吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (1): 219-230.doi: 10.13229/j.cnki.jdxbgxb20200770

• 农业工程·仿生工程 • 上一篇

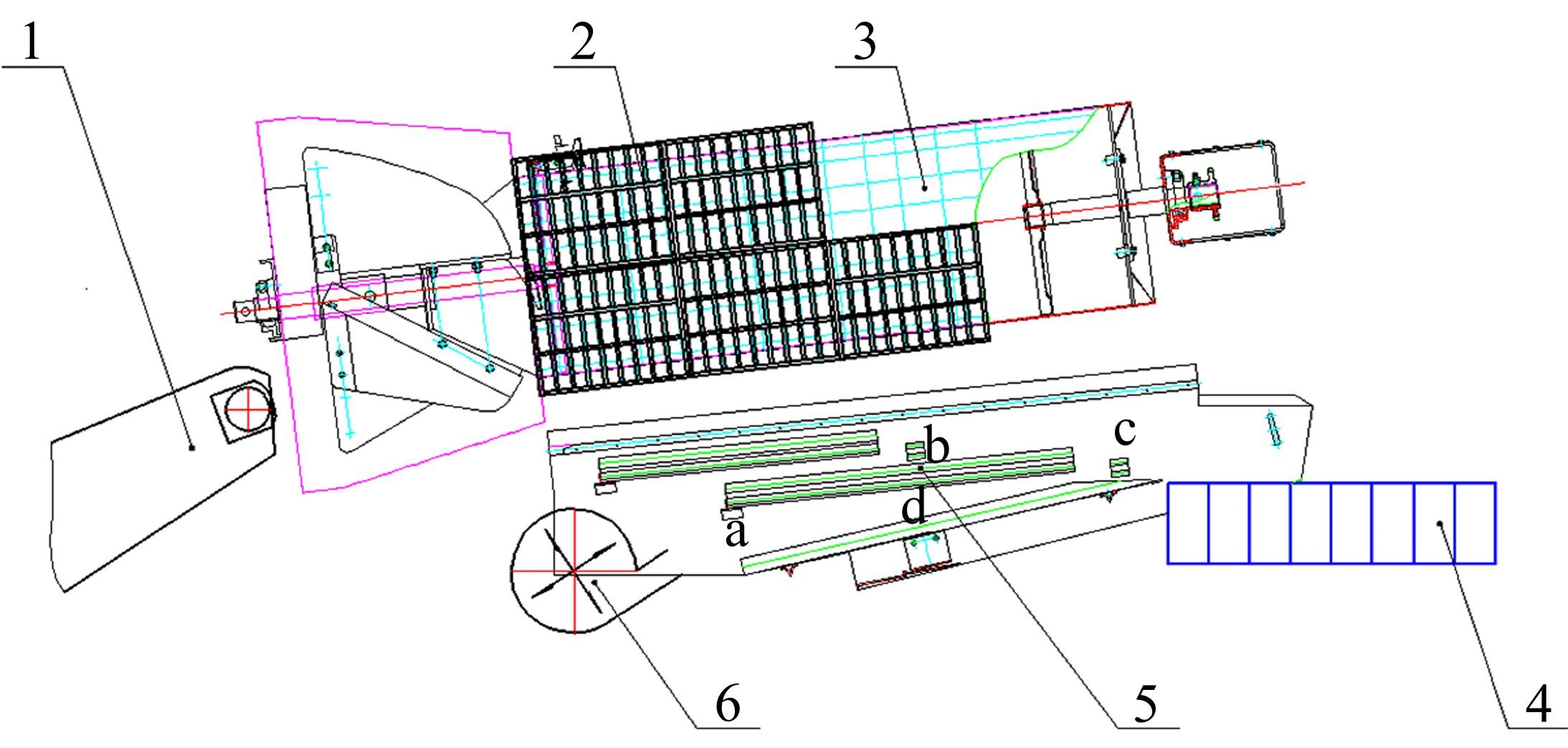

小麦联合收获机清选机理分析与优化试验

耿端阳1( ),牟孝栋1,张国栋1,王宗源1,朱俊科1,徐海刚2

),牟孝栋1,张国栋1,王宗源1,朱俊科1,徐海刚2

- 1.山东理工大学 农业工程与食品科学学院,山东 淄博 255000

2.山东时风(集团)有限责任公司,山东 聊城 252800

Analysis and optimization of cleaning mechanism of wheat combine harvester

Duan-yang GENG1( ),Xiao-dong MU1,Guo-dong ZHANG1,Zong-yuan WANG1,Jun-ke ZHU1,Hai-gang XU2

