吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (11): 3293-3304.doi: 10.13229/j.cnki.jdxbgxb.20220139

• 农业工程·仿生工程 • 上一篇

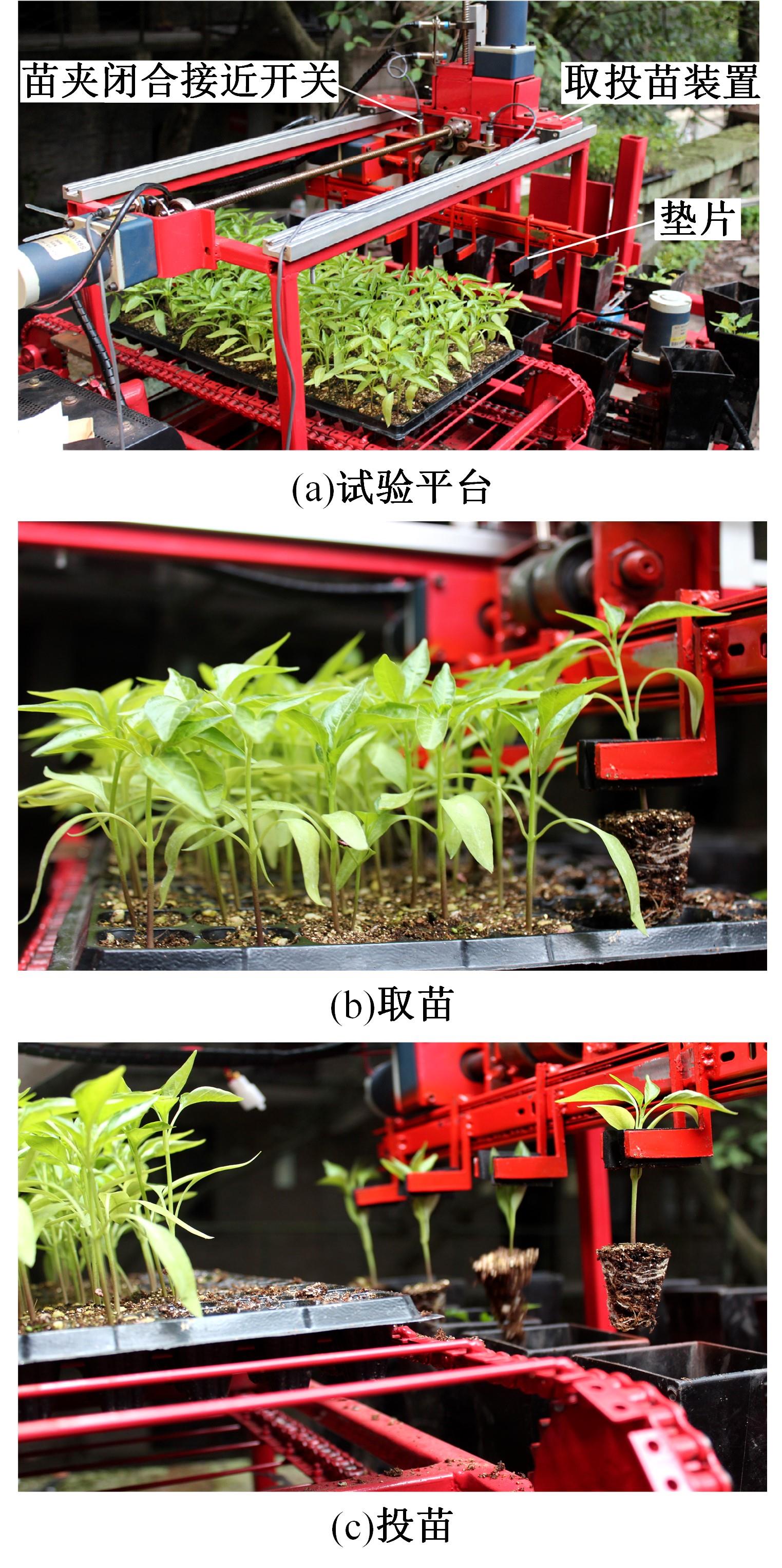

基于钵苗力学特性取投苗装置动力学分析与试验

谢守勇1( ),张小亮1,刘凡一1,2,刘军1,2,苑晓亮1,刘伟1,王鹏1

),张小亮1,刘凡一1,2,刘军1,2,苑晓亮1,刘伟1,王鹏1

- 1.西南大学 工程技术学院,重庆 400715

2.西南大学 丘陵山区农业装备重庆市重点实验室,重庆 400715

Kinetic analysis and experiment of seedling taking and throwing device based on mechanical properties of plug seedlings

Shou-yong XIE1( ),Xiao-liang ZHANG1,Fan-yi LIU1,2,Jun LIU1,2,Xiao-liang YUAN1,Wei LIU1,Peng WANG1

),Xiao-liang ZHANG1,Fan-yi LIU1,2,Jun LIU1,2,Xiao-liang YUAN1,Wei LIU1,Peng WANG1

- 1.School of Engineering and Technology,Southwest University,Chongqing 400715,China

2.Chongqing Key Laboratory of Agriculture Equipment for Hilly and Mountainous Regions,Southwest University,Chongqing 400715,China

摘要:

