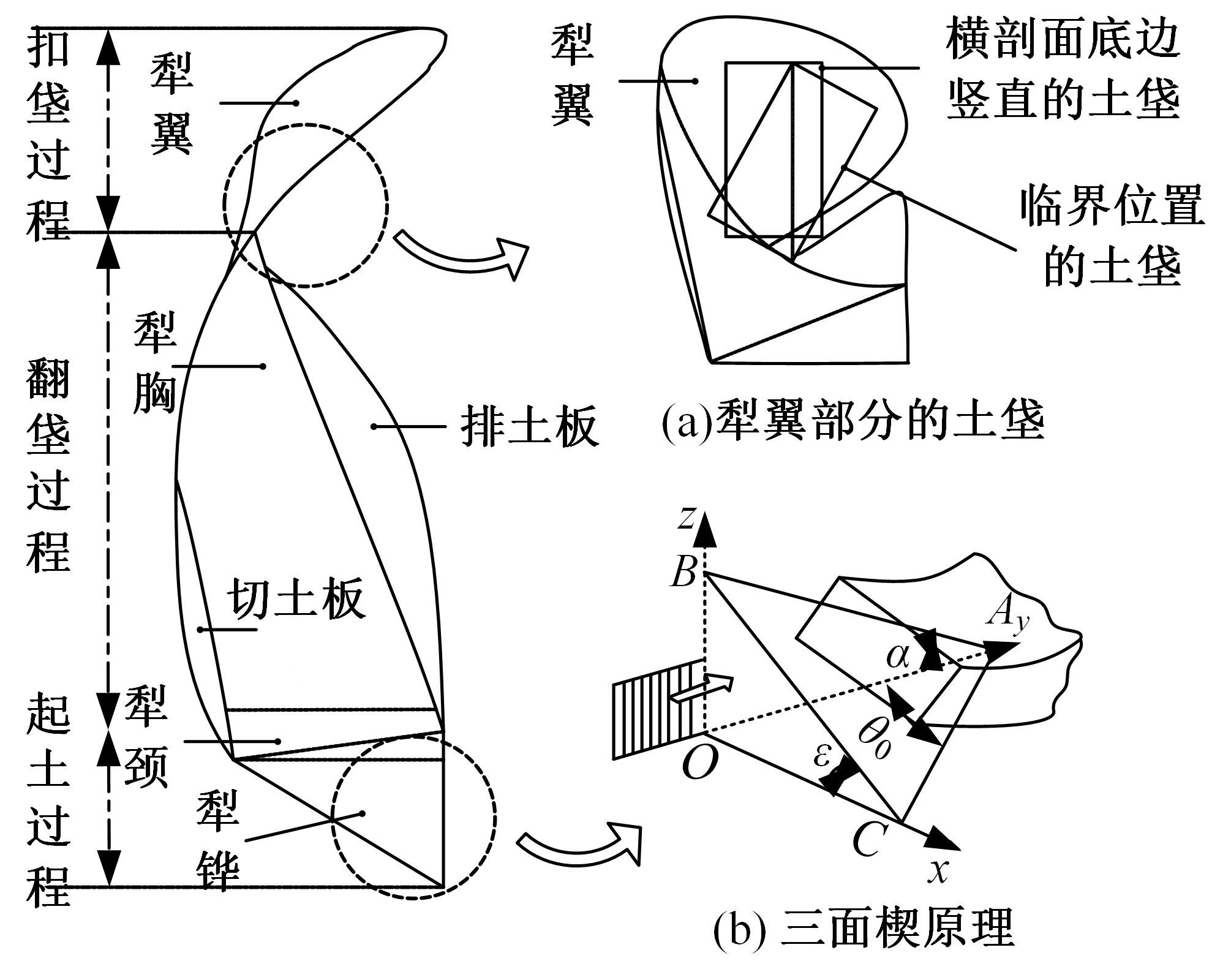

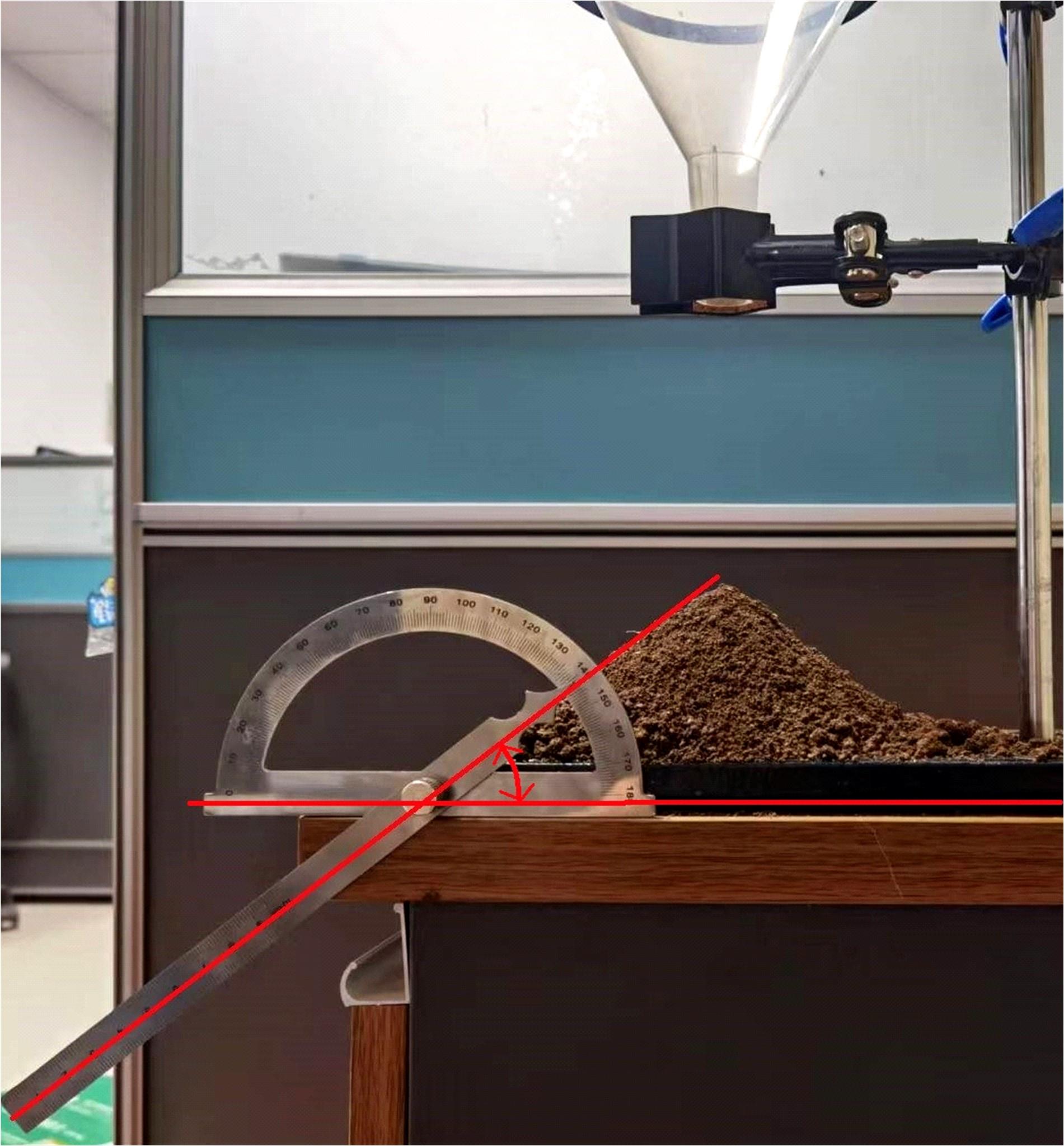

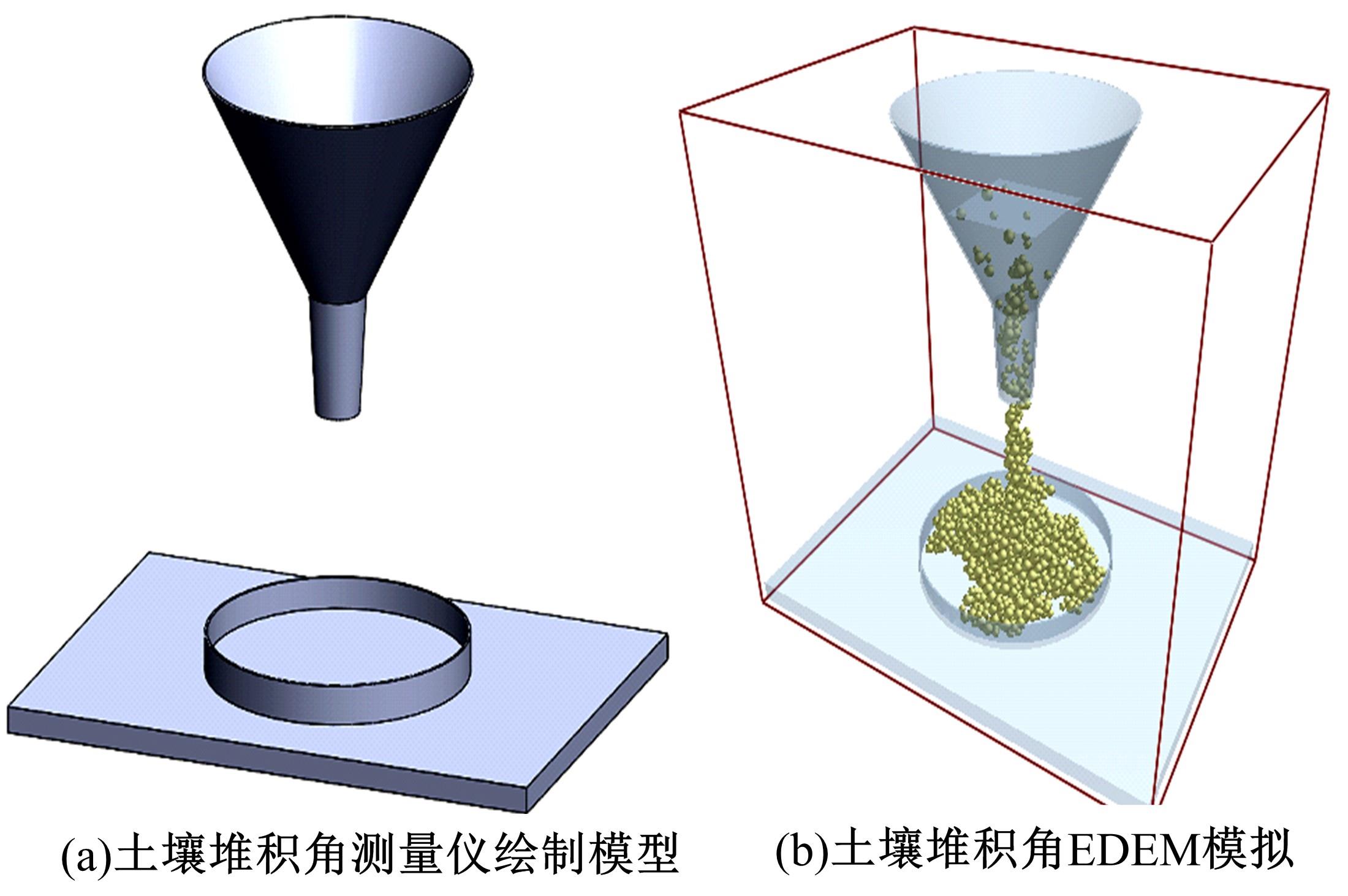

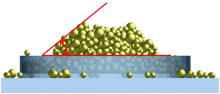

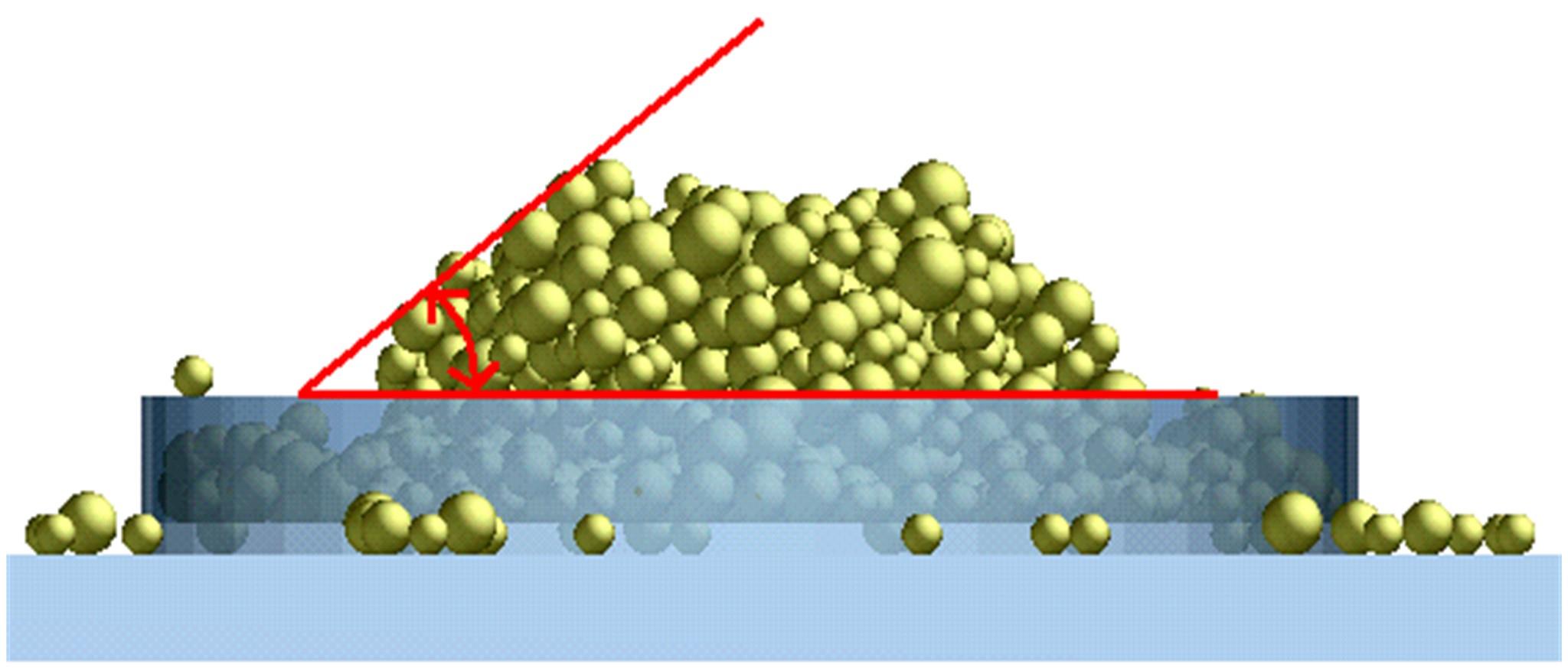

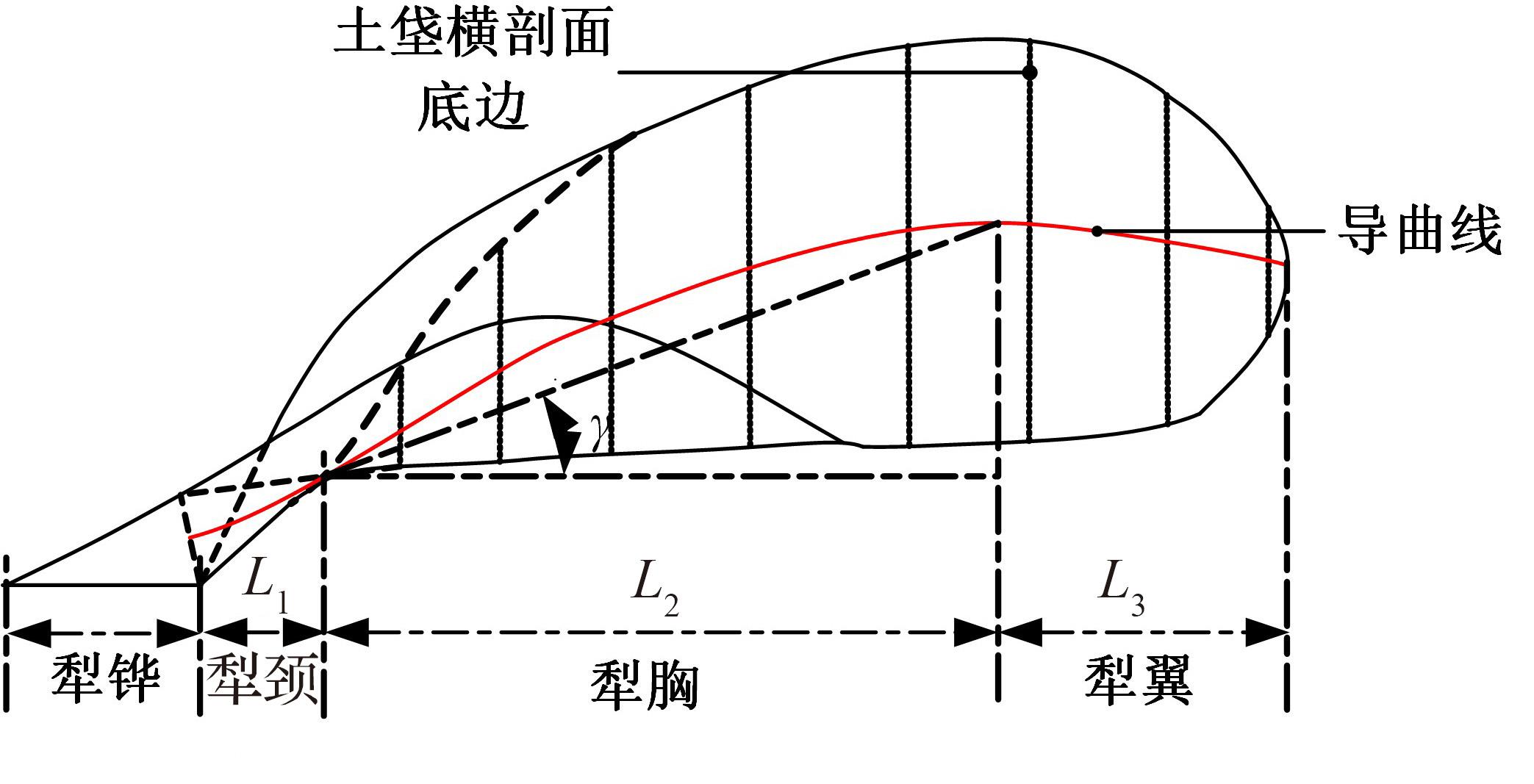

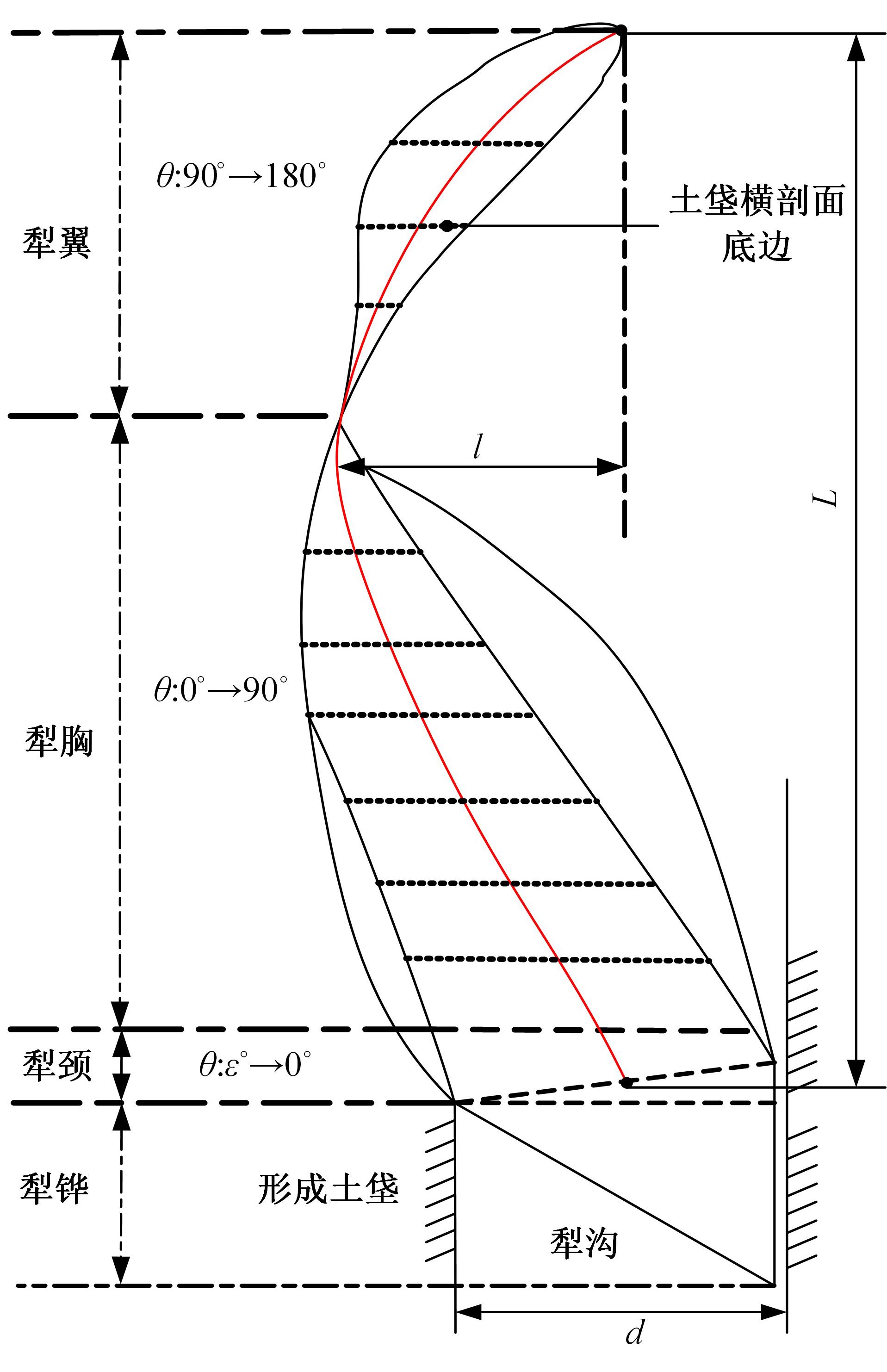

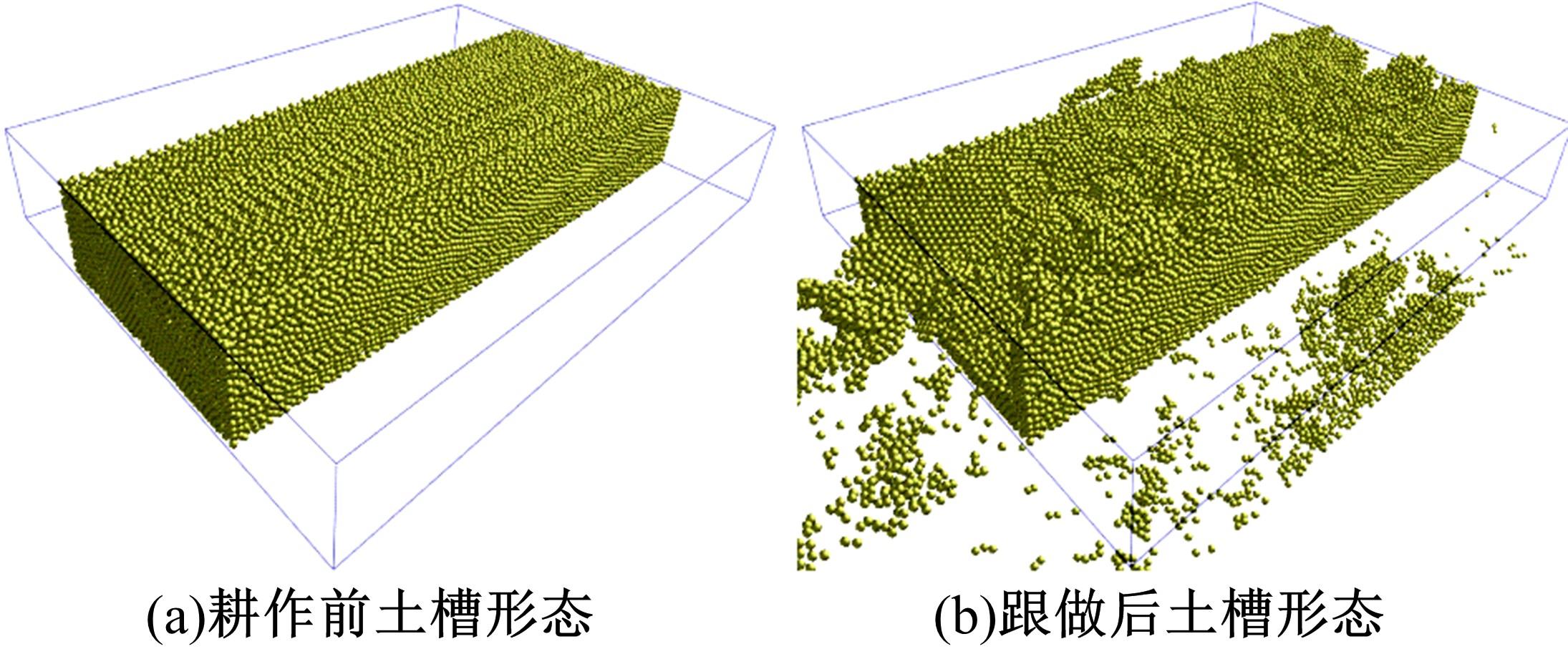

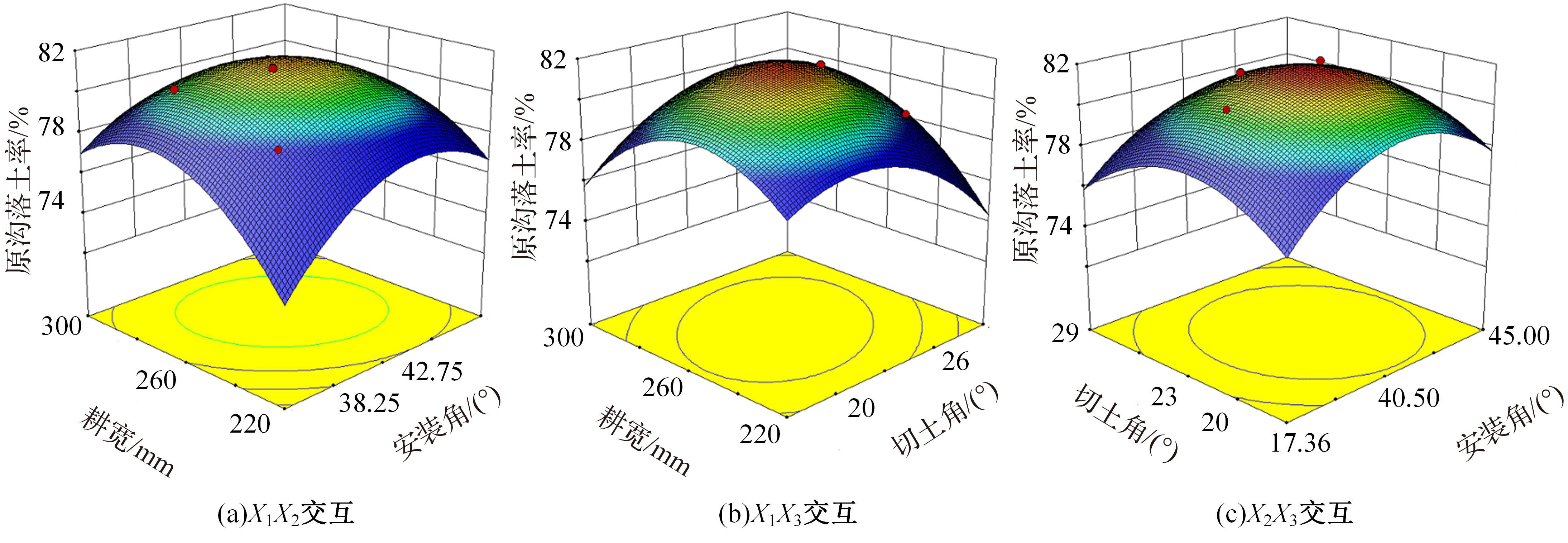

针对设施农业空间狭小,土壤病虫害严重,无法使用铧式犁深翻的问题,提出一种就地翻土解决办法。