),Xiao-dong MU1,Guo-dong ZHANG1,Zong-yuan WANG1,Jun-ke ZHU1,Hai-gang XU2

- 1.School of Agricultural and Food Engineering,Shandong University of Technology,Zibo 255000,China

2.Shi Feng Group Co. Ltd. ,Liaocheng 252800,China

摘要:

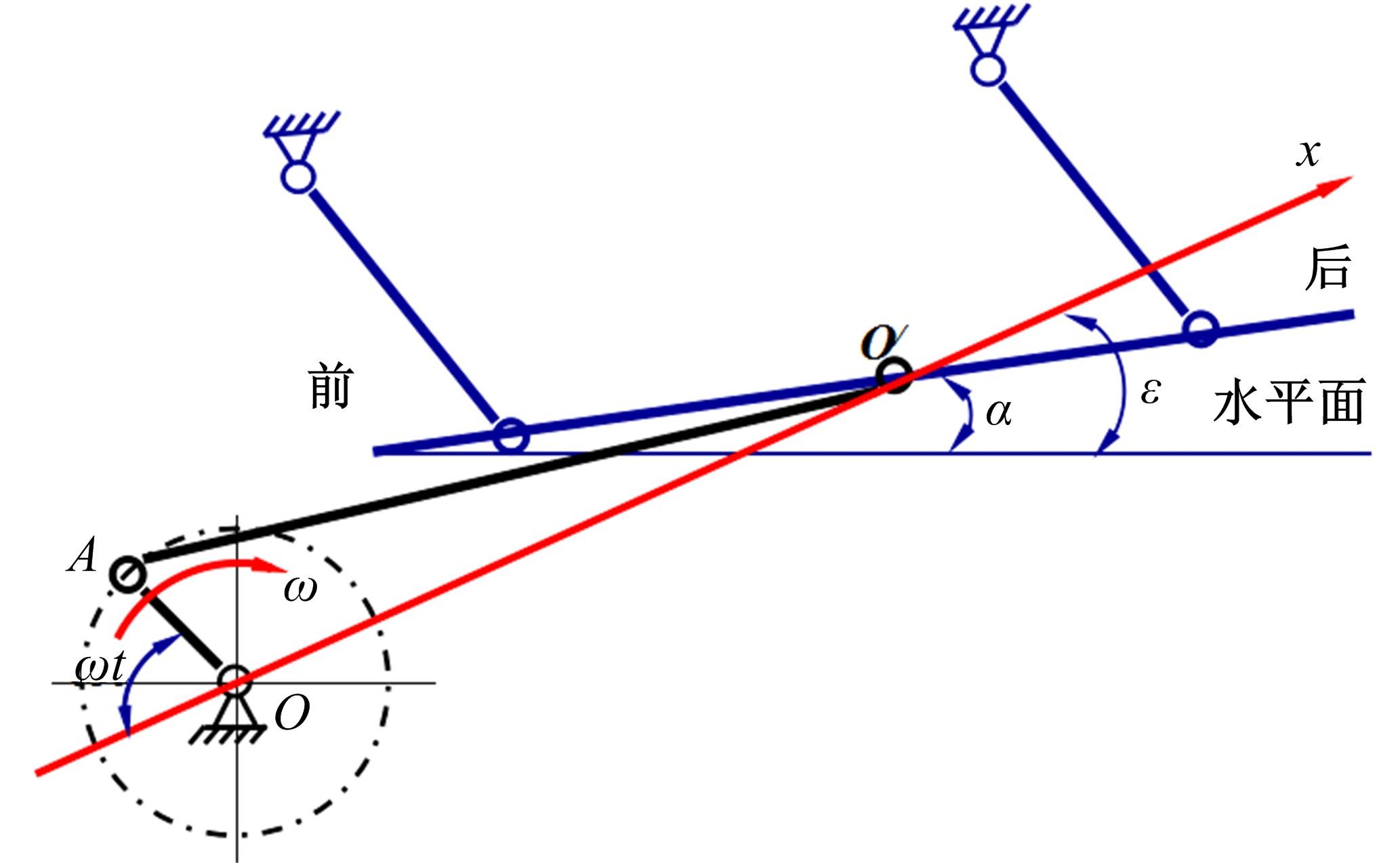

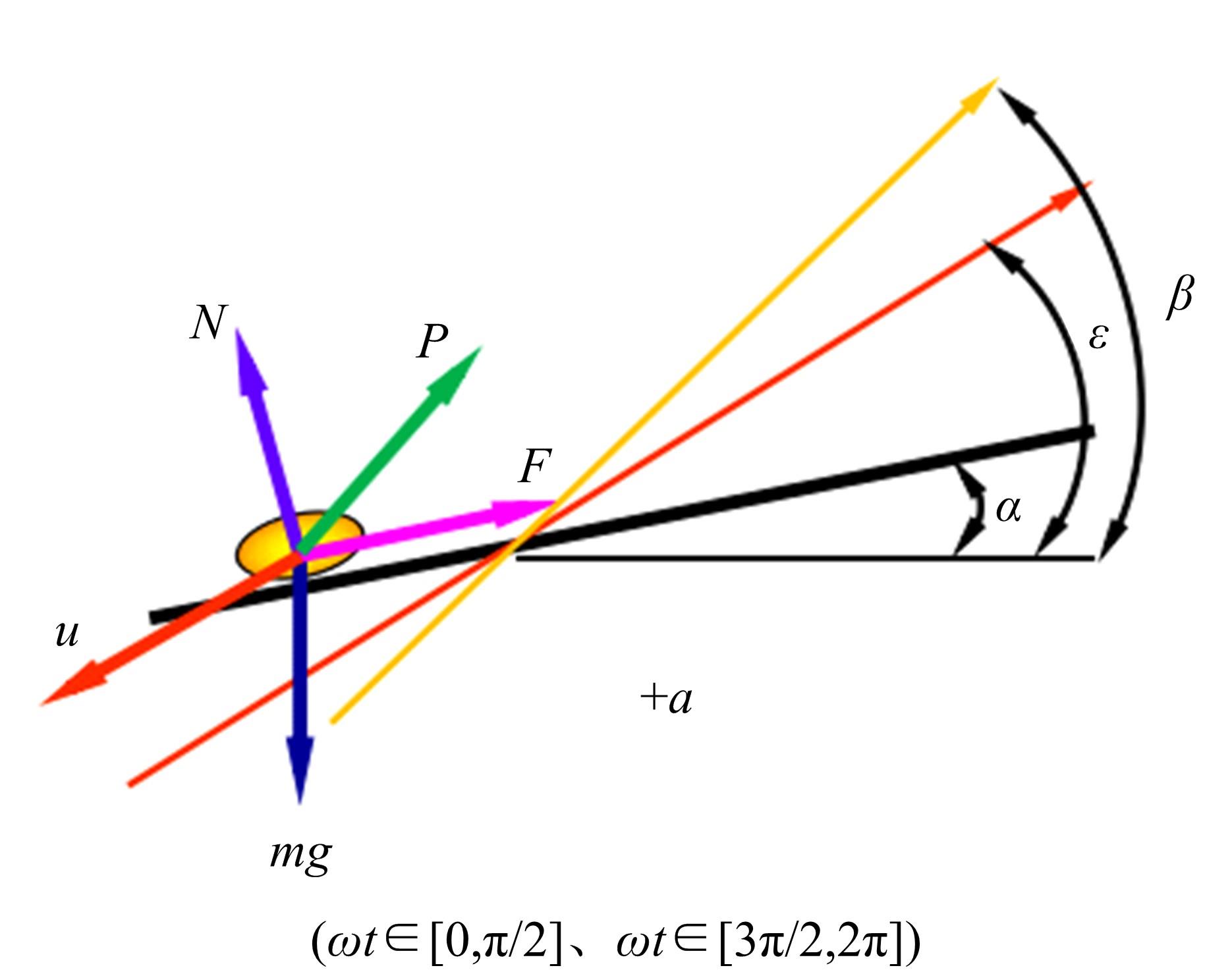

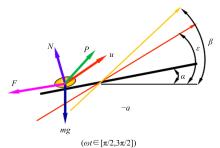

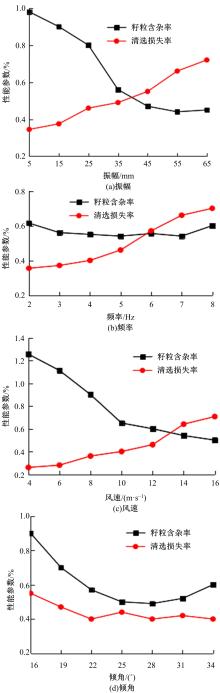

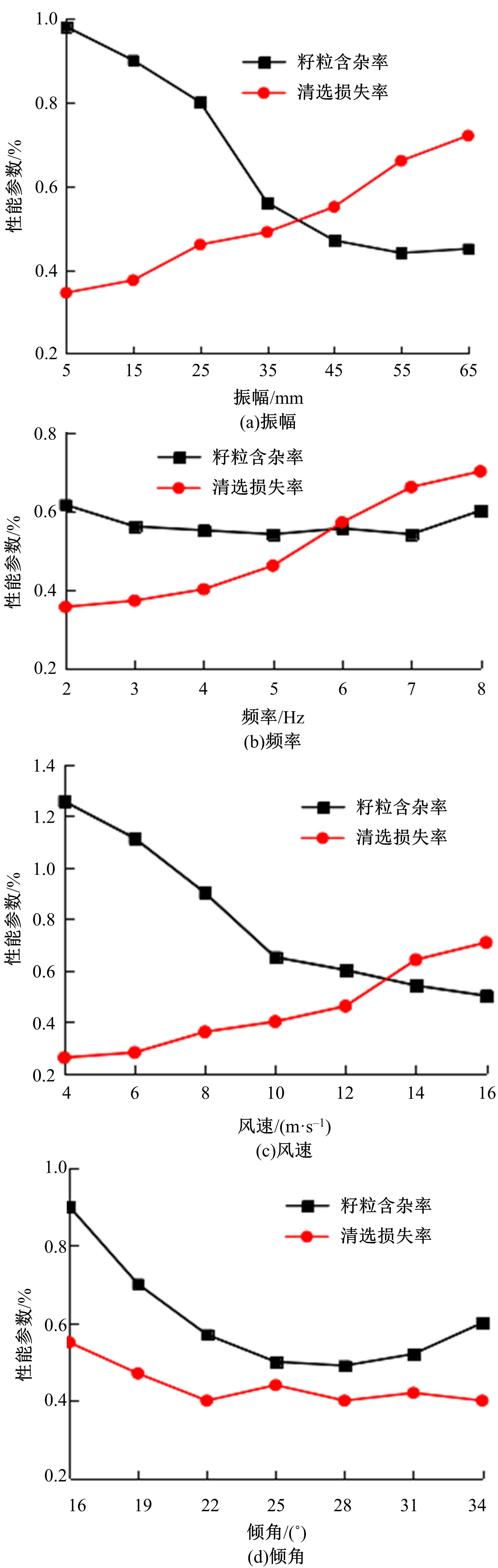