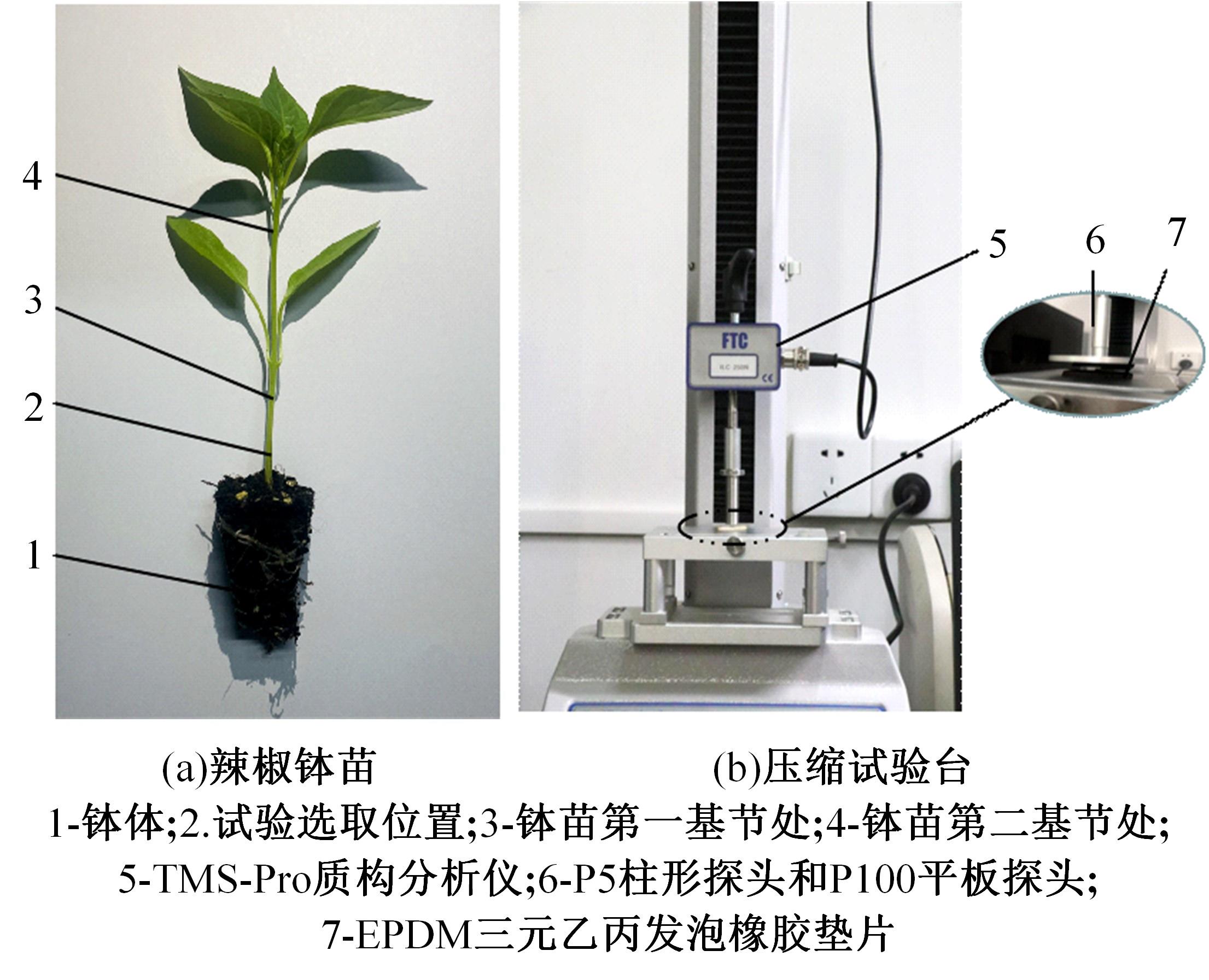

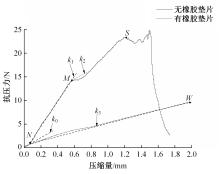

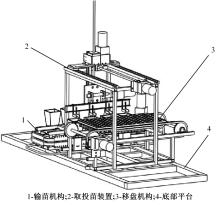

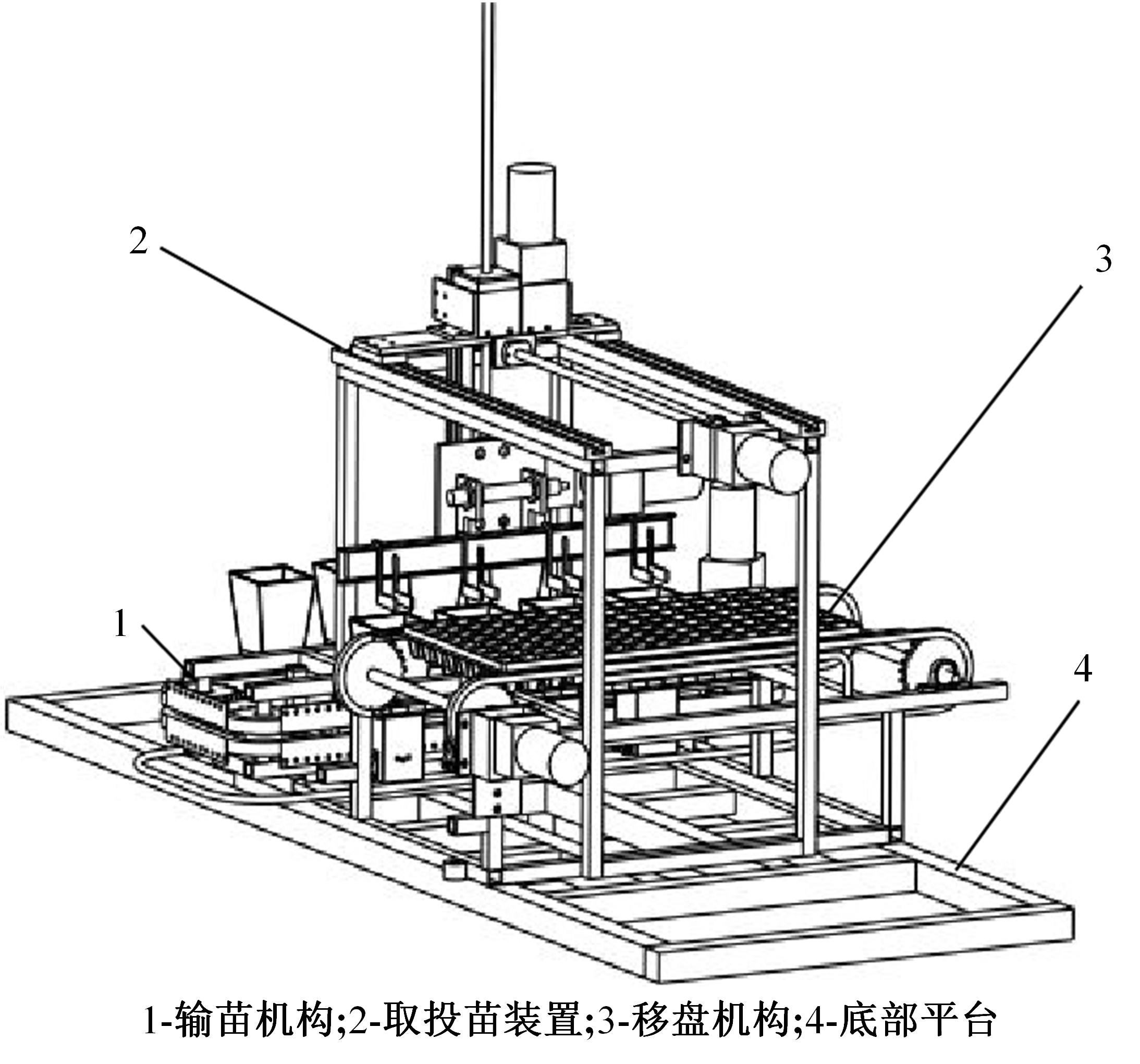

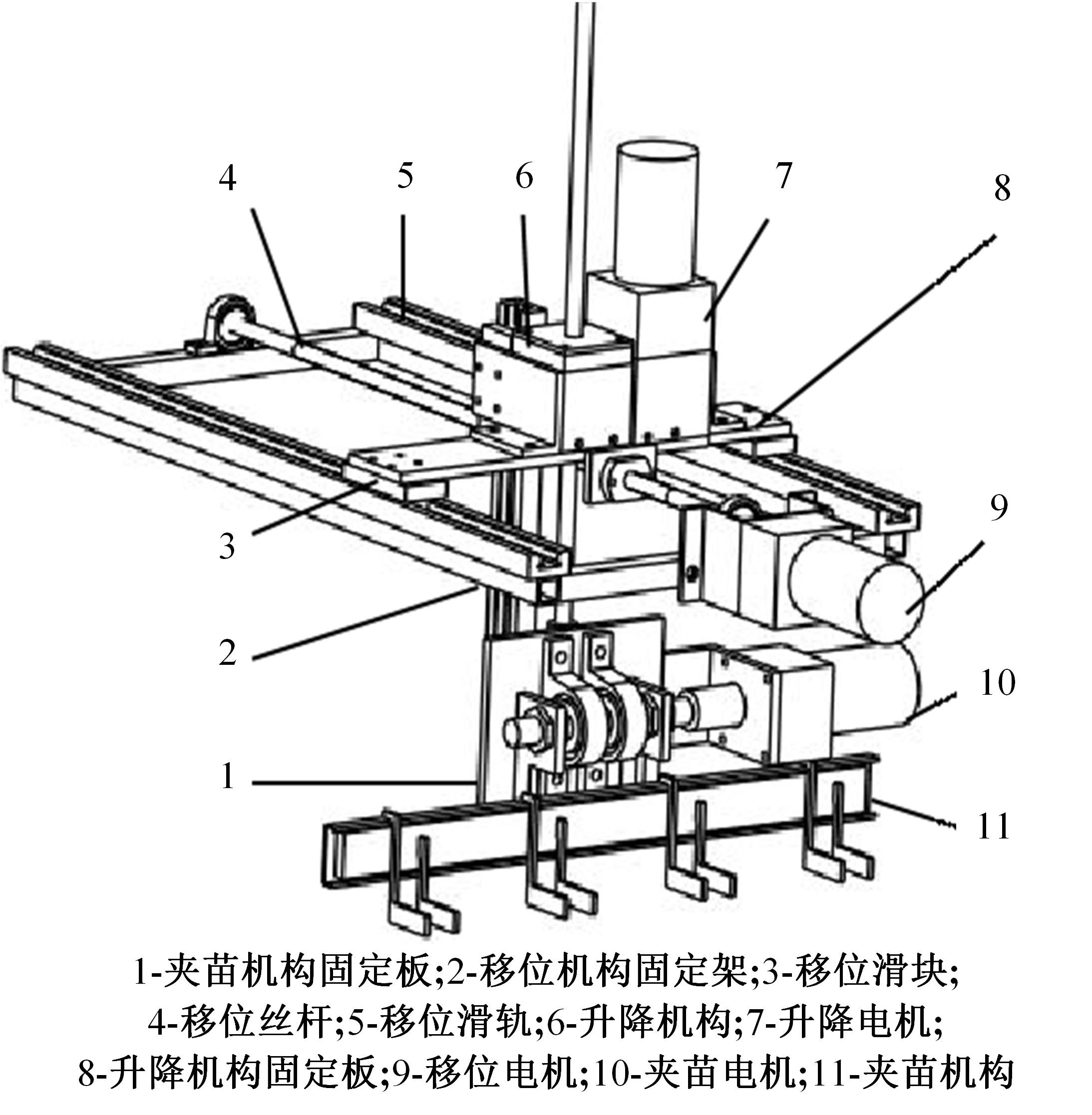