根据逆向工程得到就地翻土犁犁体逆向曲面,通过现有犁体成型原理,参照铧式犁犁体耕宽、耕深、犁体安装角、切土角、导曲线提升角、开度、犁体长度等参数,创设就地翻土犁犁体正向曲面;实测设施农业土壤相对湿度为34.57%、土壤堆积角为39°,通过EDEM软件中的接触参数数据库GEMM得到接触参数范围,标定土壤颗粒间表面能为4.19 J/m2、碰撞恢复系数为0.282、动摩擦因数为0.051、静摩擦因数为0.629,创设试验土槽;引入原沟落土率概念;构建原沟落土率与曲面参数间的相互作用模型,得到最佳原沟落土率曲面参数;利用Design-Expert软件进行分析,以原沟落土率为响应指标,使用Plackett-Burman试验设计方法开展多因素两水平显著性筛选试验,得到影响原沟落土率耕宽、犁铧安装角、切土角3个显著性因素;对3因素进行Box-Behnken试验设计,得到278.392 mm耕宽、40.522°犁铧安装角、23.211°切土角最佳设计参数。针对优化结果进行试验,得到试验结果与预测结果误差为3.13%,试验结果表明,所研究就地翻土犁可以达到就地翻垡的目的,并为解决设施农业内土壤深翻问题提供参考。