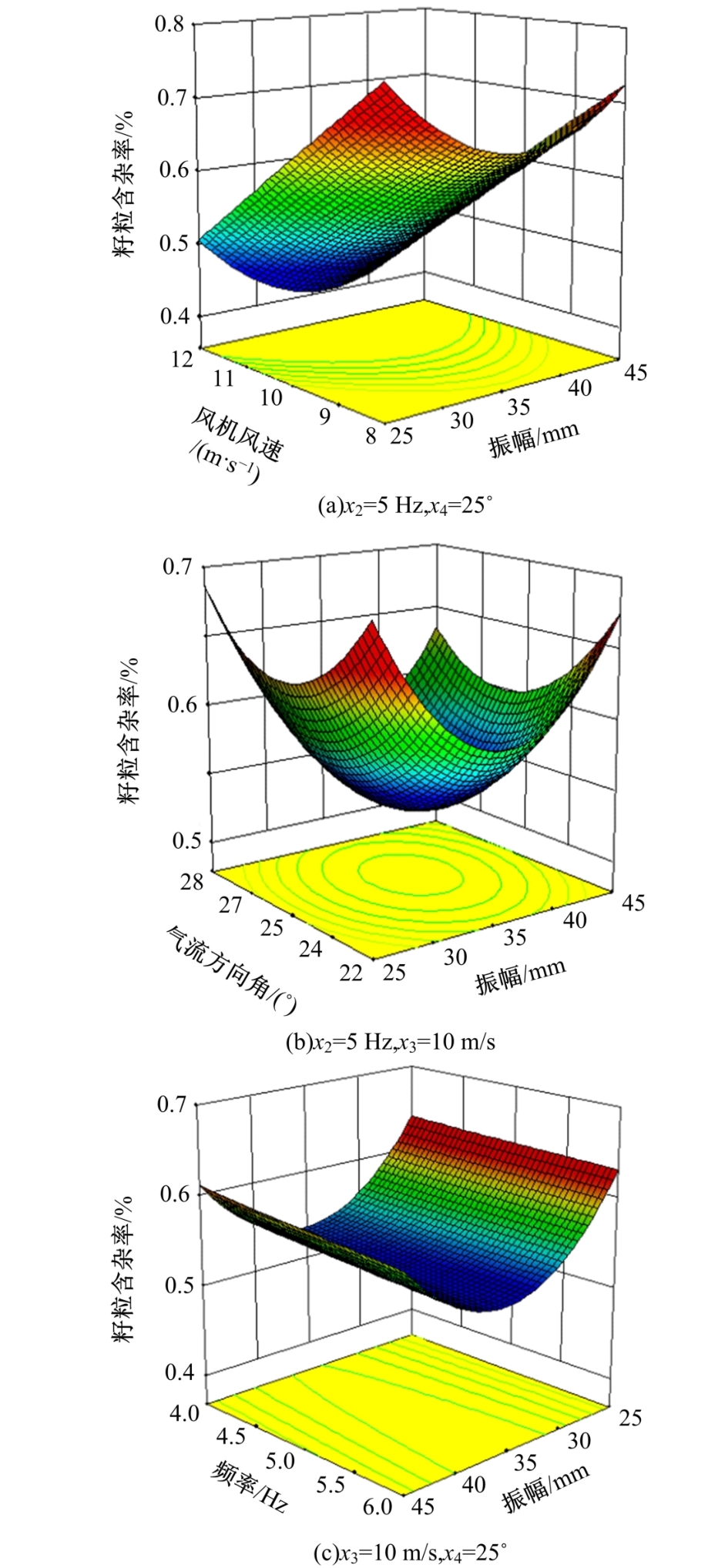

针对小麦联合收获机作业过程清选损失和籽粒含杂率“双高”的问题,开展小麦联合收获机清选作业参数优化试验,探究整机清选装置作业参数对清选损失率和籽粒含杂率的影响规律,确定清选作业参数的最优组合。基于气流场籽粒运动分析,建立了风筛清选系统的试验模型;对清选筛振幅、清选筛频率、风机风速和气流方向角4个参数进行了单因素试验和响应面回归试验,结果表明:风机风速是影响籽粒含杂率的显著影响因素,振幅、频率是影响清选损失率的显著影响因素。采用响应面试验方法,应用Design-Expert建立了清选损失率和籽粒含杂率的回归数学模型,获得了最佳工作参数如下:清选筛振幅为31 mm、清选筛频率为4 Hz、风机风速为12 m/s、气流方向角为26°。最佳参数组合的试验结果如下:籽粒含杂率为0.476%,清选损失率为0.438%,与理论计算的相对误差分别为7.8%和6.4%。