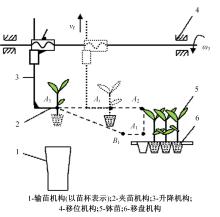

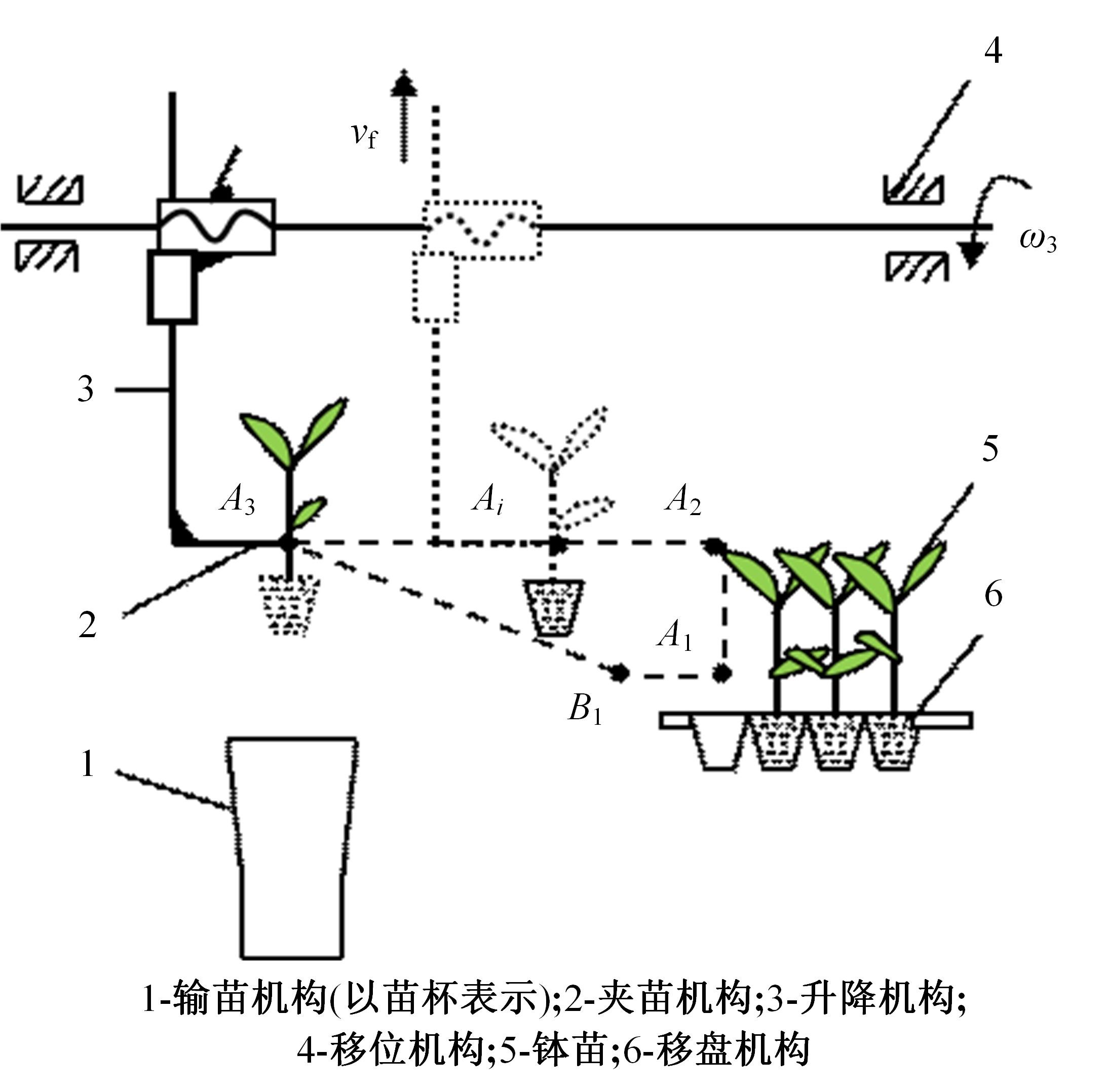

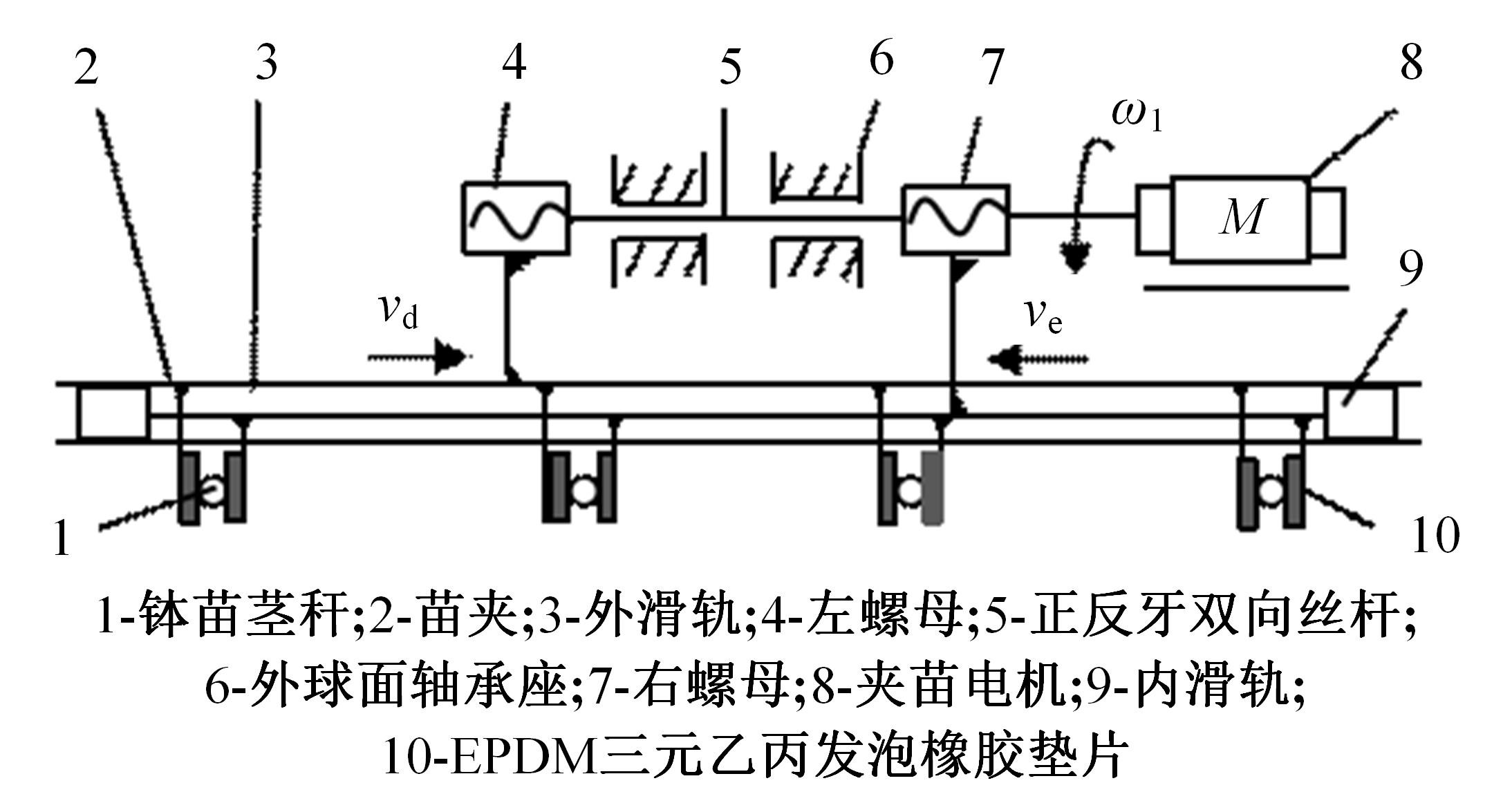

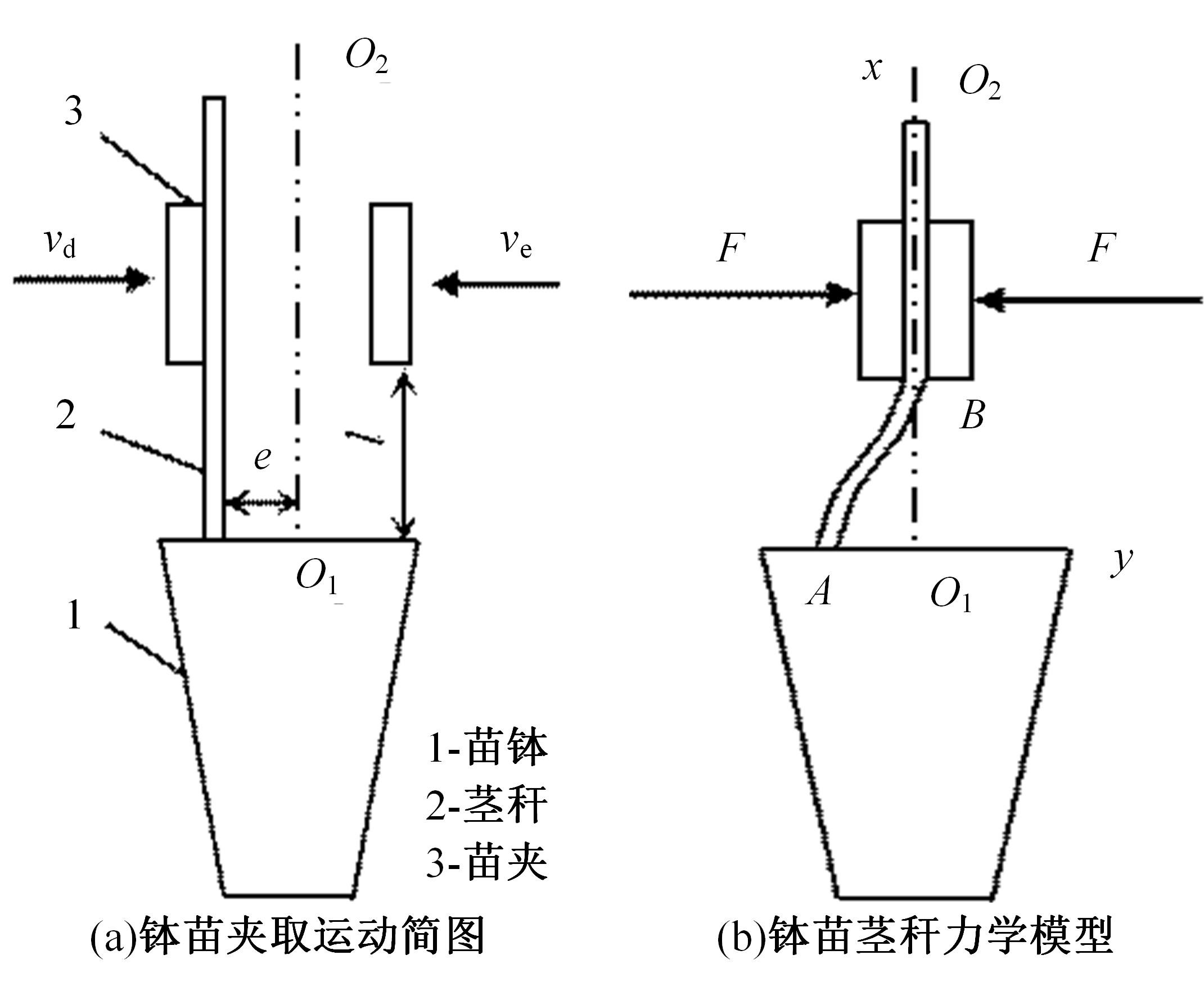

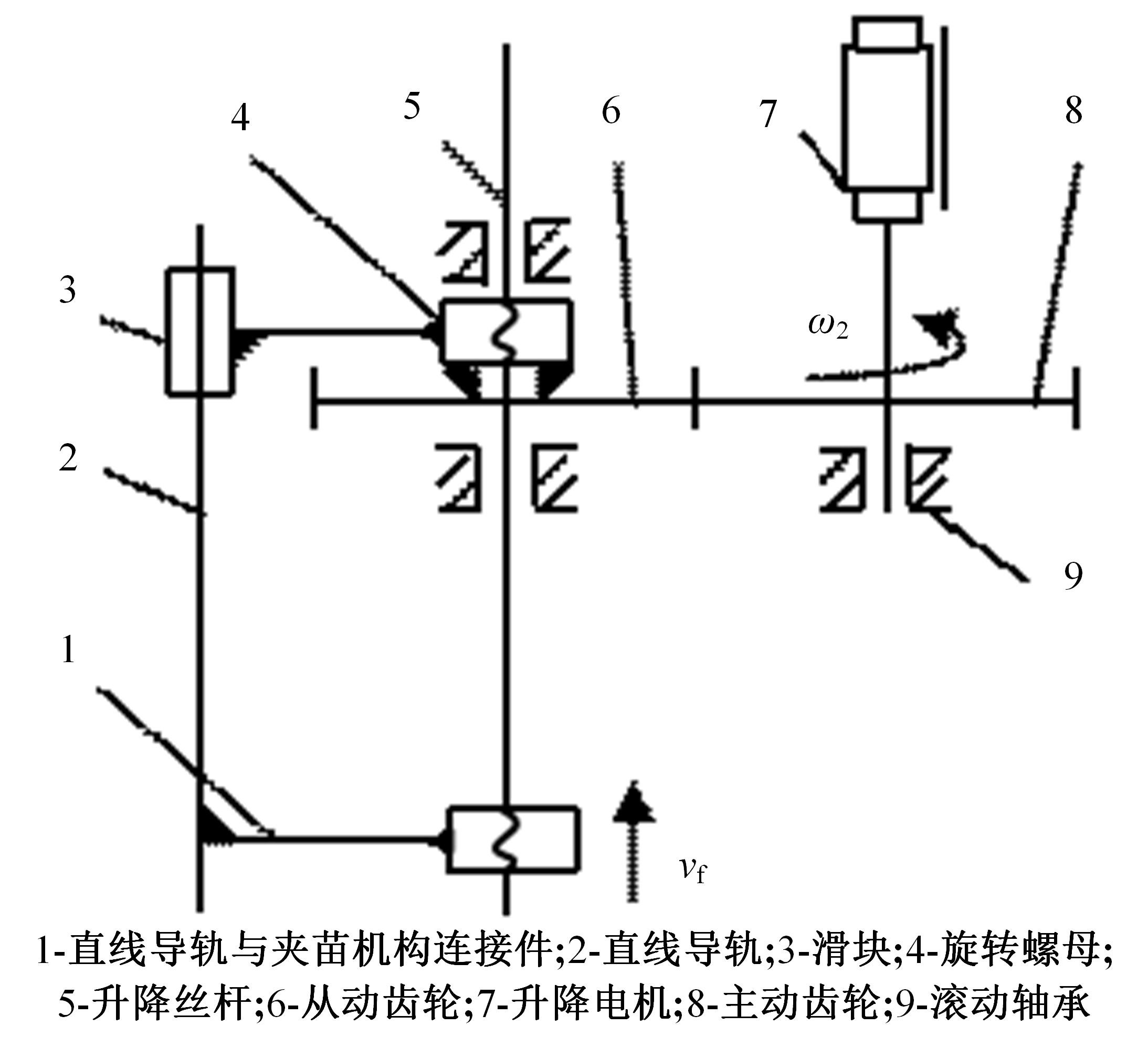