中图分类号:

- S222.19

| 1 | 宋卫堂.日光温室蔬菜生产全程机械化的一种解决方案[J].中国农机化学报,2018,39(9):26-29. |

| Song Wei-tang. A complete mechanization solution for greenhouse vegetable production[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(9): 26-29. | |

| 2 | 付学谦,周亚中,孙宏斌,等.园区农业能源互联网:概念、特征与应用价值[J].农业工程学报,2020,36(12):152-161. |

| Fu Xue-qian, Zhou Ya-zhong, Sun Hong-bin,et al.Park-level agricultural energy internet:Concept, characteristic and application value[J].Transactions of the Chinese Society of Agricultural Engineering,2020,36(12):152-161. | |

| 3 | 骆飞,徐海斌,左志宇,等.我国设施农业发展现状、存在不足及对策[J].江苏农业科学,2020,48(10):57-62. |

| Luo Fei, Xu Hai-bin, Zuo Zhi-yu,et al.Current situation,deficiency and countermeasures of China's facility agriculture[J].Jiangsu Agricultural Sciences,2020,48(10):57-62. | |

| 4 | 刘霓红,蒋先平,程俊峰,等.国外有机设施园艺现状及对中国设施农业可持续发展的启示[J].农业工程学报,2018,34,42(15):1-9. |