中图分类号:

- S225.3

| 1 | 徐立章,李洋,李耀明,等.谷物联合收获机清选技术与装置研究进展[J]. 农业机械学报,2019,50(10):1-16. |

| Xu Li-zhang,Li Yang,Li Yao-ming,et al. Research progress on cleaning technology and device of grain combine harvester[J].Transactions of the Chinese Society for Agricultural Machinery,2019,50(10):1-16. | |

| 2 | 孙伟,那明君,冯江,等.割前摘脱收获机立式离心分离复脱清选装置优化[J]. 农业机械学报,2018,49(7):73-81. |

| Sun Wei,Na Ming-jun,Feng Jiang,et al. Optimization of centrifugal separating-rethreshing-cleaning apparatus for stripper combine harvester[J].Transactions of the Chinese Society for Agricultural Machinery,2018,49(7):73-81. | |

| 3 | 苏天生,韩增德,崔俊伟,等. 谷物联合收割机清选装置研究现状及发展趋势[J]. 农机化研究,2016(2):6-11. |

| Su Tian-sheng,Han Zeng-de,Cui Jun-wei,et al. Research status and development trend of cleaning unit of cereal combine harvesters[J]. Journal of Agricultural Mechanization Research,2016(2): 6-11. | |

| 4 | 王乐刚,张晓辉,冷峻,等.谷物联合收获机清选装置疲劳寿命分析[J]. 农业机械学报,2018,49():282-287. |

| Wang Le-gang,Zhang Xiao-hui,Leng Jun,et al. Fatigue life analysis of grain combine harvester cleaning device[J].Transactions of the Chinese Society for Agricultural Machinery,2018,49(S1):282-287. | |

| 5 | 李洋,徐立章,周蓥,等.脱出物喂入量对多风道清选装置内部气流场的影响[J]. 农业工程学报,2017,33(12):48-55. |

| Li Yang,Xu Li-zhang,Zhou Ying,et al. Effect of extractions feed-quantity on airflow field in multi-ducts cleaning device[J]. Transactions of the Chinese Society of Agricultural Engineering,2017,33(12): 48-55. | |

| 6 | 樊晨龙,崔涛,张东兴,等.纵轴流联合收获机双层异向清选装置设计与试验[J]. 农业机械学报,2018,49():239-248. |

| Fan Chen-long,Cui Tao,Zhang Dong-xing,et al. Design and experiment of double-layered reverse cleaning device for axial flow combine harvester[J].Transactions of the Chinese Society for Agricultural Machinery,2018,49(S1):239-248. | |

| 7 | 李骅,张美娜,尹文庆,等.基于CFD的风筛式清选装置气流场优化[J]. 农业机械学报,2013,44():12-16. |

| Li Hua,Zhang Mei-na,Yin Wen-qing,et al. Optimization of airflow field on air-and-screen cleaning device based on CFD[J]. Transactions of the Chinese Society for Agricultural Machinery,2013,44(S2):12-16. | |

| 8 | 马征,李耀明,徐立章. 仿生非光滑筛面近筛层微观气流场研究[J]. 农业机械学报,2011,42():74-77, 9. |

| Ma Zheng,Li Yao-ming,Xu Li-zhang. Micro flow field on adjacent screen of bionic nonsmooth cleaning screen[J].Transactions of the Chinese Society for Agricultural Machinery,2011,42(S1) : 74-77,9. | |

| 9 | 李耀明,赵湛,陈进,等.风筛式清选装置上物料的非线性运动规律[J]. 农业工程学报,2007,23(11):142-147. |

| Li Yao-ming,Zhao Zhan,Chen Jin,et al. Nonlinear motion law of material on air-and-screen cleaning mechanism[J].Transactions of the Chinese Society of Agricultural Engineering,2007, 23(11):142-147. | |