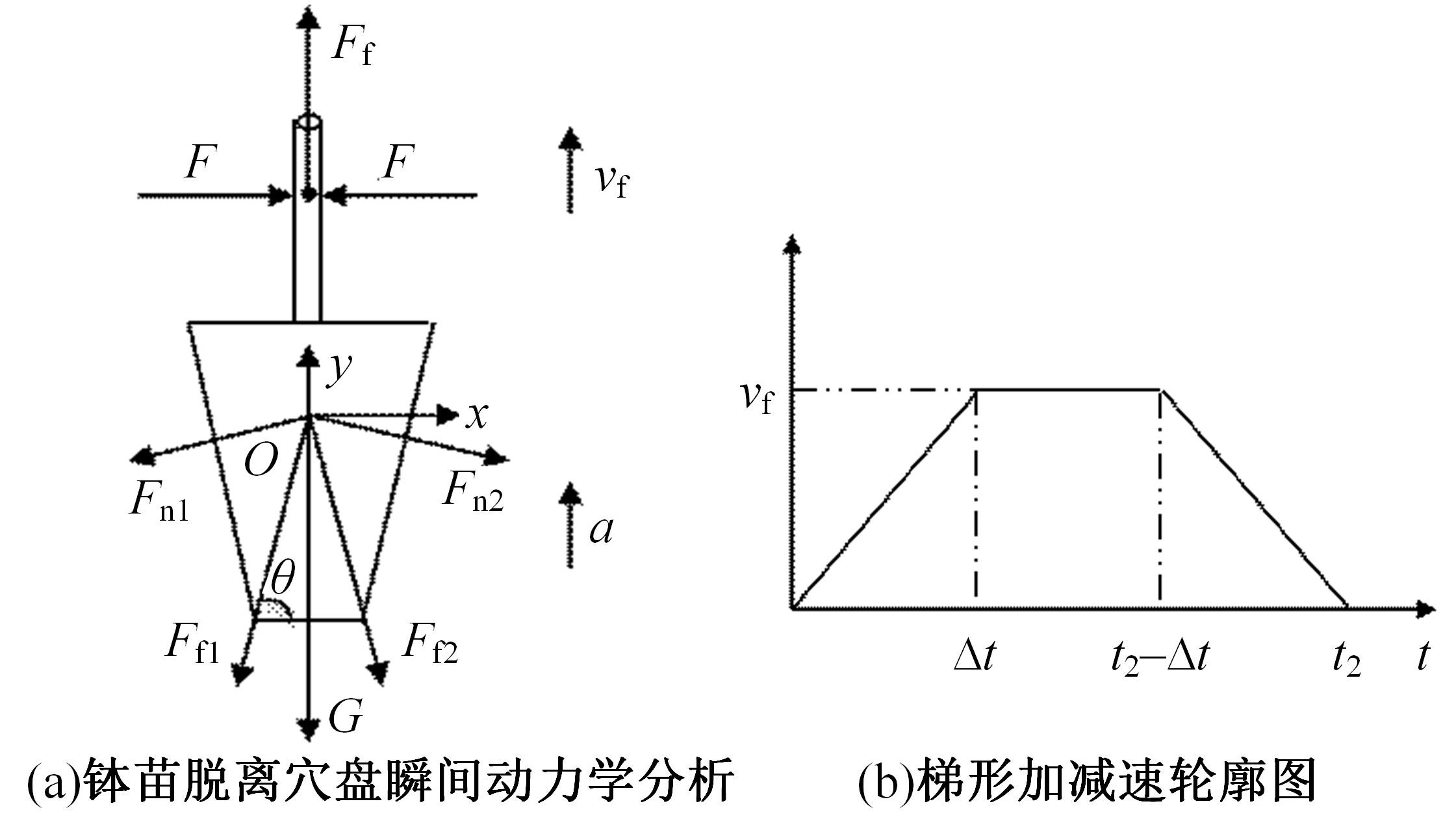

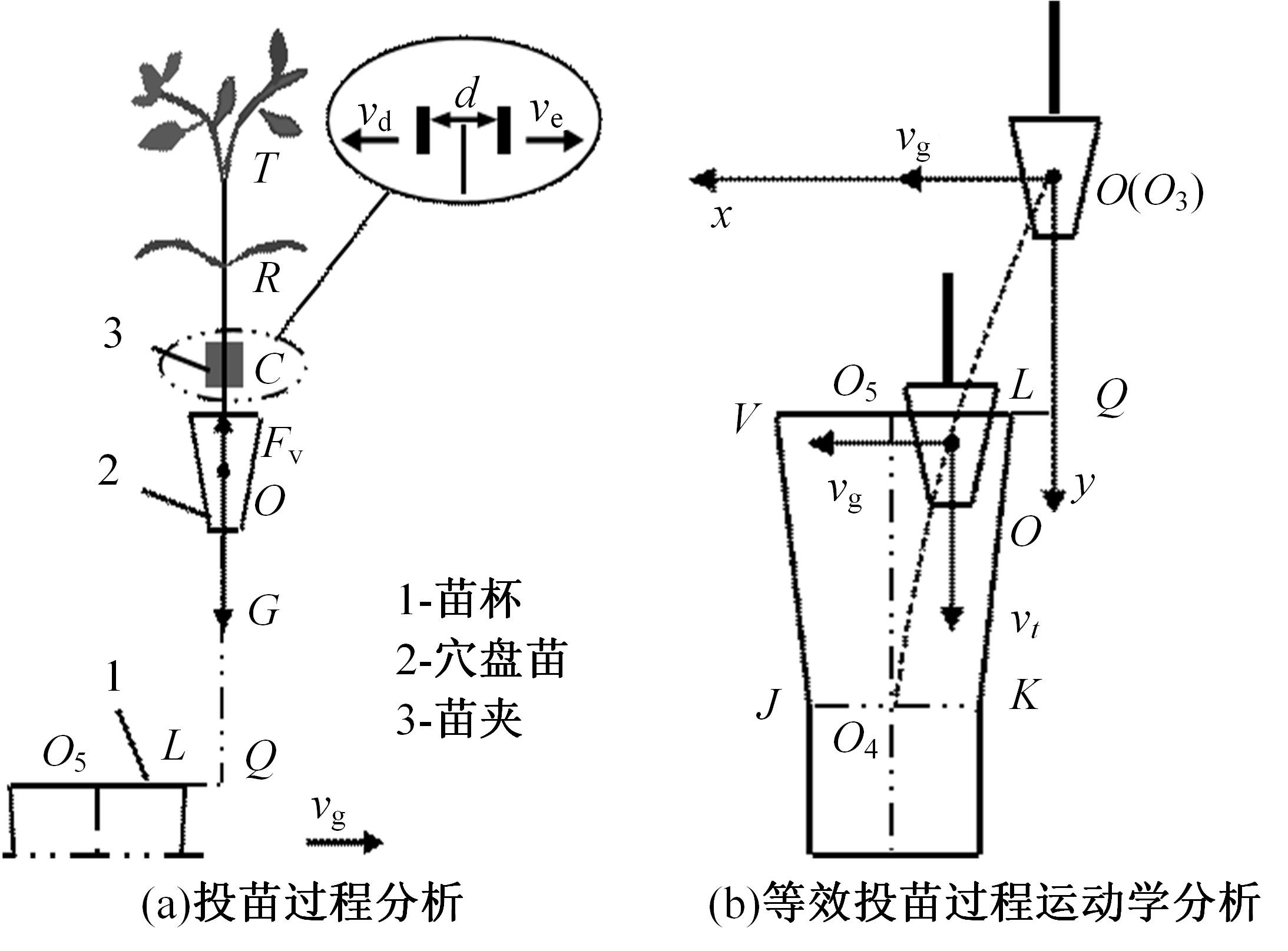

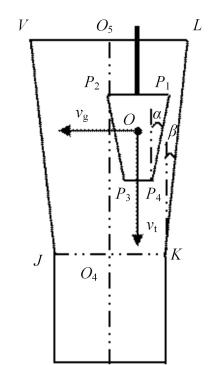

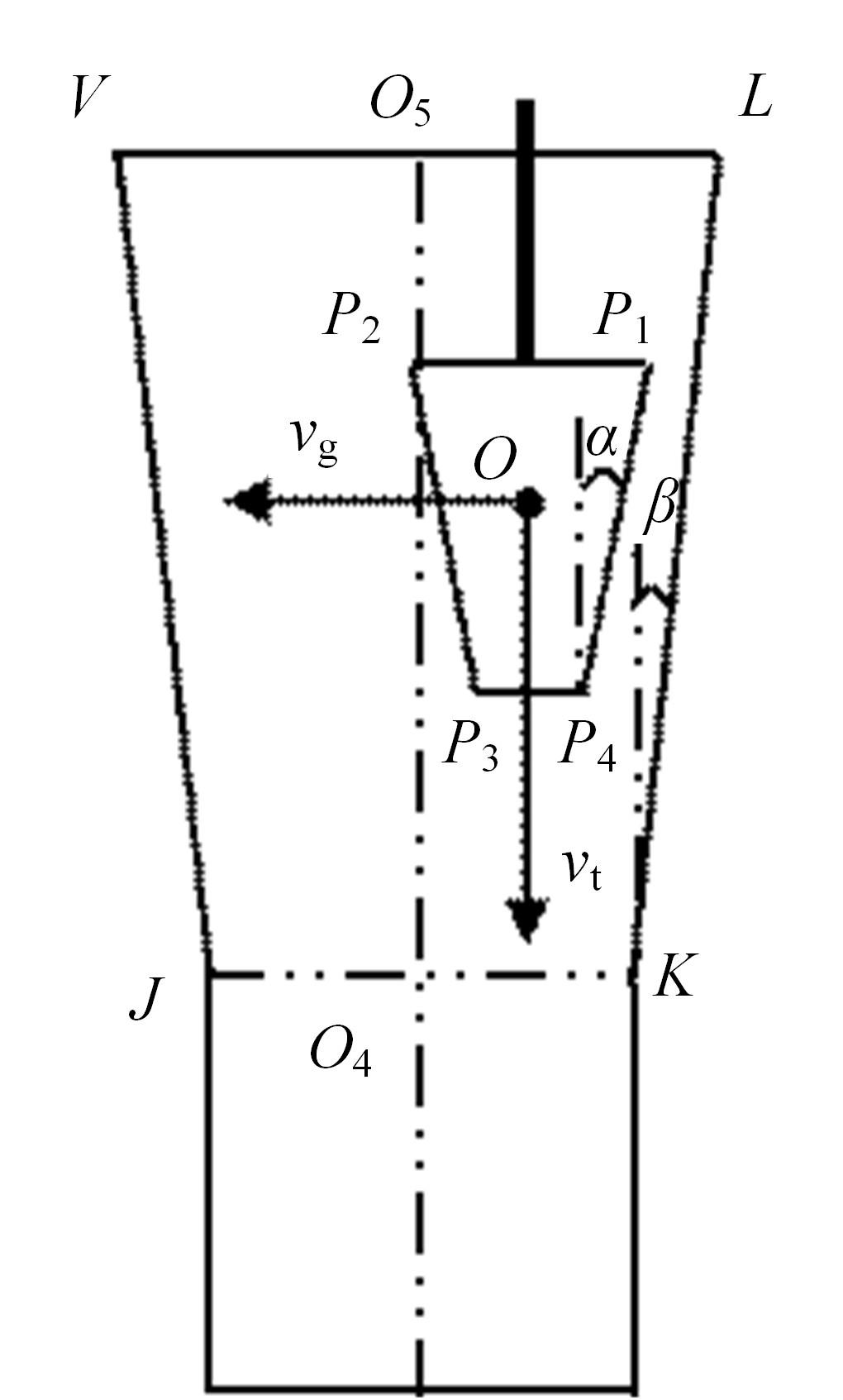