| Liu Ni-hong, Jiang Xian-ping, Cheng Jun-feng,et al.Current situation of foreign organic greenhouse horticulture and its inspiration for sustainable development of Chinese protected agriculture[J].Transactions of the Chinese Society of Agricultural Engineering,2018,34,342(15):1-9. | |

| 5 | 熊平原,杨洲,孙志全,等.基于离散元法的旋耕刀三向工作阻力仿真分析与试验[J].农业工程学报,2018, 345(18): 113-121. |

| Xiong Ping-yuan, Yang Zhou, Sun Zhi-quan,et al.Simulation analysis and experiment for three-axis working resistances of rotary blade based on discrete element method[J].Transactions of the Chinese Society of Agricultural Engineering,2018,345(18):113-121. | |

| 6 | 秦柳. 国外设施农业发展的经验与借鉴[J]. 世界农业, 2015, 436(8): 143-146. |

| Qin Liu.The development experience and reference of facility agriculture abroad[J].World Agriculture,2015,436(8): 143-146. | |

| 7 | 马廷玺.土垡原地翻转横排犁[J].粮油加工与食品机械,1978(11): 49-51. |

| Ma Ting-xi.Horizontal plow of in-situ tilling soil[J].Cereals and Oils Processing,1978(11): 49-51. | |