| 10 | 李洪昌,李耀明,唐忠,等. 风筛式清选装置振动筛上物料运动CFD-DEM数值模拟[J]. 农业机械学报,2012,43(2):79-84. |

| Li Hong-chang,Li Yao-ming,Tang Zhong,et al. Numerical simulation of material motion on vibrating screen of air-and-screen cleaning device based on CFD-DEM [J]. Transactions of the Chinese Society for Agricultural Machinery,2012,43(2):79-84. | |

| 11 | 李洪昌,李耀明,唐忠,等.基于EDEM的振动筛分数值模拟与分析[J]. 农业工程学报,2011,27(5):117-121. |

| Li Hong-chang,Li Yao-ming,Tang Zhong,et al. Numerical simulation and analysis of vibration screening based on EDEM[J].Transactions of the Chinese Society of Agricultural Engineering,2011,27(5): 117-121. | |

| 12 | 李洪昌,李耀明,唐忠,等.基于神经网络的风筛式清选装置研究[J]. 农业机械学报,2011,42():65-68. |

| Li Hong-chang,Li Yao-ming,Tang Zhong,et al. Air-and-screen cleaning device based on neural network[J]. Transactions of the Chinese Society for Agricultural Machinery,2011,42(S1):65-68. | |

| 13 | 李杰,闫楚良,杨方飞. 联合收割机振动筛的动态仿真与参数优化[J]. 吉林大学学报:工学版,2006,36(5):701-704. |

| Li Jie,Yan Chu-liang,Yang Fang-fei. Dynamic simulation and parameter optimization of the combine harvester vibration sieve[J]. Journal of Jilin University( Engineering and Technology Edition),2006,36(5): 701-704. | |

| 14 | 卢琦,徐兵,刘芸,等. 基于ADAMS的往复式谷物振动筛设计与试验[J]. 山西农业大学学报:自然科学版,2019,39(2):98-104. |

| Lu Qi,Xu Bing,Liu Yun,et al. Design optimization and experimental evaluation of a reciprocating grain vibrating screen based on ADAMS system[J].Shanxi Agricultural University(Natural Science Edition),2019,39(2):98-104. | |

| 15 | 张舰,刘凡一,陈军.基于DEM的谷物清选筛振动筛分虚拟试验研究[J].农机化研究,2019,41(2):187-191. |

| Zhang Jian,Liu Fan-yi,Chen Jun. Virtual vibration screening experiments of grain cleaning sieve based on DEM[J]. Journal of Agricultural Mechanization Research,2019,41(2):187-191. | |

| 16 | Wang L J,Ding Z J,Meng S,et al. Kinematics and dynamics of a particle on a non-simple harmonic vibrating screen [J]. Particuology,2017,32(3):167-177. |

| 17 | 孙进. 基于高速摄像的风筛式清选装置中物料运动规律的研究[D]. 镇江:江苏大学机械工程学院,2007. |

| Sun Jin. Study on motion law of materials in air-and-screen cleaning mechanism based on high-speed imaging system[D]. Zhenjiang: School of Mechanical Engineering,Jiangsu University,2007. | |

| 18 | 宁小波,许磊,孙春虎,等.联合收获机多风道清选装置气流场分布与风机参数优化[J]. 农机化研究,2019,41(6):32-37. |

| Ning Xiao-bo,Xu Lei,Sun Chun-hu,et al. Fan's parameters optimization and internal flow field distribution in multi-duct cleaning device of combine harvester[J]. Journal of Agricultural Mechanization Research,2019,41(6):32-37. | |

| 19 | 刘正怀,郑一平,王志明,等.微型稻麦联合收获机气流式清选装置研究[J].农业机械学报,2015,46(7):102-108. |

| Liu Zheng-huai,Zheng Yi-ping,Wang Zhi-ming,et al.Design on air-flowing cleaning unit of micro rice-wheat combine harvester[J].Transactions of the Chinese Society for Agricultural Machinery,2015,46(7):102-108. | |