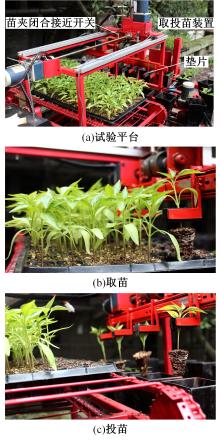

针对现有蔬菜移栽机自动取投苗装置结构复杂、存在对根系损伤等问题,提出了一种基于滚珠丝杆及直线滑轨机构的往复夹茎式取投苗装置,分析了该装置的组成及工作原理,建立了取投苗过程的钵苗动力学模型,进行了钵苗茎秆的抗压力学特性试验,为机构设计提供参考依据。为保证装置具有良好的取投苗效果,通过对夹苗过程进行夹苗力学分析,确定了不同茎秆位置下的夹苗高度,同时对取苗和投苗过程进行动力学分析,确定苗夹间距与投苗位置,并得出不同取投苗速率下各机构电机的转速。以辣椒穴盘苗为试验对象,以取苗成功率、投苗成功率、基质破碎率和茎叶损伤率为试验指标进行了取投苗台架试验。试验结果表明:当取投苗频率为90株/min时,取投苗效果最佳,此时取苗成功率为96.8%,投苗成功率为96.8%,基质破碎率为4.0%,伤苗率为1.6%,装置可靠性较高。研究结果可为全自动化取投苗装置研究提供参考。