| 8 | Caky H B A, 王梦熊.几种类型的正面犁[J].粮油加工与食品机械, 1984(12): 30-32. |

| Caky H B A, Wang Meng-xiong.Several types of horizontal plows[J].Cereals and Oils Processing,1984(12): 30-32. | |

| 9 | 尤玉锴,陈伊文.对横排犁研究中几个问题的探讨[J].农业机械学报,1987(3):99-101. |

| You Yu-kai, Chen Yi-wen.The research and discussion of several problem about horizontal plow[J].Transactions of the Chinese Society for Agricultural Machinery,1987(3):99-101. | |

| 10 | 尤玉锴,刘明亮,白立群.横排犁犁面设计初探[J].农机化研究,1987(2):12-17. |

| You Yu-kai, Liu Ming-liang, Bai Li-qun.Preliminary study on the design of horizontal plow surface[J].Journal of Agricultural Mechanization Research,1987(3):12-17. | |

| 11 | Junichi K, Wang Shi-xue. Study on a plow to invert furrow slice at the same position (Part 1)[J].Journal of JSAM, 1993, 55(3):15-22. |

| 12 | Wang Shi-xue, Junichi K. Study on a plow to invert furrow slice at the same position (Part 2)[J]. Journal of JSAM, 1993, 55(4):33-39. |

| 13 | Wang Shi-xue, Junichi K. Study on a plow to invert furrow slice at the same position (Patr 3)[J]. Journal of JSAM, 1995, 57(5):31-40. |

| 14 | 宋发成,刘元义,邴坤,等.基于TRIZ理论的就地翻土犁设计[J].中国农机化学报,2019,40(4):13-18. |

| Song Fa-cheng, Liu Yuan-yi, Bing Kun,et al.Design of in-situ tilling plow based on TRIZ theory[J].Journal of Chinese Agricultural Mechanization,2019,40(4):13-18. | |

| 15 | 于圣洁,刘元义,胥备,等.设施农业就地翻土犁结构设计与仿真[J].中国农机化学报,2021,42(3):66-71. |

| Yu Sheng-jie, Liu Yuan-yi, Xu Bei,et al.Design and simulation of in - situ tilling plow in facility agriculture[J].Journal of Chinese Agricultural Mechanization,2021,42(3):66-71. | |

| 16 | 杨继鑫,戴华伟,王英俊,等.淄博烟区土壤中微量元素特征及重金属风险评价[J].中国烟草科学,2020,41(6):44-50. |

| Yang Ji-xin, Dai Hua-wei, Wang Ying-jun,et al. Distribution characteristics of medium and trace elements and risk assessments for heavy metals in soils in Zibo tobacco-planting region[J].Chinese Tobacco Science,2020,41(6):44-50. | |

| 17 | 魏建林,谭德水,宋效宗,等.鲁中典型种植区设施番茄养分供需特征研究[J].山东农业科学,2020,52(11):15-19, 45. |

| Wei Jian-lin, Tan De-shui, Song Xiao-zong,et al.Nutrient supply and demand characteristics of greenhouse tomato in typical planting area of central Shandong Province[J].Shandong Agricultural Sciences,2020,52(11):15-19, 45. | |

| 18 | 刁海忠,杨小三,李文全,等.桓台县土壤地球化学背景值及分区特征[J].山东国土资源,2021,37(4):41-47. |

| Diao Hai-zhong, Yang Xiao-san, Li Wen-quan,et al.Geochemical background values of soil and characteristics of geochemical divisions in Huantai County[J].Shandong Land and Resources,2021,37(4):41-47. | |

| 19 | 郑侃,何进,李洪文,等.基于离散元深松土壤模型的折线破土刃深松铲研究[J].农业机械学报,2016,47(9):62-72. |

| Zheng Kan, He Jin, Li Hong-wen,et al.Research on polyline soil-breaking blade subsoiler based on subsoiling soil model using discrete element method[J].Transactions of the Chinese Society for Agricultural Machinery,2016,47(9):62-72. | |

| 20 | 刘俊安. 基于离散元方法的深松铲参数优化及松土综合效应研究[D].北京:中国农业大学工学院,2018. |

| Liu Jun-an.Study on subsoiler parameters optimization and comprehensive effect of subsoiling based on the discrete element method[D].Beijing:College of Engineering, China Agricultural University,2018. | |

| 21 | Aikins Kojo Atta, Mustafa Ucgul, Barr James B,et al. Determination of discrete element model parameters for a cohesive soil and validation through narrow point opener performance analysis[J]. Soil & Tillage Research, 2021, 213: No.105123. |

| 22 | 李金展,马军涛,郑喜平.热处理工艺对65Mn犁铧力学性能的影响[J].热加工工艺,2017,46(4):215-217. |

| Li Jin-zhan, Ma Jun-tao, Zheng Xi-ping.Effect of heat treatment process on mechanical properties of 65 Mn ploughshare[J].Hot Working Technology,2017,46(4):215-217. | |

| 23 | 成大先.机械设计手册.单行本[M].北京:化学工业出版社,2004:5-7. |

| 24 | 张喜瑞,曾望强,刘俊孝,等.基于离散元法的砖红壤斜柄折翼式深松铲设计与试验[J].农业机械学报,2022,53(3):40-49. |

| Zhang Xi-rui, Zeng Wang-qiang, Liu Jun-xiao,et al.Design and experiment of iateritic soil inclined handle folding wing subsoiling shovel based on discrete element method[J].Transactions of the Chinese Society for Agricultural Machinery,2022,53(3):40-49. | |