| 20 | 程超,付君,陈志,等.玉米籽粒收获机清选装置参数优化试验[J].农业机械学报,2019,50(7):151-158. |

| Cheng Chao, Fu Jun,Chen Zhi,et al. Optimization experiment on cleaning device parameters of corn kernel harvester[J]. Transactions of the Chinese Society for Agricultural Machinery,2019,50(7):151-158. | |

| 21 | 李骅. 风筛式清选装置设计理论与方法研究[D]. 南京: 南京农业大学工学院,2012. |

| Li Hua.Research of modern design method for air-and-screen cleaning device[D]. Nanjing: School of Engineering,Nanjing Agricultural University,2012. | |

| 22 | 成芳,王俊.风筛式清选装置主要参数的试验研究[J].农业工程学报,1998,14(12) : 217-221. |

| Cheng Fang,Wang Jun.Test study on the flow field above surface of the air and screen cleaning mechanism[J]. Transactions of the CSAE,1998,14(12): 217-221. | |

| 23 | 文小虎,戴飞,黄晓鹏,等.小籽粒种子分离清选机的改进设计[J].林业机械与木工设备,2019,47(7):28-31. |

| 24 | 周运泽,刘焘,王岩,等.联合收获机清选装置试验平台微缩设计[J].南方农机,2019,50(13):7-9. |

| 25 | 杜洪恿,王永刚,张恒,等. 联合收割机清选装置中离心风机的现状及发展趋势[J].中国农机化学报,2019,40(7):73-77. |

| Du Hong-wei,Wang Yong-gang,Zhang Heng,et al.Current status and development trend of centrifugal fan in cleaning device of combine harvesters[J].Journal of Chinese Agricultural Mechanization,2019,40(7):73-77. | |

| 26 | 苏航. 脱粒与清选装置参数匹配技术与方法研究[D].哈尔滨:东北农业大学农学院,2019. |

| Su Hang. Research on parameter matching technology and method of threshing and cleaning device[D]. Harbin:Agricultural College,Northeast Agricultural University,2019. |

| [1] | 王新彦,江泉,吕峰,易政洋. 基于参数化模型的零转弯半径割草机侧翻稳定性[J]. 吉林大学学报(工学版), 2021, 51(5): 1908-1918. |

| [2] | 张斌,程国赞,洪昊岑,赵春晓,白大鹏,杨华勇. 基于SVR的轴向柱塞泵配流盘三角槽结构优化[J]. 吉林大学学报(工学版), 2021, 51(4): 1213-1221. |

| [3] | 钱震杰,金诚谦,袁文胜,倪有亮,张光跃. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J]. 吉林大学学报(工学版), 2021, 51(3): 1121-1130. |

| [4] | 程超,付君,陈志,任露泉. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报(工学版), 2021, 51(2): 761-771. |

| [5] | 杨开宇,刘伟,王天皓,于显利,高印寒,马喜来. 一种多导体传输线串扰不确定性问题的计算方法[J]. 吉林大学学报(工学版), 2021, 51(2): 747-753. |

| [6] | 丛茜,徐金,马博帅,张晓超,陈廷坤. 基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J]. 吉林大学学报(工学版), 2021, 51(2): 754-760. |

| [7] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [8] | 杜常清,曹锡良,何彪,任卫群. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报(工学版), 2020, 50(5): 1556-1564. |

| [9] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [10] | 高锐涛,单建,杨洲,文晟,兰玉彬,张泉勇,汪洋. 植保无人机变量喷雾处方图实时解译系统的设计与试验[J]. 吉林大学学报(工学版), 2020, 50(1): 361-374. |

| [11] | 蔡中义,孟凡响,陈庆敏,赵轩. 复杂钩舌锻件近净成形的预锻形状优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 84-90. |

| [12] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [13] | 刘恩泽,吴文福. 基于综合指标品质评价算法的单色水果生长状态检测互联网架构[J]. 吉林大学学报(工学版), 2019, 49(6): 2019-2026. |

| [14] | 谷远利, 张源, 芮小平, 陆文琦, 李萌, 王硕. 基于免疫算法优化LSSVM的短时交通流预测[J]. 吉林大学学报(工学版), 2019, 49(6): 1852-1857. |

| [15] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

|

||