中图分类号:

- S223.92

| 1 | 于晓旭, 赵匀, 陈宝成, 等.移栽机械发展现状与展望[J]. 农业机械学报, 2014, 45(8): 44-53. |

| Yu Xiao-xu, Zhao Yun, Chen Bao-cheng, et al. Current situation and prospect of transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 44-53. | |

| 2 | 胡建平, 常航, 杨丽红, 等. 自动移栽机整排取苗间隔投苗控制系统设计与试验[J]. 农业机械学报, 2018, 49(6): 78-84. |

| Hu Jian-ping, Chang Hang, Yang Li-hong, et al. Design and experiment of control system for automatic transplanter pickingup and spacing casting whole row of seedlings[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(6):78-84. | |

| 3 | 文永双, 张俊雄, 袁挺, 等. 蔬菜穴盘苗移栽自动取苗技术现状与分析[J]. 中国农业大学学报, 2021, 26(4): 128-142. |

| Wen Yong-shuang, Zhang Jun-xiong, Yuan Ting, et al. Current situation and analysis of automatic seedling extraction technology for vegetable pot seedling transplantation[J]. Journal of China Agricultural University, 2021, 26(4): 128-142. | |

| 4 | 朱光强, 李天宇, 周福君, 等. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报: 工学版, 2022, 52(10): 2486-2500. |

| Zhu Guang-qiang, Li Tian-yu, Zhou Fu-jun, et.al. Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2486-2500. | |

| 5 | 周脉乐, 薛向磊, 钱孟波, 等. 探出式蔬菜钵苗打孔移栽机构优化设计与试验[J]. 农业机械学报, 2020, 51(1): 77-83. |

| Zhou Mai-le, Xue Xiang-lei, Qian Meng-bo, et al. Optimal design and experiment of potted vegetable seedling transplanting mechanism with punching hole[J]. Transactions of the Chinese Society for Agricultural Machinery,2020, 51(1): 77-83. | |

| 6 | 赵匀, 刘星, 薛向磊, 等. 茄子钵苗全自动移栽机构优化设计与试验[J]. 农业机械学报, 2018, 49(5): 152-160. |

| Zhao Yun, Liu Xing, Xue Xiang-lei, et al. Optimization design and experiment of full-automatic transplanting mechanism for eggplant pot seedlings[J]. Transactions of the Chinese Society for Agricultural Machinery,2018,49(5): 152-160. | |

| 7 | 万星宇, 廖庆喜, 蒋亚军, 等. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报: 工学版, 2022, 52(11): 2735-2745. |

| Wan Xing-yu, Liao Qing-xi, Jiang Ya-jun, et al. Discrete element simulation and experiment of mechanized harvesting and chopping process for fodder rape crop harves[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. | |

| 8 | 韩长杰, 肖立强, 徐阳, 等. 辣椒穴盘苗自动移栽机设计与试验[J]. 农业工程学报, 2021, 37(13): 20-29. |

| Han Chang-jie, Xiao Li-qiang, Xu Yang, et al. Design and experiment of the automatic transplanter for chili plug seedlings[J]. Transactions of the CSAE,2021, 37(13): 20-29. | |

| 9 | 张静, 龙新华, 韩长杰, 等. 机械驱动式辣椒穴盘苗自动取投苗系统设计与试验[J]. 农业工程学报, 2021, 37(5): 20-30. |

| Zhang Jing, Long Xin-hua, Han Chang-jie, et al. Design and experiments of mechanically-driven automatic taking and throwing system for chili plug seedlings[J]. Transactions of the CSAE, 2021, 37(5): 20-30. | |

| 10 | 王俊, 张海洋, 金鑫, 等. 穴盘苗自动移栽机苗钵夹持力检测系统设计与试验[J]. 农业机械学报, 2019, 50(5): 79-87. |

| Wang Jun, Zhang Hai-yang, Jin Xin, et al. Design and experiment of seedling bowl clamping force detection system for plug seedling automatic transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(5): 79-87. | |

| 11 | 袁挺, 王栋, 文永双, 等. 蔬菜移栽机气吹振动复合式取苗机构设计与试验[J]. 农业机械学报, 2019, 50(10): 80-87. |

| Yuan Ting, Wang Dong, Wen Yong-shuang, et al. Design and experiment of seedlings unloading mechanism based on methods of air-blowing and vibration for vegetable transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(10): 80-87. | |

| 12 | Yang Q Z, Huang G L, Shi X Y, et al. Design of a control system for a mini-automatic transplanting machine of plug seedling[J]. Computers and Electronics in Agriculture, 2020, 169: 105-226. |

| 13 | 廖庆喜, 王洋, 胡乔磊, 等. 油菜基质块苗移栽机取苗装置设计与试验[J]. 农业机械学报, 2020, 51(11): 93-102. |

| Liao Qing-xi, Wang Yang, Hu Qiao-lei, et al. Design and test of seedling taking device of rape matrix block seedling transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(11): 93-102. | |

| 14 | 刘念聪, 杨程文, 刘保林, 等. 全自动单摆式蔬菜钵苗取喂苗系统研制[J]. 农业工程学报, 2020, 36(22): 87-95. |

| Liu Nian-cong, Yang Cheng-wen, Liu Bao-lin, et al. Development of automatic single pendulum vegetable pot seedling picking and feeding system[J]. Transactions of the CSAE, 2020, 36(22): 87-95. | |

| 15 | 童俊华, 石虎峰, 武传宇, 等. 穴盘移栽指铲式末端执行器苗钵基质抓取仿真与试验[J]. 农业机械学报, 2019, 50(8): 107-116. |

| Tong Jun-hua, Shi Hu-feng, Wu Chuan-yu, et al. Simulation and experiment of seedling bowl matrix grasping of finger shovel end effector for hole plate transplanting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019,50 (8): 107-116. | |

| 16 | 尹大庆, 王佳照, 周脉乐, 等. 探出取推钵式蔬菜钵苗取苗机构优化设计与试验[J]. 农业机械学报,2019, 50(10): 64-71. |

| Yin Da-qing, Wang Jia-zhao, Zhou Mai-le, et al. Optimal design and experiment of vegetable potted seedlings pick-up mechanism for exploring and picking-pushing plugs[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(10): 64-71. | |

| 17 | 倪有亮, 金诚谦, 刘基, 等. 全自动移栽机取送苗系统的设计与试验[J]. 农业工程学报, 2015, 31(23): 10-19. |

| Ni You-liang, Jin Cheng-qian, Liu Ji,et al. Design and experiment of system for picking up and delivering seedlings in automatic transplanter[J]. Transactions of the CSAE, 2015, 31(23): 10-19. | |

| 18 | Rahul K, Raheman H, Paradkar V, et al. Design and development of a 5R 2DOF parallel robot arm for handling paper pot seedlings in a vegetable transplanter[J]. Computers and Electronics in Agriculture,2019, 166: 105-118. |

| 19 | Choi W C, Kim D C, Ryu I H, et al. Development of seedling pick-up device for vegetable transplants[J]. Transactions of the ASAE, 2001, 45(1): 13-19. |