| 25 | 李宝筏.农业机械学[M].北京:中国农业出版社,2016:321-322. |

| 26 | 习慧梅.温室大棚设施菜地土壤改良技术[J].农村实用技术,2016(3):28-31. |

| Xi Hui-mei.Soil improvement techniques in greenhouses[J].Practical Technologies of Rural Areas,2016(3):28-31. | |

| 27 | 赵江涛,崔方,张小平,等.设施农业土壤改良浅谈[J].西北园艺(综合),2021(1):36-37. |

| Zhao Jiang-tao, Cui Fang, Zhang Xiao-ping,et al.Description of soil improvement in facility agriculture[J].Northwest Horticulture,2021(1):36-37. | |

| 28 | 中国农业机械化科学研究院.农业机械设计手册[M].北京:中国农业科学技术出版社,2007. |

| 29 | 李光聚,刘天英,李秀欣,等.寿光日光温室的发展历程及创新点[J].中国蔬菜,2019(10):14-18. |

| Li Guang-ju, Liu Tian-ying, Li Xiu-xin,et al.The development history and innovation points of Shouguang solar greenhouse[J].China Vegetables,2019(10):14-18. | |

| 30 | 康建. 日光温室深旋机设计与试验研究[D].沈阳:沈阳农业大学工程学院,2020. |

| Kang Jian.Design and experimental study of deep rotary machine in solar greenhouse[D].Shenyang:College of Engineering, Shenyang Agricultural University,2020. | |

| 31 | 刘静,孙闫.设施大棚履带电动拖拉机电源系统仿真研究[J].机械工程师,2021(2):59-62. |

| Liu Jing, Sun Yan.Simulation study on power supply system of a crawler electric tractor for greenhouses[J].Mechanical Engineer,2021(2):59-62. | |

| 32 | 翟力欣,姬长英,丁启朔,等.犁体结构参数与工作参数优化设计[J].农业机械学报,2013,44(8):57-62. |

| Zhai Li-xin, Ji Chang-ying, Ding Qi-shuo,et al.Optimized design of plough body structural and working parameters[J].Transactions of the Chinese Society for Agricultural Machinery,2013,44(8):57-62. | |

| 33 | 郑乐,罗锡文,曾山,等.水稻根茬-土壤复合体剪切特性试验[J].农业机械学报,2017,48(5):63-71. |

| Zheng Le, Luo Xi-wen, Zeng Shan,et al.Shear characteristics of rice root-soil composite[J].Transactions of the Chinese Society for Agricultural Machinery,2017,48(5):63-71. | |

| 34 | 葛宜元.试验设计方法与Design-Expert软件应用[M].哈尔滨:哈尔滨工业大学出版社,2014. |

| [1] | 张延安,杜岳峰,孟青峰,栗晓宇,刘磊,朱忠祥. 基于改进遗传算法的湿式离合器压力自适应控制[J]. 吉林大学学报(工学版), 2024, 54(3): 852-864. |

| [2] | 陈学深,熊悦淞,程楠,马旭,齐龙. 自适应振动式稻田株间柔性机械除草性能试验[J]. 吉林大学学报(工学版), 2024, 54(2): 375-384. |

| [3] | 李义,吕晨阳,梁继才,梁策. 不规则Y形铝型材多点拉弯成形截面变形分析[J]. 吉林大学学报(工学版), 2024, 54(1): 105-113. |

| [4] | 王永烁,康建明,彭强吉,陈英凯,方会敏,牛萌萌,王少伟. 果树株间避障除草机设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2410-2420. |

| [5] | 金小俊,孙艳霞,于佳琳,陈勇. 基于深度学习与图像处理的蔬菜苗期杂草识别方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2421-2429. |

| [6] | 吕锋,李念,冯壮壮,张杨航. 面向用户的个性化产品服务系统协同过滤推介方法[J]. 吉林大学学报(工学版), 2023, 53(7): 1935-1942. |

| [7] | 耿端阳,孙延成,王宗源,王其欢,明家锐,杨昊霖,徐海港. 玉米籽粒直收机板齿式脱粒装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3281-3292. |

| [8] | 谢守勇,张小亮,刘凡一,刘军,苑晓亮,刘伟,王鹏. 基于钵苗力学特性取投苗装置动力学分析与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3293-3304. |

| [9] | 王斌,何丙辉,林娜,王伟,李天阳. 基于随机森林特征选择的茶园遥感提取[J]. 吉林大学学报(工学版), 2022, 52(7): 1719-1732. |

| [10] | 耿端阳,孙延成,牟孝栋,张国栋,姜慧新,朱俊科. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 693-702. |

| [11] | 温昌凯,谢斌,宋正河,韩建刚,杨倩雯. 拖拉机耐久性加速结构试验设计方法[J]. 吉林大学学报(工学版), 2022, 52(3): 703-715. |

| [12] | 李建平,边永亮,杨欣,王鹏飞,李昕昊,薛春林. 果园多风机风送喷雾机作业参数优化与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2474-2485. |

| [13] | 王国伟,朱庆辉,于海业,黄东岩. 基于数字化农机装备的青贮饲料可追溯系统[J]. 吉林大学学报(工学版), 2022, 52(1): 242-252. |

| [14] | 耿端阳,牟孝栋,张国栋,王宗源,朱俊科,徐海刚. 小麦联合收获机清选机理分析与优化试验[J]. 吉林大学学报(工学版), 2022, 52(1): 219-230. |

| [15] | 梁方,王德成,尤泳,王光辉,王宇兵,张晓明,冯金奎. 草地切根施肥补播复式改良机设计与试验[J]. 吉林大学学报(工学版), 2022, 52(1): 231-241. |

|

||