| 20 | 王蒙蒙, 宋建农, 刘彩玲, 等. 蔬菜移栽机曲柄摆杆式夹苗机构的设计与试验[J]. 农业工程学报, 2015, 31(14): 49-57. |

| Wang Meng-meng, Song Jian-nong, Liu Cai-ling, et al. Design and experiment of crank rocker type clamp seedlings mechanism of vegetable transplanter[J]. Transactions of the CSAE, 2015, 31(14): 49-57. | |

| 21 | 李华, 马晓晓, 曹卫彬, 等. 夹茎式番茄钵苗取苗机构设计与试验[J]. 农业工程学报, 2020, 36(21): 39-48. |

| Li Hua, Ma Xiao-xiao, Cao Wei-bin, et al. Design and experiment of seedling picking mechanism by stem clipping for tomato plug seedling[J]. Transactions of the CSAE, 2020, 36(21): 39-48. | |

| 22 | 王超, 刘彩玲, 李永磊, 等. 蔬菜移栽机气动下压式高速取苗装置设计与试验[J]. 农业机械学报, 2021, 52(5): 35-43. |

| Wang Chao, Liu Cai-ling, Li Yong-lei, et al. Design and test of pneumatic down pressing high-speed seedling taking device for vegetable transplanter[J]. Journal of Agricultural Machinery, 2021, 52(5): 35-43. | |

| 23 | 谢守勇, 阳尚宏, 刘军, 等. 蔬菜移栽机斜插夹钵式取投苗装置研制[J]. 农业工程学报, 2020, 36(6): 1-10. |

| Xie Shou-yong, Yang Shang-hong, Liu Jun, et al. Development of the seedling taking and throwing device with oblique insertion and plug clipping for vegetable transplanters[J]. Transactions of the CSAE,2020, 36(6): 1-10. | |

| 24 | 文永双, 张俊雄, 张宇, 等. 蔬菜穴盘苗插入顶出式取苗装置研制[J]. 农业工程学报, 2020, 36(22): 96-104. |

| Wen Yong-shuang, Zhang Jun-xiong, Zhang Yu, et al. Development of insertion and ejection type seedling taking device for vegetable plug seedlings[J]. Transactions of the CSAE, 2020, 36(22): 96-104. | |

| 25 | 马晓晓, 李华, 葛云, 等. 番茄钵苗茎秆力学特性试验研究[J]. 农机化研究, 2020, 42(8): 161-167. |

| Ma Xiao-xiao, Li Hua, Ge Yun, et al. Experimental study on mechanical properties of tomato pot seedling stem[J]. Research on Agricultural Mechanization,2020, 42(8): 161-167. | |

| 26 | 袁红梅. 小麦茎秆生物力学性能试验与抗倒伏力学评价分析[D]. 晋中: 山西农业大学农业工程学院, 2005. |

| Yuan Hong-mei. Wheat stalk biomechanical performance test and lodging resistance mechanical evaluation analysis[D]. Jinzhong: College of Agricultural Engineering, Shanxi Agricultural University, 2005. | |

| 27 | 袁志华, 冯宝萍, 赵安庆, 等. 作物茎秆抗倒伏的力学分析及综合评价探讨[J]. 农业工程学报, 2002, 18(6): 30-31. |

| Yuan Zhi-hua, Feng Bao-ping, Zhao An-qing, et al. Mechanical analysis and comprehensive evaluation of crop stem lodgin resistance[J]. Transactions of the CSAE,2002, 18(6): 30-31. | |

| 28 | 胡静, 韩绿化, 温贻芳, 等. 与自动移栽相关的不同蔬菜穴盘苗力学特性[J]. 农机化研究, 2018, 40(5): 132-136. |

| Hu Jing, Han Lv-hua, Wen Yi-fang, et al. Mechanical properties of different vegetable pot seedlings related to automatic transplanting[J]. Research on Agricultural Mechanization, 2018, 40(5): 132-136. | |

| 29 | 李智国, 李萍萍, 刘继展, 等. 不同加减速控制算法的能耗分析与比较[J]. 农业机械学报, 2009, 40(8): 193-197. |

| Li Zhi-guo, Li Ping-ping, Liu Ji-zhan, et al. Energy consumption analysis and comparison of different acceleration and deceleration control algorithms [J]. Journal of Agricultural Machinery, 2009, 40(8): 193-197. | |

| 30 | 赵晨阳, 郭俊先, 刘娜, 等. 辣椒穴盘苗力学特性及穴盘拔秧性能的试验研究[J]. 农机化研究, 2021, 43(6):172-178. |

| Zhao Chen-yang, Guo Jun-xian, Liu Na, et al. Experimental study on me chanical properties and hole tray seedling pulling performance of pepper[J]. Research on Agricultural Mechanization, 2021, 43(6):172-178. | |

| 31 | 中华人民共和国工业和信息化部. . 旱地栽植机械 [S]. |

| [1] | 金小俊,孙艳霞,于佳琳,陈勇. 基于深度学习与图像处理的蔬菜苗期杂草识别方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2421-2429. |

| [2] | 王永烁,康建明,彭强吉,陈英凯,方会敏,牛萌萌,王少伟. 果树株间避障除草机设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2410-2420. |

| [3] | 吕锋,李念,冯壮壮,张杨航. 面向用户的个性化产品服务系统协同过滤推介方法[J]. 吉林大学学报(工学版), 2023, 53(7): 1935-1942. |

| [4] | 耿端阳,孙延成,王宗源,王其欢,明家锐,杨昊霖,徐海港. 玉米籽粒直收机板齿式脱粒装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3281-3292. |

| [5] | 王斌,何丙辉,林娜,王伟,李天阳. 基于随机森林特征选择的茶园遥感提取[J]. 吉林大学学报(工学版), 2022, 52(7): 1719-1732. |

| [6] | 程亚兵,陈璐翔,葛平玉,杨泽宇,曹鹏宇. 双相正时套筒链的动力学仿真分析及磨损失效[J]. 吉林大学学报(工学版), 2022, 52(4): 781-788. |

| [7] | 耿端阳,孙延成,牟孝栋,张国栋,姜慧新,朱俊科. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 693-702. |

| [8] | 温昌凯,谢斌,宋正河,韩建刚,杨倩雯. 拖拉机耐久性加速结构试验设计方法[J]. 吉林大学学报(工学版), 2022, 52(3): 703-715. |

| [9] | 陈传海,姚国祥,金桐彤,申桂香,于立娟,田海龙. 基于响应面与遗传算法的主轴系统动力学建模及参数修正[J]. 吉林大学学报(工学版), 2022, 52(10): 2278-2286. |

| [10] | 王国伟,朱庆辉,于海业,黄东岩. 基于数字化农机装备的青贮饲料可追溯系统[J]. 吉林大学学报(工学版), 2022, 52(1): 242-252. |

| [11] | 耿端阳,牟孝栋,张国栋,王宗源,朱俊科,徐海刚. 小麦联合收获机清选机理分析与优化试验[J]. 吉林大学学报(工学版), 2022, 52(1): 219-230. |

| [12] | 梁方,王德成,尤泳,王光辉,王宇兵,张晓明,冯金奎. 草地切根施肥补播复式改良机设计与试验[J]. 吉林大学学报(工学版), 2022, 52(1): 231-241. |

| [13] | 王新彦,江泉,吕峰,易政洋. 基于参数化模型的零转弯半径割草机侧翻稳定性[J]. 吉林大学学报(工学版), 2021, 51(5): 1908-1918. |

| [14] | 钱震杰,金诚谦,袁文胜,倪有亮,张光跃. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J]. 吉林大学学报(工学版), 2021, 51(3): 1121-1130. |

| [15] | 程超,付君,陈志,任露泉. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报(工学版), 2021, 51(2): 761-771. |

|